Asbestos Textiles

Asbestos Textiles

History, Manufacture & Identification of Asbestos Cloth, Yarns, & Asbestos Fabrics

- POST a QUESTION or COMMENT about what building materials may contain asbestos, visual identification of asbestos-containing materials in buildings, and possible asbestos material identification by testing, use, age, appearance

Asbestos Textiles:

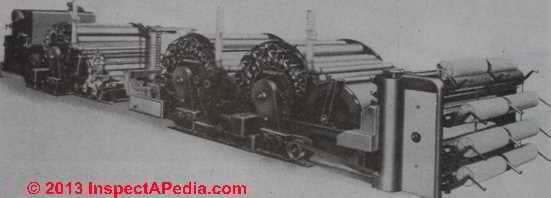

The history, manufacturing process & uses of asbestos textiles, fabrics, and fibers used in such products as fireproof blankets, safety clothing, packings, clutch facings, brake linings, plastics, and filters. Page top photo: an asbestos textile weaving operation showing standard magazine creel and loom creel - Adapted from Rosato (1959) .

This articles series about the manufacture & use of asbestos-containing products includes detailed information on the production methods, asbestos content, and the identity and use of asbestos-containing materials.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Asbestos Textiles: Manufacture, Uses, History

Introduction to the Production & Uses of Asbestos Fabrics

Introduction to the Production & Uses of Asbestos Fabrics

The following text is Adapted from Rosato (1959) p. 130-141 [1]

Next to the asbestos-cement industry, probably the most important use of asbestos is in the manufacture of yarn and cloth.

These textiles are used in such different products as safety clothing, packings, clutch facings, brake linings, plastics, and filters.

[Click to enlarge any image]

The process of manufacturing asbestos textile products follows the process that is used for other textiles. The nature and characteristic of asbestos fibers differ from organic fibers.

The asbestos cloth vibration dampener shown at left is discussed

at ASBESTOS DUCT VIBRATION DAMPERS.

Cotton fibers are rough, twisted and irregular; wool fibers are covered with scaly bands. However, asbestos fiber has none of the characteristics which enable the individual fibers to cling to each other.

This lack of spinning bond can make the manufacture of pure asbestos yarns difficult and costly, especially if fine yarns are required. Special opening and blending processes for asbestos fibers are necessary. The fibers are processed in carding machines similar to those used for wool.

The main reason for the use of asbestos fiber in the manufacture

of textiles is because of its fire and heat resistance,

acid resistance, and durability.

See ASBESTOS TEMPERATURE PROPERTIES

and ASBESTOS CHEMICAL PROPERTIES

Asbestos textiles, being mineral, are durable even under severe service conditions; e.g., they are used as padding and cover cloths on flat work ironers in commercial laundries. Another example of the durability of asbestos is its use as belting for the conveying of hot materials.

In the manufacture of wire, or galvanized materials, other materials could probably be used for the hot-metallic wiping process but they would need constant replacement. Asbestos lasts much longer.

The largest quantities of asbestos textile fibers are used for friction materials, industrial packing, electrical insulation and thermal insulation, applications where heat resistance and durability are required.

Engineering has made possible the combination of asbestos

with natural and synthetic fibers into useful yarns,

threads, cloths, and tapes.

Engineering has made possible the combination of asbestos

with natural and synthetic fibers into useful yarns,

threads, cloths, and tapes.

The utility of fibers, filaments and yarns, both natural and man made, as textile raw materials depends principally upon the physical properties of the fibers, which include mechanical, thermal, optical and electrical properties. Among the properties which make asbestos interesting is its modulus of elasticity which is 25 x 106 psi.

The asbestos cloth pipe or duct wrap shown at left is discussed

at ASBESTOS DUCT VIBRATION DAMPERS.

The longer and better grades of asbestos fiber, which are the Quebec Standard Crudes No. 1 and 2, and Group 3 are generally the only fibers used for the manufacture of asbestos textiles.

Combining or blending fibers is considered an art; it involves mixing different grades of asbestos.

Chrysotile is used predominantly. Crocidolite and amosite are sometimes blended with chrysotile. Blue asbestos textiles are manufactured for special acid-resistant applications.

In these applications, crocidolite (blue) is generally used by itself. Coarse yarns are manufactured which are considered highly specialized products.

Asbestos is the only mineral that may be fabricated into finished products by using spindles, looms, and other textile equipment. Amosite asbestos, even though it has long fiber and fairly high tensile strength, is very difficult to fabricate into textile products because of the coarse nature of the fiber. It has a tendency to pulverize in the textile operation.

The fibrous structure of long asbestos permits its use by itself in textile equipment.

The long asbestos fibers as well as other types of fibers which have length can provide the carrying action for shorter asbestos fibers such as Group 3.

The carrier fibers are definitely required for handling shorter asbestos fibers. When cotton is used with short asbestos fibers, low cost products can be produced which still provide certain degrees of heat resistance and good physical properties.

Most of the asbestos yarns manufactured are plied yarns. Single yarns are not a very satisfactory product because asbestos fibers are lacking in uniformity. Uniformity can be achieved by such special processes as chemically dispersing asbestos.

The fault of nonuniformity in mechanically opened fibers is overcome by doubling two or more strands of yarn. In twisted yarns, there are two important points to be considered; i.e., uniformity and strength. Uniformity identifies the diameter and weight of yarn.

