Asbestos Cement Products

Asbestos Cement Products

Asbestos cement roofing, siding & millboard

composition, history, production, uses, identification & safety

- POST a QUESTION or COMMENT about asbestos cement products, history, uses, materials, production, durability, and asbestos content

Cement asbestos materials: this article series describes asbestos cement products & materials and the history of their production and use.

This article includes text & data Adapted from Rosato (1959 out of print) on the production and use of asbestos-containing materials, adding photographs, inspection, repair and maintenance advice, and updates on asbestos hazards involved in the installation, repair, or demolition of asbestos cement products such as roofing and siding or asbestos millboard that remain in place on buildings.

Our page top photograph shows badly broken cement asbestos roofing shingles on a building in upstate New York.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

The History, Production Methods, & Contents / Properties of Cement Asbestos Products©

Asbestos is safe and legal to remain in homes or public buildings as long as the asbestos materials are in good condition and the asbestos can not be released into the air. - US EPA

[Click to enlarge any image]

Asbestos Cements and cementious products including some cement pipes contained asbestos fibers as a strengthening material. Asbestos cement roof ing is described just below, and cement wallboard and cement siding containing asbestos are described later in this document.

W.H. Ransom provides a succinct description of asbestos cement as it was used in roofing, siding, millboard and other products that we have annotated just slightly.

Asbestos cement is made from asbestos fibers [usually white chrysotile asbestos], ordinary Portland cement, and water [and possibly silica flour]. The cement hydrates and sets around and between the asbestos fibres which act as reinforcement.

The fibers are based on the mineral chrysolite and have an average length of around 5 mm. The relative proportions of asbestos fibre and cement used vary with the particular product to be made: for roof sheets and slates the proportion of asbestos is around 10% by weight of the dry materials. [19]

As we cite in detail in this adaptation from his original text, Rosato provided extensive historic detail about asbestos cement products and puts the asbestos content by weight as ranging from 10% to 75%.[20] Typically chrysotile asbestos is the most-common form of asbestos found in asbestos-cement products.

Ransom points out that asbestos-cement materials harden with age and that the material also loses its impact strength over time through atmospheric carbonation. Thus asbestos cement roofing in particular but perhaps also siding become more brittle and more vulnerable to impact damage. We add that such roofing may also shed asbestos in roof runoff and debris.

Cracks in asbestos cement products used outdoors may also occur due to the stresses occurring as different faces (exposed and covered) are exposed to very different degrees of atmospheric carbonation and thus differential shrinkage.

However in our own experience, damage to cement asbestos roofing and siding are most pronounced where the materials were exposed to mechanical damage from ice, impact, foot traffic, and carless contractors such as renovators or cable-TV or telephone wire instsallers.

The following text wasadapted from scanned text 8/30/2013 - History of Use of Asbestos. Edited, expanded, and illustrated with © protected materials to clarify titles; tables & illustrations from the original text are supplemented with additional product photographs, references, citations

- [1] ASBESTOS HISTORY & PROPERTIES [Book online] D.V. Roasato, engineering consultant, Newton MA, Reinhold Publishing Co., NY, 1959, Library of Congress Catalog No. 59-12535. We are in process of re-publishing this interesting historic text about the enormous number of asbestos-containing products and the processes used to manufacture these materials.

D.V. Rosato

The following text is Adapted from Rosato (1959) p. 62-66 [1] © 2013 InspectApedia.com

Types of Asbestos Cement Products

The following text is adapted & expanded from Rosato p. 62-66. [1]

The following text is adapted & expanded from Rosato p. 62-66. [1]

Introduction

Asbestos-cement products are primarily composed of Portland cement reinforced with asbestos fibers.

The proportion of cement to fiber varies over a range of approximately 10 to 75 per cent, by weight; it depends upon the physical characteristics desired in the finished product. Percentage of asbestos also can depend upon the type of manufacturing process to be used and cost of the finished product.

When compared to cement, the cost of asbestos is considered high.

The strong asbestos fibers behave similarly to the steel bars used in reinforcing concrete. With the use of asbestos fiber in cement, approximately 70 to 80 per cent of the weight of nonreinforced concrete is eliminated when roofing, siding, pipe and other similar products are manufactured.

