Electric Motor Rotation Direction

Electric Motor Rotation Direction

Which way does an electric motor spin?

Can an electric motors reverse direction spontaneously?

How to re-wire a motor to change its rotation direction

Simple test for motor winding damage

- POST a QUESTION or COMMENT about how to troubleshoot electric motors such as air conditioning compressor motors, heating equipment burner or fan motors, swimming pool motors, water well pump motors

Electric motor run direction and backwards-running motors:

Why would an electric motor suddenly start running backwards? Here we explain the causes and cures for a motor that is running backwards and we also discuss motors that are designed to reverse direction.

For those motors we give directions for a simple wire connection swap that can reverse the motor's run direction, and we include PDF downloads of detailed electric motor wiring guides that give direction reversal instructions for other electric motor brands and models.

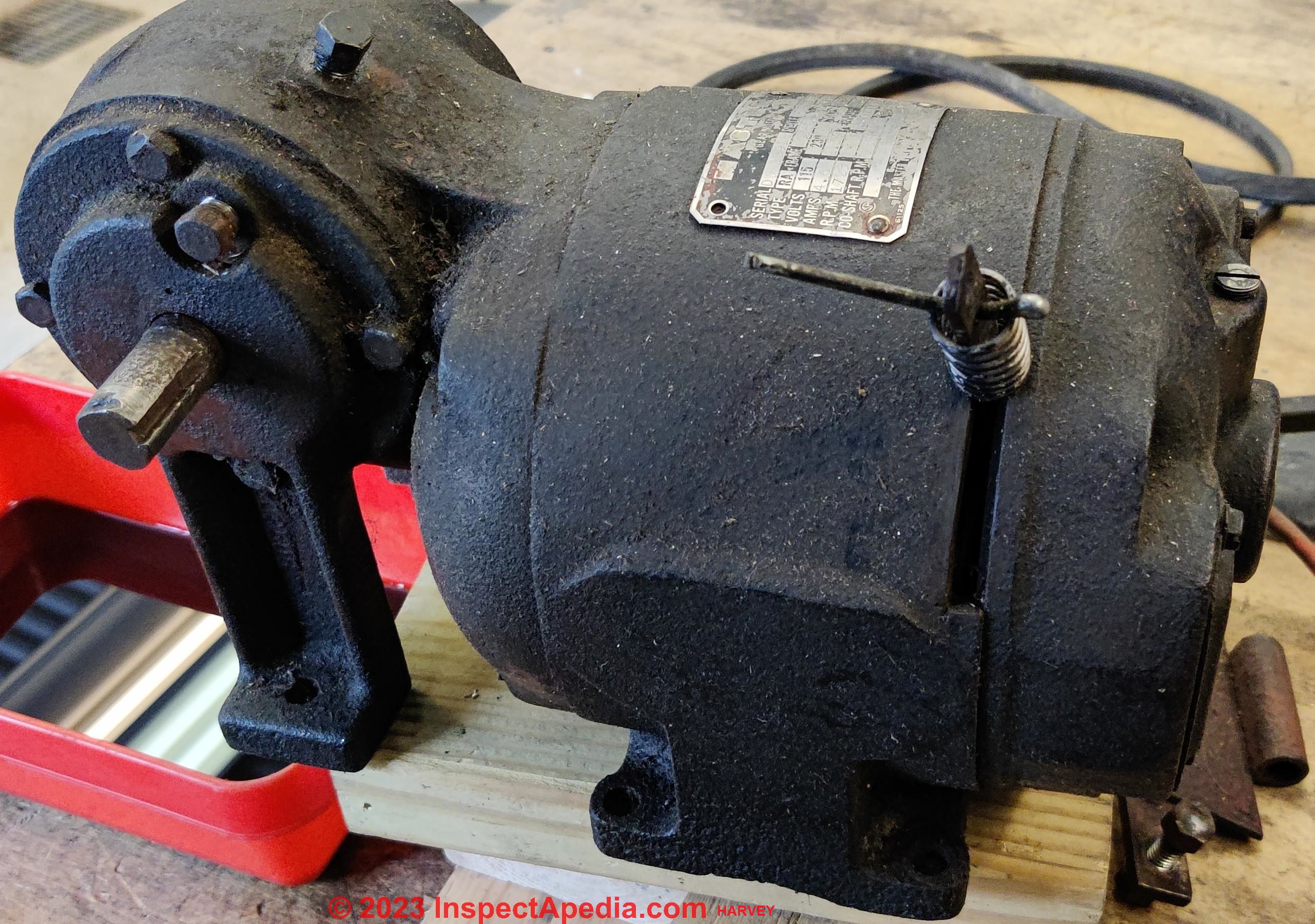

Page top photo: a Dalton brand electric motor showing how we determine its run direction.

