Used or Re-conditioned Circuit Breakers

Used or Re-conditioned Circuit Breakers

Safety Advice, Circuit Breaker Reconditioning Standards, Procedures

- POST a QUESTION or COMMENT On using re-built or reconditioned or used electrical circuit breakers

Using re-conditioned, re-built, or used circuit breakers:

This article describes about possible performance and safety concerns expressed by manufacturers and other professional sources who discuss the purchase, installation, or use of used or re-conditioned or "rebuilt" circuit breakers used in residential electrical panels. We include references to circuit breaker reconditioning standards & procedures.

Possible concerns include un-listed, un-warranted electrical products that may have been modified in ways that may make their performance less reliable or unreliable. In turn, a circuit breaker that does not perform as it should increases the risk of a building fire, electrical shock, injury, or other losses.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Used or Re-built Circuit Breakers & Electrical Panel Safety Warnings

Reader Question: questions about using re-built circuit breakers

Reader Question: questions about using re-built circuit breakers

I recently had someone try to sell me a rebuilt circuit breaker and I declined the offer. I mentioned this to the inspector who told me that used breakers of any type are not allowed I have since been told that the NEC doesn't say anything about rebuilt or used breakers and that OSHA does allow rebuilt breakers.

Now, I'm not concerned with OSHA as this was a residential installation, but I am curious about used or rebuilt breakers. I didn't ask for written evidence that certain breakers aren't allowed, but I am curious what other jurisdictions might say about this.

I'm also curious as to how one would rebuild a standard sized residential breaker; it doesn't seem that it would be cost-effective.

This is mostly out of curiosity and thanks in advance.- Anon [by private email] 15 Aug 2015

PS: From e-bay on a $15.00 breaker, plus $14+ for shipping:

"Seller refurbished: An item that has been restored to working order by the eBay seller or a third party not approved by the manufacturer. This means the item has been inspected, cleaned, and repaired to full working order and is in excellent condition. This item may or may not be in original packaging. See the seller’s listing for full details."

Reply:

I have not found a national or model code prohibition on use of used electrical equipment; after all, if I am working on an electrical panel and remove a circuit breaker that has been in use for a time, then do some repairs, then replace the breaker and return it to use, I'm "installing" a used breaker into the panel.

But if I had reason to suspect that the used breaker may not perform safely, such as if it has been wet, flooded, corroded, burned, overheated, modified, or if it were a specific product about which there are particular field failure reports, I would not use it.

There is a large industry of electrical switch and circuit breaker re-conditioning and there are voluntary industry standards that we cite below. These appear to pertain principally to commercial electrical installations rather than the usual homeowner electrical panel.

In my view the gray area is so-called "re-built" circuit breakers used in residential electrical panels, exacerbated by a lack of actual information and certification for specific used and re-conditioned circuit breakers sold for residential use.

- What does "re-built" circuit breaker mean?

As far as I know, at least residential-use circuit breakers are not designed to permit reassembly and replacement of internal parts.

Typically the breaker case is molded and perhaps even riveted together. I doubt that any circuit breaker manufacturer is going to be comfortable with promising the performance of one of these life-safety critical products that has been modified in any way by a third party. - What performance testing is performed on a used circuit breaker before re-selling it?

There are circuit breaker performance test standards (such as UL 486) but those were not written with a used or re-built product in mind. I doubt that we can find a standard for testing used breakers for return to service. - Some used, flooded, re-built, modified circuit breakers are probably unsafe:

Some, or at least one brand of circuit breaker, in the FPE line, "testing" the breaker can significantly increase the probability that it will fail in subsequent use when installed.

For example producing an over-current on one leg of a 2 pole breaker (something that does occur in real life as well) jams the breaker so that subsequently it is unlikely to trip at all.

Circuit breakers that have been exposed to water, fire extinguishment, or flooding may look fine externally but may be heat damaged, water damaged, or corroded internally and thus unsafe.

