Bulldog & ITE Pushmatic Circuit Breakers

Bulldog & ITE Pushmatic Circuit Breakers

Bulldog Electrical Panel

Design & Patent History

- POST a QUESTION or COMMENT On Bulldog & ITE Pushmatic Circuit Breaker Performance

Bulldog Pushmatic Circuit Breaker patent disclosure history & design features:

This article provides key patents describing the design of the Bulldog & Pushmatic circuit breaker & panel and the features of those components

The article series discusses the history of Pushmatic breakes, gives advice to homeowners whose building is served by a Pushmatic electrical panel, and we discuss both compatability of and concerns when using replacement circuit breakers or used Pushmatic circuit breakers sold by salvage operatoers.

We solicit field failure and field inspection reports of questionable or possibly problematic electrical equipment in buildings such as the Bulldog™ and ITE-Pushmatic® brands described here.

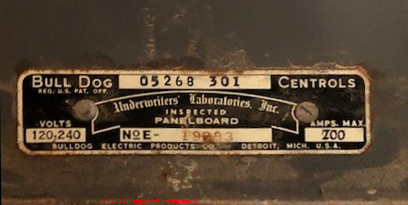

Page top photo: a Bulldog Pushmatic™ circuit breaker showing typical labeling and certifications, contributed by an InspectApedia reader Heather in 2018.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Bulldog & Pushmatic Patent Disclosure & Design Features

The original Bulldog Pushmatic electrical panel produced by the Bulldog Electric Products Co. was purchased by ITE(Gould) in 1976 and subsequently purchased from ITE by Siemens Electcric (ca 1984).

The original Bulldog Pushmatic electrical panel produced by the Bulldog Electric Products Co. was purchased by ITE(Gould) in 1976 and subsequently purchased from ITE by Siemens Electcric (ca 1984).

Bulldog / Pushmatic electrical panels were manufactured in the U.S. as early as 1930 and were installed in U.S. homes as residential electcrical panels principally between 1950 and 1970.

Below are Bulldog and Bulldog Pushmatic breaker and panel patent disclosures that give complete details of the history of the product and its features, but of course those documents do not discuss Bulldog / Bulldog Pushmatic / ITE Pushmatic / ITE Gould Pushmatic failures and hazards.

Watch out: A particular Pushmatic hazard we have observed is breaker internal jamming such that when the breaker was pushed to switch to the OFF position the breaker remained "ON" internally, risking fire or fatal electcrical shock to building occupants or to electrical workers.

It is opined by some electricians that because the breakers were "grease fed" a "lack of maitnenance" over time led to the jamming or made the breakers "difficult to operate".

These circuit breakers in at least some versions also lack an internal magnetic trip mechanism that is considered a safety feature and that is widely used in many other circuit breaker designs. Instead those breakers rely solely on an internal thermal trip mechanism, typically a bi-metallic spring.

Other Pushmatic hazards included a design that made it too easy for DIY'ers to tap a circuit directly onto the panel's bus bar without proper overcurrent protection, and a failure to perform reliably when installed outdoors.

Really? Maintenance? Owners of residential buildings never perform maintenance and rarely even examine their electrial panels and circuit breakers.

OPINION: as a building contractor performing electrical work, later as a home inspector, later as a researcher and journalist, I was disappointed to have to tag Pushmatic panels as "unsafe" (they are) because physically the original equipment was in my view built with high quality materials and workmanship.

And other electcricians cited the reliability of a bolt-on load center that was a design not used in other less-costly electrical panel brands.

However the very real safety hazards of Pushmatics derive from a combination of design and age and are at the very least documented in field reports presented in this article series.

For that information in more-detail see PUSHMATIC - BULLDOG PANELS

Bulldog Electrical Product Co. & Bulldog Pushmatic Patent History

This patent history, roughly in order from oldest to newest, gives both product and feature historical details of the Pushmatic circuit breaker and panel design and ownership.

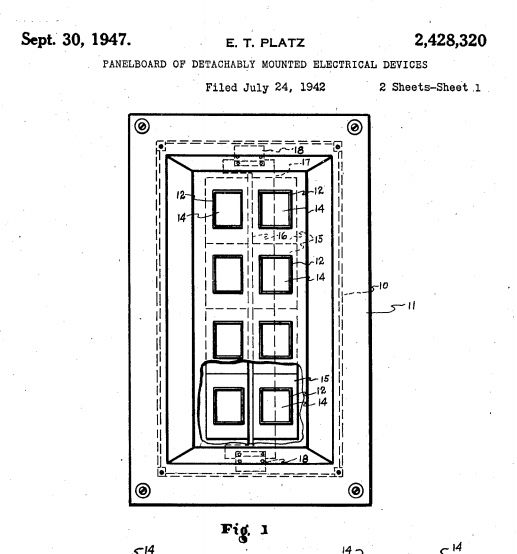

Illustrations above and below: Platz - Bulldog Electric Products Co. panelboard with detachably mounted electrical devices, US Patent 2,428,320 Sept. 30, 1947, illustrates the characteristic "Bulldog Pushmatic" circuit breaker panel design. Cited below on this page at year 1947.

- 1935: Frank, William H. ELECRTRICAL DISTRIBUTION SYSTEM [PDF] U.S. Patent 2,025,813, issued December 31, 1935.Assigdnee: Bulldog Electric Prod. Co., Bulldog Electric Products Co.

- 1936: Messing, Joseph. "Circuit breaker." U.S. Patent 2,035,743, issued March 31, 1936.

Patent information: Publication number US2035743 A Publication type Grant Publication date 31 Mar 1936 Filing date 29 Mar 1934 Priority date 29 Mar 1934, original text (with some OCR scan errors) is reproduced below: - Frank, Harrison JL, and William A. Harper. ELECTRICAL DISTRIBUTION SYSTEM [PDF] U.S. Patent 2,036,265, issued April 7, 1936.

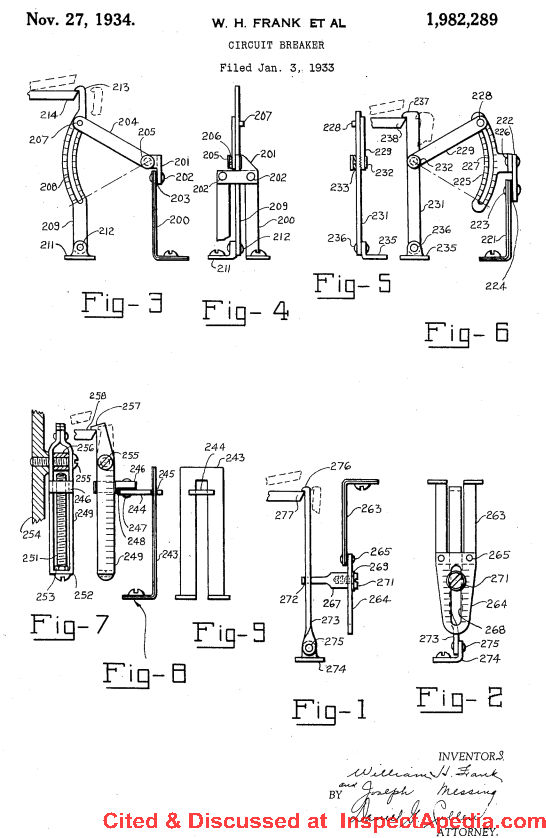

- Frank et al, March 31, 1936. w. H. FRANK ET AL CIRCUIT BREAKER Filed March 29, 1934 INVENTORS wwwajmif BY ATTORNEY,

Patented Mar. 31, 1936 PATENT OFFICE CIRCUIT BREAKER William 1!. Frank and Joseph Messing, Detroit, Mich, assignors to Bulldog Electric Products Company, Detroit, Mich, a. corporation of West Virginia Application March 29, 1934, Serial No. 717,989

12 Claims.

This application relates to circuit breakers, and discloses a novel holding means forv breaker trip pawls or levers, useful as a substitute for holding means of the character disclosed in Pat- 5 cut No. 1,982,289, November 27, 1934, Figs. 3-4.

Details of the constructions shown will be understood upon reference to the following detailed descriptive matter which relates to the appended drawing. In this drawing,

Figures 1 and 2 show holding means for a breaker pawl, in elevation and top plan view.

Figures 1 and 2 show novel holding means for breaker trip pawls or levers, useful as a substitute for a holding means like the one shown at 200-209, 2ll--2l3 of Patent No. 1,982,289, November 27, 1934, Figs. 3-4, to hold the end of a trip pawl or lever, like the end 88 of the pawl 81, pivotally mounted in the frame at 86.

On the base 66 is pivotally mounted at 2M a thermal warping element 282 urged toward the base by a coiled tension spring 283 connected in circuit through the pivot hinge at 28 l, or through a flexible jumper, and adapted to warp on overload to the right.

