Well Caps, Covers & Vents

Well Caps, Covers & Vents

Requirements for caps, covers & vents on wells

- POST a QUESTION or COMMENT about steel casing drilled water wells at residential properties

Well Cover & Cap Requirements & Well Cap Venting:

Water wells require a water-tight cap or cover to prevent contamination from surface runoff or flood waters. But some well caps also require an air vent. This article explains the requirements for well caps & covers & well cap or cover venting for drilled wells, well casings, dug wells & well pits.

This article series describes the properties & construction of drilled wells that use a steel well casing, modern drinking water wells. We discuss well problem diagnosis, testing, & repair procedures - advice about what to do when things go wrong with the well such as loss of water pressure, not enough water volume, contaminated wells, wells that have smelly water, wells that just run out of water or have a low recovery rate. We describe the parts of a water well and its piping and controls including the pitless adapter.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Well Caps, Covers, & Vents

Here we describe requirements & recommendations for a sanitary, sealed cap or cover on drilled wells, bored wells, and cover requirements for dug wells and well pits.

Here we describe requirements & recommendations for a sanitary, sealed cap or cover on drilled wells, bored wells, and cover requirements for dug wells and well pits.

The page top photo is of a modern well casing, in good condition, extended properly above ground. The small-diameter pipe parallel to the six-inch steel well casing is an electrical conduit - so we know that for this particular water supply system a submersible water pump is used and it is installed in the well itself.

The photo shown here is of an older drilled-well casing which has been placed with its casing cap at ground level - increasing the risk of well contamination from surface runoff. We also see that this well cap is not vented.

We cannot see from just the photo how successfully this well casing cover has been sealed against water entry from surface runoff.

[Click to enlarge any image]

Well casing covers on older drilled or bored wells that used a steel casing are often buried several feet below ground. Those well casing caps must also be tightly sealed against water entry from surface runoff or groundwater.

Where the pump is offset from the well or where a submersible pump is used, the opening between the well casing and any pipes or cables which enter the well shall be closed by a watertight seal or "well cap". - California DWR Chapter 10, 2016 cited below

In our sketch below we show the typical construction of a drilled water well in cross section.

A typical drilled well steel casing diameter is 6" (4" in some areas), that the well depth can be considerable (from 50 ft. to 900 ft. or more). Typically the steel well casing extends down into the bedrock or to a depth at which it can be sealed against un-wanted surface water entry.

We discuss the construction of drilled wells

at DRILLED WELLS, STEEL CASINGS.

The water pipe leaving this well to carry water to the building will be buried below ground, and in freezing climates, below the frost line. A special fitting, the "pitless adapter" is used to seal the passage cut into the round well casing. Details are at PITLESS ADAPTER

Question: What is the function of a well vent?

What is the function of a well vent?

This question was posted originally

Reply:

Good question Julian; Here are some reasons that many drilled wells with a sealed casing top or sealed cover require a vent:

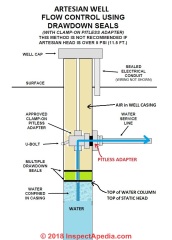

- Well cap/casing vent prevents casing vacuum: On some water wells the presence of a water tight (and thus air tight ) well casing cap can mean that when the pump is running and drawing down the static head in the well it can create a vacuum that could impede pump operation; The vent lets equalizing air into the casing.

- Well cap/casing vent allows air to vent out: The well casing top vent also allows air to exit the well as the water column rises in the well, perhaps assisting in well recovery in some well installations.

- Well cap/casing vent allows gases to vent out: A well vent also allows the venting out of any gases that might accumulate in the well bore above the static head; that can be a concern for wells whose water supply includes absorbed methane or other gases.

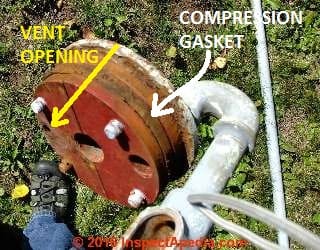

Below: a closer look at the older compression-style well casing cap removed from the well shown above.

This cap achieved a water tight seal to the interior of the well casing when the cap bolts were tightened to in turn squeeze and expand the thick rubber gasket.

A small diameter hole in the well casing cap (yellow arrow) connected to an air vent elbow on the top of the casing cover (visible in the photo above).

Below: new well cap sealed to the well casing; note that the well driller determined that this well no longer needed an air vent, probably because in the well a snifter valvewas eliminated as part of installation of a new internal-bladder type pressure tank in the building served by this well in Two Harbors MN, USA.

