3-Phase Electric Motor Selection Guide

3-Phase Electric Motor Selection Guide

Choose the right three-phase electric motor for your application

- POST a QUESTION or COMMENT about 3 phase motors

Imagine a world where industry grinds to a halt, machines standstill, and productivity drops. It could be a reality if you choose the wrong 3-phase electric motor for your application.

These silent workhorses power everything from industrial pumps to electric cars, and making the right choice is crucial. But fear not! In this comprehensive guide, we'll illuminate the path to choosing the perfect 3-phase electric motor.

Here we define the 3-phase electric motor type, we explain why three-phase motors are important, and we give details on how to choose the specific 3-phase electric motor that matches your specific application.

Choosing the right 3-phase motor will not only optimize performance but will also boost efficiency and save on motor operating costs.

We also provide a more comprehensive INDEX to RELATED ARTICLES for this topic, or you can try the page top or bottom SEARCH BOX as a quick way to find information you need.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How to Choose the Right 3-Phase Electric Motor for Your Application

To understand how to select the proper 3-phase electric motor for your needs we begin with a quick review of the basic properties of 3-phase motors and how they work.

We continue with an outline of the different types of 3-phase motors and why they offer advantages over single-phase motors.

Then we will describe differences in motor speed, power supply, environmental conditions, physical mounting requirements such as motor size and mounting flange or face and differences in motor efficiency and thus energy costs.

We explain how to read an electric motor data plate or "nameplate" and how to compare motor warranties, and other details that lead to a cost-effective motor choice.

Photo above: wiring and circuit board connectors on a 3-phase electric motor from Mamatha.

Article Contents

- WHAT IS A 3-PHASE MOTOR AND HOW DOES IT WORK

- TYPES OF 3-PHASE MOTORS

- ADVANTAGES OF 3-PHASE ELECTRIC MOTORS OVER SINGLE-PHASE MOTORS

- KEY FACTORS IN CHOOSING A 3-PHASE MOTOR

- MOTOR SPECS & HOW TO READ DATA TAG

- TIPS FOR BUYING A 3-PHASE MOTOR

...

Define 3-Phase Electric Motor

Unlike single-phase motors, three-phase motors operate using three separate phases of alternating current, hence the name.

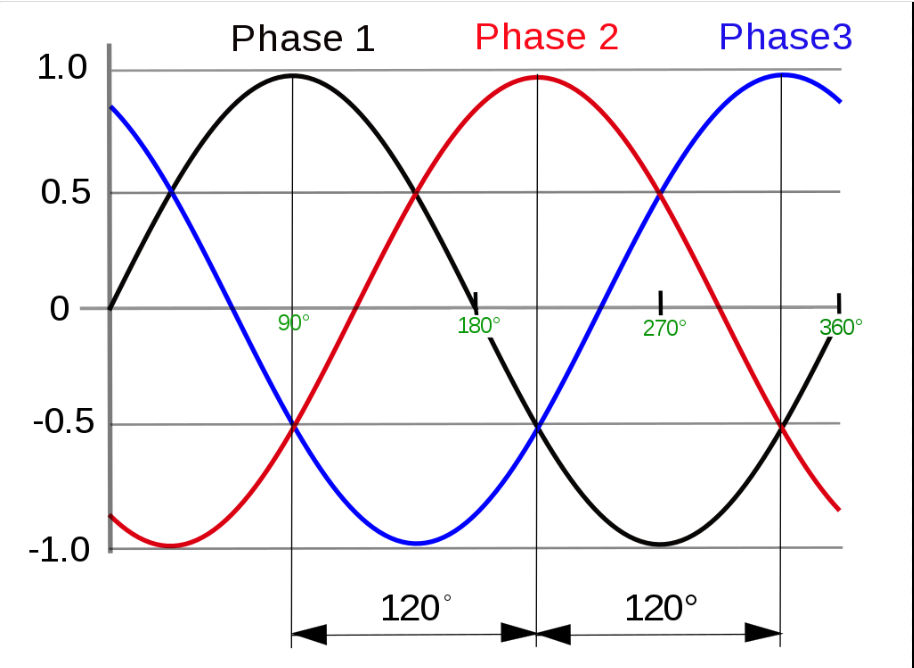

Duke Electric points out that every three phase motor will have at least 3 wires and six coils or stator windings around the rotor. The coils are spaced equally 120 degrees apart from one another to offer more constant current driving the rotor and thus the motor's output power shaft.