What effects, good or bad, might be had on breakers that are inspected, tested, or opened and "re-built" to some un-specified standard and procedure, are at the very least, unclear, undocumented, and so in my view uncertain.

There has long been a market for used electrical components, bought either by a price-conscious consumer or by someone who does not want to replace an obsolete circuit breaker panel when one of its breakers has failed.

Certainly some circuit breaker manufacturers are concerned enough about "counterfeit" or modified, or second party circuit breakers that may be installed in their equipment that they issue warnings

Eaton Cutler Hammer is among manufacturers publishing warnings about using "used" or "reconditioned" circuit breakers who list a number of concerns about "used" and "reconditioned" circuit breakers that is in my view quite credible and not simply self-serving-marketing as a few objecting readers (or vendors of those products) argue in comments or correspondence.

Excerpts of ECH's concerns with installing used or reconditioned breakers include [excerpting and paraphrasing from Eaton Cutler Hammer, "Hidden Risks of Reconditioned and Used Circuit Breakers", Eaton Cutler Hammer, 2010 cited below]:

Definition of "Refurbished" circuit breaker

The electrical code permits use of reconditioned devices.

"U.S. NEC, 110.3(A) Informational Note No. 1: Equipment may be new, reconditioned, refurbished, or remanufactured."

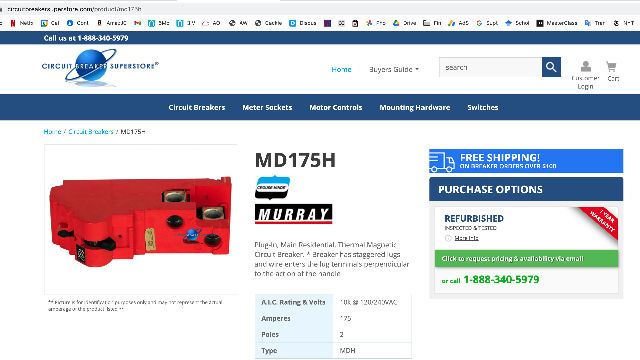

"6.2 Refurbished:

Items that have been energized. Lugs and/or external devices (i.e. handle locking devices, operators, etc.) may have been reworked or replaced. Items have been visually and physically inspected for quality purposes. Items may have cleaned or otherwise enhanced for cosmetic or aesthetic purposes. Items that have been load tested to Industry Standards with high current tester, and/or by an insulation resistance tester and/or continuity tester." - retrieved 2021/06/24, original source: https://www.circuitbreakersuperstore.com/product/md175h

Used / Reconditioned circuit breakers use [or may employ] or have these attributes

- Scavenged Parts

- Counterfeited Parts

- No Factory Specifications

- No UL Label

- Potential for Unsafe Practices

- No Manufacturer’s Warranty

[Note: some re-furbished electrical circuit breaker ads we reviewed cited a one-year warranty from the vendor. Keep in mind that circuit breakers may be expected to perform reliably for decades or longer, and that the breaker may never be called-on to respond to an over-current at which it should trip; these conditions make short term promises and "no problem observed so far" assessments of any circuit breaker unreliable. - Ed.] - Very High Risk

- Eaton Cutler Hammer (2010)

Water damaged circuit breakers may be re-sold as "used" without external signs of problems.

What appears to be in good condition on the outside may not be on the inside. Water damage, corrosion or undetected cracks may lurk just below the surface. - Op. Cit.

Reconditioned circuit breakers may have used materials that the original manufacturer would not have found acceptable.

Any change in materials can result in inferior performance. Counterfeit silver contacts can weld closed, erode prematurely, or detach from contact arms. - Op. Cit.

Reconditioning may have removed required lubricants inside the breaker and / or may have used un-approved lubricants.

Removed by solvents or sandblasting. Improper lubricants harden when cold or run when hot, collect contaminants, have the wrong electrical properties, and can even ignite. - Op. Cit.

