Asbestos Plastic Molding Compounds

Asbestos Plastic Molding Compounds

& release agents

used in the Manufacture of Asbestos Containing Plastics

- POST a QUESTION or COMMENT about what building materials may contain asbestos, visual identification of asbestos-containing materials in buildings, and possible asbestos material identification by testing, use, age, appearance

Asbestos-based plastic product molding compounds & mold release agents: this article describes the molding compounds & release agents used to produce asbestos-based or asbestos filled / reinforced plastic or molded products.

This articles series about the manufacture & use of asbestos-containing products includes detailed information on the production methods, asbestos content, and the identity and use of asbestos-containing materials.

This article series about asbestos plastics & molded materials describes the history, manufacturing process & uses of asbestos plastics and molded materials.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Properties of Molding Compounds Containing Asbestos

The Military Specification MIL-M-14, "Molding Plastics and Molded Plastic Parts, Thermosetting," lists twenty types along with twelve types being mineral filled (asbestos). This specification is considered one of the most important and useful specifications for both military and commercial applications.

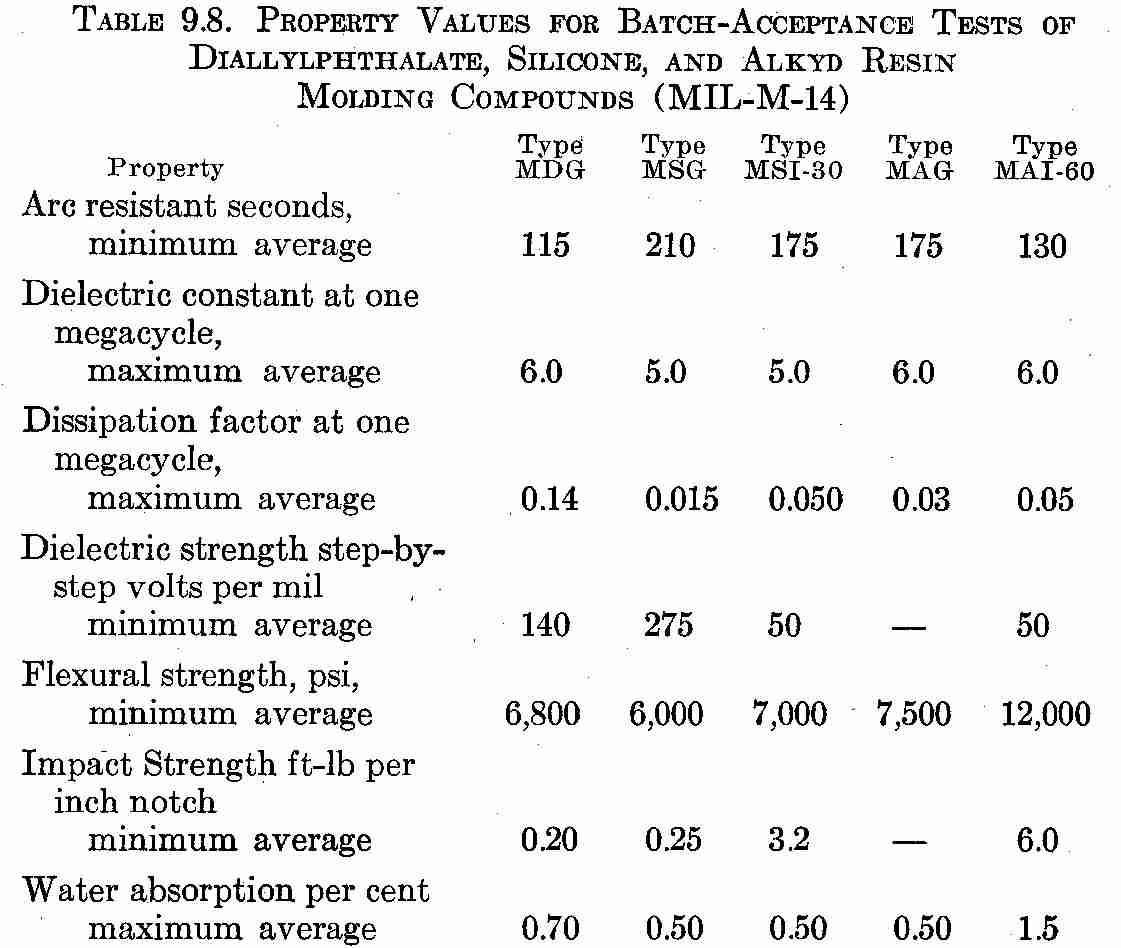

This specification lists requirements that can be met by more than just one or two compounds so that limited procurement does not exist. This situation results in listing requirements which are lower than some of the commercially available types. The specification lists requirements on mineral filled phenolics, melamine, alkyd, diallylphthalate, and silicone resins. Table 9.8 lists some of the specification requirements.