This article series describes A/C electrical motor troubleshooting: a troubleshooting guide that helps diagnose and repair most electric motor problems for motors found on HVAC equipment in buildings such as air conditioners, furnace or air handler blower fans, oil burner motors, well pumps, and condensate return pumps.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Run Direction of an Electric Motor: diagnose & fix

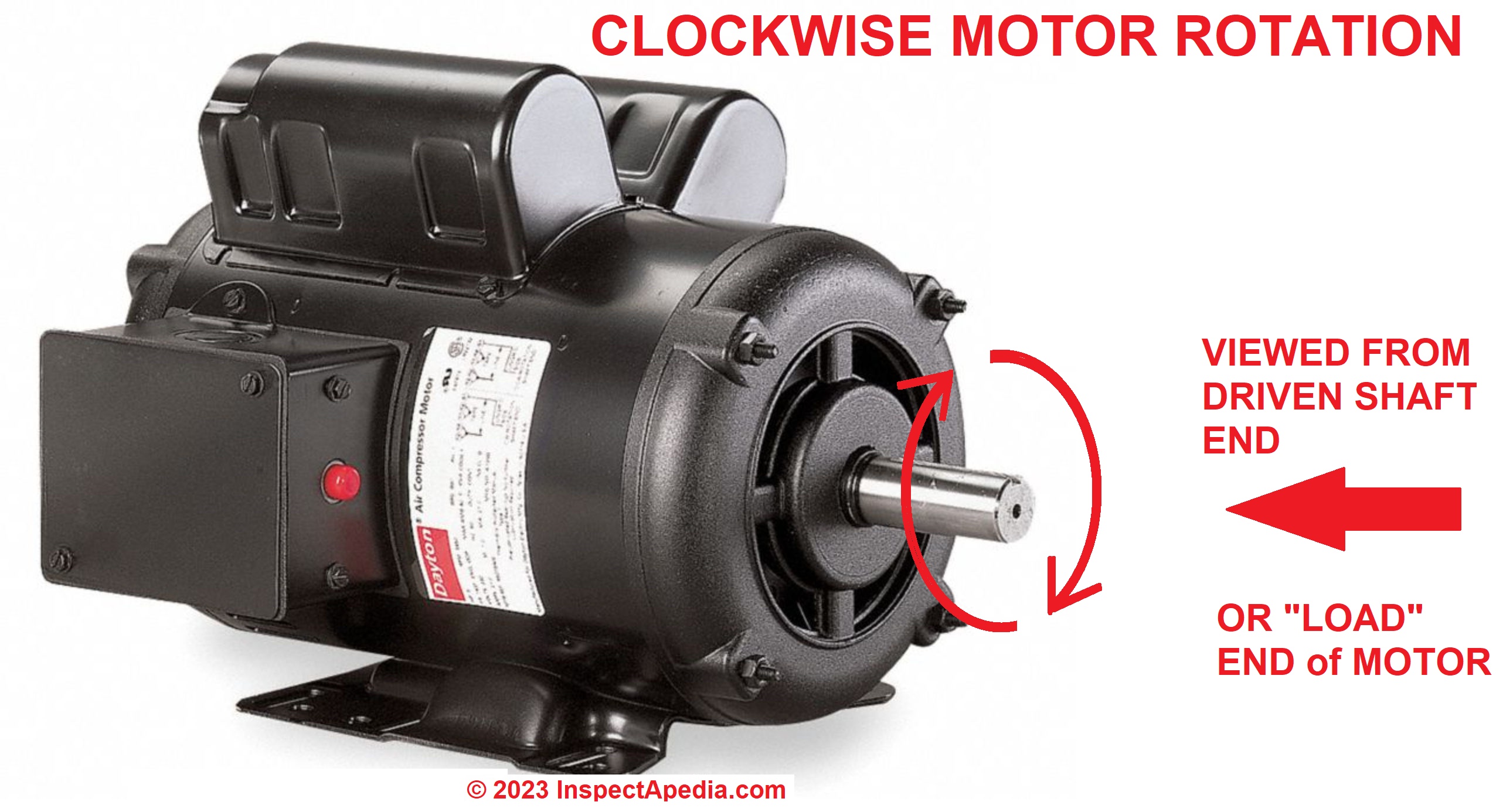

Here we describe the rotation or "run" direction of electric motors - clockwise or counterclockwise.

Here we describe the rotation or "run" direction of electric motors - clockwise or counterclockwise.

We explain why an electric motor might suddenly start running backwards, and we include instructions on how to reverse the direction of small electric motors by making simple wiring changes.

We also include a detailed example of how we reversed the direction of an antique Master Electric Co. brand motor and finally, we include free PDF downloads of detailed electric motor wiring and run direction reversal instructions.

Uni-directional electric motors run just one way: clockwise (CW) or counterclockwise (CCW) but not both.

Here our photo illustrates the motor as typically found in a direct-drive HVAC blower or air handler assembly.

While our page top photo shows the red reset button most clearly, the reset button on the motor at left may be harder to spot. Sometimes the reset button on an electric motor is hard to find, and sometimes there is no reset button!

Fatal Shock Hazard Warning: Inspecting electrical components and systems risks death by electrocution as well as serious burns or other injuries to the inspector or to others. Do not attempt these tasks unless you are properly trained and equipped.

Article Contents

- BASIC ELECTRIC MOTOR COMPONENTS

- ELECTRIC MOTOR ROTATION DIRECTION - CAN AN ELECTRIC MOTOR RUN "BACKWARDS"?

