Cutler Hammer Electrical Panels

Cutler Hammer Electrical Panels

Inspections, Field Reports & Fires / Failures

CH panels, copper bus, crowded & split bus electrical panels

- POST a QUESTION or COMMENT about Cutler Hammer electrical panel safety.

Cutler Hammer electrical panel field inspection photographs, including a CH panel fire field report:

This article describes and includes photographs of a Cutler Hammer electrical panel fire that the electrician suspects was due to a faulty circuit breaker. This website provides information about a variety of electrical hazards in buildings, with articles focused on the inspection, detection, and reporting of electrical hazards and on proper electrical repair methods for unsafe electrical conditions.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Cutler Hammer Copper Bus Electrical Panels

Cutler Hammer Spit Bus Electrical Panel

The following photographs, provided for identification, were taken by Bob Sisson, a Maryland home inspector and ASHI Member.

Mr. Sissons reported these interesting observations:

Ths electrical panel also had a GE sticker on the front, but it was a stick on label. The dead front and the Panel were Cuttler Hammer tan in color, and the deadfront was embossed Cuttler Hammer. Clearly this was an older, copper-bus Cutler Hammer split-bus electrical panel.

Sisson adds that ... several people have recommended that I recommend replacement because of the split-bus and because of the panel age and likely cost of getting additional breakers.

Another said he didn't like how the Main connected to the lower buss with the soldered wire... In any case it is "Obsolete".

Bob Sisson ACI, Inspections by Bob

ASHI Member # 212016

MD Home inspectors License #29666*

*MAC-ASHI Chapter President 2010-2012

ASHI Mid-Atlantic Group Leader 2009-2012

ASHI National Board Of Directors 2012-2015

Bob@Inspectionsbybob.com

www.inspectionsbybob.com

Email: bob@inspectionsbybob.com

(301) 208-8289

Hazards of Split Bus Electrical Panels & the Rule of 6 Circuit Breakers

Mr. Sisson's photo (shown below) and our sketch (above ) illustrate split-bus designed electrical panels. Electrical power enters this panel at the top of the enclosure (in shadow, a heavy red and black wire).

A "split bus" electrical panel is one in which circuit breaker connections are configured so that a group of breakers in the upper panel include one or more that provides power to an electrical bus in the lower half of the electrical panel.

In other words, there is not be a single "main breaker" that will turn off all electrical power.

Power on the upper bus supplies several circuits including the lower portion of the panel. See those heavy wires bringing power from the upper half of the panel down to the lower half?

The electrical panel shown appears to have more than six breakers that must be thrown to turn off all power in the building as there are eight circuit breakers in the upper portion of this equipment.

Absence of a Main Breaker: May Violate the "Rule of Six"

Split-bus electrical panels are not necessarily unsafe, and in fact some such panels like early Frank Adam panels used copper bus bars and components that appear to perform quite well.

However the split-bus design, as we explain here, can lead to having too many breakers that must be switched off in an emergency.

Watch out: experts generally agree that if more than six circuit breakers must be thrown to turn off electrical power to the building the installation is not safe and may not comply with local or model electrical codes.

Home inspectors finding a split bus panel will often report the panel as "considered obsolete" and meriting replacement even if there is no visible damage; note that given their age and design it's also likley that these panels are overcrowded - a hazard we cite below on this page.

What is the "Rule of Six" for electrical panels and sub panels?

Where six or fewer breakers must be thrown to turn off all electrical power to the building the panel meets the safety "rule of thumb" or "rule of 6" but if you are inspecting such a panel be sure that all of the breakers that must be thrown to turn off building power are labelled as "MAINS"

Note: It is possible that the panel in Bob's photo is fed from a separate main breaker or switch. If so, and ifd that main breaker is close at hand, then the "rule of six" is is not violated by this panel.

More examples of split bus electrical panels are shown and discussed at

Trouble with Crowded Electrical Panels

We can't see the rest of this electrical panel but from what we can see it may be fully populated.

If the owners of this building want to add electrical circuits that will usually require either a sub panel and some massaging of wires in this older unit or more likely, the electrician will successfully point out that it'll be cheaper and safer and "better" to just install a new electrical panel with more circuit breaker positions and a single main shut-off.

Watch out: a common hazard found in over-crowded electrical panels is double-tapping: placing more wires under individual circuit breaker screws than that connector was designed-for. (Excuse the dangling preposition.)