3-Phase motors are known for their robust power output, high efficiency, and reliability. Their balanced power distribution results in less vibration, ensuring smoother operation and a prolonged lifespan of the connected machinery.

Why Choosing the Right 3-Phase Motor Matters

Choosing the right three-phase motor is critical. Each application has its unique power, speed, and environmental requirements. The wrong choice can lead to a motor under performing or prematurely failing, leading to inefficiency, unexpected downtime, and potentially costly repairs or replacements.

Therefore, selecting the correct motor is not just about immediate cost but also about long-term reliability and operational efficiency.

Three-phase motors are chosen when high torque and higher total horsepower are required.

Three-phase electric motors are widely used in industrial applications, powering, for example, industrial pumps and electric vehicles.

However, single phase electric motors have their own advantages too, including lower cost, less maintenance, and longer service life. But single phase motors offer less torque than three-phase motors and are limited in horsepower to about 10 hp.

Single phase motors are most often used in smaller electric motors such as in hand-held power tools like drills and saws, in fans, pumps, and in smaller compressors.

Basic Operating Principles of 3-Phase Electric Motors

Three-phase electric motors operate using three phases of alternating current (AC) to cause the motor's rotor to spin.

The motor receives alternating electric current from the power source. In the motor t,hat electric current is converted into mechanical energy. How does that happen?

The electromagnetic field created by the rise and then fall of current flowing through the electric motor's stator or winding (see the drawing below) creates a rotating electromagnetic field or "force" that turns the electric motor's moving rotor, giving it an impetus to rotate, or spin.

The rotor itself surrounds a shaft or axle to which a pulley or gear can be attached to permit the motor to do work such as driving a fan, compressor or other machine.

Each of the three phases reaches its peak at a different time, thus assuring constant power output and smoother electric motor operation than a single-phase electric motor. In every 360 degrees of motor rotor and shaft rotation, current is delivered in a 3-phase motor 3 times.

That's three times as many rotating impulses as a single phase electric motor, making a 3 phase motor 150% more powerful than an equivalent single phase electric motor. (Duke 2025).

The 3 phase current voltage curve illustration above is from Wikipedia's entry on the subject - https://en.wikipedia.org/wiki/Three-phase_electric_power

Types of 3-Phase Electric Motors and their Applications

There are several types of three-phase motors, each with specific applications.