Secured to and disposed transversely across and preferably insulated from the warping element is an E-shaped magnetic material piece 284 which, together with the magnetic material plate 285 mounted upon the pedestal 286, forms a magnetic circuit with the thermal element 282 forming a single turn coil to provide the magnetomotive force.

A bracket 2M is rigidly secured to warping element 282 by rivets 262, there preferably being insulation 203 between the element and the brackets.

An arm 204 is pivotally connected to bracket 2M by a pin ZOB-and is provided with a lock washer 206 which maintains arm 20; in any desired preset position, relative to the element.

A pin 20! on the outer or free end of arm 204 rides freely in a circular slot 208 of a lever-latch 209 pivotally secured to a foot 2| l bya rivet M2 and thus mounted on the base 50. A hook M3 on the upper end of latch 209 holds the breaker pawl 81 firmly when the breaker is in the on position, or in its normal 0 position.

When an overload occurs, the warping element 282 moves to the right, due to thermal forces, or magnetic forces, or a combination of both forces. This motion is magnified by the leverage ratio 50 provided by the lever latch 209 moving the hook end 213 thereof to release the pawl 81.

Now having described an embodiment of the 5 invention. mounted that it may move bodily in accordance with stresses exerted thereon by the magnet.

2. For use in a circuit protective breaker having means normally tending to move parts into release condition when they are in reset condition and a pawl which when held prevents such action of the means, a holding means for said pawl including a circuit current controlled thermally responsive element which deflects by warping on overload into pawl releasing position and is mounted to move bodily regardless of deflection, and a circuit current controlled magnet for moving the element bodily and instantaneously 25 I into pawl releasing position on an overload of suficient magnitude to operate the magnet.

3. For use in a. circuit protective breaker having means normally tending to move parts into release condition when they are in reset condi- 30 tion and a pawl which when held prevents such actionof the means, a. holding means for said pawl including a circuit current controlled thermally responsive element which deflects by warping on overload into pawl releasing position and 35 is mounted to move bodily regardless of deflection, and a circuit current controlled magnet for moving the element bodily and instantaneously into pawl releasing position on an overload of sufficient magnitude to operate the magnet, the 40 holding means also including a holding latch connected to the element by a movement amplifying connection and operating directly on the pawl.

4. In a circuit protective device, a circuit ourrent controlled delayed action holding element, and a magnet carried by and forming part of the element for causing instantaneous movement of the element on overload, the element being so mounted that it may move bodily in accordance with stresses exerted. thereon by the magnet, the element being an energizing source for the magnet.

5. A holding and releasing means for a circuit breaker part comprising a thermally responsive element, movement amplifying means positively connecting the element to the breaker part whereby overload warping or return cooling of the element will cause amplifled movement of the breaker part, the current in said element providing a magnetic force auxiliary to the thermal force for releasing the breaker, the element being mounted to move bodily regardless of deflection in accordance with magnetic forces created by the current flowing through it.

6. A holding and releasing means for a circuit I breaker part comprising a thermally responsive bimetal element, movement amplifying means positively connecting the element to the breaker part whereby overload warping or return cooling of the element will cause amplified movement of the breaker part, and means responsive to the current flowing in said element for creating a magnetic force which assists the thermal warping force for causing release movement of said element and thereby releasing the breaker, the element being mounted to move bodily regardless of deflection in accordance with magnetic forces created by the current flowing through it.

7. A holding and releasing means for a circuit breaker part comprising a circuit current controlled element constructed to deflect itself with a delayed action to release position on a circuit fault and to deflect itself automatically to holding position thereafter, and mounted on a pivot hinge so as to be movable bodily to and from release and holding position regardless of deflection, and means operating on a circuit fault and against an adjustable resistance for, causing instantaneous movement of the element bodily to release position.

8. A holding and releasing means for a circuit breaker part comprising a circuit current controlled element constructed to deflect itself with a delayed action to release position on a circuit fault and to deflect itself automatically to holding position thereafter,.and mounted on a pivot hinge so as to be movable bodily to and from release and holding position regardless of deflection, and means operating on a circuit fault for causing instantaneous movement of the element bodily to release position.

9. A holding and releasing means for aicir-' cult breaker D811; comprising a circuit current controlled element constructed to deflect itself with a delayed action to release position on a circuit fault and to deflect itself automatically sheaves to holding position thereaften-and mounted on a pivot hinge so as to be. movable bodily to and from release and holding position regardless of deflection, and magnetically actuating means operating on a circuit fault and against an amustable resistance for causing instantaneous movement of the element bodily to release position.

10. A holdlngand releasing meansfor a circuit breaker part comprising a circuit current controlled element constructed to deflect itself with a delayed action to release position on a circuit fault and to deflect itself automatically to holding position thereafter, and mounted on a pivot hinge so as to be movable bodily to and from release and holding position regardless of deflection, and magnetically actuating means operating on a circuit fault for causing instantaneous movement of the element bodily to release position.

11. Means for moving a circuit breaker holding part comprising a circuit current controlled element constructed to deflect itself with a delayed action to move the part into release position on a circuit fault and to deflect itself automatically to move the part into holding position thereafter, and mounted so as to be movable bodily to and from release and holding position regardless of deflection, and means operating on a circuit fault for causing instantaneous movement of the element bodily to release position, the element being positively connected to the part through a movement amplifying connection so that minute movements of the element will positively cause amplied movements of the part.

12. Means for moving a circuit breaker holding part comprising a circuit current controlled element constructed to deflect itself with a delayed action to move the part into release position on a, circuit fault and to deflect itself automatically to move the part into holding position thereafter, and mounted so as to be movable bodily to and from release and holding position, - and circuit current controlled magnetically actuating means operating on a circuit fault for causing instantaneous movement of the element bodily to release position, the element being -positively connected to the part through a movement amplifying connection so that minute movements of the element will positively cause amplifled movements of the part. 1

Other Patents citing this invention

Bulldog Pushmatic Electric Products Patents |

||||

| US2424909 * | 30 Dec 1942 | 29 Jul 1947 | Frank Adam Electric Co See FRANK ADAM ELECTRICAL PANELS |

Circuit interrupting device |

| US2439511 * | 10 Apr 1944 | 13 Apr 1948 | Frank Adam Electric Co | Latching or tripping mechanism of circuit breakers |

| US2447652 * | 30 Oct 1942 | 24 Aug 1948 | Westinghouse Electric Corp | Circuit breaker |

| US2459427 * | 24 May 1945 | 18 Jan 1949 | Fed Electric Prod Co | Circuit breaker |

| US2491088 * | 29 Sep 1945 | 13 Dec 1949 | Essex Wire Corp | Thermal-magnetic circuit breaker |

| US2573306 * | 11 Aug 1948 | 30 Oct 1951 | Gen Electric | Electric circuit breaker |

| US2579673 * | 27 Sep 1947 | 25 Dec 1951 | Square D Co | Circuit breaker |

| US2588497 * | 10 Dec 1949 | 11 Mar 1952 | Westinghouse Electric Corp | Circuit breaker |

| US2590663 * | 3 Feb 1950 | 25 Mar 1952 | Westinghouse Electric Corp | Circuit breaker |

| US2624815 * | 7 May 1945 | 6 Jan 1953 | Westinghouse Electric Corp | Circuit breaker |

| US2624816 * | 9 May 1945 | 6 Jan 1953 | Westinghouse Electric Corp | Circuit breaker |

| US2631208 * | 19 Apr 1951 | 10 Mar 1953 | Gen Electric | Electric circuit breaker |

| US2673263 * | 18 May 1951 | 23 Mar 1954 | Gen Electric | Thermomagnetic electric relay |

| US2696540 * | 27 Jan 1950 | 7 Dec 1954 | Fed Electric Prod Co | Automatic circuit breaker |

| US2696541 * | 19 Feb 1953 | 7 Dec 1954 | Bulldog Electric Products Co | Circuit breaker |

| US2716679 * | 11 May 1954 | 30 Aug 1955 | Wadsworth Electric Mfg Co | Circuit breaker |

| US2738393 * | 12 Mar 1952 | 13 Mar 1956 | Cutler Hammer Inc | Circuit breakers and the like having power elements |

| US2824191 * | 5 Feb 1953 | 18 Feb 1958 | Fed Electric Prod Co | Circuit breakers |

| US2866036 * | 30 Nov 1955 | 23 Dec 1958 | Crabtree & Co Ltd J A | Electric circuit breakers |

| US3278707 * | 22 Oct 1964 | 11 Oct 1966 | Gen Electric | Circuit breaker with ambient-temperature compensating means |

Additional Bulldog & Pushmatic Circuit Breaker & Panel Patent Disclosures

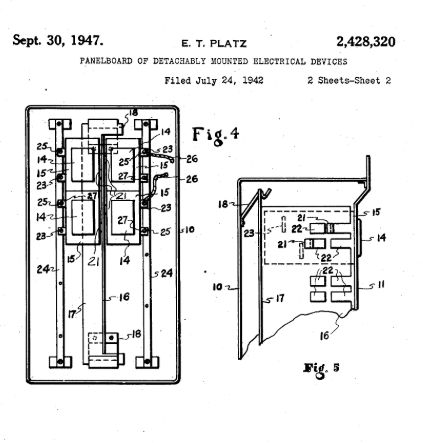

- 1936: Frank, [9] W. H. FRANK ET AL, CIRCUIT BREAKER [PDF] U.S. Patent 1,932,289, issued March 31, 1936.Bulldog Circuit Breaker Patent Nov. 27, 1934. Patent description:

Nov. 27, 1934. w. H. FRANK ET AL 1,932,289

CIRCUIT BREAKER Filed Jan. 1933 MMIIIMIMMMN INVENTORS. J, E

ATTORNEY.