See details

at DOUBLE TAPPED CIRCUIT BREAKERS

Electrical Panel Failure Risk Assessment and "OPM"

Really? All professional inspectors with an ounce of sense or two drams of experience are nervous about telling anyone not to spend money on replacing old equipment where life-safety matters pertain.

Even the most careful inspection and education cannot guarantee against all accidents.

But in discussion with a building owner or buyer client we should also consider the "OPM" problem: spending other people's money to reduce our own risk.

That sort of risk reduction is almost free to the inspector but not to the client. Using scholarly research tools (30 April 2015) we did not find research identifying unusual failure rates for the Cutler Hammer electrical panel described above.

Urgent versus Desirable Electrical Panel Replacement

So how urgent is the replacement of this obsolete Cutler Hammer electrical panel? And do we agree with the advice given to the inspector by people who may include electricians who profit by the work?

We noted that this is a copper bus CH panel. Over time and compared with aluminum and plated aluminum bus designs, copper bus electrical panels perform better than average - at least for the extent to which copper buses don't have the same arcing issues as aluminum or plated aluminum bus panels. In our opinion this means that while the panel may be "obsolete" unless the electrician or inspector found evidence of damage such as overheating or modification or corrosion, a replacement decision may be handled as recommended but not an emergency.

If an electrical panel is visibly unsafe (damaged by rust, corrosion, mechanical damage, arcing, amateur modification, improper use or other detectable events) it should be replaced promptly. Separately we discuss a more urgent replacement of FPE electrical panels

at FPE REPLACEMENT PANEL where replacement electrical panels made by Eaton Cutler Hammer are described.

Field Report: Cutler Hammer Electrical Panel Fire, Photos, Causation (?)

I have some more pictures from this CH meltdown

Speculation about possible causes of electrical panel fire - bad electric motor, panel age, corrosion

My first objective was to install the new load center, the burnout started with the two pole 15 that feeds a 20 year old pool pump. I am going tomorrow to meet the inspector for the new load center and that is when I am going to look into the "why" this Cutler Hammer electrical panel burned.

But I suspect its from a fault at the swimming pool motor, and possibly because the age of the panel, corrosion, (only a couple miles from the ocean). But I'll know more tomorrow and let you know. The homeowner is elderly.

The pool maintenance guy was there when he saw smoke coming from the panel and he shut off the main breaker.

Suspected loose or defective circuit breaker cause of electrical panel fire

So after megging [checking the electric motor with a DMM or VOM -

see ELECTRIC MOTOR DIAGNOSTIC GUIDE

and DMM DIGITAL MULTIMETER HOW TO USE]

the pool motor and the pool feeder I've determined it had to be a loose or defective breaker that started arcing out of control because the motor is fine and the feeders are fine.

Like I mentioned earlier this home is only a couple miles from the ocean, the breaker had been installed for over 25 years.

So I would guess that the breaker was loose or had loosened up.

Also something I never liked about CA is this panel sat in the sun all day long, so maybe that had to do with it as well.

- Brian Kessler, Brooks Electric, 714-883-0894, Email: brian@brooks4electric.com

NOTE: while the views above are by an experienced, licensed electrician, this field report does not include analysis nor conclusions by a professional arson investigator.

Cutler Hammer Research & Research by Cutler Hammer Engineers

- Chiste, Alan, and James Funke. "Electronic systems protection via advanced surge protective devices." In Telecommunications Energy Conference, 2002. INTELEC. 24th Annual International, pp. 22-26. IEEE, 2002.

