Asbestos Cement Production Methods

Asbestos Cement Production Methods

asbestos cement roofing, siding & millboard

composition, history, production, uses, identification & safety

- POST a QUESTION or COMMENT about asbestos cement products, history, uses, materials, production, durability, and asbestos content

Manufacture of asbestos-cement products: this article describes the processes used to manufacture asbestos cement sheet, siding, roofing, pipe, and molded products. Dry, wet, and wet mechanical processes that were used to produce cemetn asbestos products are explained and illustrated.

Cement asbestos materials: this article series describes asbestos cement products & materials and the history of their production and use. This article includes text & data Adapted from Rosato (1959 out of print) on the production and use of asbestos-containing materials, adding photographs, inspection, repair and maintenance advice, and updates on asbestos hazards involved in the installation, repair, or demolition of asbestos cement products such as roofing and siding or asbestos millboard that remain in place on buildings.

Our page top photograph shows badly broken cement asbestos roofing shingles on a building in upstate New York.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Manufacturing Processes Used for Cement Asbestos Products

The following text is adapted & expanded from Rosato p. 66-73 [1] © 2021 InspectApedia.com

The following text is adapted & expanded from Rosato p. 66-73 [1] © 2021 InspectApedia.com

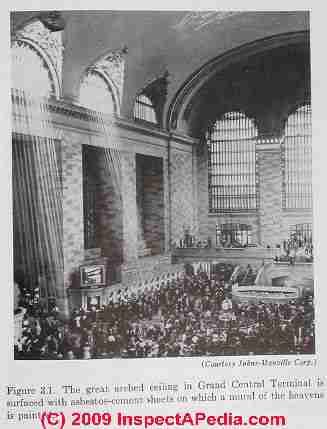

Figure 3.1 (Courtesy Johns-Manville Corp.)

The great arched ceiling in Grand Central Terminal is surfaced with asbestos-cement sheets on which a mural of the heavens is painted. [Click to enlarge any image]

More photos are in our ASBESTOS PHOTO GUIDE to MATERIALS at Asbestos Siding

Factors influencing asbestos-cement products include manufacturing process, composition, forming pressure, method of cure, and environmental conditions.

Generally, the long asbestos fibers or higher percentages of fibers will produce higher strength properties.

By using higher curing pressures or forming pressures, increased density can be achieved which in turn produces higher strength properties. The higher density products are less porous and sometimes give the effect of improving chemical resistant properties.

In the production of asbestos-cement products, as well as asbestos millboard and paper, the density of the opened fiber and its ability to remain in suspension are important factors.

These properties can be related to the buoyancy test method. The buoyancy of a fiber can be determined from a slurry of fiber in water using a definiteweight of fiber in a constant or definite volume of water. After it has been thoroughly mixed, the slurry is allowed to settle; the rate of settling for a given time is read in centimeters for a given time.

The air permeability method is another method of examining the degree to which the fiber has opened. With any manufacturing process, the asbestos fiber is required to be in proper form for best use. Usually, the fiber is opened as much as possible without excessively crushing or damaging it in order to secure the most efficient results.

The asbestos should be fluffed or separated so that it can be distributed uniformly through the product and not appear as hard clumps. Many devices are used for this processing; for some grades, it is adequately accomplished at the mines during the milling and grading operations. Hammer mills, edge mills, disintegrators, and similar equipment are used for this purpose. In some operations, the opening process is continued after the fiber, cement, and water have been mixed, by using pulp beaters, which aid also in securing uniform distribution of the fibers throughout the mixture.

Fillers and pigments may be added to reduce the raw material cost and to provide coloring. These are preferably inorganic; in order to hold true color they need to be stable against the highly alkaline nature of the Portland cement.

Asbestos Cement Molding Process

This process resembles the method used for forming asbestos plastic molded products. It is used for the manufacture of shapes and forms which would not be otherwise possible to manufacture. Manufacture by this process is limited to specialties; it represents only a very small part of the total output of asbestos-cement products.

Asbestos Cement Dry Process.