- ACCIDENTAL REVERSAL OF ELECTRIC MOTOR RUN DIRECTION - causes

- HOW TO CHANGE ELECTRIC MOTOR RUN DIRECTION - reverse the rotation / spin

- EASY TEST FOR MOTOR WINDING DAMAGE

- MANUALS of INSTRUCTIONS for CHANGING MOTOR RUN DIRECTION - free PDF downloads

...

Basic Components of an A/C Electric Motor

Such as used on heating and air conditioning equipment?

Before discussing how to diagnose air conditioner or heating system electric motors let's be sure we know what motor parts might be involved.

Or skip right to ELECTRIC MOTOR WON'T START / RUN if you prefer.

The electric motor has quite a few parts if examined in detail, switches, wires, possibly capacitors, oiling ports and more, but there are four basic parts to every HVAC electric motor:

- Electric motor rotor:

the rotor follows (turns in the direction impelled by) the rotating magnetic field and thus spins the motor shaft - Electric motor stator:

the stator consists is a device or core containing start and run windings (of copper wire) wound around a central core to create a magnetic field. - Electric motor windings:

the two windings are used to create an electrical field in the stator.- Definition of Start winding:

in an A/C (alternating current) electric motor electrical current flowing through the start winding is used just to get the motor spinning from a stopped condition.

The start winding is disconnected, usually by a centrifugal switch, when the motor is up to speed.

- Definition of Run winding:

in an A/C electric motor the run winding is what keeps the motor spinning once it has started.

Current flowing through this winding produces a rotating magnetic field in the stator that keeps the motor shaft turning after the start winding has turned off.

- Definition of Start winding:

- Electric motor start switch:

a centrifugal switch connects the A/C electrical power to the motor to the start winding on the stator until the motor has reached a speed typically of 75-80% of its full run speed (typically that's1725 rpm or 3450 rpm on newer high-speed oil burners).

Also see ELECTRIC MOTOR CENTRIFUGAL SWITCH or PTC PRD

In addition to the basic electric motor components above there are two other features to know about when troubleshooting a motor.

...

Which way does an Electric Motor Run - Can Electric Motors run Backwards?

Information found on the electric motor's data tag.

Uni-directional electric motors run just one way: clockwise (CW) or counterclockwise (CCW) but not both.

In many applications the equipment driven by the electric motor will not work properly unless the motor drive shaft spins in a predetermined direction: clockwise or counter-clockwise.

Examples include HVAC unit blower squirrel cage fans whose blades won't move air if the fan runs backwards and oil burner or well pump motors whose oil pump or water pump won't move oil or water if the pump motor is driven in the "wrong" direction.

In a fixed-direction electric motor such as on an HVAC blower fan or an A/C or heat pump compressor, each time the motor starts its start capacitor and start winding give the motor a "kick" in the right direction.

Bi-directional & self-reversing electric motors run in either direction, CW or CCW

Bi-directional electric motors run in either direction and are used in applications in which the direction in which the motor spins doesn't matter to the equipment it's driving. "What the heck?" you're saying. Well here's a cute example - your home microwave.

Electric motors require a kick or to put it more like an engineer, a starting torque to overcome the resistance when the motor is to begin spinning from a stopped position. Compared to electric motors used in oil burners and air conditioning compressors, we don't need such a costly and heavy-duty electric motor to spin the rotating table in a microwave oven.

Instead, microwave (and some other self-reversing) electric motors use a clever design that allows for elimination of the start winding winding and also allows use of a lower-cost and less powerful electric motor.

When the motor has stopped the mechanism it drives remains pressed against the motor's drive shaft, providing a "driven load" ( the microwave turntable) against the direction the motor's shaft was last rotating.

When the motor is asked to start again it encounters this extra load due to the resistance provided by a mechanical mechanism in the turntable that was itself "wound" or loaded by the table's prior rotation.

The microwave motor, encountering this load, reverses itself to begin rotating in the opposite direction, one of less load, which gives a brief "no-load" interval that lets the microwave's turntable motor get up to speed.

In sum, the combination of a load or rotation resistance provided by the turntable mechanism and an automatic direction reversing feature in the electric motor gets the microwave motor spinning and the turntable rotating - which is why each time you start your microwave it is likely to rotate in the opposite direction from that of its previous cycle.

...

Can an Electric Motor Run Backwards by Accident or Because of Damage?

Watch out: yes it is indeed possible for some electric motors to run "backwards" following damage to the motor's start capacitor or windings.

We've had an occasional report of an HVAC motor running "the wrong way" or sometimes starting to run the the wrong way. For example the blower fan motor in an air handler can start and run backwards as can some air conditioner compressor unit cooling fan motors.

Typically an electric motor running in reverse direction is caused by (in order of probability)

- A failed electric motor starting capacitor

- A single speed single-phase motor leads are reversed on the motor's start winding connections

- A single-speed 3-phase electric motor has two of its supply leads reversed

- Belt driven air handler motors attached to a blower fan in a multiple-blower HVAC system can be turned backwards with the motor OFF and the squirrel cage fan rotating backwards because of air currents created by other fans that are on in the same system

- (For 2-speed electric motors you'll need to contact your motor supplier)

See POST a QUESTION or COMMENT for what appears to be an example of a backwards-running electric motor in an air handler.