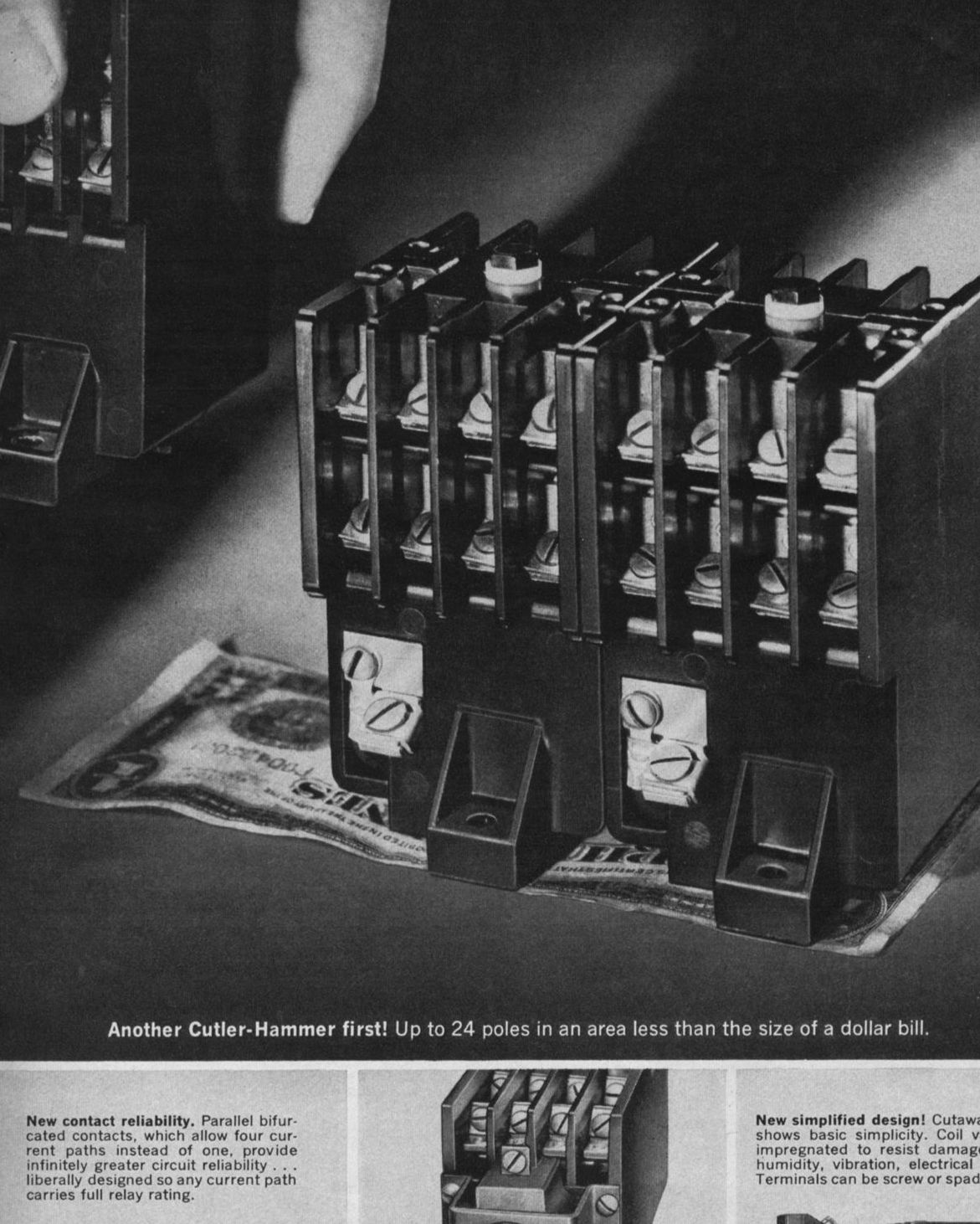

- Cutler Hammer, Cutler-Hammer COMPACT 300 CONTROL RELAY [PDF] in Electrical Engineering Magazine, Issue No. 9, Sept.-1960 pp. 16-17A, shown above.

Excerpt:

Here is the best answer yet to the need for an extremely reliable, small-size 300 V, 6 amp., industrial relay — the new ''Compact 300" from Cutler-Hammer. Every detail known that affects relay reliability has been improved in the "Compact 300/' Bifurcated contacts which make possible four current paths rather than one, add millions of operations to the "Compact 300's" electrical reliability. - Long, W., and R. Kirkland Smith. "Are all circuit breakers created equal? Not when it comes to some generator circuits." In Proc. Water Power Conference XIII, Buffalo, USA. 2003.

Abstract excerpt:

This paper summarizes unique and demanding aspects of protecting generator circuits and compares differences between the requirements for generator circuit breakers and those for standard distribution circuit breakers.

The performance capabilities of generator circuit breakers are summarized in a detailed, side-by-side comparison with the capabilities required of standard distribution circuit breakers. - Mckean, B. A. R. "Magnets and vacuum-the perfect match." (1998): 73-79.

- McCormick, James M., and Pete Theisen. Arc Fault Circuit Interrupter Development Overview. No. 2002-01-3233. SAE Technical Paper, 2002.

- Roybal, David D. "Circuit breaker interrupting capacity and short-time current ratings." In Pulp and Paper Industry Technical Conference, 2004. Conference Record of the 2004 Annual, pp. 130-134. IEEE, 2004.