The strength of the yarn depends principally upon the fiber length and the grade of fibers used.

Identification of Asbestos Textiles

Standards for numbering asbestos yarn are used. For example, ASTM (D299-52) pertains to asbestos yarns and describes methods of identifying the yarn.

The asbestos textile industry uses a numbering system for the yarn; it designates the cut, number of plies, and whether the yarn is plain or metallic. In a four digit figure, the first two digits indicate the cut, the next digit indicates the number of plies and the final digit indicates the number of metallic strands.

If the final digit is a zero, it indicates a plain yarn. In a three digit system, only the first digit indicates the cut.

The term "cut" is derived by cutting (dividing) 7,000 grains into linear mass units by the grain weight of one hundred yards of a single yarn. The number of such units expresses the number of the cut and when multiplied by one hundred, indicates the nominal yards per pound.

The term "ply" identifies the number of strands of single asbestos yarn twisted together to form a heavier yarn. Ply is a term used principally in combination with a number to designate the strands of single yarn twisted together— 2 ply, 3 ply, etc.

Plain, single asbestos yarn is generally identified by cut numbers ranging from 5 to 50 cut. A 5 cut yarn represents 500 yd of yarn weighing one pound. For a 10 cut yarn, 1,000 yd weighs one pound. The 50 cut yarn involves 5,000 yd per pound. Examples of yarn designations are No. 931 yarn (9 cut, 3 ply, 1 wire yarn) and No. 1420 yarn (14 cut, 2 ply, plain yarn).

Various methods of identifying woven asbestos cloth are used.

ASTM Specification (D677-50) pertains to asbestos cloth. An example of the Asbestos Textile Institute designation for cloth is No. 20P28. The digits that precede the letter identify the weight of the cloth in ounces per square yard. The letter identifies the weave and the remaining digits identify the cut of the yarn used in weaving.

The asbestos content of an asbestos textile is the principal and sole criterion upon which the grade of the asbestos product is based. Within each grade there may be a variety of constructions, weights, weave designs and insertions which may serve to yield fabrics having different properties for different applications.

The ASTM has established standards which classify asbestos products in accordance with the percent of asbestos content. Table 8.1 lists these percentages.

TABLE 8.1. PERCENTAGE OF ASBESTOS CONTENT IN ASBESTOS TEXTILE PRODUCTS |

|

| ASTM Grade | Asbestos Content, % by wt |

| Commercial | 75 up to but not including 80 |

| Underwriter | 80 up to but not including 85 |

| Grade A | 85 up to but not including 90 |

| Grade AA | 90 up to but not including 95 |

| Grade AAA | 95 up to but not including 99 |

| Grade AAAA | 99 up to and including 100 % asbestos |

| Adapted from Rosato (1959) p. 133 | |

One practical method of determining chrysotile asbestos content of an asbestos textile product which is not treated with resins or other foreign matter is to determine the cotton or organic content of the product in accord with ASTM procedures.

This method describes that one test specimen, weighing not less than 5 grams taken from each sample roll, dried to constant weight in an oven at 105 to 110°C, and the weights of the dried specimens reported. The specimens are placed in an electric oven and heated for not less than one hour at 800 to 8100C.

After removal from the oven they are cooled to room temperature in a desiccator, and then weighed. The weight of the residue is divided by the factor 0.86 in order to determine the original weight of the asbestos content.

This weight of asbestos content is divided by the weight of the dried specimens in order to obtain the percentage of asbestos.

The average of the determination shall be the asbestos content. In this particular example, the average of 14 per cent water of crystallization is used for chrysotile fiber. In other examples the per cent would of course vary.

High Temperature Data for Asbestos Textiles

In Table 8.2 the tensile strength of asbestos cloth at room temperature, with a 24 hr exposure at 800°F, is reported. All tensile tests were conducted at room temperature after the exposure. Tests were conducted in accord with ASTM (D577-52, Method D39, Section 10). This test is often called the tensile grab test.

These data are presented for general information based on different weaves. Temperature test data under different conditions are also reported in the chapter on Properties of Asbestos.

The weave specification affects many properties of the finished textile.