See details at

WATER TANK BLADDERS & CAPTIVE AIR

and at

Requirements & Standards for Well Casing Cap Vents

Here's an excerpt from the California DWR well standard

Air Vents. In community water supply wells to minimize the possibility of contamination caused by the creation of a partial vacuum during pumping, a casing vent shall be installed (Figure 7). In addition, to release air trapped in the pump column when the pump is not running, air release vents shall be installed (Figure 7).

Air vents are also recommended for other types of wells except those having jet pump installations requiring positive pressure (which cannot have a vent). - California DWR Chapter 10, 2016 cited below, [Emphasis by underscoring added by editor - InspectApedia.com]

Here is another excerpt from California's Chapter 10 on well construction codes:

Openings.

Openings into the top of the well which are designed to provide access to the well, i.e., for measuring, chlorinating, adding gravel, etc., shall be protected against entrance of surface waters or foreign matter by installation of watertight caps or plugs.

Access openings designed to permit the entrance or egress of air or gas (air or casing vents) shall terminate above the ground and above known flood levels and shall be protected against the entrance of foreign material by installation of down-turned and screened "U" bends (see Figures 6 and 7). All other openings (holes, crevices, cracks, etc.) shall be sealed. - op. cit.

You'll see that the vent must be properly constructed so as to prevent entry of surface runoff, flood waters or other contaminants into the well bore.

- "Water Well Standards", [PDF] California Department of Water Resources, 1416 9th Street, Sacramento CA 95814, TEl: 916-653-5791, DWR Chapter 10, retrieved 2016/06/10, original source: http://www.water.ca.gov/groundwater/well_info_and_other/california_well_standards/wws/wws_combined_sec10.html

Safety Requirements for Well Caps & Covers

We have explained above that the top of a water well needs to be sealed against surface runoff or flood waters as those waters are not sanitary and would contaminate the well water. Well construction also requires that all below-ground well openings such at a pitless adapter must also be sealed against the entry of outside water.

We have explained above that the top of a water well needs to be sealed against surface runoff or flood waters as those waters are not sanitary and would contaminate the well water. Well construction also requires that all below-ground well openings such at a pitless adapter must also be sealed against the entry of outside water.

But well caps and covers must also be secured to prevent other safety hazards such as the following:

- The well cap must be secured against casual removal

that would permit tossing of debris, disposal of varoius chemicals or liquids, or dropping of objects into the well as accidental, criminal, mischevious acts. In most situations that simply means that the cap can't be lifted off by hand but has fasteners that must be removed: that's enough to prevent a child from opening the well. - Community wells require additional protection:

Enclosure of Well and Appurtenances. In community water supply wells, the well and pump shall be located in a locked enclosure to exclude access by unauthorized persons. -California DWR Chapter 10 op. cit. - Dug wells should have a child-proof cover to prevent a child from climbing into or falling into the well.

See DUG WELLS, by HAND

and

See WELL SAFETY WALL & COVER - Well pits should have a child-proof cover

also to prevent a child from falling or climbing into the well pit. Because the cover of a well pit is often at or close to ground level, the cover should also be strong enough to prevent collapse and injury to someone walking over or standing on it.

Also see WELL PITS

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-08-18 by inspectapedia.com.moderator (mod) - Property Transfer water Tests for vacant home.

@Darlene,

@Darlene,

My goodness that does sound extreme.

In New York licensed plumbers and also drilled well construction companies are completely capable of tightening a loose well casing cap - in fact if all that's needed is tightening a few screws or bolts that snug the cap to the casing top, anyone with a screwdriver or an adjustable wrench could do it.

But on the other hand if the well casing is not well above ground and if the cap was found off entirely and / or if the proper kind of cap was not installed in the first place, then the well may not be protected from surface contaminants; in that case it may be that a proper cap needs to be installed.

Call your local well driller, ask them to inspect the casing top and either secure the cap or tell you if a different one is needed.

In NYS any well driller in business has got to be NYS DEC registered.

The Simmons water-tight well casing cap shown below costs about $60. U.S. to which you'll add the cost of a well driller service call.

On 2021-08-18 by Darlene

Property Transfer Tests for vacant home. The New York Erie County Health denial reads Well water failed due to loose cap. It states that I need to hire a New York State Department of Environmental Conservation Registered Well Driller to put a new cap on and then they will proceed to do water test.

Is this a legal requirement to have this kind Specialized Registered person to replace a cap?

The health department inspector will not answer me as to why they did not do the water test. He said the Health department will not talk to me since I am now not the owner—but I explained to him I paid for the test, my money is held in escrow to pay for septic/well repairs and my sellers contract states I am the one to hire repair person, not the new owner. My lawyer is not helpful. I don’t know the law.

On 2021-08-04 by James M

@inspectapedia.com.moderator, Thanks for the great tips!