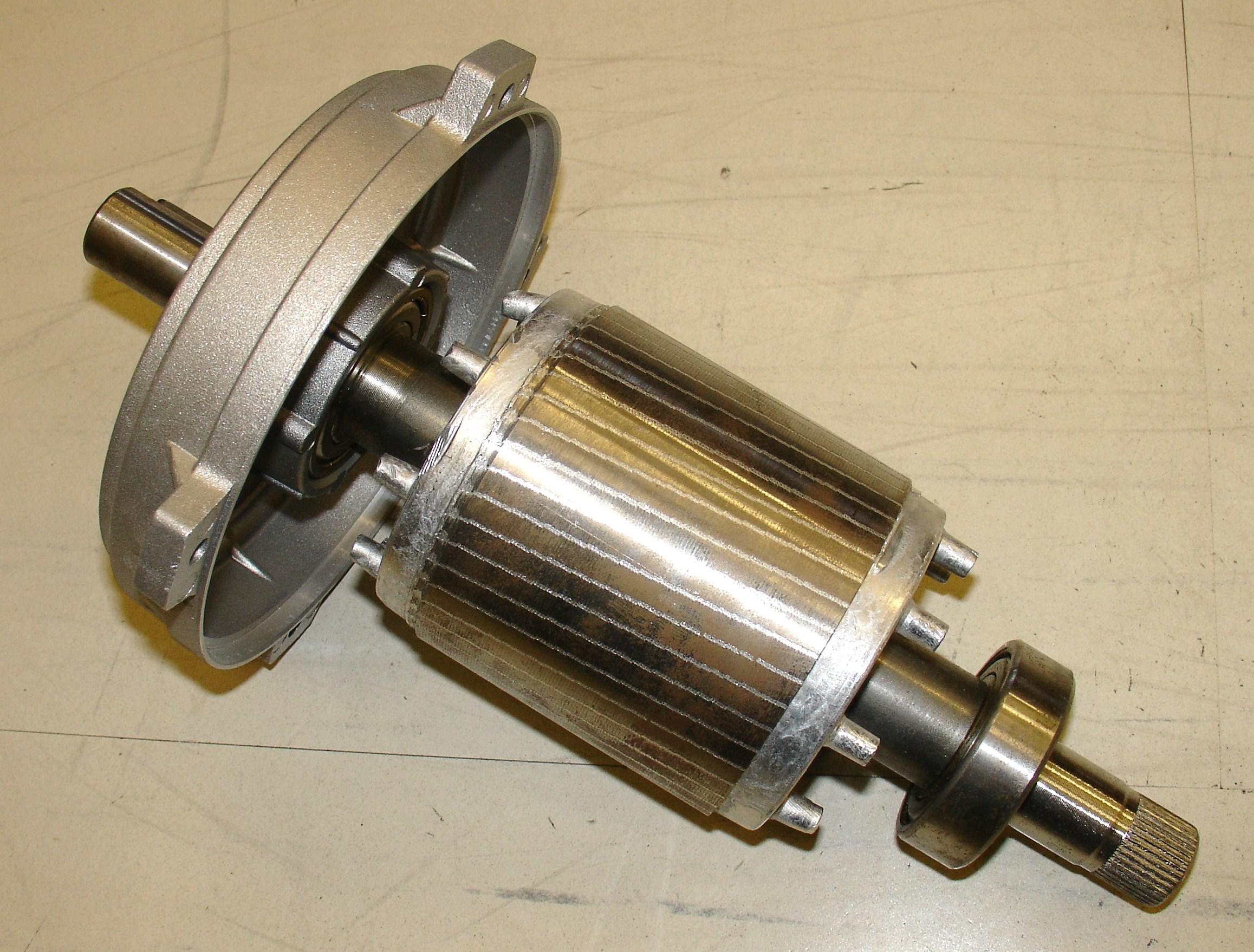

Above: the central rotor of a squirrel cage induction motor - Wikipedia.

- Squirrel cage induction 3-phase induction motors

In a squirrel cage electric motor the rotor or "rotating part" of the motor is made of steel bars or laminations on the surface of a cylinder (the "squirrel cage"). The rotating electromagnetic field from the stator winding is what causes the squirrel cage rotor to spin.

Squirrel cage 3-phase motors are the most commonly used due to their robustness and low maintenance needs, making them ideal for continuous-duty applications like conveyor systems or water pumps.

- Wound rotor 3-phase motors, also known as slip ring motors,

Unlike the squirrel cage motor above, the rotor in a slip ring motor is connected to external resistors by means of slip rings and brushes. This is a brush-type motor. The use of external resistors permits the rotor's resistance to be changed during operation, such as reducing the resistance at the time the motor is being started.

Wound rotor slip ring motors are used for applications requiring high starting torque or adjustable speed, like elevators or hoists. - Synchronous 3-phase motors

In a synchronous 3-phase electric motor the motor's stator is made up of three separate phase windings. The three phase windings provide a rotating electromagnetic field. But in these motors the rotor is "excited" by a DC power supply that provides a constant electrical field or flux.

Synchronous 3-phase motors are preferred for their constant speed operation and power factor control, often used in large industrial applications like air compressors or vacuum pumps.

Reference: Goodman, Damond, "3-phase Motor Types: Synchronous and Induction Motors" [Web article] (2022) Control.com - retrieved 2025/01/05 -

Excerpt:

Differences between synchronous and induction motors, as well as the two types of induction motors: squirrel cage and wound rotor.

Advantages of 3-Phase Electric Motors over Single-Phase Motors

Three-phase motors offer several advantages over single-phase motors.