In this process, the raw materials are mixed dry, and spread in an even layer on an endless canvas belt. The thickness of the dry stock sheet is greater than the final thickness desired. It is sprinkled with water and compressed between pressure rollers to make it dense. The amount of water used at this point is critical, because insufficient water can lead to breakage when the product is removed from the belt; and excessive water can result in the material sticking to the roller.

The lower of these rollers is generally smooth; the upper roller may be textured or contoured to produce a pattern on the finished product. Cutters can be fitted on the rollers and simultaneously, the sheet can be trimmed to its final size and shape. The product is then removed from the belt, either mechanically or by hand, and stacked on pallets or frames for setting and curing.

Usually, the color is applied as a veneer on the exposed surface. This may be done as a dry addition before or after wetting the spread layer, or it can be sprayed on after the first pressure rolling operation.

This dry process is used principally for shingles, but it may be also used for other sheet products. It is not suitable for the manufacture of pipe or for any product where the sheet must be deformed after final pressing. It has several advantages and disadvantages, relative to the other processes.

The product is essentially equal in strength in all directions (isotropic). There are no such material losses through filtering as occur with the wet processes. The machine does not require continuous operation.

The product tends to have a lower unit strength than the wet process products; only relatively thin products can be made if the operation is to be practical. Unless the dry stock is spread evenly with uniform control, there are apt to be low density spots or nonuniform thickness.

The Hatschek Machine for Production of Asbestos Sheet Goods

The following excerpt is not from Rosato. Amy Lamb Woods in her article "Keeping a Lid on It" Asbestos-Cement Building Materials" gives this helpful historical comment on the production of sheet asbestos products:

The following excerpt is not from Rosato. Amy Lamb Woods in her article "Keeping a Lid on It" Asbestos-Cement Building Materials" gives this helpful historical comment on the production of sheet asbestos products:

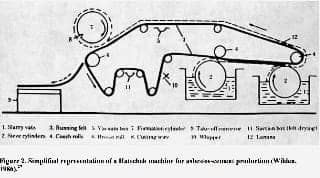

It was not until 1907 that the invention by an Austrian engineer, Ludwid Hatschek, made possible the manufacture of pre -formed asbestos-cement products. The Hatschek machine, a wet transfer roller, was used to produce the initial asbestos-cement sheets, while two other manufacturing processes included the Mazza process for pipes, and the Magnani semi-dry process for corrugated sheets. - Woods (2000)

[Click to Enlarge any Image]

Figure adapted from both Wilden (1986) and Woods (2000) at above left illustrates the 12 key parts and stages of a simplified Hatschek asbestos sheet goods production machine. The roller at 7. would have formed corrugated roof shape, embossed wood-grain in siding products, etc.

From the right side of the illustration these include

1. a Slurry vat,

2. Sieve cylinder,

3. Running felt,

4. Couch rolls,

5. Vacuum box,

6. Breast roll,

7. Formation Cylinder,

8. Cutting wire,

9. Take-off conveyor,

10. Whipper,

11. Suction box (felt drying),

12. Lamina.

After being formed, most products were steam cured to achieve the optimum microstructure for strength and durability. It is these asbestos-cement building products that hav e many desirable material characteristics, such as being lightweight, impermeable to water, durable, tough, resistant to rot, termites, soiling, corrosion, warping, and fire, and easy to clean and maintain.

Asbestos-cement also possesses low thermal conduc tivity and is therefore a good electrical insulator. These highly desirable material characteristics, apparent in the new found material, sparked growth in manufacture of a plethora of forms and styles to suit different needs.

With the refinement of the asbestos and cement mixture, as well as the forming and curing procedures, the market soon developed major commercial products of synthetic roof an d wall shingles, corrugated wall and roof panels, flat millboard, and decorative wall and ceiling moldings.

Additional manufactured products included water pipes, simulated ceramic bathroom tiles, facings of acoustical materials, electrical switchboard panels, laboratory tabletops, electrical conduits, and even smaller diameter pipes were used for purlins and trusses in wartime construction to conserve steel and lumber.