Patented Nov. 27, 1934 UNITED STATES CIRCUIT BREAKER William H. Frank Micln, assignors Company, Virginia Application January 3,

6 Claims.

The invention of this application relates to circuit breakers.

A principal object of the invention is to provide, for circuit breakers, novel-forms of holding devices which may be calibrated, as desired by the operator, to release the circuit breaker at various overload amperages. More specifically, there are provided holding devices including fulm crumed holding levers connected to thermal warping elements by variable connections which constitute the calibration means, the connections being varied to vary the effects of the warping elements on the holding elements.v

Still further objects of the invention will be readily apparent to those skilled in the art upon reference to the following detailed description of embodiments of the invention, the same to be read in connection with the appended drawing. Referring to the drawing, it will be seen that Figs. 1 and 2 are elevation and end views of one form of holding device;

Figs. 3 and 4 are elevation and end views of another form of breaker holding device, shown 5 in On (full lines) and overload 011" (dash lines) positions;

Figs. 5 and 6 are similar views of still another form of breaker holding device;

Figs. 7, 8, and 9 show still another form of holding device in left end view, elevation view, and right end view, respectively. L

In Figures 1 and 2, there is shown a device which consists of a U-shaped thermostatic or bimetallic warping element 263, whose legs are connected respectively to a contact element of a breaker and to a line. A bracket 264 is rigidly secured to warping element 263 by rivets 265 and is insulated therefrom.

An arm 267 is slidably mounted in an elongated slot 268 of bracket 264, 0 being clamped to the latter by a washer 269 and a screw 271 tapped into arm 267. The other end of am 267 is grooved, at 272 so as to receive the edge of a latch 273 pivotally secured at its lower end to foot 274 by rivet 275. The upper end of.

latch 273 is provided with a hook 276 which holds pawl 277 firmly when the circuit breaker is in either "On or normal Off position.

Under overload conditions the warping element 263 moves to the right. This motion is transmitted through arm 267 to latch 273, moving hook end 276 to release pawl 277.

The different positions of arm 267 in latch 273 vary the throw of latch 273' and therefore the device can be calibrated to release at various overload amperages, which can be indicated by graduations along a surface of bracket 264.

and Joseph Messing, Detroit, to Bulldog Electric Products Detroit, Mich., a corporation of West 1933. Serial No. 649,988

is pivotally connected to bracket 201 by a pin 205 provided with a lock washer 206 which maintains arm 204 in any desired position, relative to the element. A pin 207 on the outer or free end of arm 204, rides freely in a circular slot 208 of a latch 209 pivotally secured to a foot 211 by a rivet 212. A hook 213 on the upper end of latch 209 holds a breaker pawl 214 firmly when the breaker is in its "On position or in its normal Oif" position.

When an overload occurs, the warping element 200 moves to the right. This motion is transmitted through arm 204 to latch 209, moving the hook end thereof to release pawl 214. I

The different angular positions of' arm 204 about pivot 205 vary the throw of end 213 of latch 209 and therefore the device can be calibrated to release at various overload amperages. To indicate these amperages, latch 209 can he graduated along the edge of elongated slot 208.

For reset, pawl 214 presses downward on end 213 of latch 209 forcing it to the right, when pawl 214 is in normal position, the end of latch 209 again snaps back to its normal position.

In Figures5 and 6 there is shown a device which consists of a U-shaped thermostatic or bimetallic warping element 221, whose legs are connected respectively to a contact element of a breaker and to a. line. A bracket 222 is rigidly secured to warping element 221 by rivets 223, there being insulation 224, between the element and the bracket.

A sector 225 is rigidly fastened to bracket 222 by rivets 226, and is provided with an arcuate slot 227 in which rides a pin 228 rigidly connected to arm 229, which may be fixedly positioned radially within the liniits of arcuate slot 227 in sector 225. The latter is pivotally connected to latch 231 by pin 232 provided with a lock washer 233.

Latch 231 is pivotally connected at one end to foot 235 by rivet 236 and its other end is provided with a hook 237' which holds pawl 238 firmly, when the circuit breaker is in either "On or normal "Oi!" positions.Under overload conditions, the thermal element 221 moves to the right. This motion is transmitted through arm 229 to latch 231, moving the hook end 237 to release pawl 238.

The difierent angular positions or arm 229 about pivot 232 vary the throw of end 237 of latch 231 and therefore the device can be calibrated to release the pawl at various overload amperages.- These amperages can be indicated by graduations along the edge of elongated slot 227 in latch 225.

For reset, pawl 238 presses downward on end 237 of latch 231 forcing it to the right. When pawl 238 is in normal position, the end of latch 237 again snaps back in normal position.

In Figures 7, 8, and 9, there is shown a device which consists of a U-shaped thermostatic or bimetallic warping element 243, whose legs are connected respectively, to the contact element of a breaker and to a line. An arm 244 of insulation, and doubly grooved on its edges at 245 is slidably connected to warping element243 and is rigidly secured to a slidable 246 by rivets 247, being insulated from arm 246 by insulation 248.

The slidable arm 246 is doubly grooved on its edges to receive the sides of latch 249. slidable arm 246 is tapped to receive adjusting screw 251 which passes through a hole in the end 252 of latch 249, there being a check nut 253 on screw 251, to check against and positively position slidable arm 246 in latch 249. The latter is pivotally connected to a. frame part 254 of the breaker by a screw 255, surrounded by spacer 256. The upper end of latch 249 is provided with a hook 257 which holds pawl 258 firmly when the circuit breaker is in either On or normal 011 positions.

1 Under overload conditions the warping element 243 moves to the left. This motion is transmitted through slidable arm 246 to latch 249, moving hook end 257 to release pawl 258.

The different positions or slidable arm 246 vary the throw of latch 249 and therefore the device can be calibrated to release at various overload amperages. These can be indicated by graduations along a surface of latch 249, substantially as shown.

Now having described various embodiments of the invention, selected by way of example, reference will be had to the appended drawing which determines the scope of the invention, it being understood that, except as set out in the claims, the invention is not to be limited to the embodiments disclosed.

We claim:

1. In a controlling device of the character described, latching means in the nature of a lever,

thermally responsive mean also in the nature of a lever, and afiected by changes in circuit conditions, and a connection between the means whereby the latching means will be released by the effect of such changes on the thermally responsive means, the connection being movable so as to vary the leverage ratio of bothof the means so that the release-causing eflect of such changes on the latching means can be varied.

2. Ina controlling device of the character described, latching means in the nature of a lever, thermally responsive means also in the nature of a lever, and thermally affected by changes in circuit conditions, and a connection between the means whereby the latching means will be released by the efiect of such changes on the thermally responsive'means, the connection being movable so as to vary the leverage ratio of one of the means so that the release-causing effect of such changes on the latching means can be varied.

3. In a controlling device of the character described, latching means in the nature of a lever, thermally responsive means also in the nature of a lever and thermally affected by changes in circuit conditions, and a connection between the means whereby the latching means will be re- ,leased by the effect of such changes on the thermally responsive means, the connection being movable so as to vary the leverage ratio of the first mentioned one of the means so that the release-causing effect of such changes on the latching means can be varied.

4. In a controlling device of the character described,'latching means in the nature of a lever, thermally responsive means also in the nature of a lever and thermally affected by changes in circuit conditions, and a connection between the means wherebythe latching means will be released by the efiect of such changes on the thermally responsive means, the connection being movable so as to vary the leverage ratio otthe' second mentioned one of the means so that the release-causing effect of such changes on the latching means can be varied.

5. In a controlling device of the character described, latching means in the nature of a lever, thermally responsive means thermally afiected by changes in circuit conditions, and a connection between the means whereby the latching means will be released by the effect of such changes on the thermally responsive means, the connection being movable so as to vary the leverage ratio of the holding means so that the release-causing effect of such changes on the latching means will be varied. p

6. In a controlling device of the character described, latching means, thermally responsive means in the nature of a lever and thermally affected by changes in circuit conditions, and a connection between the means whereby the latching means will be released by the effect of such changes on the thermally responsive means, the connection being movable so as to vary the leverage ratio of the second mentioned means so that the release-causing effect of such changes on the latching means will be varied.