Read the Information on an Electric Motor Data Tag to Determine the Motor Run Direction

In our photo at left you can see the notation on this electric motor data tag indicating the the motor is non-reversing and rotates counter-clockwise - designated by the words CCW ROTATION (red arrow).

If you enlarge the photo [Click any image to see an enlarged, detailed version] you will see text above the red arrow noting that this is a NON-REVERSING motor.

At ELECTRIC MOTOR DATA TAG we explain all of the information that can be found on the electric motor data tag.

Watch out: when buying replacement electric motors, fuel units, and blower fan assemblies to be sure they all are compatible. For example on oil fired heating equipment, the oil burner fuel units (the mechanical heating oil pump driven by the oil burner electric motor via a coupling) can be purchased as CW or CCW devices.

All three components have to be designed to rotate in a common direction:

- the electric driving motor,

- the oil burner combustion air blower fan assembly, and

- the oil burner fuel unit or oil pump.

If the fuel unit is not rotated in the proper direction the heating appliance won't run - it won't receive fuel, and the driving motor and coupling parts may be damaged.

If a squirrel cage blower fan on an oil burner or inside of an air handler is spun backwards it will not move much air and equipment will not function properly.

...

How to Change Electric Motor Run Direction

Watch out: Determine proper rotation BEFORE coupling motor to load. Keep hands and clothing away from rotating parts.

Watch out: as we warn throughout all of these articles on electrical work, if you are not trained in proper, safe electrical work, stay out of your electric motor - you could be shocked or killed.

Manually-reversible Electric Motor Run Direction

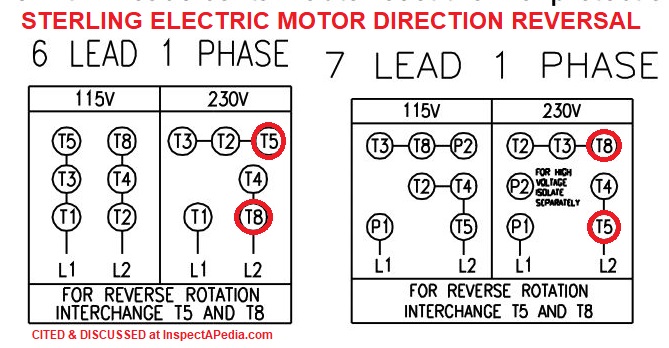

By swapping wire connections on some electric motors it is possible to change or reverse the motor direction.

Typically purple and yellow wires or wire pairs permit this change. But depending on your electric motor type, phases (1 phase vs 3 phase), and voltage (120VAC or 240 VAC or other), other wires and wire color schemes will be used. We'll give several examples below showing which wires to swap to change electric motor run direction.

Typical 120V motor Wire Swap: Purple & Yellow

- Purple to purple = rotate clockwise

- Purple to yellow = rotate counter-clockwise

or

if your motor doesn't use purple, and if wiring differs (depending on whether the motor runs on 120V or 240V or other), here are some other wire change examples to switch electric motor run direction:

- Switch Yellow and Blue wires (ending with RED->Yellow & BLUE->Black)

Concept: we're reversing polarity at the motor start winding. When you find the start winding, just swap the two wires that connect to the two ends of the start winding - that should change its direction and thus the rotation direction of the motor at start-up.

So if you can identify the start winding that'll be helpful.

How to Identify the Electric Motor Start Winding

If your motor uses a starting capacitor, see which motor winding is wired to the start capacitor - that's the start winding.

Besides following the start capacitor wiring to the winding, another way to identify the start winding of your motor is to measure electrical resistance across the winding.

A start winding will have higher resistance than the run winding (for smaller 120VAC motors the start winding has about 3x the resistance of the run winding - perhaps around 4 ohms while a 240VAC motor will have more, perhaps 16 ohms on the start winding more than 2x the run winding)

Swap Leads to the Motor Start Winding

Besides following the start capacitor wiring to the winding, another way to identify the start winding of your motor is to measure electrical resistance across the winding.

A start winding will have higher resistance than the run winding (for smaller 120VAC motors the start winding has about 3x the resistance of the run winding - perhaps around 4 ohms while a 240VAC motor will have more, perhaps 16 ohms on the start winding more than 2x the run winding)

For motors that can be wired to run on either 120VAC or 240VAC the start winding will usually be just 120VAC - powered by one leg of your two 240VAC wires.