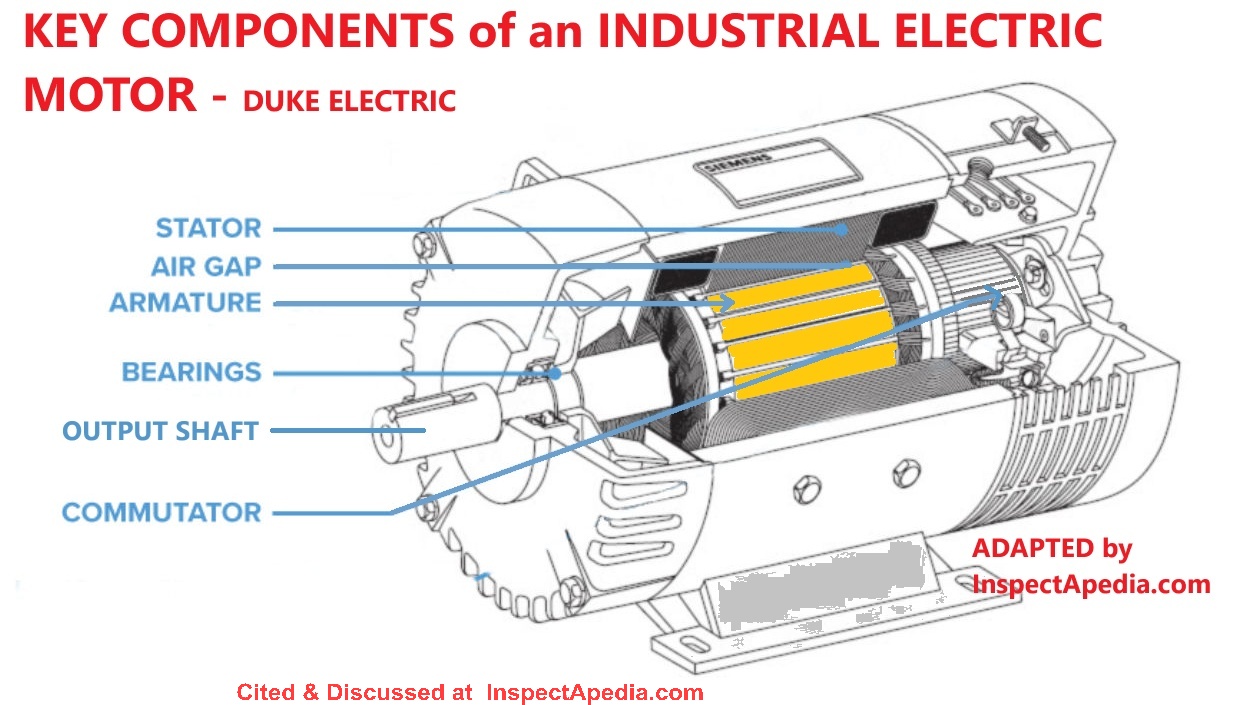

Illustration of Components of an Industrial 3-Phase Electric Motor above, adapted from Duke Electric, cited below.

The commutator, not discussed in detail here, has the job of making sure that the current flowing through the rotor windings is always in the same direction and that each coil on the rotor is energized at the right time with respect to the field coils induced by the stator.

The stator is a laminated core and insulated wire wound in coils that, when energized by alternating current, creates the rotating magnetic field that induces spin in the armature / rotor.

- 3-Phase motors provide a

higher power density,

meaning they deliver more power for their size. This is especially important in industrial settings where high power output is necessary.

References:

Duke Electric, 3 Phase Induction Motors vs Single Phase Induction Motors [Web article] (1/2/2025) Duke Electric, 986 Barton St. East, Hamilton, ON L8L 3C7 Canada Tel: 905-547-9171 - local copy on file as 3-Phase-Induction-Motors-Duke.pdf

Duke Electric, 6 Key Components of an Industrial Electric Motor [Web article] (2025) Duke Electric, Op. Cit. Local copy on file as Electric-Motor-6-Components-Duke.pdf

- Three-phase

motors ensure smoother, vibration-free operation

due to the constant power delivered by the three-phase system. This reduces wear and tear on the motor and the machinery it powers, leading to longer lifespans and less maintenance. - Three-phase motors are more efficient.

They use power more effectively, about 150% more powerful than a single phase motor of equivalent size, leading to lower electricity costs in the long run, making them the preferred choice for heavy-duty and continuous operation applications.