This patent is cited by

US3278707 * 22 Oct 1964 11 Oct 1966 Gen Electric Circuit breaker with ambient-temperature compensating means

- 1936: Frank, 10]

Nov. 3,1936. w- H. FRANK ET A1.

C IRCUI T BREAKER Original Filed Jan. 3,. 1935 INVENTORS /f/d MMUJ, if

Patented Nov. 3, 1936 UNITED STATE cracm'r nimma William H. Frank and Joseph Messing, Detroit, Mich., assignors to Bulldog Electric Products Company, Detroit, Mich., a corporation of West Virginia Original application January 3, 1933, Serial No. l ,649,983,lk now Patent No. 1,982,289, November Divided and this application October 26, 1934, Serial No. 750,161

6 Claims. (Cl. 20o-121) This application discloses a circuit breaker unit and is a division of our copending application Serial No. 649,98, filed January 3, 1933, now Patent No. 1,982,289 of November 27, 1934, class 200, sub-class 116.

[11]Publication number US2035743 A Publication type Grant Publication date 31 Mar 1936 Filing date 29 Mar 1934 Priority date 29 Mar 1934 Inventors Frank William H, Joseph Messing Original Assignee Bulldog Electric Prod Co

Publication number US2035743 A Publication type Grant Publication date 31 Mar 1936 Filing date 29 Mar 1934 Priority date 29 Mar 1934

Excerpt from patent text

A holding and releasing means for a circuit breaker part comprising a thermally responsive element, movement amplifying means positively connecting the element to the breaker part whereby overload warping or return cooling of the element will cause amplifled movement of the breaker part, the current in said element providing a magnetic force auxiliary to the thermal force for releasing the breaker, the element being mounted to move bodily regardless of deflection in accordance with magnetic forces created by the current flowing through it.

(OCR text may contain errors)Description:

March 31, 1936. w. H. FRANK ET AL CIRCUIT BREAKER Filed March 29, 1934 INVENTORS wwwajmif BY t W A TORNEY,Patented Mar. 31, 1936 PATENT OFFICE CIRCUIT BREAKER William 1!. Frank and Joseph Messing, Detroit, Mich, assignors to Bulldog Electric Products Company, Detroit, Mich, a. corporation of West Virginia Application March 29, 1934, Serial No. 717,989

12 Claims.

This application relates to circuit breakers, and discloses a novel holding means forv breaker trip pawls or levers, useful as a substitute for holding means of the character disclosed in Pat- 5 cut No. 1,982,289, November 27, 1934, Figs. 3-4.

Details of the constructions shown will be understood upon reference to the following detailed descriptive matter which relates to the appended drawing. In this drawing,

Figures 1 and 2 show holding means for a breaker pawl, in elevation and top plan view.

Figures 1 and 2 show novel holding means for breaker trip pawls or levers, useful as a substitute for a holding means like the one shown at 200-209, 2ll--2l3 of Patent No. 1,982,289, No-

vember 27, 1934, Figs. 3-4, to hold the end of a trip pawl or lever, like the end 88 of the pawl 81, pivotally mounted in the frame at 86.

On the base 66 is pivotally mounted at 2M a thermal warping element 282 urged toward the base by a coiled tension spring 283 connected in circuit through the pivot hinge at 28 l, or through a flexible jumper, and adapted to warp on overload to the right. Secured to and disposed transversely across and preferably insulated from the warping element is an E-shaped magnetic material piece 284 which, together with the magnetic material plate 285 mounted upon the pedestal 286, forms a magnetic circuit with the ther- 30 mal element 282 forming a single turn coil to provide the magnetomotive force.

A bracket 2M is rigidly secured to warping element 282 by rivets 262, there preferably being insulation 203 between the element and the brackets. An arm 204 is pivotally connected to bracket 2M by a pin ZOB-and is provided with a lock washer 206 which maintains arm 20; in any desired preset position, relative to the element. A pin 20! on the outer or free end of arm 204 rides freely in a circular slot 208 of a lever-latch 209 pivotally secured to a foot 2| l bya rivet M2 and thus mounted on the base 50. A hook M3 on the upper end of latch 209 holds the breaker pawl 81 firmly when the breaker is in the on position, or in its normal 0 position.

When an overload occurs, the warping element 282 moves to the right, due to thermal forces, or magnetic forces, or a combination of both forces. This motion is magnified by the leverage ratio 50 provided by the lever latch 209 moving the hook end 213 thereof to release the pawl 81.

Now having described an embodiment of the 5 invention.

mounted that it may move bodily in accordance with stresses exerted thereon by the magnet.

2. For use in a circuit protective breaker havl5 ing means normally tending to move parts into release condition when they are in reset condition and a pawl which when held prevents such action of the means, a holding means for said pawl including a circuit current controlled ther- 20 mally responsive element which deflects by warping on overload into pawl releasing position and is mounted to move bodily regardless of deflection, and a circuit current controlled magnet for moving the element bodily and instantaneously 25 I into pawl releasing position on an overload of suficient magnitude to operate the magnet.

3. For use in a. circuit protective breaker having means normally tending to move parts into release condition when they are in reset condi- 30 tion and a pawl which when held prevents such actionof the means, a. holding means for said pawl including a circuit current controlled thermally responsive element which deflects by warping on overload into pawl releasing position and 35 is mounted to move bodily regardless of deflection, and a circuit current controlled magnet for moving the element bodily and instantaneously into pawl releasing position on an overload of sufficient magnitude to operate the magnet, the 40 holding means also including a holding latch connected to the element by a movement amplifying connection and operating directly on the pawl.

4. In a circuit protective device, a circuit ourrent controlled delayed action holding element, and a magnet carried by and forming part of the element for causing instantaneous movement of the element on overload, the element being so mounted that it may move bodily in accordance with stresses exerted. thereon by the magnet, the element being an energizing source for the magnet.

5. A holding and releasing means for a circuit breaker part comprising a thermally responsive element, movement amplifying means positively connecting the element to the breaker part whereby overload warping or return cooling of the element will cause amplifled movement of the breaker part, the current in said element providing a magnetic force auxiliary to the thermal force for releasing the breaker, the element being mounted to move bodily regardless of deflection in accordance with magnetic forces created by the current flowing through it.

6. A holding and releasing means for a circuit I breaker part comprising a thermally responsive bimetal element, movement amplifying means positively connecting the element to the breaker part whereby overload warping or return cooling of the element will cause amplified movement of the breaker part, and means responsive to the current flowing in said element for creating a magnetic force which assists the thermal warping force for causing release movement of said element and thereby releasing the breaker, the element being mounted to move bodily regardless of deflection in accordance with magnetic forces created by the current flowing through it.

7. A holding and releasing means for a circuit breaker part comprising a circuit current controlled element constructed to deflect itself with a delayed action to release position on a circuit fault and to deflect itself automatically to holding position thereafter, and mounted on a pivot hinge so as to be movable bodily to and from release and holding position regardless of deflection, and means operating on a circuit fault and against an adjustable resistance for, causing instantaneous movement of the element bodily to release position.

8. A holding and releasing means for a circuit breaker part comprising a circuit current controlled element constructed to deflect itself with a delayed action to release position on a circuit fault and to deflect itself automatically to holding position thereafter,.and mounted on a pivot hinge so as to be movable bodily to and from release and holding position regardless of deflection, and means operating on a circuit fault for causing instantaneous movement of the element bodily to release position.

9. A holding and releasing means for aicir-' cult breaker D811; comprising a circuit current controlled element constructed to deflect itself with a delayed action to release position on a circuit fault and to deflect itself automatically sheaves to holding position thereaften-and mounted on a pivot hinge so as to be. movable bodily to and from release and holding position regardless of deflection, and magnetically actuating means operating on a circuit fault and against an amustable resistance for causing instantaneous movement of the element bodily to release position.

10. A holdlngand releasing meansfor a circuit breaker part comprising a circuit current controlled element constructed to deflect itself with a delayed action to release position on a circuit fault and to deflect itself automatically to holding position thereafter, and mounted on a pivot hinge so as to be movable bodily to and from release and holding position regardless of deflection, and magnetically actuating means operating on a circuit fault for causing instantaneous movement of the element bodily to release position.

11. Means for moving a circuit breaker holding part comprising a circuit current controlled element constructed to deflect itself with a delayed action to move the part into release position on a circuit fault and to deflect itself automatically to move the part into holding position thereafter, and mounted so as to be movable bodily to and from release and holding position regardless of deflection, and means operating on a circuit fault for causing instantaneous movement of the element bodily to release position, the element being positively connected to the part through a movement amplifying connection so that minute movements of the element will positively cause amplied movements of the part.