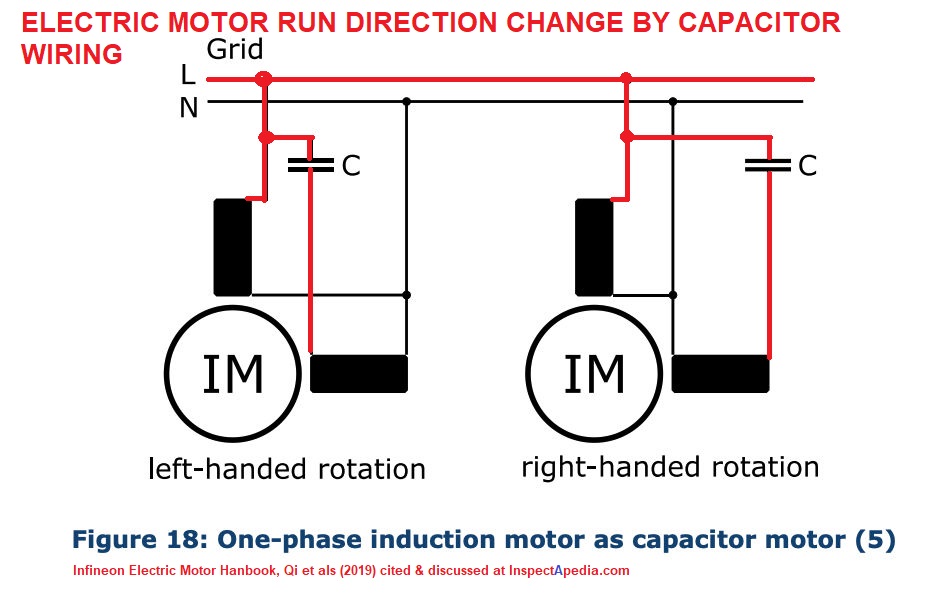

For common small induction motors it may be easiest to reverse the motor rotation direction by swapping the motor start capacitor leads in front of or behind the auxiliary (start) winding. (Qi 2019).

Small 3-Phase Electric Motor Run Direction Change

The above is for single phase electric motors; a 3-phase motor will be different.

On a 3-phase motor - provided it is fed with just 3 leads - you reverse its direction very easily by simply swapping any two power leads.

For a 3-phase motor with more than 3 leads you'll need the wiring diagram for the motor.

Below we provide IO manuals for ECM motors, single phase motors, and 3-phase electric motors.

Example of Re-Wiring a Motor to Change Run Direction

See HOW TO CHANGE RUN DIRECTION for a MASTER ELECTRIC 115V / 230V MOTOR - wiring an antique electric motor

...

Simple Test for Motor Winding Damage

General advice: Electrical Tests to Check HVAC Blower Fan Motor or Outdoor Compressor Fan Motor Winding on Heating or Cooling Equipment or on Other Electrical Motors

Example: testing a blower fan motor winding: referring to the electrical diagram for your equipment, unplug electrical connectors at the fan motor.

Measure the resistance between each lead wire with a multimeter or VOM. The multimeter should be set in the X1 range.

For accuracy, don't measure when the fan motor is hot, allow it to cool off.

When the resistance between each lead wire are those listed in the specifications for your equipment the fan motor should be normal.

Zero resistance or infinite resistance are indicators of a problem.

See the electrical test tool & equipment articles listed at MORE READING

...

Electric Motor Manuals Include Changing Run Direction

The antique electric motor shown here is discussed in detail

at MASTER ELECTRIC COMPANY MOTORS

For an examples of electric motor wiring that includes wiring to select electric motor speed options as well as direction of rotation see the following guides.

Watch out: if you are not trained in proper, safe electrical work, stay out of your electric motor - you could be shocked or killed.

- COPELAND ELECTRICAL HANDBOOK [PDF] a helpful reference.

- MASTER XL RIGHT-ANGLE GEAR MOTORS & C-FACE REDUCERS SERVICE & REPAIR MANUAL [PDF] (2010) Master Power Transmission, 3300 Tenth St., Columbus IN 47201 USA, Web: www.master-pt.com - this manual is just gears - no motor. - retrieved 2023/04/18, original source: d1odbfykel3oe2.cloudfront.net/wp-content/themes/reverie-master/images/pdf/manuals/E3614-XL-RA-12-28.pdf

- INSTALLATION, OPERATION AND MAINTENANCE OF RELIANCE® STANDARD INDUSTRIAL AC INDUCTION MOTORS - PDF is a book of wiring diagrams for the same series of motors when produced later under Baldor - as I'll explain in a historical note below.

- INSTALLATION, OPERATION AND MAINTENANCE OF RELIANCE® STANDARD INDUSTRIAL AC INDUCTION MOTORS - [PDF] book of wiring diagrams for the same series of motors produced later under Baldor

- Dayton Electric MOTOR WIRING DIAGRAM [PDF], Dayton Electric Mfg. Co., 5959 W. Howard St., Niles IL 60714 USA, retrieved 2017/07/09, original source: Grainger.com

- IRONTON ELECTRIC MOTOR OWNER'S MANUAL [PDF] Northern Tool Northern Tool + Equipment Co., Inc. Burnsville, Minnesota 55306 USA NorthernTool.com Made in China - retrieved 2021/04/04 original source https://www.northerntool.com/images/downloads/manuals/29560.pdf

- Marathon, AC INDUCTION MOTORS [PDF] 56-5000 Frame, Manufactured for Allen-Bradley by Marathon

Electric, Inc., retrieved 2021/04/04 original source: https://literature.rockwellautomation.com /idc/groups/literature/ documents/um/1329m-um001_-en-p.pdf

Excerpts:

These instructions must be followed to ensure safe and proper installation, operation and maintenance of the motor. They should be brought to the attention of all persons who install, operate or maintain this equipment.

Changing Rotation

1. Keep hands and clothing away from rotating parts.

2. Determine proper rotation BEFORE coupling motor to load.

3. Check rotation by jogging or bumping. Apply power to the motor leads for a short period of time, enough to just get motor shaft to rotate a slight amount to observe shaft rotating direction.