Reconditioning may have used lacquer to make the product look new and clean but that may interfere with proper breaker operation.

To create the illusion of new, lacquer is often applied inside and out. This practice is DANGEROUS and may slow or prevent operation, result in hot spots, or lead to volatile reaction during arc interruption. - Op. Cit.

Disassembling a circuit breaker for any reason may involve un-approved (or no) sealant when the device is reassembled.

Original sealant removed to replace stationary contacts. Silicone rubber does not protect against arcing and ionized gases. - Op. Cit.

Besides CIRCUIT BREAKERS RE-CONDITIONED USED several other InspectApedia.com articles discuss the use of used or re-conditioned circuit breakers and safety or performance questions that have been raised, usually by manufacturers. Those are included in the citations given below. A scholarly search for "Performance of re-built circuit breakers" and similar terms did not find much that was interesting but we will continue to research the topic and will add updates here.

Research on Used or Re-Conditioned Circuit Breaker Performance & Safety

- Cooper, Keith R. "Proposed IEEE blue book-application guide for low voltage molded case circuit breakers and power circuit breakers." In Industrial and Commercial Power Systems Technical Conference, 1991. Conference Record. Papers presented at the 1991 Annual Meeting, pp. 1-2. IEEE, 1991.

- Bopp, Dick, "Are Reconditioned Circuit Breakers a Good Idea", Electrical Construction and Maintenance (2001), retrieved 15 Aug 2015, original source: http://ecmweb.com/content/are-reconditioned-breakers-good-idea - note that this discussion pertains to the commercial environment, not residential properties - Ed.

Excerpt:

Many facilities managers use reconditioned and retrofitted circuit breakers with complete confidence. Reconditioning can decrease the number of unplanned facility outages while increasing personnel safety. This would seem obvious since you're replacing worn or damaged parts with new components. What is not so obvious is you can also add technology the breaker didn't originally have.

How to ensure a good reconditioning job. Let's put one myth to rest. You are not taking a risk to save a few bucks by reconditioning a breaker - provided you find the right firm to do the job. However, the manufacturer is not your only source of high-quality reconditioning work. You can also use a reconditioning center. Ideally, a reconditioning center will have a history with a variety of power breaker manufacturers, database of all manufacturer information, quality control process, testing program per ANSI/IEEE standards, and technician training/certification program.

What is reconditioning? The IEEE says power breaker reconditioning is "the process of maintaining existing power switchgear equipment in operating condition as recommended by the manufacturer's instructions, using only the original manufacturer's designed parts."

[Note: Eaton Cutler Hammer and other manufacturers make a point that they do not sell residential circuit breaker parts such as would be needed for reconditioning of residential circuit breakers, making any such claims, in their words, "counterfeit".]

A list of such parts could include add-ons developed since the purchase of your breaker. High-quality reconditioning should include complete disassembly of the power breakers, component-specific cleaning and analysis, reassembly, and a final inspection and test. Then, you should log the entire testing profile into the reconditioning company's database for future breaker reference.

...

In the 1980s, engineers traced the sudden rash of breaker malfunctions to reconditioned breakers from certain firms. Suddenly, buyers everywhere were skittish about using any reconditioned breakers. Those few offshore companies who did the bad reconditioning didn't follow industry practices or manufacturer guidelines. These companies mislabeled their breakers, didn't test them, and often sold them as new.

The resulting furor left a stain on the breaker reconditioning industry. It's a classic "guilty by association" problem, but one that results in a lower safety level than when you use properly reconditioned breakers as part of your overall maintenance program. - Brice, Charles W., Roger Dougal, and Jerry L. Hudgins. "Review of technologies for current-limiting low-voltage circuit breakers." Industry Applications, IEEE Transactions on 32, no. 5 (1996): 1005-1010.

- BULLDOG PUSHMATIC BREAKER REPLACEMENTS. Examples that suggest that the problems are more than just theoretical arm-waving can be read at PUSHMATIC BREAKER FAILURE REPORTS.