- Roybal, David D. "Circuit breaker interrupting capacity and short-time current ratings." In Pulp and Paper Industry Technical Conference, 2004. Conference Record of the 2004 Annual, pp. 130-134. IEEE, 2004.

- Shea, John J. "Identifying causes for certain types of electrically initiated fires in residential circuits." Fire and Materials 35, no. 1 (2011): 19-42.

Abstract

While there are many circumstances that can lead to residential electrical fires, it is useful and practical to identify and document potential hazardous conditions and provide physical explanations of electrically initiated fires.

Failure modes for a variety of parallel and series arc faults are described along with circuit breaker response, electrical data, photos, and video frames to explain the conditions that led to a hazardous condition. This work identifies some of the various conditions that can create overheated hazardous conditions and shows how wire insulation is commonly the first to ignite.

Conditions explored include bundled extension cords under rugs, abused NM-B at a load center entrance, broken wires and loose connections. Physical phenomena investigated include glowing connections, series and parallel arcing faults.

Low and high current arc energies are discussed and compared to the combustible energy of volatile gases produced from wire insulation to illustrate the wide difference in the arc energy compared to chemical combustion energy from the decomposed PVC.

Electrical wire insulation properties were also measured on various wire types to show the effects of thermal aging. Hardness of the wire insulation and cracking of the insulation was used as a measure of insulation lifetime at 140°C. - Shea, J., B. DeVault, and Chien Yun-Ko. "Blow-open forces on double-break contacts." Components, Packaging, and Manufacturing Technology, Part A, IEEE Transactions on 17, no. 1 (1994): 32-38.

- Shipp, David D., Thomas J. Dionise, Visuth Lorch, and Bill G. MacFarlane. "Transformer failure due to circuit breaker induced switching transients." In Industrial and Commercial Power Systems Technical Conference (I&CPS), 2011 IEEE, pp. 1-10. IEEE, 2011.

- Slade, Paul G., and Erik D. Taylor. "Electrical breakdown in atmospheric air between closely spaced (0.2 μm-40 μm) electrical contacts." In Electrical Contacts, 2001. Proceedings of the Forty-Seventh IEEE Holm Conference on, pp. 245-250. IEEE, 2001.

- Slade, Paul G. "Vacuum interrupters: the new technology for switching and protecting distribution circuits." Industry Applications, IEEE Transactions on 33, no. 6 (1997): 1501-1511.

- Sweetser, C., W. J. Bergman, G. Montillet, A. Mannarino, E. J. O'Donnell, R. William Long, J. Nelson, R. Gavazza, and R. Jackson. "Strategies for selecting monitoring of circuit breakers." Power Delivery, IEEE Transactions on 17, no. 3 (2002): 742-746.

...

Continue reading at ELECTRIC PANEL INSPECTION - home where additional listings of failing electrical panels & wiring types are provided, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- AMPACITY, MAIN DISCONNECT

- DOUBLE TAPPED CIRCUIT BREAKERS

- ELECTRICAL PANEL AMPACITY

- FRANK ADAM ELECTRICAL PANELS

- INSPECT CIRCUIT BREAKERS, FUSES

Suggested citation for this web page

CUTLER HAMMER ELECTRICAL PANELS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thanks to reader Brian Kessler, Brooks Electric, 714 883 0894, email: brian@brooks4electric.com for discussing his field experience with Cutler Hammer Electrical Panel failures, February 2011.

- "Electrical System Inspection Basics," Richard C. Wolcott, ASHI 8th Annual Education Conference, Boston 1985.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "How to plan and install electric wiring for homes, farms, garages, shops," Montgomery Ward Co., 83-850.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "Home Wiring Inspection," Roswell W. Ard, Rodale's New Shelter, July/August, 1985 p. 35-40.

- "Evaluating Wiring in Older Minnesota Homes," Agricultural Extension Service, University of Minnesota, St. Paul, Minnesota 55108.

- "Electrical Systems," A Training Manual for Home Inspectors, Alfred L. Alk, American Society of Home Inspectors (ASHI), 1987, available from ASHI. [DF NOTE: I do NOT recommend this obsolete publication, though it was cited in the original Journal article as it contains unsafe inaccuracies]

- "Basic Housing Inspection," US DHEW, S352.75 U48, p.144, out of print, but is available in most state libraries.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.