4. Three phase - interchange any two (2) of the three (3) line leads.

Single phase - reconnect per the connection diagram on the motor. Normally Open (N.O.) motor thermostats may be used in conjunction with controls installed by an OEM. - MASTER ELECTRIC 115V / 230V MOTOR RUN DIRECTION CHANGE [Web page] Q&A on changing the wiring an antique electric motor

- MOTOVAIRO USE & MAINTENANCE INSTRUCTIONS for ELECTRIC MOTORS [PDF] (2019) Motovario, Teco Group, Motovario S.p.A. Via Quattro Passi 1/3 41043 Formigine (MO) Italy Tel. +39 059 579700 Paid-in Capital: Euro 18.010.000 i.v. Rea: R.E.A. di Milano n. 1863844 Website: www.motovario.com

- Qi, Fang, Daniel Scharfenstein, Claude Weiss, Clemens Müller, Ulrich Schwarzer ELECTRIC MOTOR HANDBOOK [PDF] (2019) Infineon, retrieved 2021/04/04 original source: https://www.infineon.com /dgdl/Infineon-motorcontrol_handbook-Additional TechnicalInformation-v01_00-EN.pdf?fileId= 5546d4626bb628d7016be6a9aa637e69

Excerpt:

The rotation direction can be set by the position of the capacitor in front or behind of the auxiliary winding as can be seen in Figure 18. [shown above]

- Sterling, SINGLE PHASE ELECTRIC MOTOR INSTALLATION & MAINTENANCE MANUAL [PDF] (2006) Sterling Electric Co., Irvine, California (800) 474-0520

Indianapolis, Indiana (800) 866-7973

Hamilton, Ontario (800) 809-0330

e-mail: sales@sterlingelectric.com

www.sterlingelectric.com retrieved 2021/04/04 original source: sterlingelectric.com/manuals/Single Phase Motor O M Manual 032106.pdf

Excerpt: Disconnect load and start motor. Check direction of rotation. Consult connection diagram on motor nameplate to change direction of rotation on bi-directional motors. - Sterling, 3 Phase AC Induction Motors INSTALLATION AND OPERATION MANUAL [PDF] (2018)

- WEG, INSTALLATION AND

MAINTENANCE MANUAL

FOR NEMA LOW VOLTAGE

ELECTRIC MOTORS [PDF] WEG Electric Motors Corp.

2100 Brighton-Henrietta Townline Road

Rochester NY 14623

USA Tel: 716-240-1000

, retrieved 2021/04/04 original source: https://www.stevenbrownassociates.com/ pdf/drivers/electric/weg/motor.pdf

Excerpt: This manual covers all the three-phase and single-phase asynchronous squirrelcage induction motors, from 140T to 580T frame sizes. The motors described in this manual are subject to continuous improvement and all information is subject to change without notice. For further details, please consult WEG. - WWE, AC INDUCTION MOTOR IO MANUAL [PDF] Installation And Maintenance For

Fractional Single-Phase and Polyphase

AC Induction Motors

This Manual Covers WorldWide Electric’s

NT, NAT, NATE, NTJ, NATJ, NATEJ, WSSNV, WSS,

NAWSS, NAWSSE, SSPE, FM, and FD Models - WorldWide Electric Corporation

3540 Winton Place, Rochester, NY 14623

Sales Support: (800) 808-2131

Technical Support: (844) 993-7378

www.worldwideelectric.net

Excerpts:

This manual includes procedures for the safe and proper transportation, storage, installation, connection, operation and maintenance of WorldWide Electric motors. For your protection, please read these instructions carefully before attempting to install, operate or service the motor.

If rotation must be changed allow the motor to stop completely. Interchange any two incoming power leads of a three-phase motor to change the direction of the rotation. See wiring diagram.

...

...

Continue reading at CAPACITORS for HARD STARTING MOTORS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see ELECTRIC MOTOR RUN DIRECTION FAQs - questions & answers posted originally at this article

Or see these

Recommended Articles

- BLOWER FAN OPERATION & TESTING

- ANALOG VOMs & MULTIMETERS

- AMPS MEASUREMENT AUTOMOTIVE DC

- AMPS MEASUREMENT METHODS

- DEFINITION of ELECTRICAL POWER PHASES - Single Phase vs Two vs Three Phase Electrical Power

- ELECTRIC MOTOR DIAGNOSTIC GUIDE - home

- A/C ELECTRIC MOTOR COMPONENTS

- BURNED-OUT COMPRESSOR

- CAPACITOR TYPES, for MOTORS

- CAPACITORS for HARD STARTING MOTORS

- CHATTERING RELAY CONTROL SWITCHES

- COPELAND ELECTRICAL HANDBOOK [PDF]