TABLE 82. TENSILE STRENGTH OF ASBESTOS CLOTH VS. TEMPERATURE* |

|||||||||

| 127 | 400 | 254.0 | 237.0 | 234.0 | 232.0 | 96.6 | 90.1 | 89.0 | 88.3 |

| 600 | 238.0 | 237.0 | 236.0 | 222.0 | 90.5 | 90.1 | 89.8 | 84.5 | |

| 800 | 258.0 | 254.0 | 249.0 | 248.0 | 98.1 | 96.5 | 94.8 | 94.4 | |

| 166 | 400 | 150.0 | 125.0 | 125.0 | 119.0 | 92.6 | 77.2 | 77.2 | 73.5 |

| 600 | 120.0 | 108.0 | 106.0 | 106.0 | 74.0 | 66.6 | 65.5 | 65.5 | |

| 800 | 110.0 | 111.0 | 106.0 | 108.0 | 68.5 | 68.5 | 65.5 | 66.5 | |

| 134 | 400 | 143.0 | 116.0 | 114.0 | 105.0 | 95.0 | 77 | 75.0 | 70.0 |

| 600 | 106.0 | 101.0 | 99.0 | 97.0 | 70.0 | 66 | 76.5 | 65.0 | |

| 800 | 103.0 | 95.0 | 91.5 | 88.0 | 69.0 | 63 | 60.5 | 59.0 | |

| 147 | 400 | 159.0 | 133.0 | 131.0 | 122.5 | 94.0 | 78.7 | 77.5 | 72.5 |

| 600 | 110.0 | 109.4 | 98.0 | 97.0 | 65.0 | 64.6 | 58.0 | 57.5 | |

| 800 | 94.5 | 98.5 | 96.6 | 96.0 | 56.0 | 58.4 | 57.2 | 56.8 | |

| 126 | 400 | 157.0 | 100.5 | 92.9 | 82.8 | 80.5 | 51.5 | 47.5 | 42.5 |

| 600 | 60.9 | 58.2 | 58.1 | 56.2 | 31.2 | 29.8 | 29.8 | 28.8 | |

| 800 | 56.5 | 54.0 | 54.0 | 53.0 | 29.0 | 27.7 | 27.7 | 27.2 | |

| 124 | 400 | 98.0 | 52.0 | 39.0 | 39.0 | 81.5 | 43.3 | 39.0 | 32.5 |

| 600 | 31.5 | 30.6 | 27.9 | 27.9 | 26.2 | 25.4 | 24.0 | 23.2 | |

| 800 | 28.5 | 28.1 | 28.0 | 28.0 | 23.8 | 23.4 | 23.4 | 23.3 | |

Notes to the Table Above

* Asbestos Textile Institute, Philadelphia, Penna., Report No. 23 ( Dec., Tests conducted at room temperature after temperature exposure.)

Adapted from Rosato (1959) p. 135

[Note that apparently the order of the two right-most columns were reversed in the original text; also we inserted decimal places missing in the original text - Ed.]

Notes to the table above

Adapted from Rosato (1959) p. 135

Manufacturing Processes for Asbestos Textiles

Basically the first step in the textile mill involves fiberizing asbestos and freeing it from rock impurities.

The fibers are first carded into a sheet, then separated into rovings which are wound on jack spools, and spun into yarn. Yarn can be made into thread, cord or rope.

Metallic yarns are made by adding strands of fine brass, copper or lead wire to the strands of asbestos. The yarns can be put into looms and woven into fabrics by dry or wet processes using textile operations. See Figure 8.1 below.

Figure 8.1. Asbestos loom showing weaving operation with standard magazine creel and creel for loom. Courtesy The Johns-Manvill Corporation.

Crude fiber is generally prepared for spinning at the factory where it is to be spun. Preliminary treatment of fiber is usually accomplished in a pan crusher. This type of equipment consists of steel wheels approximately 1 1 /2 to 2 ft in diameter with a flat surface on the periphery which in turn rolls around in a circular pan.

Crude fiber is fed into the pan and scrapers push .the fiber under the rotating wheel. This operation is very critical since it can mechanically break the fibers. Special techniques and such engineered rolls as rotary-toothed cylinders have been devised to reduce damage of fibers.

After crushing, the fibers are transferred to opening devices which actually fiberize the product further. The opened or fiberized fibers pass over shaking screens or through trommel screens where they are again cleaned. Final operation generally involves lifting of suitable asbestos fibers by air suction.

Blending of such fibers as asbestos with cotton can be preformed in the preliminary mixing operation prior to the carding operation. However, the blending is generally performed during the carding operation.

Carding rolls are fitted with a series of sharp steel bristle rotating brushes which comb the fibers into specific positions.

During this combining operation short fibers and minute contaminating products such as rocks are removed. The result of carding is that opened asbestos fiber is formed into a loose continuous sheet or blanket.

Figure 8.2. A line of up-to-date carding machinery. Courtesy Davis & Furber Machine Co.

The carding process involves fiber material which is fed from a hopper to a weighing pan on the lifter apron of the carding machine.

See Figure 8.2 above. A comb which passes over the apron spreads the moving mass and prevents accumulation of fibers. The weighing pan continuously supplies a predetermined amount of fibers.

The fibers drop onto a conveyor apron of the carding table which carries it to the "licker-in" rolls.

In the carding machine, the fibers are combed by passing them between the main cylinder and the worker cylinders. The combining action is provided by the excess surface speed of the main cylinder over that of the worker The fibers are rubbed into loosely compact strands between oscillating surfaces.

These strands or rovings are then wound on jack spools for spinning.

Figure 8.3. Asbestos roving is being wound on jack spools after asbestos sheets leave carding machines. Courtesy Johns-Manville Corporation.

When fibers such as cotton are added to asbestos, they are added during the carding process. By means of a weighing scale, different percentages of fibers can be made into a web.

The web is lifted from the main cylinder of the carding machine by the doffer comb.

From there it is divided into narrow ribbons corresponding to the number of rovings. Figure 8.3 shows roving being wound on jack spools as it leaves an asbestos carding machine.

The rovings are condensed in a rub apron and are spooled singly on paper cores or together on a jack spool. These rovings obtain strength by a spinning process.

The strength which asbestos roving lacks is supplied by twisting in the spinning frames which are standard textile equipment. After the spinning operation, it can be plied with similar rovings.

Asbestos yarns can be made up with such different core as fine metal wires, cotton, glass and nylon. The uniformity of the asbestos yarn is principally directly related to the carding operation.