- Classified CIRCUIT BREAKER WARNING - issued by Square D Corporation

- Eaton Cutler Hammer, "Hidden Risks of Reconditioned and Used Circuit Breakers", Eaton Cutler Hammer, Tel: (800) 386-1911, Tel: 1+ (440) 523-4400 , 2010, from which I quote below. [Good luck trying to find a corporate address]

Contact Eaton Cutlher Hammer about this topic at : UnauthorizedProducts@eaton.com

- retrieved 15 Aug 2015, original source: http://www.eaton.com/ecm/groups/public/@pub/@electrical/documents/content/pct_313106.pdf - FPE REPLACEMENT BREAKERS where we note that even "new" or "new old stock replacement circuit breakers are not necessarily going to perform acceptably.

- "Identifying Counterfeit Square D Circuit Breakers" No. 2008-01, Los Alamos National Laboratory, HSS Office of Health, Safety and Security Safety Bulletin, January 2008, retrieved 15 August 2015, original source https://www.lanl.gov/safety/electrical/docs/counterfeit_squared_circuit_breakers.pdf

Excerpt:

In the last two years Square D had filed numerous lawsuits and won several settlements aimed at halting the sale and distribution of counterfeit breakers which infringe upon Square D’s patents and trademarks. As many as a half-million counterfeit Square D

breakers may have entered U. S. markets since 2005.

Three distributors have issued recalls in cooperation with the Consumers Product Safety Commission (CPCS ):

http://www.cpsc. gov/CPSCPUB/PREREL/prhtml08/08151.html

http://www.cpsc.gov/CPSCPUB/PREREL/prhtml08/08054.html

http://www.cpsc.gov/CPSCPUB/PREREL/prhtml07/07036.html

Square D also has a Counterfeit Circuit Breaker Homepage at: http://www.squared.com/us/squared/corporate_info.nsf/unid/7A9875AC2EF40B9D852572FE004E5FD7/$file/Counterfeit_CB_Frameset.htm

...

The counterfeit circuit breakers are black and are labeled as Square D QO-series models 110, 115, 120, 130, 210, 215, 220, 225, 230, 235, 240, 250, 260, 280, 1515, 1520, 2020, 2125, 315, 340, 350, 360, and 3100.

...

[The article continues with more identification information including of actual (non-counterfeit) Square D circuit breakers. ] - Natti, Satish, Panida Jirutitijaroen, Mladen Kezunovic, and Chanan Singh. "Circuit breaker and transformer inspection and maintenance: probabilistic models." In Probabilistic Methods Applied to Power Systems, 2004 International Conference on, pp. 1003-1008. IEEE, 2004. Excerpt from Abstract:

Circuit breakers and transformers are two of the most common components in the power system. Catastrophic failure of these components will result in high cost associated with the loss of load and component replacement. Preventive maintenance may reduce these costs by extending the components' lifetime and increasing availability. However, too much maintenance may be costly while too little maintenance may result in catastrophic failure. - "PEARL Reconditioning Standards Revision 6", ratified by the PEARL Board of Directors on April 1, 2014. Professional Electrical Apparatus Recyclers League

10200 W. 44th Avenue, Suite 304

Wheat Ridge, CO 80033

Tel: 720-881-6043

Fax: 720-881-6101

Email: pearl@pearl1.org - original source: http://www.pearl1.org/download_PEARL_reconditioning_standards.htm

Excerpt:

PEARL Reconditioning Standards provide inspection, cleaning, reconditioning, testing and documentation instructions that, when followed by trained technicians, will return electrical devices to "as good as new" condition without compromise.

Electrical devices that pass the PEARL Reconditioning Standards are then ready for installation and service and will benefit from extended service life and reliability.