The principle manufactured products used in building construction were, in order of th eir production volume: siding shingles, flat sheets, roofing shingles, and corrugated sheets. These asbestos-cement products lent themselves to rapid construction techniques and, therefore, were particularly useful for lightweight housing and industrial buildings. - Woods (2000)

Asbestos Cement Wet Process.

In this process, the raw materials are usually blended dry, using any of several common types of mechanical mixer, and transferred in weighed batches to wet mixing tanks located higher than the press. Each weighed batch is sufficient for just one sheet, and its quantity depends upon the size, thickness, and density desired for the product to be made.

Weighing may be either manual or automatic; the number of wet mixing tanks required depends upon the mixing time relative to the pressing cycle.

Sufficient water is added to the batch to form a slurry that will flow readily; after it has been properly mixed, it is passed by gravity to the mold chamber of the press. The consistency of the slurry, particularly for large sheets, frequently requires a quick hoeing in the mold, to aid in the distribution across the chamber. Here, it is compressed to a dense, hard, and homogeneous sheet. The excess water is filtered out under the pressures supplied, and a dwell time at these pressures is required to permit escape of all of the excess water.

The formed sheets are usually placed on steel plates and allowed to set and harden for a period of 24 to 48 hr.

They are then cured in accord with the standard practice, prior to final trimming and shipment.

This process permits some variations in the form and shape of the manufactured products; e.g., corrugated sheets may be made directly. Their strength tends to be equal in all directions; they are not likely to have soft or low-density areas. The operation can be shut down without loss of raw materials; however, some material losses occur through filtering.

Asbestos Cement Wet Mechanical Process.

The wet mechanical process can mass produce varied shapes by the addition of mechanical operations to the basic process. The machinery used is similar to a paper making machine.

The mixing of the asbestos and cement slurry is highly important in the wet mechanical process, because the slurry must be distributed to form a thin film across the entire width of the machine. In some processes, the opened fibers are combined with the cement and mixed with water in a conventional pulp beater (Hollander) and fitted with knives in order to eliminate clusters of fibers.

The relatively heavy paste mixture in the pulp beater is delivered to a stirring vat where it is thinned, by the addition of water, usually recirculated to this mixer from the filtration cycle at the wet machine. It is important that agitation be constant and effective in order to prevent separation and settling of the solids in the slurry.

Other mixing systems are employed which have replaced the cumbersome Hollander mixer. Some of the modern procedures start with dry mixing, followed by a wet mixing just before the stock is fed to the machine. By this method, excessive hydration of the cement and the asbestos is avoided, faster filtration rates can be maintained, and a higher production rate obtained.

These dry mixers have the added advantage that asbestos and cement, if mixed in the dry state, adhere one to the other.

The dry cement crystals become entwined in the asbestos fibers and after a short time this mixture is so well mixed that it would be difficult to separate most of the cement from the asbestos fibers. Another advantage is that parts made by this process have a higher specific gravity (approximately 2.0), than the average value of asbestos-cement sheets (1.8 or 1.9).

The slurry flows to cylinder vats which are fitted with paddle agitators to prevent settling of the stock. There are usually three to four of these vats on each machine. Each vat contains a horizontal cylinder covered with a fine wire mesh screen, and fitted with seals at its ends so that flow can occur out of the vat and only through the wire, thus leaving a thin, even film of stock deposited on its surface while removing the major part of the water.

The thickness of the film depends upon the slurry level in the vat, its consistency, and the speed of rotation of the cylinder. The machine is usually operated so that the film deposited is approximately .02 to .10 in. thick.

The continuous woven felt travels above these cylinders, with its hairy side toward them; it is kept in firm uniform contact with them by heavy rubber covered rolls. At the contact surface, the film of stock is transferred to the felt and some water is removed. Each cylinder adds its film thickness to the web of stock on the felt. Additional water is drawn from the web by means of a vacuum box placed under the felt as it travels toward the cast iron or steel accumula-tor roll. There may be other vacuum boxes between the vats, to seat the stock web firmly on the felt.