Description of Asbestos Textile Products

In the manufacture of asbestos textiles, the carded blanket or web is cut into narrow strips identified as slivers. Asbestos lap is made by combining in a parallel layup varying numbers of slivers to form different weights. Asbestos lap is wound into roll form which is supplied to fabricators which recard them for insulating electrical wires and cables.

These narrow strips of the carded web (or lap) when rubbed mechanically into untwisted strands are called rovings.

Yarn can be made as plain and metallic (or wire-inserted yarn). The standard insert is one or more strands of 8-mil brass wire but for special purposes wire of different diameter may be used. Other metals or alloys of copper, zinc, nickel, "Nichrome," "Inconel," and "Monel" are used in place of the brass.

When yarns are wetted with water during the weaving operations, the finished product is harsher and more open than cloth woven dry. Numerous patents have been issued for improving strength properties of asbestos yarn. American Cyanamid Company has British Patent 563,678 (1944) which specifies that in order to strengthen asbestos yarn, the yarn is impregnated with a melamine resin.

Figure 8.4. Flue cleaning hose is covered with a braid of heat resistant asbestos cord. Such a cover protects the hose from the hot walls of flues and resists the transfer of heat to the hands of the operator. (Courtesy The Gates Rubber Co.)

Such varied methods have been developed to produce new textile products as combining asbestos fibers with glass or ceramic fiber strands. Another interesting process is the use of short asbestos fiber with no long fiber carriers to produce yarn.

Asbestos, paper strips are used to produce the yarn.

The fiber is separated in a beater and mixed with a liquid to form a pulp. The pulp is transferred to a paper machine where the fibers adhere to moving rolls.

An endless blanket picks up the matted fiber and carries it on into a continuous sheet. The sheet is peeled off, dried and wound in a large roll. Then it can be cut into narrow strips and with special machines it can be spirally wound into single yarns.

Other textile products include braided and knitted fabrics, wick for caulking and seals, rope for boiler expansion joints and gaskets, loose carded fiber for filtration, felts for belting and packing, tape for electrical and thermal barriers, tubing or sleeving for electrical cables, and mechanical abrasion protection of items subject to heat.

See Figure 8.4 above.

They provide for

- parachute pack covers

- theater curtains,

- firesmothering blankets - see ASBESTOS FIRE BLANKETS

- fire fighting suits,

- fuel and oil hose,

- conveyor belts,

- clothing for industrial plants,

- ironing pads,

and others as listed in the introductory chapter.

1966 race car luggage box used FibraFrax heatproof material - Identify it? Asbestos? Modern Alternative?

On 2022-04-27 reader Pekay asks:

I'm trying to find some information on this old 1960s heatproof material that was was affixed as a lining inside some luggage boxes fitted to a race car in 1966. It seems to have been called 'FIBROFAX' on some documents we found, (but could possibly be a mis-spelling of 'FIBROFIX' ?).

I'm trying to find some information on this old 1960s heatproof material that was was affixed as a lining inside some luggage boxes fitted to a race car in 1966. It seems to have been called 'FIBROFAX' on some documents we found, (but could possibly be a mis-spelling of 'FIBROFIX' ?).

We need to understand the original spec and find some better photos , or ideally a sample, so we can replicate the exact appearance of this material on a restoration of an old car that we are working on.

The exact description of this material as shown on the drawing is "FIBROFAX 9705 Heat Reflecting Material".

Can anyone help with more information please?

On 2022-04-27 by Inspectapedia Com Moderator - 1960s "heatproof" material

@Pekay,

1. The hazard of what's there:

Certainly asbestos was used in some such applications. The amount in your photo is trivial - and might be removed and cleaned using appropriate damp wipe and HEPA vac before installing a replacement. This is a case where the Wise Lady from Philadelphia tells us it's more reasonable to treat a tiny amount of material as harmful than to spend more than its replacement cost on testing.

2. The history of the fire-resistant luggage box liner in 1960s race cars

Take a look at "Fiberfrax " - a product featured by what is now Unifrax Company - https://www.unifrax.com/about-us/

Website excerpts:

Unifrax is a global leader in high-performance specialty fibers and inorganic materials used in high-temperature industrial, automotive, and fire protection applications.

The spirit of innovation that began more than 75 years ago with our Fiberfrax® ceramic fiber product line ...

3. Replacement materials - asbestos free - for fire resistance in cars

That said, you might take a look at some of the modern fire-retardant fabrics

That said, you might take a look at some of the modern fire-retardant fabrics

such as Fiberfrax Ceramic Fiber Paper - 550K - sold currently online various vendors and still made by Unifrax - that's a white ceramic fiber paper - probably closest to what was in your original installation, described as

Fiberfrax offers a unique set of ceramic fiber products which consist primarily of a alumino-silicate fiber in a non-woven matrix with a latex binder system. A specialized process is used to form uniform, lightweight, flexible sheets. Unifrax provides a wide range of paper and blanket products, only one of which is listed here. This product is rated at 2300 degrees F.

Typical applications include gaskets for ovens, stoves and heaters, automotive and aerospace heat shields, backup insulation in glass tanks, among others.

Fiberfrax® Ceramic Fiber Papers are a unique class of products which consists primarily of an alumino-silicate fiber in a non-woven matrix with a latex binder system. A specialized paper-making process is used to form uniform, lightweight, flexible sheets.

By blending different fibers, binders, and additives while varying the manufacturing process, Unifrax Corporation now produces a variety of Fiberfrax paper products for a wide range of applications.