The following example is from Introduction to PEARL Standard 1100, Rev. 6, Inspection, Testing and Reconditioning of Low Voltage Disconnect Switch Reconditioning:

III. Testing and Inspection

The PEARL Section 1100 Low Voltage Disconnect Switches standards begin with the definition of the term "Reconditioning" as "the process of returning electrical equipment to safe and reliable operating condition based upon the design of the original manufacturer at the time of manufacturing."

This is followed by reference tables used to calculate test results and tolerances and the necessary test equipment required by the standard. The standard continues with a Recondition Evaluation, which is a detailed inspection of all parts of the low voltage disconnect switches, including but not limited to the components listed above.

The following test equipment is required to perform the testing requirements for the Low Voltage Disconnect Switches reconditioning standards:

Insulation Resistance Test Set (Megohmeter) 1000 Vdc minimum

One of the following pieces of test equipment is required to perform the conduct resistance testing requirements of this reconditioning standard:

Digital Low Resistance Ohmmeter (DLRO - 10 amp unit is sufficient.)

DC Current Source and a Millivoltmeter

The second part of the Section 1100 standards tell the reconditioning technician to test the disconnect switch for insulation resistance using a 1000Vdc or greater Megohmeter to identify weaknesses in insulation between current carrying and non-current carrying parts of the switch.

Insulation isolates the enclosure or frame of the disconnect switch from the current carrying areas thus protecting users and bystanders. It also isolates the phases of the disconnect switch from each other protecting against phase-to-phase faults.

Testing continues with a DLRO (digital low resistance ohmmeter) or a current source and millivoltmeter to test for resistance along the current carrying path within the disconnect switch, including bus connections and bus or contact pivot points. This test reduces the likelihood of heat build up anywhere along the current carrying path.

IV. Reconditioning

After "Reconditioning Evaluation", Section 1100 standards continue with a Reconditioning Section that explains how to clean, polish, deburr, paint, lubricate, adjust or torque individual parts of the disconnect switch. The reconditioning steps are listed in a specific order to help the technician disassemble each subassembly in a logical order. After reconditioning, subassemblies can be reinstalled in the now cleaned and painted enclosure or frame.

Assembly of the reconditioned components and subassemblies is followed by final inspection and testing. As with all testing, inspection, and reconditioning operations, final inspection and test results are recorded onto the Evaluation and Test forms included with the standard. If a PEARL certified technician follows the reconditioning standard, the low voltage disconnect switches is eligible for a Blue PEARL Reconditioned Quality Seal. - Rossi, C. E. "NRC Information No. 91-48: False certificates of conformance provided by Westinghouse Electric Supply Company for refurbished commercial-grade circuit breakers." In Nuclear EQ sourcebook: A compilation of documents for nuclear equipment qualification. 1992.

- Sprague, Michael, J., "Service-Life Evaluations of Low-Voltage Power Circuit Breakes and Molded-Case Circuit Breakers", Michael J Sprague

Member, IEEE

Cutler-Hammer, Inc.

130 Commonwealth Drive

Warrendale, PA 15086

USA, retrieved 3 April 2015, original source: http://www.eaton.eu/ecm/groups/public/@pub

/@electrical/documents/content/ct_129977.pdf

Abstract

This paper summarizes the methods that are typically used in industry to evaluate the servicelife of low-voltage power circuit breakers and moldedcase circuit breakers. It reviews the electrical ratings and endurance requirements set forth in manufacturing standards, the ways that these endurance requirements can be used to develop expectations of circuit breaker life, the methods of maintenance inspections and the interpretations of these inspections.

...