TABLE 9.8. PROPERTY VALUES FOR BATCH-ACCEPTANCE TESTS OF DIALLYLPUTHALATE, SILICONE, AND ALIYD RESIN MOLDING COMPOUNDS ( MIL-M-14) [click to enlarge]

Other types of compounds include asbestos-tetrafluoroethylene resins. Such combinations improve mechanical properties of the base resin and permit compositions based on the asbestos content to be tailored to such a wide variety of chemical, mechanical, and electrical applications as resistance to deformation under load, resistance to wear, stiffness, thermal conductivity, compressive strength and hardness.

Originally, when molding compounds were manufactured using phenolic resin as the basic component, expensive procedures were use The ingredients were mixed with an alcoholic resol solution and were thoroughly impregnated in agitators. After this operation the solvents were evaporated and the usual procedure of grinding the mixture on ball mills followed.

The general procedure presently being used is to take the phenol resin and grind it with other ingredients. The mixtures can also be kneaded on heated rolls. For some mixtures, premastication in a Banbury mixer is required prior to the heated roll operation. During the roll operation, the resin melts and thoroughly impregnates the fillers and other ingredients.

After thorough mixing of ingredients has been accomplished, the homogeneous sheet is ground in a mill. In the case of novolacs, hexamethylene is added during the rolling operation. When the hexamethylene is added a quick reaction occurs where ammonia is liberated from the hexa and acts as a catalyst. Immediately when this reaction occurs, the mixture is removed from the rolls.

Various automatic techniques are used for mixing and preparing phenolic molding compounds. The usual technique is to take the rolled sheet and automatically convey it by means of a conveyor belt to a grinder or a mixing screw.

When difficulty exists in obtaining proper treatment of fiber fillers or other types of fillers, it is sometimes required that the fillers be impregnated with an alcohol solution of the resin. Another method is to mix the ingredients in a hollander to produce a pulp slurry. Generally, in this type of operation the slurry is made into a preform. The preform is made by vacuum suction on a sieve which produces a shape approximately similar to the final article.

During the preparation of the molding compound, it is important that the correct amount of condensation occurs. If the condensation is too high, a poor flowing product is produced, if insufficient condensation occurs, a free flowing compound will be produced.

However, excess water of condensation produced during the curing cycle in turn can result in excessive sticking of the compound in the mold cavity, producing blemished surface, poor electrical properties or requiring the part to have a long curing cycle.

The heat conductivity of the compound also contributes to the hardening velocity. Asbestos-filled mixtures heat up quicker than wood flour filled mixtures, thus giving better hardening conditions.

The time required for the compound to harden may not be sufficient to harden the part completely, as in general, the cure of a part takes place after the initial set. When thick wall sections are to be cured, the heat conductivity of the molding compound is indeed an important function. As the thickness of the wall increases, the hardening time naturally increases and this increase is in exponential relation to the wall thickness.

Premix Molding Compounds of Asbestos-Containing Plastics

These types of compounds have relatively low raw material costs. Various types of mixes are prepared which are dependent upon the specific applications. The end users of these materials are largely in the automotive, electrical, electronics, home appliance, refrigeration, and industrial equipment fields. Production runs are long.

A blend of reinforcing fibers (glass, asbestos, sisal, etc.) fillers (asbestos, gypsum, talc, clay, etc.), polyester, or phenolic resins, catalyst for polyester (benzoil peroxide) pigments, and release agent (stearic acid, lecithin, silicone, etc.), makes up a premix compound. It is important that the blends are uniform and properly mixed. They are generally prepared in a kneader, in a similar mixer such as the Banbury mixer or special screw conveyors.