Fiberfrax ceramic fiber papers are differentiated by thickness, density, fiber index, and chemistry.

see https://www.unifrax.com/product/fiberfrax-ceramic-fiber-papers/

Fiberfrax is sold in a range of thicknesses and formats. An example is shown below.

Thicker versions are available if that's what you need.

Fibrofax is further described in these patent disclosures (read the patents using Google Scholar)

- Ashen, D. J., G. C. Bromberger, and T. J. Lewis. "Kinetics of the reduction of silicon tetrachloride and trichlorosilane by hydrogen." Journal of Applied Chemistry 18, no. 12 (1968): 348-352.

- Best, Willie H. "Radiant burner." U.S. Patent 3,561,902, issued February 9, 1971.

- Reed, Thomas B. "High temperature furnace." U.S. Patent 3,414,661, issued December 3, 1968.

and in this NASA document: - NASA, DARK CONDUCTIVITY OF CdS AS A FUNCTION OF S-VAPOR PRESSURE DURING HEAT TREATMENT BETWEEN 500' and 7OO0C Technical Report 16 NASA NsG-573 GODDARD SPACE FLIGHT CE - original source: https://ntrs.nasa.gov/api/citations/19680002800/downloads/19680002800.pdf

On 2022-04-27 by Pekay

What a fantastically helpful and detailed reply you've given. Many many thanks for all the information! Take care

On 2022-04-27 by Inspectapedia Com Moderator

@Pekay,

It was an interesting question and we were glad to assist your project. We have moved this discussion over onto the homepage for this topic at

ASBESTOS TEXTLES [you are on that page - Ed.]

And if you want to add a photo of the car, that would be fun for readers to see. Especially if you want to do before and after photos.

Asbestos fabrics coated with metallic or rubber base compounds have been developed as heat and flame reflectors or insulators.

Various ASTM and Federal Specifications have been prepared which pertain to these different textile products.

Asbestos fabrics are also used in and discussed

at ASBESTOS PACKINGS & GASKETS.

Research, History, Patents involving Asbestos Cloth, Textiles, Yarns & Threads

- Anolick, Colin, Vivian M. Robinson, and Charles W. Stewart Sr. "Upholstered furniture having improved flame resistance." U.S. Patent 4,174,420, issued November 13, 1979. -

The word "asbestos" does not appear in this patent; - ASBESTOS FIRE BLANKETS

- ASBESTOS FURNITURE PADDING

- ASBESTOS-CONTAMINTATED JUTE BAGS

- Clarkson, R. "Production of asbestos yarns." U.S. Patent 3,811,262, issued May 21, 1974.

- Cruz, M. J., J. Sampol, M. Pallero, E. Rodríguez, and J. Ferrer. "Asbestos-related disease in upholsterers." Archives of environmental & occupational health 73, no. 3 (2018): 186-188.

- Edward, Rambusch. "Ceiling carried fabric louver structure." U.S. Patent 2,527,031, issued October 24, 1950.

- Foster, Boutwell H., and Herbert E. Sunbury. "Dish towel." U.S. Patent 2,413,964, issued January 7, 1947.

These desirable properties are imparted to the dish towel herein contemplated by making the yarn of which the fabric forming the toweling is woven, primarily of cotton fibers but which cotton fibers have mixed therewith a substantial amount of asbestos fibers. - Gibbons, Willis A. "Fire repellent pile fabric." U.S. Patent 2,239,457, issued April 22, 1941.

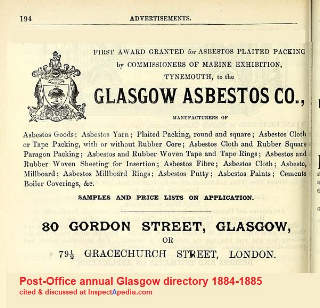

- Glasgow Asbestos Co, ca 1884-1885, [illustrated below] FIRST AWARD GRANTED for ASBESTOS PLAITED PACKING

by COMMISSIONERS OF MARINE EXHIBITION,

TYNEMOUTH, to the

GLASGOW ASBESTOS CO.,

MANUFACTURERS OF

Asbestos Goods ; Asbestos Yarn ; Plaited Packing, round and square ; Asbestos Cloth or Tape Packing, with or without Rubber Core ; Asbestos Cloth and Rubber Square Paragon Packing ; Asbestos and Rubber Woven Tape and Tape Rings ; Asbestos and Rubber Woven Sheeting for Insertion ; Asbestos Fibre ; Asbestos Cloth ; Asbesto, Millboard ; Asbestos Millboard Rings ; Asbestos Putty ; Asbestos Paints ; Cements Boiler Coverings, &c.

SAMPLES AND PRICE LISTS ON APPLICATION.

80 Gordon Street, Glasgow, or 794 Gracechurch Street, London. - source: Scottish Post Office Directory, p. 194, https://digital.nls.uk/directories/browse/archive/84565819?mode=transcription

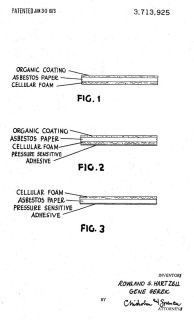

- Hartzell, R., and Gene Gerek. "Asbestos sheet material directly adhered to a cellular foam substrate." U.S. Patent 3,713,925, issued January 30, 1973.