Continue reading at CIRCUIT BREAKER FAILURE RATES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

Or see these

Electrical Circuit Breaker Articles

- AFCIs ARC FAULT CIRCUIT INTERRUPTERS

- CIRCUIT BREAKER FAILURE RATES

- BACK-WIRED ELECTRICAL DEVICES

- BRYANT ELECTRICAL PANEL AGE & PROPERTIES

- Classified CIRCUIT BREAKER WARNING

- FEDERAL PIONEER PANEL SAFETY

- FEDERAL PACIFIC FPE HAZARDS - home

- FPE FAILURE FIELD REPORTS

- MURRAY CIRCUIT BREAKER HAZARDS

- MURRAY SIEMENS Recall

- PUSHMATIC - BULLDOG PANELS

- SIEMENS MURRAY Recall

- SPLIT BUS ELECTRICAL PANEL HAZARDS

- SQUARE-D AFCI RECALL 2004

- SQUARE-D COUNTERFEIT BREAKER RECALL

- TEST MAIN BREAKERS & FUSES

- UBI FPE CIRCUIT BREAKER TEST RESULTS

- ZINSCO CIRCUIT BREAKER INDEPENDENT TESTS

- ZINSCO CIRCUIT BREAKER TEST REPORT

- CIRCUIT BREAKER / FUSE INSPECTION

- CIRCUIT BREAKER LOCKS

- CIRCUIT BREAKER HANDLE TIES

- CIRCUIT BREAKER MAIN or FUSE TEST

- CIRCUIT BREAKER REPLACEMENT

- CIRCUIT BREAKER RESET STEPS

- CIRCUIT BREAKERS RE-CONDITIONED USED

- CIRCUIT BREAKER RELIABILITY TESTS

- CIRCUIT BREAKER SIZE for A/C or HEAT PUMP

- GFCI PROTECTION, GFCI CODES

- GFCI DEVICE SELECTION & WIRING

- GFCI TEST PROCEDURES

- MOBILE HOME ELECTRICAL GFCI DIAGNOSIS

Suggested citation for this web page

CIRCUIT BREAKERS RE-CONDITIONED USED at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & Answers on Bulldog & ITE Pushmatic Circuit Breaker Performance.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Personal communication: Email, David Carrier, P.E. to Daniel Friedman, 28 March 2011.

- [2] Matthew Steger, CRI, WIN Home Inspection, 717-361-9467: msteger@wini.com

- [3] Greg Bell, a Florida home inspector: http://www.bellinspection.com/files/Electric_panels.pdf at www.bellinspection.com Bell Inspection Service provides Inspection Services to Daytona Beach, Melbourne and Orlando Florida.

- [4] http://www.selfhelpforums.com/archive/index.php/t-10032.html - conversation about Pushmatics, field failure report

- Patent infringement lawsuit: Westinghouse v Bulldog http://bulk.resource.org/courts.gov/c/F2/206/206.F2d.574.6544.html A copy of the court document is available here.

- [5] Journal of Light Construction online help forum: http://forums.jlconline.com/forums/showthread.php?t=30720 - this article talks about home inspectors "playing it safe" by "failing" a Pushmatic panel - without supporting data.

- [6] Peter Bennett, A Full House Inspection Co., provided technical editing of this text. Mr. Bennett can be contacted in New Jersey at 732-758-9887 or Cell: 732-245-9817, or by email to: afullhouseinspectionco@gmail.com Thanks to Mr. Bennett for discussing ITE Bulldog Pushmatic circuit breaker differences, compatibility, and substitution, May 2010.

- Messing, Joseph. "Circuit breaker." U.S. Patent 2,035,743, issued March 31, 1936.

Patent information: Publication number US2035743 A Publication type Grant Publication date 31 Mar 1936 Filing date 29 Mar 1934 Priority date 29 Mar 1934, original text (with some OCR scan errors) is reproduced at BULLDOG PUSHMATIC DESIGN HISTORY - "Electrical System Inspection Basics," Richard C. Wolcott, ASHI 8th Annual Education Conference, Boston 1985.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "How to plan and install electric wiring for homes, farms, garages, shops," Montgomery Ward Co., 83-850.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "Home Wiring Inspection," Roswell W. Ard, Rodale's New Shelter, July/August, 1985 p. 35-40.

- "Basic Housing Inspection," US DHEW, S352.75 U48, p.144, out of print, but is available in most state libraries.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.