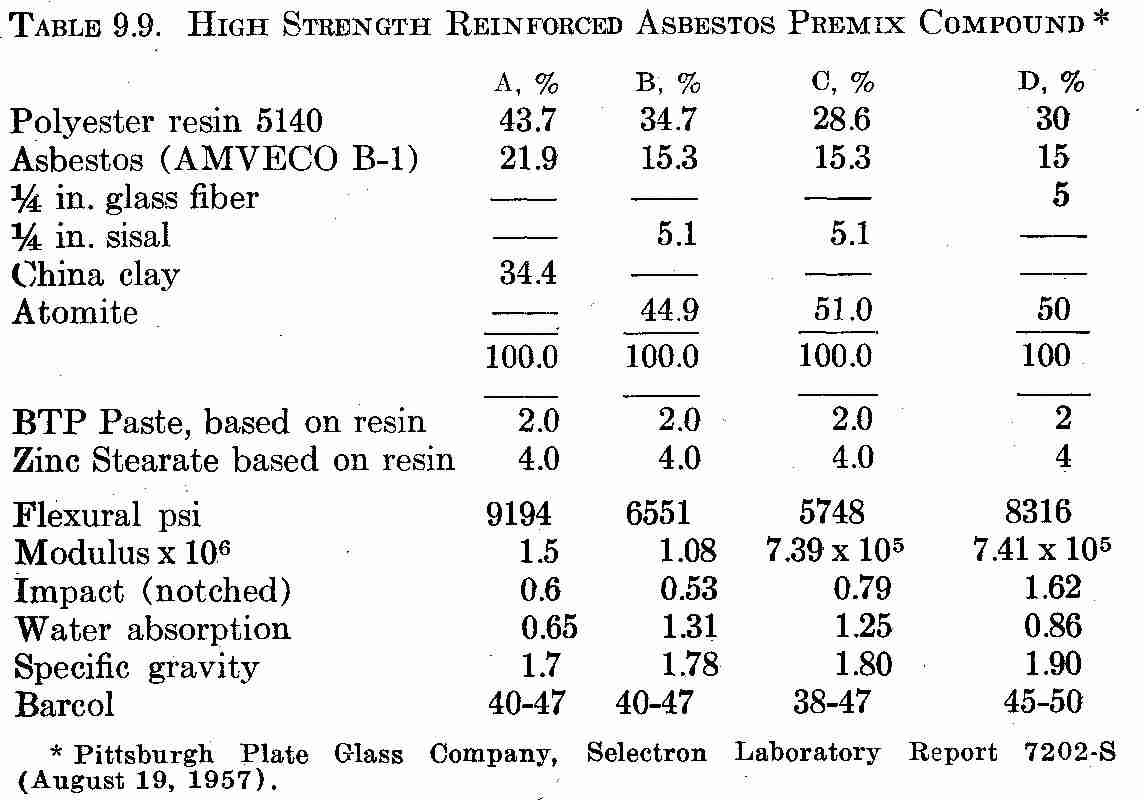

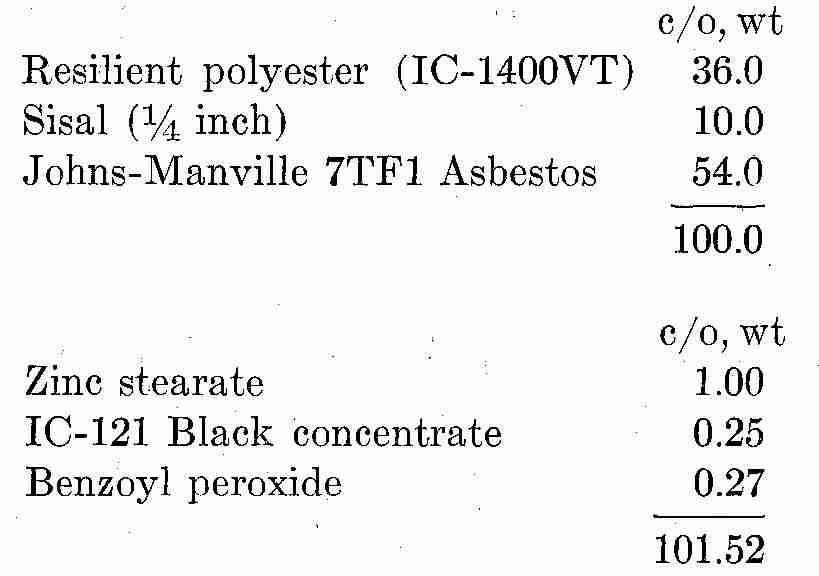

TABLE 9.9. HIGH STRENGTH REINFORCED ASBESTOS PREMIX COMPOUND *

[click to enlarge or clarify table contents]

* Pittsburgh Plate Glass Company, Selectron Laboratory Report 7202.S ( August 19, 1957).

During mixing of phenolic compounds, heat is required to alter the chemical nature of the resin so that it is suitable for molding (similar to preparing phenolic prepreg sheet).