12. Means for moving a circuit breaker holding part comprising a circuit current controlled element constructed to deflect itself with a delayed action to move the part into release position on a, circuit fault and to deflect itself automatically to move the part into holding position thereafter, and mounted so as to be movable bodily to and from release and holding position,

- and circuit current controlled magnetically actuating means operating on a circuit fault for causing instantaneous movement of the element bodily to release position, the element being -positively connected to the part through a movement amplifying connection so that minute movements of the element will positively cause amplifled movements of the part. 1

JOSEPH MESSING.

- 1936: Frank, William H., and Joseph W. Harper. "Electrical distribution system." U.S. Patent 2,041,675, issued May 19, 1936.

- Frank, Harrison JL, and William A. Harper. "Electrical distribution system." U.S. Patent 2,042,778, issued June 2, 1936.

- 1937: Frank, William H., and Joseph W. Harper. "Electrical distribution system." U.S. Patent 2,088,105, issued July 27, 1937.

- Frank, William H. "Electrical distribution system." U.S. Patent 2,082,281, issued June 1, 1937.

- Frank, William H. "Electrical distribution system." U.S. Patent 2,086,611, issued July 13, 1937.

- Frank, William H. ELECTRICAL DISTRIBUTION SYSTEM [PDF] U.S. Patent 2,086,795, issued July 13, 1937.

- Frank, H.J. and Harper, W.A., BULLDOG ELECTRIC PROD CO, 1937. Electrical distribution system. U.S. Patent 2,090,725.

- 1938: Frank, Harrison JL. "Electrical distribution system." U.S. Patent 2,107,412, issued February 8, 1938.

- 1939: Frank, William H., and Joseph W. Harper. "Electrical distribution system." U.S. Patent 2,146,812, issued February 14, 1939.

- 1941: Frank, William H., and Joseph W. Harper. "Electrical distribution system." U.S. Patent 2,251,403, issued August 5, 1941.

- Frank, William H. ELECTRICAL DISTRIBUTION SYSTEM [PDF] U.S. Patent 2,264,075, issued November 25, 1941. Assignee: Bulldog Electric Prod. Co. Bulldog Electric Products Co.

Excerpt: This application relates to electrical distribution systems of the bus duct thype as shown in a prior application, Serial No. 231,712, of September 26, 1938, now abandoned. - Frank, William H., and Joseph W. Harper. "Electrical distribution system." U.S. Patent 2,251,404, issued August 5, 1941.

- Herman, Gottheimer. "Electrical distribution system." U.S. Patent 2,254,280, issued September 2, 1941.

- Togesen, Alva A., and Lawrence E. Fisher. "Electrical distribution system." U.S. Patent 2,262,067, issued November 11, 1941.

- 1942: Togesen, Alva A., and Lawrence E. Fisher ELECTRICAL DISTRIBUTION SYSTEM [PDF] U.S. Patent 2,287,502, issued June 23, 1942. Application filed by Bulldog Electric Products Co.

- Fisher, Lawrence E., and Alva A. Togesen. "Electrical distribution system." U.S. Patent 2,288,078, issued June 30, 1942.

- 1943: Frank, William H., and Arthur S. Bassette. Electrical distribution system." U.S. Patent 2,310,024, issued February 2, 1943.

- 1944: Frank, William H., and Lawrence E. Fisher. ELECTRICAL DISTRIBUTION SYSTEM [PDF] U.S. Patent 2,350,601, issued June 6, 1944 .Application filed by Bulldog Electric Products Co.

- Frank, William H., Lawrence E. Fisher, and Robert L. Frank. "Electrical distribution system." U.S. Patent 2,343,216, issued February 29, 1944.

- Togesen, Alva A. ADJUSTABLE CONNECTOR FOR ELECTRICAL DISTRIBUTION SYSTEMS U.S. Patent 2,343,232, issued February 29, 1944. Assignee: Bulldog Electric Prod. Co.

- 1947: Platz, E.T., BULLDOG ELECTRIC PROD CO, 1947. PANELBOARD OF DETACHABLY MOUNTED ELECTRICAL DEVICES. [PDF] U.S. Patent 2,428,320. Illustrated above.

1952 Bulldog Electrical Panel using ITE Circuit Breakers

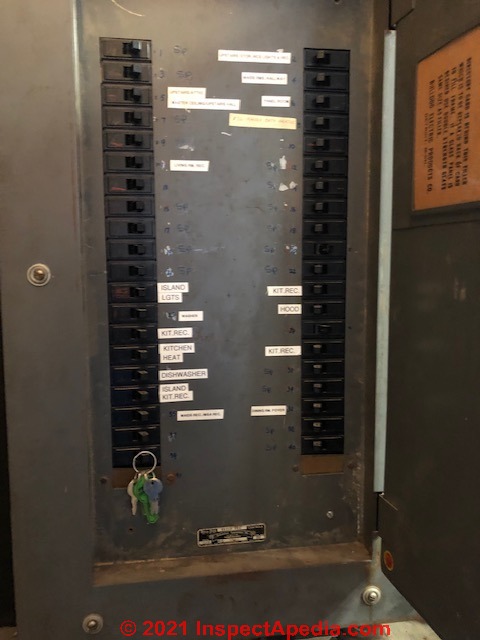

Special thanks to an anonymous InspectApedia.com reader who has provided these photographs of a 1952 Bulldog Electric Panel. The main breaker appears to be a Pushmatic circuit breaker, but the individual circuit breakers are marked as an ITE product.

This 200-Amp electrical panel is installed in an older home in Wilmington, Delaware.

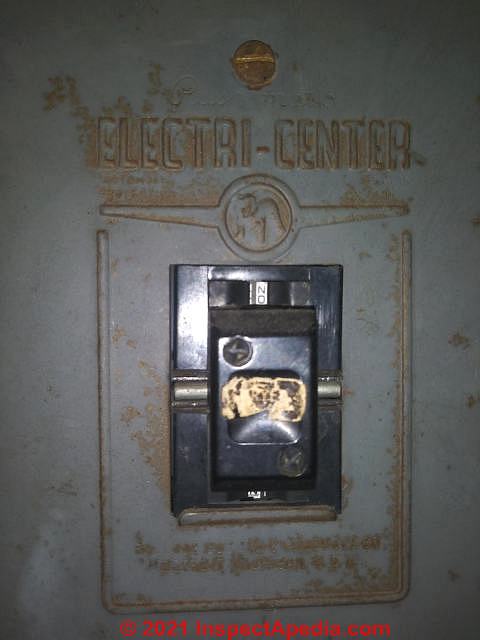

Above: a Pushmatic-type main breaker in this 1950s Bulldog Controls brand electrical panel.

Above and below: ITE-circuit breakers in the same electrical panel

- 1961: Walter, Staskowski. "Electrical distribution system." U.S. Patent 2,968,781, issued January 17, 1961.

- 1966: [13] Bulldog Pushmatic circuit breaker - relevant patent US 3278706, 1966

Publication number US3278707 A Publication type Grant Publication date 11 Oct 1966 Filing date 22 Oct 1964 Priority date (The priority date is an assumption and is not a legal conclusion.) 22 Oct 1964 Description (OCR text may contain errors)

K. W. KLEIN Oct. 11, 1966 CIRCUIT BREAKER WITH AMBIENT-TEMPERATURE COMPENSATING MEANS Filed Oct. 22, 1964 5 Sheets-Sheet 1 IN VEN '1 0R. /(/TH KLEIN KMJZTQ Oct. 11, 1966 w, KLEIN 3,278,707

CIRCUIT BREAKER WITH AMBIENT-TEMPERATURE COMPENSATING MEANS Filed 001;. 22, 1964 5 Sheets-Sheet 2 N MM INVENTOR KE/n/ 14/ r e 147T ORA E Y Oct. 11, 1966 Filed Oct. 22, 1964 RATED CURRENT CIRCUIT BREAKER WITH AMBIENT-TEMPERATURE GOMPENSATING MEANS 5 Sheets-Sheet 3 K. W. KLEIN DERATNG CURVE.

36C 4'oc AMEAENT TEMPERATURE FIG.11

lNVENTOR KEITH I (LE/A/ 4 770/? A/E Y United States Patent 3,278,707 CIRCUIT BREAKER WITH AMBIENT-TEMPERA- TURE COMPENSATING MEANS Keith W. Klein, Simsbury, Conn., assignor to General Electric Company, a corporation of New York Filed Oct. 22, 1964, Ser. No. 405,699 9 Claims. (Cl. 200-116)

The present invention relates to electric circuit breakers, and more particularly to circuit breakers of the type incorporating thermal current responsive means to cause tripping upon the occurrence of predetermined abnormal current conditions therethrough.