Key Factors to Consider When Choosing a 3-Phase Electric Motor

Electric 3-Phase Motor Load Requirements

Understanding whether the motor will be used for continuous duty or intermittent duty is crucial.

- Continuous-duty motors

are designed to permit continuous operation under a fixed load for long periods of time without overheating. In concept a continuous motor could run indefinitely without needing cool-down rest cycles. - Intermittent

duty motors

are designed for intermittent periods of work followed by periods of rest, like in a car lift. If you run an intermittent-duty electric motor continuously it is at risk of overheating and failure. - Starting torque requirements

should also be considered. Starting torque is the rotating force necessary to bring an electric motor from an "off" or "standstill" condition to beginning to rotate. Starting torque is always greater than running torque because it has to overcome the inertia of the motor rotor at rest.

Some applications require a high starting torque, which can be provided by specific types of motors, like the wound rotor motor.

3-Phase Motor Speed

Determining whether the application needs fixed speed or variable speed is essential.

Fixed speed electric motor applications might use squirrel cage induction motors.

Variable speed electric motor applications might use wound rotors or synchronous motors.

The speed of the electric motor has a significant impact on its performance and should match the application's speed needs.

An example of a fixed-speed electric motor is the motor that drives the cooling fan in a small electric heater. The fan speed never varies.

A second fixed speed electric motor is that used in a typical "high speed" residential oil burner that operates at 3450 rpm. Older oil burner motors operated at half that or 1725 rpm.

An example of a variable speed electric motor is the motor that drives a variable speed electric drill. As the user squeezes the drill's trigger further inwards the drill speed increases.

The range of variable speed electric motors is from 0 rpm to 100% of the motor's maximum design speed - that in turn varies by the motor's design and purpose. A typical variable speed cordless electric drill ranges from 0 to 600 rpm, while other variable speed electric motors may range from 0 rpm to 3000 rpm.

Some manufacturers give variable speed motor ranges as a ratio such as 10:1 speed range or 6 to 60 Hz, or for an electric motor rated at 1725 rpm, its variable speed range of 1:10 would mean it can be operated anywhere between 175 rpm and 1750 rpm.

3-Phase Electric Motor Power Supply

Different motors operate at different voltages and frequencies. Ensure that the selected motor matches your available power supply (120 VAC, 240VAC, 250VAC etc.)

Supply fluctuations can affect motor performance, and considering them will help avoid potential damage or under performance.

3-Phase Motor Environmental Conditions: temperature, corrosivity

Temperature, humidity, and altitude can significantly affect motor performance.

For example high temperatures can lead to overheating, and high altitudes can decrease cooling efficiency.

The external surface temperature of a typical 3-phase electric motor will be between 65-115°C or 150-240°F.

The temperature range over which a 3-phase electric motor can operate without damage depends on its insulation class.

- B-Class Insulated motors can operate to 130°C / 266°F

- F-Class Insulated motors can operate to 155°C / 311°F

- H-Class Insulated motors can operate to 180°C / 356°F

Motors used in corrosive or explosive environments must have special construction to prevent accidents and damage.

3-Phase Motor Physical Size and Installation Considerations

The mounting style of the motor (flange, foot, face) should fit your application. Motor frame size and weight are crucial for space and load-bearing considerations.

Efficiency and Energy Costs of 3-Phase Electric Motors

The energy efficiency of an electric motor is computed by dividing its mechanical power output by its electrical power input. (Both must be in the same unit, such as watts).

Motors with higher efficiency ratings use less power for the same performance, leading to lower energy costs.

Electric motor efficiency classes range from IE1 (lease efficient) to IE4 (most efficient), and as we've noted, because each coil in the motor is impelled to rotate three times through each 360 degree rotation of the rotor and output shaft, such motors are more efficient than single phase motors.

While high-efficiency motors may cost more upfront, they often result in long-term savings on energy costs, making them a cost-effective choice in the long run.

Example: an IE3 3 phase electric motor that is operated continuously for a year would save approximately 1580 kWh of energy compared with an IE2 motor.