Asbestos fibers are generally used which contribute to the desirable properties in a premix compound. They will increase flexural strength when they are used in the reinforcement. It is a highly absorbent material; it improves processing qualities of a mix by drying it to such a that stickiness does not occur. However, if too much asbestos is added in certain compounds, there may tendency toward sticking and pregelation. A trend exists toward the use of the longer fibers as reinforcements.

A typical formulation using asbestos as a reinforcement is shown in Table 9.9 above.

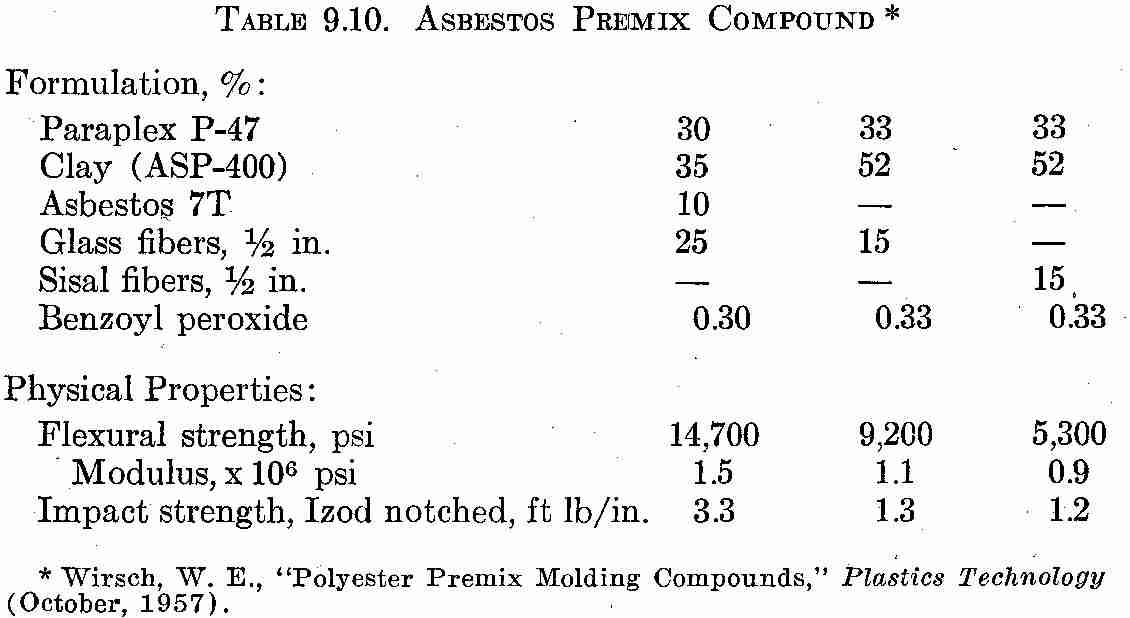

Below iIn Table 9.10, asbestos is used filler.

TABLE 9.10. ASBESTOS PREMIX COMPOUND * [Click to enlarge]

* Wirsch, W. E., 'Polyester Premix Molding Compounds," Plastics Technology

(October, 1957).

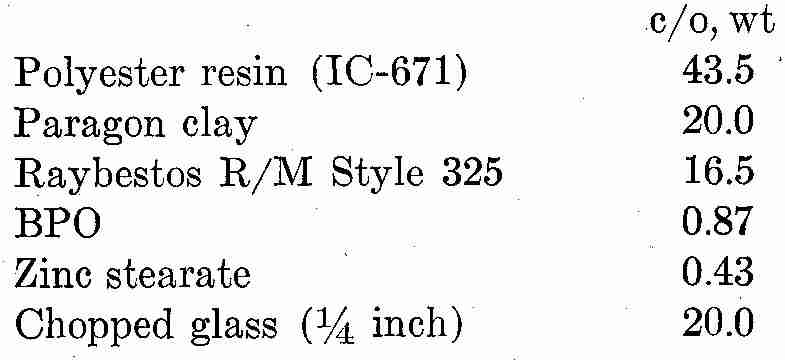

* Interchemical Corporation, Bulletin 50-3

A vinyl toluene rigid type of asbestos-based resin compound for high strength and good flow properties is composed of:

A low cost asbestos plastic compound built around fibrous asbestos is composed of *

* Interchemical Corporation, Bulletin 50-3

Release Agents Used with Asbestos-Reinforced Plastic Products

In any molding operation, there is a tendency for the molding compound to adhere to the mold surface. Release agents are available in such various forms as sprays, liquids, pastes, and powders.