As the web of stock passes under the accumulator roll, it is transferred to the roll in a continuous operation, until the sheet is built up to the desired thickness. Then the sheet is knifed along a groove in the roll and peeled from it to a conveyor table which draws the sheet clear of the machine. See Figure 3.2. During this operation, the machine continues to run, and a new sheet begins to form immediately on the accumulator roll.

Figure 3.2. Wet sheet of asbestos-cement is cut from the accumulator drum of a Hatschek machine prior to continuing on a conveyor to be made into building boards, etc.

(Courtesy The Ruberoid Co.)

The water removed during this operation is returned to the mixing area of the machine. This water contains a small quantity of asbestos and cement from the stock that has passed through the screens and the felts

. It is first retained for a period of time in settling tanks to clarify it. In addi-tion, the water very rapidly becomes saturated with soluble materials from the Portland cement.

This latter operation is generally beneficial because it eliminates further leaching of li me from the cement as the process continues. The solids separated from the water in the settling tanks are returned to the mixing chambers separately from the clarified water. Wet material, trimmed from the sheets, after it has been removed from the machine is also returned to the mixers and reduced to a pulp.

When the felt is returned toward the vats it is cleaned by means of shower sprays and whippers to remove any adher-ing stock particles. It is subjected to considerable strain and wear; usually, it has an effective life of only six to twelve days. Similarly, it is necessary to prevent the cylinder screens from clogging. They are cleaned continuously during operation with a shower spray immediately after the film of stock has been released and before it is dipped into the vat for a new film.

Treatment of the sheet formed after it has been separated from the accumulator roll depends upon the product to be made. If it is to remain as a flat sheet, it is usually lifted by suction and placed on a steel platform for setting and curing. It may be trimmed mechanically while it is on the table or after it has been transferred to the curing platform.

Sheets that are to be cut into shingles are usually passed mechanically through a pair of steel press rolls as they are removed from the machine. The lower roll is smooth, the upper roll is fitted with die cutters for the required shingle or other shape; it may also be contoured to impress a decorative texture into the surface of the material.

Sheets may be corrugated after removal from the wet machine. There are several methods of performing this operation; it includes both manual and mechanical processes. For example, the sheet may be positioned over a corrugated die, and lengths of pipe put on top of it in the corrugations.

Such an operation is preferably started at the center of the sheet, working toward both edges to permit the flat sheet to draw out evenly. The corrugated sheet is stored for curing between thin steel separators having matching corrugations. Another method of producing corrugated sheets provides for removal through a suction process of the sheet from the conveyor belt to a corrugated die, where the sheet automatically is pressed into the corrugations. Trans-fer and lifting of the wet sheets by suction bars provides for another process.

These bars are later pushed together, to produce the desired corrugations. The wet corrugated sheet is then placed on a corrugated die for final curing.

The character of the wet mechanical process furnishes several advantages over the other processes. It is the most flexible of the processes; it has a wide range of products that can be made and it has a high production rate; it offers a convenient way of applying a uniform color veneer.

The process needs to be maintained in continuous shifts for best economy; attention to cleanliness is important; otherwise, there may be clogging of the cylinder screens and the felt, and an inferior product may result (typical paper machine problems).

...

Continue reading at CEMENT ASBESTOS PRODUCT CURING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Also see ASBESTOS LIST of PRODUCTS

Suggested citation for this web page

CEMENT ASBESTOS PRODUCT MANUFACTURE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Roger Hankey is principal of Hankey and Brown Inspections, Winter Park, CO. Mr. Hankey is a past chairman of the ASHI Standards Committee and served in other ASHI chapter and national leadership roles. Mr. Hankey is a National Radon Proficiency Program certified measurement professional and a Level II infrared thermographer. Contact Roger Hankey at: 970-393-6604 - rogerhankey47@gmail.com . Website: www.HankeyandBrown.com Mr. Hankey is a frequent contributor to InspectAPedia.com.

- Arlene Puentes [Website: www.octoberhome.com ] , an ASHI member and a licensed home inspector in Kingston, NY, and has served on ASHI national committees as well as HVASHI Chapter President. Ms. Puentes can be contacted at ap@octoberhome.com

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.