Thermal current responsive means have been used for many years in electric circuit breakers to detect abnormal current conditions to cause actuation of the circuit breaker to interrupt the circuit. Such thermal current responsive means have two major advantages over other types of current responsive means such, for example, as magnetic current responsive means.

These advantages are:

(1) thermal current responsive means have an inherent heat storage characteristic which can be made to match quite closely the heat storage characteristics of the circuit conductors which electric circuit breakers are ordinarily utilized to protect.

Secondly, thermal current responsive means can be constructed relatively inexpensively, by use of bimetallic current responsive members, such as an elongated strip of bimetallic material.

Thermal current responsive means, however, have a characteristic not shared by magnetic type devices which, although it is a further advantage in some applications, constitutes a disadvantage in certain other applications. This characteristic is the fact that thermal current responsive devices are affected by heat which originates from sources other than the particular heat sources which are primarily intended to affect them. More specifically, such devices are affected by the temperature of the circumambient air (referred to hereinafter for convenience simply as ambient temperature.

Thus, for example, a circuit breaker including a thermal current responsive means may sometimes trip and disconnect the circuit primarily because the temperature of the surrounding air has increased to a predetermined point, even though the current through the circuit breaker has not reached a level which would ordinarily be dangerous.For this reason, it is customary to advise users of thermal current responsive devices such as circuit breakers, that the device must be derated if used at elevated ambient temperatures. In other words, the user is advised for example that a circuit breaker which is rated at 15 amperes will carry 15 amperes indefinitely at an ambient temperature of 25 C. At an ambient temperature of 50 C., however, the same breaker will carry not more than 13.8 amperes without tripping.

The breaker must therefore be derated to 92% of its nominal value if used in an ambient of 50 C. As previously mentioned, such ambient sensitivity is sometimes desirable, for the following reason.The ultimate object of automatic circuit protection is to prevent the conductor which is connected to the protecting device from reaching a temperature which might be dangerous to itself, such as by causing melting, or might be dangerous to adjacent material such as the wire insulation or adjacent building material, so as to possibly start a fire. It will be apparent that if a large portion of the temperature of the conductor is caused by means such as by a high ambient temperature, then the conductor should not be permitted to carry as much current as it otherwise could.

Nevertheless, up until a certain danger point is reached, it is desirable to prevent ambient temperature from unduly restricting the ability of a circuit protective device to remain in the closed condition. For this reason, a variety of schemes have been devised over the years for compensating or correcting thermal current responsive devices for ambient temperatures.

Such ambient compensation means have commonly included the use of supplementary bimetallic strip means which is exposed to the ambient temperature in the same way that the current responsive bimetallic member is, but which is not exposed to heated caused by electrical current carried by the circuit, or at least not to the same degree as the main current responsive thermal element. Examples of thermal current responsive means including such ambient compensating structures, are shown in the following patents: 2,253,390, Muller; 2,703,351, Hulbert.

All of such prior art ambient compensating or correcting means for thermal current responsive devices have shared a major disadvantage in common. This disadvantage is that they have added significantly to the cost of such devices.

In addition, since they have commonly added more parts and complicated the structure involved, their use increases the likelihood of some difliculty being encountered in the use of the device.

A further disadvantage of such prior art structures is 'that since they have ordinarily involved the use of a supplementary bimetallic member which acts contrary to the action of the main current responsive bimetal, the compensating action becomes greater with greater ambient temperatures, without practical limit.

The use of such ambient compensating structures over a period of years has made it evident that some means should be used to limit the compensating action.

Thus, for example, if the ambient temperature surrounding a circuit protective device increases to extremely high values, such, for example, as because of a fire nearby, it would be desirable for the protective device to operate to a tripped condition for general safety purposes.

This would not be possible with prior art ambient compensating schemes.For such reasons, it has been found necessary to include in devices of this type some means for limiting the compensating action provided, so that the compensating means operates over a certain range of ambient temperature, but after a certain predetermined ambient temperature is reached, the compensating means no longer functions.

Examples of ambient compensating structures including such limiting means are shown, for example, in the following patents: 2,214,640, Marshall; 2,656,440, Dorfman.

In accordance with appli-cants present invention, a thermal current responsive device is provided which does not include a separate ambient compensating element, but which exhibits an ambient correcting or compensating action which is virtually indistinguishable from the action of prior art thermal current responsive devices including separate ambient compensating means.

This is achieved, moreover, without the use of any more parts than utilized in prior art uncompensated thermal current responsive devices.

In brief, the present inventor has discovered that the action of ambient temperature on a bimetallic strip can be distinguished from the action of heat caused by electric current therethrough even though the current passes through the entire length of the bimetallic strip in question.

Accordingly, it is an object of applicants invention to provide a thermal current responsive device which is not adversely affected by elevated ambient temperatures, and which does not require the use of a separate ambient compensating means.

It is another object of applicants invention to provide an electric circuit protective device including a thermal current responsive means which is not adversely affected by elevated ambient temperatures because of the inclusion of correcting means, and which does not require rence of predetermined current conditions.

means limiting the action of the corrective means at extremely elevated ambient temperatures.

It is a further object of the invention to provide an electric circuit protective device including a thermal current responsive means which may be readily combined with te-ctive device is provided incorporating thermal current responsive means including an elongated bimetallic strip :and means for heating the bimetallic strip in accordance with current passing through the circuit breaker.

Means is also provided connecting the movable end of the current responsive bimetallic strip to a latch member to cause releasing movement of the latch member on the occur- The aforesaid means connecting the bimetallic strip and the releasable latch member is constructed in such a way as to provide a corrective action upon deflection of the bimetallic strip.

That is, its motion includes a component which,

"relative to the bimetallic strip, is in a direction to counteract the main tripping motion of the bimetallic strip. When the bimetallic strip is heated solely by ambient temperature, this corrective action is more accentuated than when the strip is heated solely by electric current.

Because of this, the assembly exhibits the characteristics of an ambient-compensated thermal responsive means without the necessity for use of a separate ambient compensating bimetallic member.

In accordance with applicants invention in one form, the connecting means comprises a rigid member having one end thereof connected to the movable end of the bimetallic strip and having its major portion extending gen erally parallel to the bimetallic strip in the direction toward the fixed end thereof and terminating in a latchactuating portion which is spaced from the bimetallic strip a predetermined distance.

The arrangement is such that upon heating of the bimetallic strip due to current passing therethrough, the spacing of the latch actuating portion of the connecting member from the body of the bimetallic strip does not change appreciably, but when the bimetallic strip is heated by ambient temperature, the spacing of the latch actuating portion of the connecting member from the main body of the bimetallic strip does increase significantly, thereby counteracting the general effect of deflection of the main portion of the bimetallic strip, and providing acorrective action.

The invention will be more fully understood from the following detailed description, and its scope will be pointed out in the appended claims.

In the drawings,

FIGURE 1 is a side elevation view of an electric circuit breaker constructed in accordance with the invention, a part of the insulating casing closest to the observer being omitted to show the internal parts;

FIGURE 2. is a perspective view of the current responsive means of the circuit breaker of FIGURE 1;

FIGURE 3 is a side elevation view of a portion of the circuit breaker of FIGURE 1, the parts being shown in a condition which they assume when the assembly is heated substantially entirely by elevated ambient temperature;

FIGURE 4 is a view similar to FIGURE 3, but showing the parts in a thermally tripped condition;

FIGURE 5 is a fragmentary perspective view of a portion of thermal current responsive means of another embodiment of the invention;

FIGURE 6 is a side elevation view of the thermal curvention;

FIGURE 7 is a side elevation view of a thermal current responsive means of a fourth embodiment of the invention;

FIGURE 8 is an exploded perspective view of the thermal current responsive means of FIGURE 7;

FIGURE 9 is a view similar to FIGURE 7 but showing the parts in a position which they occupy upon tripping magnetically.

FIGURE 10 is a view similar to FIGURE 9 but showing the parts in the position which they occupied when heated primarily by ambient temperature;

FIGURE 11 is a graphical representation showing various characteristics of the invention.

Referring first to FIGURE 1, the invention is shown as incorporated in an electric circuit breaker comprising a generally rectangular insulatingcasing, including a generally tray-shaped body portion 10 and a generally planar cover, not shown, fitting on the body 10 and closing the side exposed to the observer in FIGURE 1.

A stationary line terminal member 11 is mounted in a conforming recess in the casing 10. The line terminal 11 is generally U-shaped and is adapted to receive a bladetype stationary terminal, not shown. The terminal 11 includes an integral lug portion 11A carrying a stationary contact 11B thereon.

A movable contact 12 is fixedly carried by a contact arm 13. The contact arm 13 is pivotally mounted at a pivot point 13A on an insulating handle 14, which in turn is pivotally supported in the casing 10 on an integral pivotal support or hub 15.