- ELECTRIC MOTOR 3-PHASE MOTOR SELECTION

- ELECTRIC MOTOR 3-PHASE TROUBLESHOOTING

- ELECTRIC MOTOR CENTRIFUGAL SWITCH or PTC PRD

- ELECTRIC MOTOR DATA TAG

- ELECTRIC MOTOR HORSEPOWER & CIRCUIT WIRE SIZE

- ELECTRIC MOTOR LUBRICATION

- ELECTRIC MOTOR NOISE DIAGNOSIS

- ELECTRIC MOTOR OFF on RESET

- ELECTRIC MOTOR OVERHEATS

- ELECTRIC MOTOR OVERLOAD RESET SWITCH

- ELECTRIC MOTOR RUN DIRECTION - backwards

- ELECTRIC MOTOR START SWITCH

- ELECTRIC MOTOR WON'T START / RUN

- ELECTRIC MOTOR TESTS

- ELECTRIC MOTOR WIRING DIAGRAMS & GUIDES

- HARD STARTING COMPRESSOR MOTORS

- HARD STARTING ELECTRIC MOTOR CAUSES

- MASTER ELECTRIC COMPANY MOTORS

- OIL BURNER NOISE DIAGNOSTIC INDEX

- RESET BUTTON, ELECTRIC MOTOR

- TIGHT or SEIZED AC COMPRESSORS

- WATER PUMP PROTECTION SWITCH

- DMM DIGITAL MULTIMETER HOW TO USE

- DMMs & VOMs, Using Safely

- TEST EQUIPMENT, ELECTRICAL GUIDE

- VOLTS MEASUREMENT METHODS

Suggested citation for this web page

ELECTRIC MOTOR RUN DIRECTION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Beckett Oil Burners, "Burner Motor Service Facts", Beckett Corporation, Technical Information, 15 June 1989 [copy on file as PDF].

- [2] N. Srinivasan, MSEE, is a senior member of IEEE with 30 years experience in the electrical industry. Mr. Srinivasan is in Vienna VA.

- [3] Louis P. Babin generously contributed technical editing about the effects of doubling ampacity in an electrical circuit (September 2007)

- [4] Digisnap DSA-500 snap-around digital multimeter, A.W. Sperry Instruments Inc., 2150 Joshua's Path, Suite 202, Hauppage NY 11788, Tel: 800-645-5398, Email: cat@awsperry.com, Website: www.awsperry.com

- [5] Fluke Corporation, 6920 Seaway Blvd, Everett, WA 98203, USA, PO Box 9090 Everett, Washington 98206, Tel: +1(425) 347-6100, Technical support: 1(800) 44-FLUKE (1(800) 443-5853), Website: www.fluke.com,

Fluke Europe B.V, PO Box 1186 Eindhoven, The Netherlands, Tel: +31 (0)40 2 675 200 +31 (0)40 2 675 222, Website: www.fluke.eu- Fluke India: TTL India Pvt. Ltd. (A Fluke Company), Deodhar Center, 424, Marol Maroshi Road, Andheri (E), Mumbai, 400076, Tel: 1 800 209 9110, Email: info.india@fluke.com, Website: http://www.fluke.com/fluke/inen/products/Digital-Multimeters.htm

- Digital 287/289 Digital Multimeter, Users Manual, retrieved 9/5/21, original source: http://assets.fluke.com/manuals/287_289_umeng0200.pdf, [copy on file as Fluke_287_289_umeng0200.pdf]

- [6] Simpson Electric, P.O. Box 99, 520 Simpson Avenue, Lac du Flambeau, WI 54538-0099 Tel: 715-588-3311, customer service: 715-588-3947, Email: support@simpsonelectric.com, Website: www.simpsonelectric.com/

- Simpson 260® Series 6XLM Volt-Ohm-Milliammeter Instruction Manual, retrieved 9/5/2012, original source: http://www.simpsonelectric.com/uploads/File/datasheets/260-6xlm.pdf, [copy on file as Simpson_260-6xlm.pdf]

- [7] tif 300cc Tic Tracer voltage detector, Tif Instruments Inc., 9101 NW 7th Avenue, Miami, Florida 33150

- [8] Greenlee® GT-16 adjustable voltage detector, Greenlee Textron Inc., Website: greenlee.com, Tel: 800-435-0786 , Email: echsupport@greenlee.textron.com,

- [9] Jensen VOMs, no longer available

- [10] Mastech VOMs and DMMs (made in China), Shanghai Hihua V&A Instrument Company, 881 Ye Cheng Road Jia Ding District, Shanghai 201821, China, Email: mastech@vip.sina.com, Tel: +86 21 69523164 +86 21 69523225, Website: http://www.mastech.com.cn/

- [11] Equus Multimeters by Innova, Equus Products, Inc., 17352 Von Karman Ave., Irvine, CA 92614, U.S.A., Tel: 714-241-6800, Website: http://www.equus.com/

- [12] Actron DMMs & VOMs, Website: http://www.actron.com/

- [13] ExTech DMMs & VOMs, ExTech Corp. a FLIR company, Extech Instruments Corporation, 9 Townsend West, Nashua, NH 03063, U.S.A., Email: support@extech.com, Tel: 877-239-8324 Option 3, Website: http://www.extech.com

- [15] Dr. Jess Aronstein, consulting engineer, Poughkeepsie NY, 1991 protune@aol.com

- [16] Rex Cauldwell, master electrician and contributor to the Journal of Light ConstructionOn electrical topics

- [17] New York State Central Hudson Gas and Electric Company, G&E/1-2/85 consumer safety pamphlet

- [21] ASHI Technical Journal, Vol. 2. No. 1, January 1992, "Determining Service Ampacity," Dan Friedman and Alan Carson, and the

- [22] ASHI Technical Journal, Vol. 3. No. 1, Spring, 1993, "Determining Service Ampacity - Another Consideration," Robert L. Klewitz, P.E., with subsequent updates and additions to the original text ongoing to 2/19/2006. Reprints of the originals and reprints of the Journal are available from ASHI, the American Society of Home Inspectors www.ashi.com.