Photo at above-left shows transite (cement asbestos) air ducts buried in a building slab. Sewer gas leaks from a failed cast iron sewer line entered this duct system. Click to enlarge any image at InspectAPedia.

Generally, most asbestos-cement products are made under pressures varying from 100 to 10,000 psi. The specific pressure generally depends upon the type of product or process being used. This particular industry uses the greatest quantity of asbestos. Chrysotile fiber is used principally. Some crocidolite is used; amosite is rarely used because of its low strength.

The fibers used involve group 4 of the Canadian classification.

This grade of chrysotile asbestos as well as groups 5 and 6 are generally classified as medium length fiber; they are used extensively in the manufacture of such asbestos- cement products as pipes, flat or corrugated sheets, roofing or siding shingles, clapboard, hand molded products, and wall boards.

The general characteristics of asbestos-cement products are given in Table 3.1 (below).

One basic requirement for the asbestos is that it must be fully fiberized prior to mixing it with cement in order to obtain the best properties in the final product. It is also important to remove or minimize such impurities as dust and grit.

In the United States, the standard grade of Portland cement is a low-heat cement or an aluminous cement. Products are manufactured by processes generally classified as the molding process, the dry process, the wet press process and the wet mechanical process.

Asbestos-cement mixtures do not lend themselves readily to extrusion processes. There has been time spent experimentally in attempting to develop suitable processes but commercially there is little manufacturing by this method.

Ludwig Hatschek, an Austrian, invented the asbestos-cement shingle in 1900 which has now developed into a major commercial product. The original wet process which was developed produced a variety of flat sheets. Later, a dry process was developed which initially provided for competitive development with regard to wet versus dry process. The wet mechanical process is the principal process used today.

Asbestos-cement products lend themselves to rapid construction; therefore, they have been particularly useful for lightweight housing and for industrial buildings. In the last few years, approximately one-half of the asbestos used in the United States was used for asbestos-cement sheets and pipes as well as for floor tiles. It is reported that in 1950 approximately one billion sq ft of asbestos-cement products for building had been produced.

TABLE 3.1. GENERAL CHARACTERISTICS OF ASBESTOS-CEMENT PRODUCTS * |

|||||||

| Group | Use | Grade or Type | Process of Manufacture | Modulus of Rupture, PSI | Tensile Strength PSI | Compression Strength PSI | Water Absorption % |

| Shingles | Roofing or Siding | Plain, veneered & textured surface | Wet machine, semi-dry machine | 2,000 - 5,000 PSI | 500 - 1,500 PSI | 4,000 - 12,000 PSI | 12 - 30 |

| Clapboards | Siding | Plain & textured surface | Wet machine, wet-press | 2,000 - 5,000 | 500 - 2,000 | 4,000 - 16,000 | 12 - 30 |

| Flat Sheets | Walls, sheathing, industrial & residential construction, industrial equipment, insulation | Plain, impregnated, integrally waterproofed | Wet machie, wet process | 500 ! to 5,000 | 150 ! to 5,000 | 1200 ! to 30,000 | 0.31 to 1401 |

| Corrugated sheets | Roofing, siding, ornamenal | Plain gray with different sized corrugations | Wet machine, wet press | 2,000 to 6,000 | 500 to 3,000 | 4,000 to 20,000 | 2.02 to 25 |

| Pipe | Water works, drainage, sewage, industrial processing | 3-36-in. diameter up to 13 ft. long | Wet machine | 2,600 to 6,000 | 1,500 to 6,000 | 6,000 to 15,000 | 22 to 25 |

| Molded Products | Industrial purposes | Plain, impregnated | Molding | 500 to 5,000 | 150 ! to 2,500 | 1,000 to 15,000 | 0.32 to 251 |

Notes to the table above

* Encyclopedia of Chemical Technology, Vol. 2, New York, The Interscience Encyclopedia, Inc.