On 2021-08-01 by inspectapedia.com.moderator (mod)

@James M,

RE:

1. Run conduit down and connect to conduit running from the house to protect the wires.

if you use underground feeder at adequate depth you don't need conduit below ground but I'd not expect to see wires exposed like in your case - conductors with no insulation and I prefer to see conduit above ground to protect the wire from damage

2. Add some form of insulation. Perhaps like a thermal blanket for hot water heater?

There is no reason to insulate the casing above ground; the water should be leaving the casing below ground, below the frost line, by a pitless adapter

3. Replace cap with proper fitting one

Yes one that fits and connects both casing and conduit

4. Do I fill in or build something to leave a "work space" around the well?

The casing can be left exposed above ground if wired and capped properly; Don't bury it or it may leak and contaminate your well; it should extend above ground.

On 2021-08-01 by James M

@inspectapedia.com.moderator, yeah it's sketchy. The conduit is there when it runs to the house. So your recommendation is:

1. Run conduit down and connect to conduit running from the house to protect the wires.

2. Add some form of insulation. Perhaps like a thermal blanket for hot water heater?

3. Replace cap with proper fitting one

4. Do I fill in or build something to leave a "work space" around the well?

On 2021-08-01 by inspectapedia.com.moderator (mod)

@James M,

@James M,

This looks like an improper and unsafe submersible well pump installation.

I see bare wires, no conduit and not even protective insulation run loose through a rocky ground surface, up into a well casing cap that, if it sits loosely atop the casing, is perhaps the wrong size - too big - thus also not secure against movement, wiring damage, and not able to prevent its removal or contaminants from being dumped down the casing at its top.

You will want at least

- a water-tight well casing top of the right size for your well casing so that it can be secured and sealed

- proper conduit to protect the pump's electrical wires

- a water test to confirm that the water is potable and safe

On 2021-08-01 by James M

I recently purchased a home with a drilled well. The pump is inside the well itself.

The cap just sort of sits on top. There was a pit dug around it with rotten wood laid flat at ground level, surrounding the well pipe. There was styrofoam packaging used as insulation...

My question is, what is the best way to cover this back up? The hole goes deep enough to see where the power and piping shoot off to the house. Do I need to build something around this for access if there's a problem, or just fill it with dirt and gravel?

On 2021-03-29 y danjoefriedman (mod)

@Kate smith, the first and most essential question is that of safety and be absolutely certain that no one including a curious child, can fall into the well.

With that taken care of if you're going to remove the roof you may want to simply cover the wall to prevent surface water and dust and rain from entering it.

On 2021-03-28 by Kate smith

I have a well in my garden with a 3 foot wall and sloping roof above it. There is a metal grill set inside the wall to prevent falling into the well. I would like to remove the sloping rood as I think its rather naff. Would this affect the well. We dont actually use it.

On 2020-07-24 by Pat

Our well flooded from sump pump in well housing not working, pressure tank came loose again, four packrats in the housing, water tastes like a swamp and looks like little organisms in it. Could pressure tank, pipe between well casing and pressure tank have developed leaks?

On 2020-05-23 by (mod) - If you are going to bury an above ground well casing ca

Cinda,

Thank you for asking a helpful question.

If you are going to bury an above ground well casing cap (this is NOT recommended), then it's important to first assure that the top is completely sealed against water entry.

Otherwise leaks into the well may contaminate your water supply.

A plastic bag was a clever idea, but not reliable.

Also, some well casing caps include an air vent that should not be blocked.

On 2020-05-23 by Cinda

I have a well, and a well head in my front yard, I landscaped bricks around and put in a flower bed, I did cover the well head with plastic , will this give me a problem. Thank you

On 2020-03-13 by (mod)

Yes, the well-cap might be buried - hopefully also sealed against water entry. That's particularly likely in an older home. Modern drilled wells are normally brought above grade; other older wells may have the well head exposed in a well pit that is usually closed by a removable cover.

Take a look at WELL LOCATION, HOW TO FIND https://inspectapedia.com/water/Well_Location.php

On 2020-03-12 by Kevin Browne

I just moved in to a residential home that has a drilled well. The as-built shows its location, but there is no visable well cap. Is there such a thing as a subsurface well cap?

On 2019-03-04 by Anonymous

10-4 thx

On 2019-03-03 by (mod) - shower drain gurgles after toilet is flushed.

That might work provided your vent piping is of sufficient diameter, slope, is routed with pitch so that it doesn't clog and is protected so that it doesn't get smashed by inadequate protection from vehicle passage.

However keep in mind that it sounds as if you're driving right over the well casing top- the well casing top needs both protection from damage AND ease of future access for maintenance or repair. Don't just pave over it.