Reference

- Rai, Keerti, S. B. L. Seksena, and A. N. Thakur. Economic Efficiency Measure of Induction Motors for Industrial Applications [PDF] International Journal of Electrical & Computer Engineering (2088-8708) 7, no. 4 (2017). Local copy on file as Electric-Motor-Efficiency-Rai.pdf

3-Phase Electric Motor Specifications

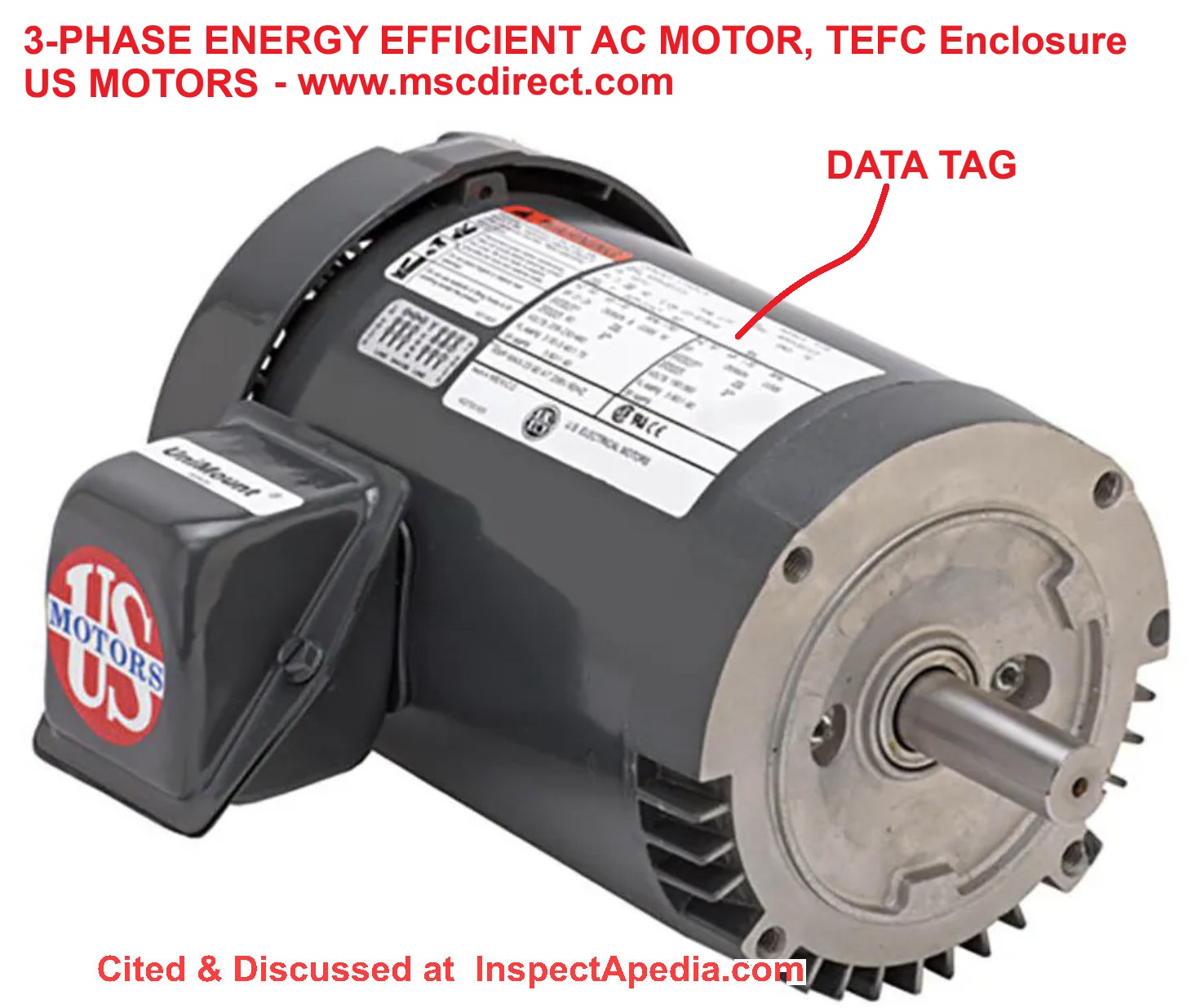

Above: data tag and other tags on a Three Phase Energy Efficient AC Motor: TEFC Enclosure, by US Motors, sold by mcsdirect.com