1 These values refer to low-density products, which are usually used as thermal insulation.

2 These values refer to impregnated and waterproofed products.

- Cement-Asbestos corrugated roofing & siding -

see CORRUGATED CEMENT ASBESTOS ROOFING - Cement-Asbestos HVAC ducts -

see TRANSITE PIPE AIR DUCTS - Cement-Asbestos roofing shingles or roofing tiles -

see ASBESTOS ROOF MATERIALS which describes in detail asbestos cement roof shingles (or "tiles") and asbestos cement corrugated roof panels - Cement-Asbestos building siding -

see ASBESTOS CEMENT SIDING which describes asbestos-containing building siding shingles. - Cement asbestos pipes - see

Decorative asbestos-cement building products are available and conform with modern structural and color design.

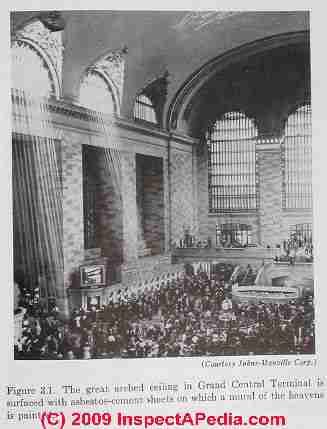

See the asbestos-cement sheeted Arched Ceiling in New York's Grand Central Station shown in Figure 3.1 below. In the case of chemical plants as well as other plants or buildings, there exists the prime requirement that roofing be resistant to corroding fumes.

This requirement also exists in chemical transporting pipes. Durable and fireproof roofing is obtained by the use of asbestos-cement corrugated boards which can be installed as quickly as sheet iron or aluminum roofing. The asbestos roof does not need paint, will not rot; it is close to being permanent.

How to visually distinguish drywall or plasterboard from cement asbestos millboard

Above we illustrate a fragment of cement asbestos millboard that is about 1/8" thick and his hard - cementious. [Click to enlarge any image]

Below we take a look at the edges of two layers of drywall or plasterboard in an older home - showing that that material, principally made of gypsum, is comparatively soft, paper-faced, and easily cut with a knife.

On that wall the original covering was a soft wood-product fiberboard - pointed to by the tip of my pen. Wood fiberboard or paper based insulating board are not asbestos products.

This photo is a close-up of layers of edges of wall material found in an older home that included in layers from left to right:

- Concrete, part of the building's exdterior wall structure

- Wood, probably furring or framing around what was a window opening

- Soft fibreboard (pointed to by my penpoint) installed as the first layer of the interior wall surface, often used as a plaster base

- Plaster that was applied in a thick layer followed by a thin skim-coat and then paint over the fiberboard

- Modern gypsum board or "drywall" (the cracked material) that has paper on both its back and front sides.

See SHEATHING, FIBERBOARD for more about fiberboard that was used as both a finsihed interior wall surface and / or as a base for plaster.

See SHEATHING, FIBERBOARD for more about fiberboard that was used as both a finsihed interior wall surface and / or as a base for plaster.

As we stated earlier, asbestos cement board is a cementious product distinguished by eye from friable and dangerous soft asbestos panels used as building fireproofing tremolite asbestos ceililng panels [image].

More about these tremolite panels can be read

at ASBESTOS FIREPROOFING SPRAY-On Coatings.

Figure 3.1 (Courtesy Johns-Manville Corp.)

This illustration shows the great arched ceiling in Grand Central Terminal that was, in original construction, surfaced with asbestos-cement sheets on which a mural of the heavens was painted.

More photos of asbestos cement productgs are found in our

ASBESTOS PHOTO GUIDE to MATERIALS

Research on the Asbestos Content & Hazard in Asbestos Cement or Fibre-Cement Products

- TRANSITE PIPE AIR DUCT ASBESTOS RISKS includes a definition of the composition of Transite and other typical asbestos cement products. Asbestos cement products in general contain a significant percentage of chrysotile asbestos. That asbestos can be released at hazardous levels when the material is demolished, ground, sawn, chopped, or when it is badly weathered.