This particular subject is so important that recently the ASTM set up a new section on "Mold Release" under Sub-Committee IX, Plastic Committee D-20. Baking varnishes and enamels are available as mold release agents which are generally phenolics or melamines. Fungicidals can be incorporated in the release agent. There are many different commercially available varnishes or enamels.

With phenolic-resin systems, glossy and attractive parts can be made when using a methyl cellulose parting agent. The usual procedure is to combine one pound of methyl cellulose powder (Dow Chemical Company, Pharmaceutical grade) with 15 lb of hot water (120 to 130°F) and to allow the mixture to soak overnight.. After the soaking period, approximately 10 lb of cold water is added. This mixture an be added directly to the mold surface, or on the molding compound if layers of laminated materials are used.

For general use with phenolic, furane and urea type resin systems, carnauba wax directly on the mold surface is the most desirable. Other types of compounds are Dow Corning's DC-20 or DC-200, Ram Chemical Corporation's Garan 225 or Minnesota Mining and Manufacturing's compound FC-400.

When using epoxy resin base systems, various parting agents can be used, such as Dow Corning's DC-135A, cellophane No. 600PT, "Teflon" sheet or sintered powder and Garan mold release No. 225. In regard to polyester base resin systems, du Pont's "Zelec" UN mold release agent is applicable.

...

Continue reading at ASBESTOS PLASTIC DESIGN GUIDES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ASBESTOS, ITS INDUSTRIAL APPLICATIONS, ROSATO 1959

- ASBESTOS ORIGIN & NATURE - p. 1-36

- ASBESTOS PROPERTIES - p. 37-61

- ASBESTOS CEMENT PRODUCTS - p. 62-66

- CEMENT ASBESTOS PRODUCT MANUFACTURE - p. 66-73

- CEMENT ASBESTOS PRODUCT CURING - p. 73-75

- CEMENT ASBESTOS SHEET PRODUCTS - p. 75-78

- CEMENT ASBESTOS PIPE MANUFACTURE - 78-85

- ASBESTOS TILE MANUFACTURE - p. 86-93

- ASBESTOS INSULATION - 94-105

- ASBESTOS ELECTRICAL WIRE INSULATION - p. 106-112

- ASBESTOS FRICTION MATERIALS - p. 113-129

- ASBESTOS TEXTILES - p. 130-141

- ASBESTOS in PLASTICS - p. 142-177

- ASBESTOS PACKINGS & GASKETS - p. 178-184

- ASBESTOS FILTERS - p. 185-193

- ASBESTOS OTHER PRODUCTS - p. 194-200

- ASBESTOS BIBLIOGRAPHY - p. 201-207

Suggested citation for this web page

ASBESTOS PLASTIC MOLDING COMPOUNDS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] ASBESTOS HISTORY & PROPERTIES [Book online] D.V. Roasato, engineering consultant, Newton MA, Reinhold Publishing Co., NY, 1959, Library of Congress Catalog No. 59-12535. We are in process of re-publishing this interesting text. Excerpts & adaptations are found in InspectApedia.com articles on asbestos history, production & visual identification in and on buildings.

- [2] "Asbestos in Plastic Compositions", A.B. Cummins, Modern Plastics [un-dated, pre 1952]

- [7] Asbestos products and their history and use in various building materials such as asphalt and vinyl flooring includes discussion which draws on ASBESTOS, ITS INDUSTRIAL APPLICATIONS, ROSATO 1959, D.V. Rosato, engineering consultant, Newton, MA, Reinhold Publishing, 1959 Library of Congress Catalog Card No.: 59-12535 (out of print, text and images available at InspectAPedia.com).

- [8] "Handling Asbestos-Containing roofing material - an update", Carl Good, NRCA Associate Executive Director, Professional Roofing, February 1992, p. 38-43

- [9] EPA Guidance for Controlling Asbestos-Containing Materials in buildings, NIAST, National Institute on Abatement Sciences & Technology, [republishing EPA public documents] 1985 ed., Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- EPA ASBESTOS MATERIALS BAN: CLARIFICATION 1999

- Basic Information about Asbestos, US EPA, web search 08/17/2010, original source: http://www.epa.gov/asbestos/pubs/help.html

- [copy on file as] /hazmat/Vermiculite_Health_Canada.pdf] Vermiculite Insulation Containing Amphibole Asbestos - September 2009, Health Canada

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.