Durable sheet products are provided by coated asbestos sheet material adhered to a cellular foam substrate. In preferred embodiments a vinyl foam, a polyurethane foam or polystyrene foam is produced in contact with asbestos paper coated with an organic coating composition; in some cases the foam has an adhesive layer on the exposed surface or the coating on the asbestos is an adhesive.

... Such coated asbestos-foam laminates are suitable, for example, for flooring, decorative wall covering or panels, insulating panels, protective coverings, tops for furniture or counters, and the like.

See the illustration above-left. - Hartzell, Rowland S., and Gene Gerek. "Asbestos-foam laminates." U.S. Patent 3,522,140, issued July 28, 1970.

Excerpt:

Such coated asbestos-foam laminates are suitable, for example, for flooring, decorative wall covering or panels, insulating panels, protective coverings, tops for furniture or counters, and the like. - NAAC, North American Asbestos Corporation, Chicago IL., and in Canada, Cape Asbestos (Canada) Ltd., 200 Bloor St. E., Toronto, Canada, produced Noramite, a group of fibre or yarn products described as below. Both companies were subsidiaries of The Cape Asbestos Company, Ltd., London. The Noramite trademark was filed in Canada 1961-04-05 and was inactivated in 1992, by the North American Asbestos Corporation.

Noramite ... Crocidolite and Amosite asbestos products for reinforcement of plastics. Noramite identifies a group of new products which greatly extend the range of properties normally available in reinforcing fibers.

Noramite products, all based on Amosite or Crocidolite abestos, include prepared fibers, rovings, ropes, and fabrics. Greater chemical resistance, higher modului, and greater heat resistance are among the principal advantages.

- Rene, Leboime, and Jacqueau Henri. "Balloon envelope fabric." U.S. Patent 2,523,312, issued September 26, 1950.

- Stedman, Theodore W. "Plastic fabric." U.S. Patent 2,354,435, issued July 25, 1944.

- Tucker, Jesse L. "Insulating fabric." U.S. Patent 2,561,891, issued July 24, 1951.

Excerpt:

The instant invention relates to fabrics particularly for use in the fabrication of safety clothing such as gloves, shoes, boots, suits, and the like employed as a protection to the human body against hot oils, flame, chemicals, gases, etc.

Conventional garments of this type, particularly those used for fire fighting, have been made of woven asbestos cloth. These fabrics have the disadvantage that they are pervious to fluids.

For example, in the case of fires involving oils or other inflammable liquids, where the suits are exposed to contact with the liquids, they may act as a carrier for, rather than as a protection against, fire. Also. such suits do not have the desired thermal insulating qualities.

Attempts have been made to overcome these disadvantages but prior to the instant invention they have not met with complete success.

The instant invention has for its principal object the provision of a fabric retaining the advantages of the conventional asbestos fabrics but which is resistant to penetration by fluids and which is of relatively high insulating efficiency.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-10-27 by Anonymous - Asbestos was not a component in yarn found at hobby stores in the 60s and 70s, correct?

This feels like a stupid question, but Google yields unhelpful and conflicting results.

This feels like a stupid question, but Google yields unhelpful and conflicting results.

Asbestos was not a component in yarn found at hobby stores in the 60s and 70s, correct?

To me, it would make no sense to sell such a yarn, but one never knows what has once been deemed acceptable to sell.

Reply by inspectapedia.com.moderator (mod) - Asbestos yarn widely sold even to the present

@Anonymous,

It's not a stupid question, but it is one that is guaranteed to give ambiguous results.

And no, not "correct" as you put it. One can not say authoritatively that asbestos yarn was never sold in hobby stores nor that it is not sold in stores even today.

The reason is that what makes sense or no sense to you or me is never going to be a complete, nor accurate accounting of all of the possible uses of asbestos, nor where asbestos may be found in materials and products.

Having worked on this question for nearly fifty years I can tell you that the places where asbestos shows up vary beyond any one person's experience or imagination.

"Yarn" that contained asbestos was certainly produced, if one allows a bit of freedom in use of that word. For example asbestos "yarn" was used as packings, gaskets, and heavy asbestos threads or strings appeared in some specialty fabrics such as HVAC vibration duct dampeners, asbestos wicking, and in fire-resistant clothing used by firefighters.

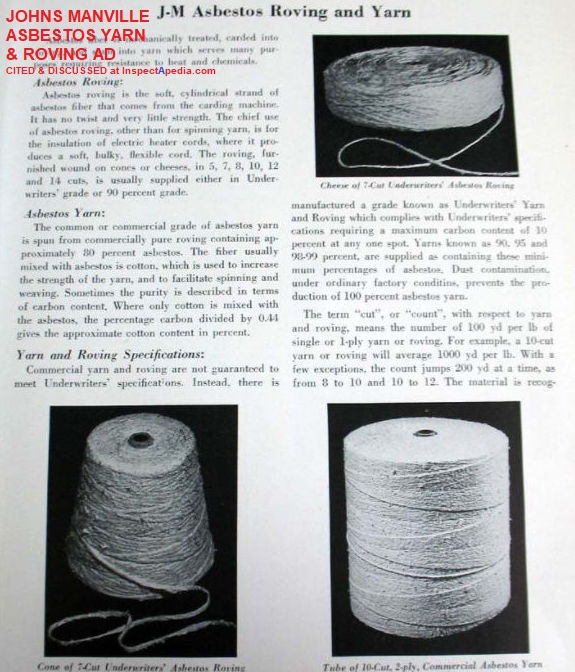

Below we show an old Johns Manville advertisement for Asbestos Yarn and Roving that might have been sold anywhere during its popular era, and in the U.S. up to the 1980s.