When that material is not exposed to damage or weathering or when its surface has been sealed (by paint for example) the level of fibre release is likely to be very low. - Burdett, G., INVESTIGATION OF THE CHRYSOTILE FIBRES IN AN ASBESTOS CEMENT SAMPLE , HSL/2007/11, [PDF] (2006), U.K. Health and Safety Executive, Website: http://www.hse.gov.uk/, retrieved 2017/11/20, original source: http://www.hse.gov.uk/research/hsl_pdf/2007/hsl0711.pdf

Excerpts: To investigate whether claims of a physical and chemical change to chrysotile fibres in a cement matrix (A/C), are valid and merit further investigation. ... When the cement is broken or crushed the chrysotile fibres are released from the cement.

The fibres released were examined by analytical transmission electron microscopy (TEM) to determine whether they had been altered and were no longer identifiable as chrysotile asbestos....

Claims have been made in correspondence to HSE and in various media outlets (Bridle and Stone, 2006), that the chrysotile asbestos in asbestos cement products is altered, by an unexplained process, into a non-asbestos fibrous material.

The claims being made suggest that this process is 100% efficient and no chrysotile asbestos remains in the matrix and also no “actionable release” of airborne asbestos fibres can occur.

Conclusions:

The fibres found from a well-characterised asbestos cement sample showed that both the bulk and air samples had the same morphology as a reference standard of chrysotile asbestos. Many fibrils in the sample, when viewed at higher magnification, showed the characteristic tubular structure associated with chrysotile fibrils.

Individual fibres analysed by energy dispersive X-ray (EDX) analysis showed chemistry is similar to a reference standard of chrysotile and to published compositions for chrysotile from various source mines around the world (when adjusted for water content).... Only a small percentage of “coated” fibres have been observed.

HSE considers that the risk of exposure to airborne asbestos fibres is lower in asbestos cement products compared with some other asbestos containing products due to:

- The relatively lower amount of asbestos used in this product compared to others;

- the hard resistant nature of the cement matrix which makes it more difficult to release airborne fibres;

- the high use of chrysotile asbestos compared to amosite and crocidolite asbestos.

This low risk factor is why the asbestos cement products can be removed without the need to notify HSE, or the mandatory use of a licensed asbestos removal contractor. However all asbestos containing materials are subject to the Asbestos Regulations 2006.

The external surface of an asbestos cement sheet is subject to weathering of both the cement and the asbestos. The surface weathers at a rate largely dependent on the cement, which may corrode at a rate of 0.02 – 0.1 mm/year in most environments depending on the acidity of the rain and other factors. The chrysotile is more resistant and these fibres will be preferentially exposed on the surface in some environments. ...

Sensitive animal tests based on intraperitoneal injection in rats have shown that there was no reduction in the carcinogenic potency of magnesium depleted weathered chrysotile compared to UICC chrysotile asbestos standards. - Campopiano, Antonella, Deborah Ramires, Aneta Maria Zakrzewska, Rosa Ferri, Antonio D'annibale, and Giancarlo Pizzutelli. "Risk assessment of the decay of asbestos cement roofs." Annals of occupational hygiene 53, no. 6 (2009): 627-638.

Abstract:

Objectives: In an assessment of the risk of asbestos fibres release from asbestos cement materials, an important role is played by the assessment of the surface corrosion and by the disaggregation of asbestos cement. The aim of this work is to evaluate the differences among several methods used for the risk assessment that lead to a specific choice of abatement techniques.

Methods: The state of deterioration of 40 asbestos cement roofs was evaluated using two priority assessment algorithms elaborated in Italy, the ‘pull-up test’ described by the Italian Organization for Standardization and the indicators described in the Italian legislation coupled with the observation of a small sample, taken from each roof, by a stereomicroscope.

Results: The results obtained with the methods, proposed in this study, for the risk assessment of the decay of asbestos cement roofs show slight differences among them, only one deviates from the others in judgement on the state of conservation of the roof.

Conclusions: It is very important to train the operator conducting the study since a completely subjectivity-free method does not exist. Whatever method is used will always be affected by the subjectivity linked to the competency and the training of the operator.

Moreover, each method on its own cannot assess the risk of exposure to asbestos, but reliable assessment of asbestos-containing materials requires the use of more than one method, such as visual inspections, a pull-up test, and an assessment algorithm. - Nakaza, M., T. Toyama, and T. Tsunoda. "Chrysotile fiber count in asbestos-cement board plants (author's transl)." Sangyo igaku. Japanese journal of industrial health 21, no. 5 (1979): 417-421.