A generally U-shaped releasable support 16 is also pivotally supported in the casing body 10 on a pivot pin 17, and a tensiontype operating spring 18'is interconnected between the contact arm 13 and an anchor point 19 on the handle 14.

Rotation of the handle 14 about its pivotal support 15 in the casing moves the pivotal support point 13A of the contact arm 13 back and forth across the line of action of the tension spring 18 and moves the contact arm 13 be tween open and closed circuit positions with respect to the stationary contact 11B with a snap-action.

The end 16A of the releasable support 16 remote from its pivotal supporting pin 17 is releasably latched in the position shown in FIGURE 1 by current-responsive means to be described.

When the contact arm 13 is in closed-circuit position and the support member 16 is released from the currentresponsive means, the tension spring 18 acts on it to cause rotation in clockwise direction as viewed in FIGURE 1. Clockwise rotation of the support member 16 moves the anchor point 19 of the spring 18 across the pivot point 13A of the contact arm 13, thereby reversing the bias of the spring 18 on the contact arm 13 and moving the contact arm to automatically-opened or tripped position.

Following tripping action, the parts may be returned to the off position as indicated in FIGURE 1 by rotating the handle 14 clockwise about its pivotal support 15 back to its FIGURE 1 position.

This causes the projection 14A of the handle 14 to engage a pin 20 carried by the releasable support member 16, and to rotate the support member 16 counterclockwise about its pivotal support 17 to relatched position as shown in FIGURE 1.

It should be understood that the particular operating mechanism utilized may be of any suitable type including a member which is moved to cause automatic opening, and that the particular mechanism illustrated herein is chosen merely as an example.

The construction and operation of the mechanism illustrated is more specifically described in co-pending application S.N. 405,757 filed concurrently herewith and assigned to the same assignee as the present invention.

Current responsive means For the purpose of normally restraining the releasable support member 16 and for releasing it upon the occurrence of predetermined conditions in accordance with the invention, current responsive means is provided which will now be described.

The current responsive means includes a combined armature-latch member of sheet metallic material 22, which is pivotally supported at 23 in the insulating casing, and is biased for clockwise rotation about its pivotal support by a compression spring 24. The armature-latch member 22 includes a widened portion 25 to enhance its operation as a magnetic armature, in a manner to be described, and an integral bentover latch projection 26.

An elongated bimetallic strip 28 is also included which is rigidly attached by suitable means, such as by welding, to an end portion 29A of a terminal strap member 29. The terminal strap member 29 is fixedly attached to the insulating body at an intermediate point by suitable means such as by a screw 30, and includes at its outer end a. wire-connecting screw 31.

For the purpose of adjustably positioning the bimetallic strip 28, a calibrating screw 32 is provided which is threadedly engaged in a nut 33 trapped in a conforming recess in the body 10. -The inner end of the screw 32 bears on the end 29A of the strap 29, and adjustment of the screw 32 causes more or less bending of the strap 29 intermediate the end 29A and the screw 30, thereby changing the angle of the bimetallic strip 28 in the casing 10.

The bimetallic strip 28 also carries a generally U- shaped magnetic field piece 34 attached thereto by suitable means such as by welding.

The bimetallic strip 28 is connected to the armaturelatch member 22 by means of an angularly-extending connecting piece 35. The movable end of the bimetallic strip 28 is electrically connected to the movable contact member 13 by means of a flexible conductor 36.

The current path through the circuit breaker therefore is from the line terminal 11 to the stationary contact 11B, to the movable contact 12, to the flexible conductor 36, to the movable end of the bimetallic strip 28, to the terminal strap 29, to the load terminal 31.

The current responsive means operates to cause release or tripping of the circuit breaker in either one of two ways, depending upon the magnitude of the excess current, that is, either magnetically or thermally.

Magnetic tripping takes place upon the occurrence of extremely high overload currents, such as those of short-circuit value.The magnetic field piece 34 is energized and attracts the armature portion 25 of the armature-latch member 22, and withdraws the latch projection 26 from the portion 16A of the member 16 against the bias of the spring 24, thereby causing tripping. In accordance with the embodiment of the invention shown in FIGURE 5, the sensitivity of magnetic field piece 34 may be greatly increased by the provision of additional turns such as 34A which are between the bimetallic strip 28 and the flexible conductor 36.

The addition of the extra coils 34A is made ossible by making the magnetic field piece 34 substantially wider than the bimetallic stri 28.

Thermal tripping takes place upon the occurrence of electrical currents 'which are above the normal or rated value of the circuit breaker and below the excessively high or short-circuit values which cause magnetic tripping.

Such intermediate overload currents cause warping of the bimetallic strip 28 so as to move the lower end thereof to the right as viewed in FIGURE 1, thereby acting through the means of the connecting mean-s 35, on the armature-latch member 22 to move it to the right to cause tripping.

In accordance with the invention, the thermal tripping means comprising the bimetallic strip 28, the latch 22, and the connecting means 35, is so constructed in such a manner that elevated ambient temperatures do not have the adverse eflect upon the thermal tripping characteristics which they do in comparable prior art thermal current responsive devices.

Because of the construction provided by the present invention, the thermal tripping means responds with a greater latch-moving action to heating due to electric current than to heating due to elevated ambient temperatures.

It is possible, in accordance with the invention to construct a thermal current responsive device which is entirely unaffected by elevated ambient temperatures. In the preferred form, however, the current-responsive means of the invention is slightly sensitive to heating due to ambient temperature action.

This is for purposes of safety, since it is desired to allow the circuit breaker to trip if the bimetallic strip is heated due solely to ambient temperature of a sufficiently high degree.

In accordance with the invention, the connecting member 35 which connects the movable end of the bimetallic strip 28 to the lat-ch member 22 extends a substantial distance back toward the fixedly mounted end of the bimetallic strip 28, and the end 35A engages the latch member 22 at a point spaced a substantial distance from this movable end.

In accordance with a particular embodiment of the invention, it has been found that an adequate ambient correcting or compensating action is obtained which meets all requirements of such devices, including the requirements of the Underwriters Laboratories for ambient compensated circuit breakers, with a construction as follows: Circuit breaker rating 15 amperes; bimetallic strip total length 1.750 inches; length of connecting member .750 inch; original distance of end 35A from the nearest point of the bimetallic strip .187 inch.

The significant characteristics of this embodiment are shown in the graph entitled Derating Curve of FIGURE 11. This graph indicates the percentage of derating which is necessary for various ambient temperatures.

The line A represents the curve of a prior art breaker of this corresponding type without ambient compensating action. Line B represents the corresponding curve of the above-mentioned embodiment of the present invention.

As indicated in the graph of FIGURE 11, the prior art circuit breaker is capable of carrying 122% of its normal rated current at an ambient temperature of 25 C. When the ambient temperature is increased to 50 C., however, this same circuit breaker will carry only 93% of its rated current without tripping.

The circuit breaker constructed in accordance with the present invention, however, carries 113% of its rated current at 25 C., and at 50 C. carries 107% of its rated current. In other words, the current-carrying capacity of the circuit breaker incorporating the present invention is much less aiIected by ambient temperature than the illustrated prior art circuit breaker.

It is not certain that the theory of operation of applicants invention is completely understood.

This is because its operation involves the interaction of many factors such as: rate of heat generation by electric current in the various conducting parts; rate of heat exchange of both generated heat and heat from the circumambient air, by conduction, radiation and absorption; friction forces; and deflection versus loading characteristics of the bimetallic member, all of which act over a period of time during which all or most of these factors are acting dynamically. It is applicants hypothesis, however, that the invention operates in accordance with the following principles. 1

It is believed that the basic principle on which applicants invention operates is that there is a difference in the deflecting action of a bimetallic strip of the type illustrated when it is heated by ambient temperature as compared to its deflection when it is heated by the passage of electric current therethrough.

Specifically, when the bimetallic strip is heated by ambient temperature, it is heated uniformly throughout, and all adjacent parts and parts in contact with it are also heated at substantially precisely the same rate.

Thus, all points of the bimetallic strip 28, as well as the magnetic field piece 34, the terminal strap 29, and the flexible conductor 36 all have substantially the same temperature at all times. Accordingly, if the ambient temperature is increased, the temperature of all these parts increases uniformly therewith.

When the bimetallic strip is heated by such ambient temperatures therefore, it deflect-s equally throughout its length and assumes a condition closely approximating a segment of a circle, the radius of the circle decreasing as the ambient temperature is increased.

When the bimetallic strip 28 is heated by the passage of current therethnough, however, it is not heated uniformly throughout its length even though the current passes through the entire strip. This is because the heat generating, heat storage, and heat radiating characteristics of the various components involved are different.

Specifically, it is believed that when bimetallic strip 28 is heated by current passing therethrough, it deflects more sharply adjacent its fixedly supported end than it does adjacent its movable end. This is believed to be due to several factors such as the fact that the conductor 29 is ordinarily selected to act partly as a heater, whereas the flexible conductor 36 is not. In addition, the magnetic field piece 34 acts as a heat sink and also :as a heat radiator.