- [24] "Electrical System Inspection Basics," Richard C. Wolcott, ASHI 8th Annual Education Conference, Boston 1985.

- [25] "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- [26] "How to plan and install electric wiring for homes, farms, garages, shops," Montgomery Ward Co., 83-850.

- [27] "Electrical System Inspection Basics," Richard C. Wolcott, ASHI 8th Annual Education Conference, Boston 1985.

- [28] "Home Wiring Inspection," Roswell W. Ard, Rodale's New Shelter, July/August, 1985 p. 35-40.

- [29] "Evaluating Wiring in Older Minnesota Homes," Agricultural Extension Service, University of Minnesota, St. Paul, Minnesota 55108.

- [30] Jim Simmons: Personal communication, J. Simmons to Daniel Friedman, 9/19/2008. Photographs contributed to this website by Jim P. Simmons, Licensed Electrician, 360-705-4225 Mr. Electric, Licensed Master Electrician, Olympia, Washington Contact Jim P. Simmons, Licensed Master Electrician, Mr. Electric, 1320 Dayton Street SE

Olympia, WA 98501, Ph 360-705-4225, Fx 360-705-0130 mrelectricwa@gmail.com - [31] Kenneth Kruger: Original author of the sidebar on testing VOM DMM condition: Kenneth Kruger, R.A., P.E. AIA ASCE, is an ASHI Member and ASHI Director in Cambridge, MA. He provided basis for this article penned by DJ Friedman.

- [32] Paul Galow [Website galowconsulting.com ] - technical consultant on networking, LAN design, applications support. Galow Consulting Services [Website galowconsulting.com ] , 914-204-1749, email: paulgalow@galowconsulting.com

- [33] LB Miller, "A simple Do-It-Yourself test fixture that will allow you to measure the DC resistance (Rm) of RC Model Electric Motors", San Marcos C, HobbyKing.com, retrieved 9/12/12, original source: http://www.rcgroups.com/forums/showthread.php?t=580151 [copy on file as Miller_Test.pdf]

- [34] "Electrical Systems," A Training Manual for Home Inspectors, Alfred L. Alk, American Society of Home Inspectors (ASHI), 1987, available from ASHI. [DF NOTE: I do NOT recommend this obsolete publication, though it was cited in the original Journal article as it contains unsafe inaccuracies]

- [35] "Basic Housing Inspection," US DHEW, S352.75 U48, p.144, out of print, but is available in most state libraries.

- [36] Wikipedia Web: https://www.wikipedia.org/ provided background information about some topics discussed at this website provided this citation is also found in the same article along with a " retrieved on" date. NOTE: because Wikipedia entries are fluid and can be amended in real time, we cite the retrieval date of Wikipedia citations and we do not assert that the information found there is necessarily authoritative.

WikiHow: "How to Check Out an Electric Motor", retrieved 9/12/12, original source: http://www.wikihow.com/Check-an-Electric-Motor - [37] Andy Page, "The Basics of Motor Circuit Analysis", Reliable Plant, (Noria Corporation), 1328 E. 43rd Court, Tulsa, OK 74105

Tel: 800-597-5460; Email: pagea@alliedreliability.com, retrieved 9/13/12, original source: http://www.reliableplant.com/Read/10686/motor-circuit-analysis, [copy on file as THE BASICS of MOTOR CIRCUIT ANALYSIS [PDF] ] - Quoting:

MCA online [tests performed while the motor is operating] can be further split into two categories - current analysis and voltage analysis. Current analysis is primarily focused on the rotating components. Loose or broken rotor bars, cracked end rings, rotor eccentricity, misalignment and coupling/belt problems are some of the "big-hitter" failure modes detected in the current signature. Power quality issues like harmful harmonics, voltage imbalances and under/over-voltages are among the issues identified with voltage analysis.

MCA offline is most famous for the resistance-to-ground measurement. But other measurements make motor circuit defects easy to find. Measuring electrical characteristics like impedance, inductance and capacitance tell the analyst plenty about the condition of the windings. Inductance is a great indicator of turn-to-turn shorts. Capacitance to ground measures the amount of winding contamination (water, dirt, dust, etc.). Changes in each of these affect impedance (total resistance of an AC circuit). These characteristics are measured phase to phase and phase to ground and compared to each other and to percent change from baseline to identify motor circuit defects.

Motor circuit analysis (MCA) is often and easily confused with motor current analysis (MCA), which is an abbreviated version of motor current signature analysis (MCSA). - [38] BETTA-FLO JET PUMP INSTALLATION MANUAL,[PDF] National Pump Company, 7706 North 71st Ave., Glendale, AZ 85303, Tel: (800) 966-5240 Email: info@natlpump.com, website: http://www.nationalpumpcompany.com, retrieved anew 9/13/12, original source: http://www.nationalpumpcompany.com/pdf/Betta_Flo_IOM_Jet_Pump.pdf

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.