On 2019-03-03 by vic kelly

My vented sebmersible well pump well ended up where I need to drive over it. I would like to lower the sealed/vented lid, cover/seal and run a vent to a more convenient above grade location vented and screened. That OK ??? .

On 2019-01-17 by john

my brother has a 3' diameter dug well that has a concrete top/lid. He's at an age where he can no longer remove the top to chlorinate the well. Is there an approved top/lid he can get to replace his concrete top/lid

On 2018-12-20 by Lyle

If I place a wooden wishing well over my well cap, does this create any problems for cpas vent?

On 2017-10-02 by Scooby

I just moved into a new house and the water was tested to be potable drinking water.

However, when I run the water inside the house, (shower, toilet, or kitchen sink) I can visibly see water sprinkling from different areas from underneath the cap on the well casing outside.

I spoke to the person that drilled with well, and he was trying to tell me that this was normal because we have a lot of pressure in the well. My concern is that there is a lot of water running out and I have quite the puddle around it which is a concern for the winter time as it will turn to ice and build up.

On 2017-06-26 by Barbara Carroll

I have been turning my water pump off at the elect. box for several weeks at a time. (i was out of town) I had no trouble with it coming back on when I needed it to. last time, my son had to prime it, using a gallon of water. The next time however, when I primed it, it would come on, hold the prime for a minute. pressure went to 38 then quickly lose its prime. what could be causing this. would turning it off so much, and for extended times cause it to quit priming? I

On 2016-11-13 by (mod) - I have to walk all the way down to the well head turn on the deepwell pump just to fill five gal buckets of from the spicket

Pete, please Use the on-page search box at the top or bottom of this page to find and check out the diagnostics in this article WELL WATER PRESSURE DIAGNOSIS. https://inspectapedia.com/water/Private_Well_Pressure_Diagnosis.php

On 2016-11-13 by Pete E

Question:

deepwell pump pressure problem. Water output has degraded & now water barely makes it to ground level. NOTE: I think well is aprox 5yrs old w no pressure tank, but still use to pump the water from the well aprox 200yds & aprox and another+100' higher in elevation to the 2000gal tank on the hill.

Water from tank (elev aprox 40' higher than house elev). Then the grunlove house pump (w pressure external tank located at the house) would draw out & receive a little help in pressure from gravity.

Now I have to walk all the way down to the well head turn on the deepwell pump just to fill five gal buckets of from the spicket thats connected to the well head. any ideas to the problem?

Can I hook up a craftsman 390.2519 to help it? *The craftsman pump has 1 1/4 " suction line and 1" drive line, and a port for pressure tank or injected air option.

The shallow or deep pump head option is sold seperately & I don't have either one.

Thanks Pete

On 2016-08-27 by (mod) - artificial rock to cover my well pipe

Diane if your well casing included a top vent, and if the equipment hasn't been modified to make that vent unnecessary, I'd keep the vent working; that might mean that you need to extend it around your decorative rock.

Also be sure that you don't change the ground height so as to increase the risk of sending surface runoff into the well around the casing cap. On an older well that cap may not be water-fight.

On 2016-08-24 by Diane A

I just installed an artificial rock to cover my well pipe. My pipe looks exactly like the first photo on the page. Does this artificial rock need to be vented?

...

Continue reading at WELL CONSTRUCTION & MAINTENANCE - home or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- DRILLED WELLS, STEEL CASINGS

- HAND PUMP for WELLS - sanitation & vent covers for wells using a hand-operated pump

- PITLESS ADAPTERS - Definition & use of a pitless adapter at water wells

- WELL CASING LEAK REPAIRS

Suggested citation for this web page

WELL CAPS & COVERS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS & SPRINGS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about steel casing drilled water wells at residential properties.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- NSF International P.O. Box 130140 789 N. Dixboro Road Ann Arbor, MI 48105, USA e info@nsf.org p +1 734 769 8010 f +1 734 769 0109 Toll Free USA +1800 NSF MARK (800 673 6275) Website: http://www.nsf.org/

- Access Water Energy, PO Box 2061, Moorabbin, VIC 3189, Australia, Tel: 1300 797 758, email: sales@accesswater.com.au Website: http://www.accesswater.com.au/

Moorabbin Office: Kingston Trade Centre, 100 Cochranes Rd, Moorabbin, VIC 3189

Australian supplier of: Greywater systems, Solar power to grid packages, Edwards solar systems, Vulcan compact solar systems, water & solar system pumps & controls, and a wide rage of above ground & under ground water storage tanks: concrete, steel, plastic, modular, and bladder storage tanks. - Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Crystal Clear Supply provides portable ceramic water filter purifiers and portable reverse osmosis water treatment equipment - see http://www.crystalclearsupply.com/category_s/7.htm

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.