The net result, therefore, is believed to be such that on current-generated thermal tripping, most of the deflection which operates to move the end 35A occurs in the upper portion of the bimetallic strip 28. Since heating occurs primarily by current, the lower part of the bimetallic strip does not deflect as much as the upper portion, and the net result of the components of movement on the member 35 is such as to move the portion 35A to the right to cause tripping.

When deflection occurs primarily because of elevation of ambient temperature, however, the lower portion of the bimetallic strip 28 deflects equally with the upper portion, and the movable end 28A of the bimetallic strip 21 not only moves to the right as viewed, but also changes its angle substantially as it does so.

This change of angle tends to tilt the connecting member 35 counterclockwise with respect to its original position, thereby moving the end 35A to the left as viewed.

This tilting action tends to offset or counteract the movement of the piece to the right as viewed, and pnovides a compensating action.

In the embodiment of the invention shown in FIG- URE 6, there is illustrated an expedient whereby the compensating action of the assembly can :be further increased by passing current only through the major upper portion of the bimetallic strip 128.

The operation of this form of the invention is substantially the same as that described in connection with FIGURES 1 through 5. The fiorm shown in FIGURES 1 through 5, is preferred for use in applications of relatively low rated breakers, such for example as 15-20 amperes, and the form shown in FIG- URE 6 is preferred for use in higher rated breakers such for example as 30-50 amperes.

In FIGURES 7-10, there is shown another embodiment of the invention. In accordance with this embodiment, a bimetallic strip 228 has a magnetic field-piece 234 rigidly attached thereto at the point 234A by suitable means such as by welding.

The member 234 has an opening or window 234B through which a portion of the bimetallic strip 228 extends, so that a portion of the bimetallic strip 228 lies in the same plane as a portion of the member 234.

An armature piece 235 is hingedly supported on the lower end of the magnetic field-piece 234 and includes a projecting lug 235A which engages a bent-out tab or lug 222A of the latch member 222.

A coil 240 is wound about the field piece 234, also encircling the portion of the bimetallic strip 228 that passes therethrough. The end 240A of the coil 240 is rigidly connected to the bimetallic strip, by suitable means such as by welding, adjacent the fixedly mounted end of the field-piece 234.

The other end 240B of the coil 240 is connected to the flexible conductor 236. The lower end of the bimetallic strip 228 therefore is not in the electrical circuit, which passes from the flexible conductor 236 through the coil 240 to the bimetallic srip 228, and out the terminal strap 229.

The thermaldeflecting and ambient-correcting action of this form of the invention is generally similar to that of FIGURE 6. It will be noted in this connection that the spacing of the lug 235A from the main body of the bimetalic strip, which controls the amount of latch engagement, is controlled by an extension 235B which engages the lowest extreme end 228A of the bimetallic strip 228.

Deflection of the lower end of the bimetallic strip 228, occurs primarily due to ambient-temperature changes, and this permits the lug 235A to move away from the body of the bimetallic strip, in a correcting direction.

Thermal tripping occurs by deflection of the upper portion of the bimetallic strip 228, which moves the lower assembly to the right as viewed substantially as a unit, to cause tripping movement of the latch 222.

In the form of the invention shown in FIGURES 7-10, the piece 235 serves also as a magnetic armature, which is attracted to the piece 234 upon the occurrence of sufficient current through the coil 240. The portion 234A of the member 234 acts as a magentic pole piece to attract the armature, as shown in FIGURE 9.

Although the invention has been described in connection with particular embodiments, it will be readily appreciated that many modifications thereof may readily be made by those skilled in the art, and it is intended therefore by the appended claims to cover all such modifications as fall within the true spirit and scope of the invention.

What I claim as new and desire to secure by Letters Patent of the United States is:

1. An electric circuit breaker comprising:

(a) a support,

(b) at least one pair of cooperating contacts supported on said support and movablebetween open and closed circuit positions,

(c) a first member mounted on said support,

(d) means connecting said first member to at least one of said contacts to move said contacts from said closed to said open position upon predetermined movement of said first member,

(e) an elongated bimetallic strip fixedly mounted at one end on said support and having its other end movable,

(f) connecting means carried by said bimetallic strip and connecting said movable end of said bimetallic strip to said first member, said connecting means comprising an elongated member having one end thereof in contact with said movable end of said bimetallic strip and extending from said one end in a direction generally parallel to said bimetallic strip toward said fixedly mounted end of said bimetallic strip and having a second end in contact with said first member at a point spaced from said movable end of said bimetallic strip in the direction toward said fixedly mounted end thereof, and means preventing said elongated member from moving away from said bimetallic strip beyond a position having a predetermined angular relation to the major planar surface of said movable end of said bimetallic strip,

(g) said bimetallic strip having its high expansion side at the same side thereof as said connecting means, whereby uniform deflection of said bimetallic strip moves said connecting means in the general direction of movement of said movable end of said bimetallic strip and also moves said second end of said connecting means in a direction away from said high expansion side of said bimetallic strip.

2 An electric circuit breaker comprising:

(a) a support,

(b) at least one pair of cooperating contacts supported on said support, and movable between open and closed circuit positions,

(c) a first member mounted on said support,

(d) means connecting said first member to at least one of said contacts to cause movement of said contacts from said closed to said open circuit position upon predetermined movement of said first member,

(e) an elongated bimetallic strip fixedly mounted on said support at one end and having its other end movable,

(f) connecting means connecting said movable end of said bimetallic strip to said first member, said connecting means comprising an elongated member having a first end rigidly attached to said movable end of said bimetallic strip and extending from said first end in a direction generally parallel to said bimetallic strip toward said fixedly mounted end of said bimetallic strip and having its other end in contact with said first member,

(g) said bimetallic strip having its high expansion side 3. An electric circuit breaker comprising: (a) a support, (b) at least one pair of cooperating contacts supported on said support, and movable between open and closed circuit positions,

'(c) a first member mounted on said support,

(d) means connecting said first member to at least one of said contacts to cause movement of said contacts from said closed to said open circuit position upon predetermined movement of said first member,

(e) an elongated bimetallic strip fixedly mounted on said support at one end and having its other end movable,

(f) connecting means connecting said movable end of said bimetallic strip to said first member, said connecting means comprising an elongated member having a first end rigid-1y attached to said movable end of said bimetallic strip and extending from said first end in a direction generally parallel to said bimetallic strip toward said fixedly mounted end of said bimetallic strip and having its other end in contact with said first member,

(g) said bimetallic strip having its high expansion side at the same side of said strip as said connecting means, whereby uniform deflection of said bimetallic strip moves said connecting means in the general direction of movement of said movable end of said bimetallic strip, and also changes the angular position of said connecting means with respect to said bimetallic strip to increase the distance of said other end of said connecting means from the nearest adjacent point of said bimetallic strip,

(h) a terminal member carried by said support, (i) means electrically connecting said terminal member to said fixedly mounted end of said bimetallic strip,

(j) flexible conductor means electrically connecting said movable end of said bimetallic strip to one of said contacts, whereby electric current passing through said contacts also passes through said bimetallic strip.

4. An electric circuit breaker comprising: (a) a support, (b) at least one pair of cooperating contacts supported on said support and movable between open and closed circuit positions,

(c) a latch member pivotally mounted on said support, (d) operating means connecting said latch member to at least one of said contacts to cause movement of said contacts from said closed to said open circuit 10 position upon predetermined movement of said latch member,

(e) an elongated bimetallic strip fixedly mounted at one end on said support and having its other end movable,

(f) connecting means connecting said movable end of said bimetallic strip to said latch member, said connecting means comprising an elongated member having a first end rigidly attached to said movable end of said bimetallic strip and extending from said first end in a direction generally parallel to said bimetallic strip toward said fixedly mounted end of said bimetallic strip and having its other end in contact with said latch member,

(g) a generally U-shaped magnetic field piece fixedly attached to said bimetallic strip at a point intermediate said movable end and said fixed end,

(h) said latch member including an armature portion adjacent said magnetic field piece, said bimetallic strip extending between said field piece and said armature portion whereby current passing through said bimetallic strip energizes said field piece and causes attraction of said armature portion,

(i) said bimetallic strip having its high expansion side at the same side of said strip as said connection means whereby uniform deflection of said bimetallic strip moves said connecting means in the general direction of movement of said movable end of said bimetallic strip and also changes the angular position of said connecting means with respect to said bimetallic strip and increases the distance of said other end of said connecting means from said bimetallic strip.

5. An electric circuit breaker as set forth in claim 4 wherein said circuit breaker also includes:

(a) a terminal member supported on said support,

(b) means electrically connecting said terminal member to said fixed end of said bimetallic strip,