Considering the range of products sold by some hobby stores in the 1940s through 1960s on one should rule out the possibility of having bought an asbestos product in one such store or by mail order.

So your question is far too broad in concept to expect a solid yes or now answer documented by any authoritative source.

That said, one would not expect to find asbestos yarn, thread, fabric, in typical children's toys, private home seat cushions like the one shown on this page), nor sold for typical sweater-knitting or sock-knitting uses.

But the moment we realize that the word "yarn" was used far more broadly than for knitting socks, no one with any sense would promise you that no one could have bought "asbestos yarn" in any store, hobby or otherwise, over the course of the life of sale and use of asbestos materials around the world.

And depending on where you live, asbestos yarn products are still, in 2021, sold, as we illustrate in this advertisement shown below, retrieved today , 2021/1027

On 2021-10-13 by Anonymous - Is this bench fabric asbestos?

We have an old bench at our cabin, age unknown. As asbestos seems to have been used virtually everywhere, also in fabrics, I am wondering: is there a risk that the bench upholstry contains asbestos? (I think it is a homemade bench with homemade cushion. See picture, enclosed.)

...

I forgot to attach the picture. Here it is. Perhaps you could evaluate the fabric based on it?

Anyway, from what I can see in your articles, it doesn't seem very likely that our cushion upholstery contains asbestos (?) - Anon by private email 2021/09/18

Reply by inspectapedia.com.moderator (mod)

That upholstery looks pretty new and in all events the use of asbestos in a needle-point bench cover seems unlikely.

But

better than trying to invent a reply de-novo off-the-cuff here, I ask you to take a look at

DOES THIS MATERIAL CONTAIN ASBESTOS? - 5 easy questions to tell if a BUILDING MATERIAL probably contains asbestos -

while the eye and a photo are no substitute for an asbestos lab test, to me that looks like cotton.

On 2021-08-09 by WM - Was asbestos ever used in cloth textile window cord sashes?

Was asbestos ever used in cloth textile window cord sashes? We have likely original 1920s - we don’t use them and honestly rarely even open those shades or curtains. One is broken and frayed.

I can find a few websites that say so but mostly the fear mongering websites. My husband says since don’t use them to open the windows it’s not worth getting tested but I worry about my children. We’ve lived here for 7 years and I never really thought about it.

On 2021-08-09 by inspectapedia.com.moderator (mod)

@WM,

Asbestos "rope gaskets" were produced and widely used in wood and coal stoves and on some other heating equipment;

I've not found asbestos window sash cord -it seems unlikely but, then, ... you might try a patent search.

I agree with your husband. The worry is a greater health hazard than the unused window sash ropes.

On 2021-08-09 by WM

@inspectapedia.com.moderator, thank you! It’s just so hard when I read things on the internet - it says with age it will break down and fibers with movement and I don’t know if the curtains being moved and brushing them or a fan blowing in that direction would be considered a hazard since it’s in the room we use the most. I will see if I can figure out how to conduct a parent search.

On 2021-08-13 by inspectapedia.com.moderator (mod)

@WM,

Let's keep our perspective here; there is no evidence that your window ropes are asbestos, or ever were, and no measurable hazard from them.

The cost of the anxiety over this is the greater health risk than the window ropes.But rather than risk your health and a lot of time worrying over this, why not send a sample of window rope material to a certified asbestos test lab. Their fee may be worth your peace of mind.

On 2021-05-28 1 by RV - Is this cat-torn-up furniture stuffing asbestos?

I have an old chair my cats have absolutely torn up. I never thought the filler could be Asbestos. Is it?

Here's another section

On 2021-08-09 by (mod) - white chair stuffing looks like cotton

@RV,

While the eye and a photo are no substitute for an asbestos lab test, to me that looks like cotton

See details at

Question: asbestos in antique Stickley furniture cushion stuffing?

I wonder if you've ever heard of asbestos being used in antique Stickley furniture.

I wonder if you've ever heard of asbestos being used in antique Stickley furniture.

Specifically, I have 100-year-old chairs whose cushion material has dried out and turned into a powdery material.

I'm interested in your thoughts.

Thank you for your time.

- Anonymous by private email 2021/07/06

Moderator reply: no; more-common: cellulose, or wood product, or animal hair

I would not expect Stickley furniture itself to use asbestos materials - it's wood and glue.

Cushions would not normally contain or use asbestos fabric (and certainly not an asbestos stuffing) except in case furniture was particularly modified for fire-resistance, such as in a theatre.

More common cushion covering for the primary layer was cotton or burlap or jute fabric, over which a decorative slip cover of cotton or other material is typically installed.

In your photo that looks like a cellulose-wood-type fibre insulation but it's not so sharp and detailed that I can say for certain.

It is fibrous, woody, and brown-tan in colour- not suggestive of asbestos.

More-often by the time we find an antique chair that is still in use, its original cushions have been replaced.

The antique wood chair shown in our photo below, with Stickley-like components, sports modern cushions stuffed using a single block of foam and covered with cotton fabric.

Note that the chair above is not the Stickley chair discussed by our reader - Ed.