Abstract:

An asbestos fiber counting trial has been conducted in 19 asbestos-cement board plants throughout Japan, based on the phase-contrast microscopic count on membrane filter samples. In the four working places, i.e., bag carrying-in, bag opening, board cutting and shipping, airborne chrysotile fiber counts in 1 cm3 of air, the geometric mean and standard deviation were 1.86 (1.73), 3.87 (3.01), 2.34 (2.59) and 1.26 (2.17) respectively.

Mean size distribution (geometrical length) of the fiber in bag opening and board cutting were 8.91 micrometers (sigmag 2.88) and 5.51 micrometers (sigmag 1.22) respectively by measuring on the magnified photomicrographs. As the clearing agent of filters, dimethyl phthalate with diethyl oxalate containing dissolved filter material was used. - UK HSE, Asbestos Cement & Cleaning Asbestos Cement Roofs, retrieved 2017/11/20, original source: https://www.aic.org.uk/asbestos-cement/

Excerpt: Asbestos cement is primarily a cement-based product where about 10-15% w/w of asbestos fibres are added to reinforce the cement. - U.K. HSE, Removing asbestos cement (AC) sheets, gutters etc and dismantling a small AC structure [PDF], retrieved 2017/11/20, original source: http://www.hse.gov.uk/pubns/guidance/a14.pdf

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

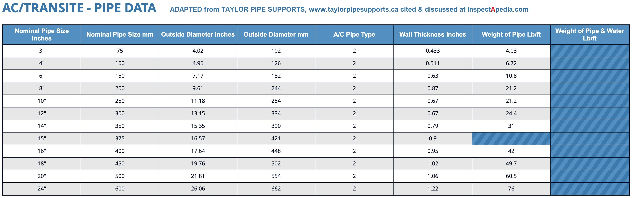

Above: example of AC/Transite pipe properties such as thickness and weights, from Taylor Pipe Supports cited in detail below.

[Click to enlarge any image]

Question: what does asbestos cement pipe weigh?

2021/03/18 Mick O'Shea · 5 hours ago

Can you confirm the weight of 850mm Diameter x 4.0m Lenght AC pipe

Moderator reply:

@Mick O'Shea,

Weights of Asbestos Cement Pipe per Meter or Foot

an 850mm fiber cement pipe would of course have a different weight per meter than older asbestos-cement pipe (I am guessing by AC you refer to "Asbestos Cement").

Rosato gives some of asbestos cement product specifications on the page above.

But you'll note in our two companion articles on transite air ducts and water pipes

that the properties of these pipes vary depending on their use, including pipe thickness.

Without a thickness measurement or similar specifications on your particular "AC pipe" just knowing its diameter and length are not enough to know its weight.

I can give some examples from current data:

From Taylor Pipes, a Canadian company currently producing AC/Transite pipe,

- A 24" diameter (600mm) AC/Transite pipe (type 2) has a wall thickness of 1.22 inches and weighs 76 lbs per foot [data from Taylor cited below]

- A 24" diameter x 13 foot long AC/Transite pipe would weigh about 990 pounds, and if filled with water, would have a total weight of 3460 pounds [data from logard cited below]

Your 850mm pipe is outside this size range and would certainly be heavier.

Watch out: you don't give the conditions of your particular AC pipe. If the pipe is wet it will be heavier; and if the pipe contains water or sewage it will be much heavier-still.

Data sources for weights of fiber cement and asbestos cement pipes & other products

- American WEIGHTS of ASBESTOS-CEMENT (A-C) Pipe, American [pipe], P.O. Box 2727 Birmingham, AL 35202 USA, Tel: 1-205-325-7701 retrieved 2021/03/18, original source: https://american-usa.com/products/valves-and-hydrants/ductile-iron-tapping-sleeves/series-2800-a-for-asbestos-cement-a-c-pipe/weights

- Logard, ASBESTOS CEMENT PIPE WEIGHT WITH or WITHOUT WATER [image] (2005) Logard, 201, Bishop street Portneuf (Québec) CANADA G0A 2Z0 Phone number : (418) 913-0992 Email: info@logard.com Website: http://www.logard.com retrieved 2021/03/18, original source: http://www.logard.com/en/Supports/weight.aspx

- Taylor Pipe Supports, PROPERTIES of CEMENT ASBESTOS PIPE [image] Taylor Co., 5305 John Lucas Dr., Burlington, Ontario Canada L7L 6A8 Tel: 1.800.263.8652 (Founded 1982) Email: linda@taylorpipesupports.ca Website: taylorpipesupports.ca/AC-Transite-pipe-data.php

- West Coast Pipe, THEORETICAL WEIGHTS PER LINEAR FOOT for CEMENT MORTAR COATING (of pipe] [Image], West Coast Pipe, 2180 N. Locust Ave.

Rialto, CA 92377 USA, Email: 2180 N. Locust Ave.

Rialto, CA 92377 USA, Tel: (909) 356-5670 Website: http://www.westcoastpipe.com/ CML/CMC Weight Charts, retrieved 2021/03/18 original source: http://www.westcoastpipe.com/charts_weights.html

(mod) · Feb 8, 2017

Anon - who asked: what's the best sealant to stop my Cemesto roof from leaking

Most likely on your Cemesto roof the joints are intended to shed water by the roof's slope or gravity, not to prevent leaks by a seal.

...

Continue reading at CEMENT ASBESTOS PRODUCT MANUFACTURE - a continuation of the original Rosato text as adapted and expanded, and where we discuss processes used to make various asbestos and cement based products, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ASBESTOS CEMENT PRODUCTS

- ASBESTOS & FIBER CEMENT ROOFING

- ASBESTOS CEMENT SIDING

- ASBESTOS CEMENT SIDING REPLACEMENT

- CEMENT ASBESTOS PRODUCT MANUFACTURE

- CEMENT ASBESTOS PRODUCT CURING

- CEMENT ASBESTOS ROOF SHINGLE ASBESTOS TEST

- CEMENT ASBESTOS SHEET PRODUCTS

- CEMENT ASBESTOS PIPE

- TRANSITE ASBESTOS CHIMNEYS, DUCTS, PIPES

- TRANSITE PIPE AIR DUCT ASBESTOS RISK

- TRANSITE PIPE CHIMNEYS & FLUES - Guide to Identifying Asbestos Transite Chimneys & Flues & their Hazards in buildings

- TRANSITE PIPE WATER SUPPLY PIPING - Guide to Identifying Asbestos Cement Transite Water Pipes & their Hazards in buildings

- ASBESTOS FLOOR TILE COMPOSITION

- ASBESTOS PRODUCING COMPANIES & TRUSTS complete list of companies that produced products containing asbestos

- DOES THIS FLOOR CONTAIN ASBESTOS? - 5 easy questions to tell if your FLOOR probably contains asbestos -

- DOES THIS MATERIAL CONTAIN ASBESTOS? - 5 easy questions to tell if a BUILDING MATERIAL probably contains asbestos -

Suggested citation for this web page

ASBESTOS CEMENT PRODUCTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Comments

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] ASBESTOS HISTORY & PROPERTIES [Book online] D.V. Roasato, engineering consultant, Newton MA, Reinhold Publishing Co., NY, 1959, Library of Congress Catalog No. 59-12535. We are in process of re-publishing this interesting text. Excerpts & adaptations are found in InspectApedia.com articles on asbestos history, production & visual identification in and on buildings.

- [2] "Asbestos in Plastic Compositions", A.B. Cummins, Modern Plastics [un-dated, pre 1952]

- [3] "Asbestos in Your Home," Spokane County Air Pollution Control Authority, Spokane WA 509-477-4727 www.scapa.org provides a one-page image, a .pdf file drawing of a house warning of some possible sources of asbestos in the home. The sources are not ranked according to actual risk of releasing hazardous levels of airborne asbestos fibers and the list is useful but incomplete.