Reader follow-up: asbestos not found in Stickley chair cushion stuffing

I just wanted to update you about the material from would have to see a sample of the material up-close or under the microscope to identify the fibres for certain.

It does not look like asbestos.

On 2020-01-17 by TB - Expect possible asbestos in products made in China

I purchased a purse liner made of felt and wool from China. Is there any chance it could contain asbestos?

On 2020-01-18 by (mod) -

TB

I hate to be glib but gee I just have no idea except to say that we have no product control and no data on purses imported from China. While there's no obvious reason that some one would think asbestos was necessary in the purse fabric, well you know the history of some of these products.

The history of this topic is an old and long one. "Under the Han and throughout the third century, the Chinese accepted asbestos products as a fact, without inquiring into the nature of the mineral or the causes of its wonderful

properties. " Laufer, Berthold. "Asbestos and salamander." T'oung Pao 16 (1915): 299.

The expanded polystyrene (EPS) panels were imported from China and were thought to be asbestos-free, but subsequent testing by the National Association of Testing Authorities (NATA) has shown they contain chrysotile asbestos. https://www.safework.nsw.gov.au/hazards-a-z/asbestos/asbestos-in-imported-goods

There's been a great deal of coverage in the media recently related to the importation of asbestos materials inside products manufactured in China. https://www.coffey.com/en/ingenuity-coffey/from-china-with-asbestos/

The surge in asbestos imports is attributed to the revamped Toxic Substances ... China is second with 400,000 metric tons while Brazil is a close third with ... https://www.asbestos.com/news/2017/10/06/asbestos-imports-double-united-states/

exposed to a booming trade in Chinese products laced with asbestos ... Importers are responsible for ensuring the goods they import are free [from asbestos] https://www.theaustralian.com.au/nation/foreign-affairs/made-in-china-with-asbestos/news-story/e7e2ff6ab0663099409e6006325193b9

On 2019-11-05 by M

Hi,

I have an old desk from the 60s. I have been using it for 13 years but only recently started wondering about a pad covered in plastic at the back.

It seems to have a few tears and in it there is some white substance.

Could this be asbestos and how badly do you think it would have affected my health so far.

On 2019-11-07 - by (mod) -

M

Usually asbestos fabrics were used in special applications where the product needed fire resistance.

In the live links at RECOMMENDED ARTICLES list at the bottom of this page check out

ASBESTOS CLOTH discussed in ASBESTOS LIST of PRODUCTS

Also see ASBESTOS FURNITURE PADDING in that same listThe place to start with your health question is with your doctor.

On 2018-02-28 by Robert - Was asbestos used in upholstery fabric like to cover chairs and beds for home use?

Was asbestos used in upholstery fabric like to cover chairs and beds for home use? The fabric I am concerned about looks like gold and silver silk materials.

On 2018-11-23 - by (mod) - generally no

Asbestos was used in or as upholstery fabric in some special applications where fire resistance was needed, but not likely to have been in most ordinary fabric-covered furniture.

Examples of asbestos use in fabrics are given by more article links at the end of this page and in the ARTICLE INDEX found there.

...

Continue reading at ASBESTOS in PLASTICS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see ASBESTOS TEXTILE FAQs - questions & answers posted originally on this page

Or see these

Recommended Articles

- ASBESTOS CLOTH

- ASBESTOS DUCT VIBRATION DAMPENERS

- ASBESTOS ELECTRICAL WIRE INSULATION

- ASBESTOS FURNITURE PADDING

- ASPHALT-ASBESTOS FELT FLOORING

- ASBESTOS LIST of PRODUCTS - home

- ASBESTOS MAIL BAGS

- ASBESTOS MACHINE GUN MITTENS

- ASBESTOS in MATTRESSES

- ASBESTOS PACKINGS & GASKETS

- ASBESTOS PILLOWCASES

- ASBESTOS TEXTILES

- BICYCLE ASBESTOS USES

- DOES THIS MATERIAL CONTAIN ASBESTOS? - 5 easy questions to tell if a BUILDING MATERIAL probably contains asbestos -

- HAZARD vs RISK - what's the difference, why you should care

Suggested citation for this web page

ASBESTOS TEXTILES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] ASBESTOS HISTORY & PROPERTIES [Book online] D.V. Roasato, engineering consultant, Newton MA, Reinhold Publishing Co., NY, 1959, Library of Congress Catalog No. 59-12535. We are in process of re-publishing this interesting text. Excerpts & adaptations are found in InspectApedia.com articles on asbestos history, production & visual identification in and on buildings.

- [4] The US EPA provides a sample list of asbestos containing products epa.gov/earth1r6/6pd/asbestos/asbmatl.htm

- [6] ASBESTOS IN YOUR HOME U.S. EPA, Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- [7] Asbestos products and their history and use in various building materials such as asphalt and vinyl flooring includes discussion which draws on ASBESTOS, ITS INDUSTRIAL APPLICATIONS, ROSATO 1959, D.V. Rosato, engineering consultant, Newton, MA, Reinhold Publishing, 1959 Library of Congress Catalog Card No.: 59-12535 (out of print, text and images available at InspectAPedia.com).

- EPA ASBESTOS MATERIALS BAN: CLARIFICATION 1999

- Basic Information about Asbestos, US EPA, web search 08/17/2010, original source: http://www.epa.gov/asbestos/pubs/help.html

- EPA, ASBESTOS IN YOUR HOME [PDF] - U.S. EPA, Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.