- [4] The US EPA provides a sample list of asbestos containing products epa.gov/earth1r6/6pd/asbestos/asbmatl.htm

- [5] "Characterization of asbestos exposure among automotive mechanics servicing and handling asbestos-containing materials", Gary Scott Dotson, University of South Florida, 1 June 2006, web search 3/9/2012 original source: scholarcommons.usf.edu/cgi/viewcontent.cgi?article=3505&context=etd [copy on file as /hazmat/Automotive_Asbestos_Exposure.pdf ].

- [6] Photos of theater wiring possibly containing asbestos are from http://filmhacks.wordpress.com/2007/07/10/photos-and-a-question/ - used by permission, September 2008. Thanks to randomblogmail

- [7] Thanks to Susan Kimball, Argus Pacific Corp., Puget Sound, WA, for pointing out that some products are permitted to contain more than 1% asbestos fibers by current standards provided that the fibers are encapsulated in an appropriate binder. Argus Pacific, in Seattle, WA 98119, 206.285.3373, is an industrial hygiene firm who also provide OSHA and DOSH regulated training in Washington State, providing classes in asbestos, lead, mold, hazardous waste, emergency response, and other occupational health, safety, and professional development topics. -- September 2008.

- [8] " Work Practice for Window Removal and Window Putty Patching With Less Than Or Equal To 1% Asbestos Window Putty and Caulking" University of Washington, 2002 http://www.washington.edu/admin/asbestos/1putty.html

- [9] How do I Manage Asbestos in our House or Apartment Building?, Illinois Department of Environmental Conservation, provides this article at http://www.epa.state.il.us/small-business/asbestos-in-home/

- [11] Damian Murphy, Marin OHS&E Consulting,Mairin OHS&E Consulting Pty Ltd 18-20 Kirk Street Moe Vic 3825 P: 03 5127 2311 F: 03 5127 2399 E: enquiries@mairin.net.au, personal correspondence to Daniel Friedman. 3/12/2013 Website: www.mairin.net.au

- [12] Asbestos in buildings - employee notice, University of Washington dept. of Environmental Safety, http://www.ehs.washington.edu/ohsasbestos/index.shtm

- [13] Window putty to be exempted from asbestos removal by State of Maine - http://list.uvm.edu/cgi-bin/wa?A2=SAFETY;wYpdKg;20010307113643-0500A

- [14] EPA Region 6 identifies window putty as asbestos containing - http://www.epa.gov/earth1r6/6pd/asbestos/asbmatl.htm

- June 1997 - Window Putty - OSHA case cites contractor for asbestos exposure during removal of window putty http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=NEWS_RELEASES&p_id=1091

- [15] Asbestos Identification and Testing References

- Asbestos Identification, Walter C.McCrone, McCrone Research Institute, Chicago, IL.1987 ISBN 0-904962-11-3. Dr. McCrone literally "wrote the book" on asbestos identification procedures which formed the basis for current work by asbestos identification laboratories.

- Stanton, .F., et al., National Bureau of Standards Special Publication 506: 143-151

- Pott, F., Staub-Reinhalf Luft 38, 486-490 (1978) cited by McCrone

- [16] EM>ASBESTOS IN YOUR HOME U.S. EPA, Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- "Handling Asbestos-Containing roofing material - an update", Carl Good, NRCA Associate Executive Director, Professional Roofing, February 1992, p. 38-43

- [17] EPA Guidance for Controlling Asbestos-Containing Materials in buildings, NIAST, National Institute on Abatement Sciences & Technology, [republishing EPA public documents] 1985 ed., Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- [18] EPA ASBESTOS MATERIALS BAN: CLARIFICATION 1999

- [19] Building Failures, Diagnosis & Avoidance, 2d Ed., W.H. Ransom, E.& F. Spon, New York, 1987 ISBN 0-419-14270-3

- [20] Asbestos products and their history and use in various building materials such as asphalt and vinyl flooring includes discussion which draws on ASBESTOS, ITS INDUSTRIAL APPLICATIONS, ROSATO 1959, D.V. Rosato, engineering consultant, Newton, MA, Reinhold Publishing, 1959 Library of Congress Catalog Card No.: 59-12535 (out of print, text and images available at InspectAPedia.com).

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.