How to Read a Motor Nameplate or Data Tag

The motor nameplate provides vital information about the motor. Reading it properly is key to making an informed choice. Here are some important elements on most nameplates:

- Electric Motor Type:

This tells you the kind of motor, such as "Induction" or "Synchronous." - Electric Motor Rated Power:

This is the power that the motor can deliver continuously without overheating. It's usually stated in horsepower or kilowatts. - Electric Motor Rated Voltage and Frequency:

These values indicate the voltage and frequency the motor needs for optimal operation. - Electric Motor Speed:

This refers to the motor's speed at its rated load, typically given in revolutions per minute (RPM). - Electric Motor Efficiency Class:

This indicates the motor's energy efficiency. Higher-efficiency motors may cost more upfront, but they save on energy costs in the long run. - Electric Motor Duty Type:

This indicates whether the motor is designed for continuous operation or intermittent use. - Electric Motor Frame Size:

This refers to the physical dimensions of the motor. It must match the space available in your application. - Electric Motor Enclosure Type:

This tells you how the motor is protected from its environment. For example, "TEFC" stands for "Totally Enclosed Fan Cooled," which is dust-tight and has a fan for cooling.

See more on electric motor data tags like the air conditioning system data tag above

Tips for Buying a 3-Phase Motor

Choose a Reliable Motor Vendor

Selecting a reliable vendor is a critical part of purchasing a 3-phase electric motor.

A reputable vendor will offer high-quality products that meet all necessary standards and regulations. They should have a good track record in the industry and positive reviews from previous customers.

It's also important to choose a vendor that offers technical support and can guide you through the selection process, ensuring you get the right motor for your needs.

Warranty and After-sales Support

A warranty is a guarantee of the product's quality and reliability. It gives you peace of mind that you're protected in case of any manufacturing defects or early failures.

Furthermore, good after- sales support can make a significant difference.

It means the vendor will be there to assist you with any installation issues, maintenance requirements, or unforeseen complications.

Make sure to review the warranty terms and after- sales services before making a purchase.

Reference:

- US DOE, Extend the Life of Your [Electric] Motor [PDF] U.S. Department of Energy, retrieved 2025/01/06 - local copy on file as Extend-operating-life-your-motor.pdf

Compare Prices and Make a Cost-Effective Decision

Price is undoubtedly a crucial factor when buying a motor. However, don't just go for the cheapest option. Remember to consider the motor's quality, efficiency, and durability as well. A more expensive motor might be more cost-effective in the long run if it lasts longer and uses less power.

In January 2025 we found for sale at online vendors such as Amazon, in the range of 1hp to 3hp and from 1725 to 3450 rpm, from $176 to $$1229.

Take your time to compare different options, consider all costs involved (including installation and maintenance), and choose the one that offers the best value for money.

Conclusion

Choosing the right 3-phase electric motor for your application is an essential step toward efficient and reliable operations. It's not just about picking a motor but about selecting one that aligns with your specific requirements, whether they are load conditions, speed, power supply, or environmental factors.

Understand your application's needs, learn to read motor specifications, consider the long-term energy costs, and purchase from a reliable vendor to ensure that you are investing wisely.

Remember, the most cost-effective decision isn't necessarily the cheapest option upfront but one that offers reliability, performance, and efficiency in the long run.

Contributing author

Mamatha K is an instrumentation engineer at Challaturu IndMALL Automation, Chennai Office: D.No: 10, S2, Rathna Swamy Complex, Chitlapakkam Main Rd, Gomathy Nagar, Selaiyur, Chennai, Tamil Nadu 600073 India, Web: indmall.in, Tel: +91 79955 44066, Email: mamatha@indmall.in. IndMALL supplying 3-phase electric motors along with a wide range of industrial automation components to customers across Chennai, Bangalore, Hyderabad, and PAN India.

[Extensive editing & additions by InspectApedia staff - Daniel Friedman]

InspectApedia.com® is an independent publisher of building, environmental, and forensic inspection, diagnosis, and repair information provided to the public at no cost. In order to absolutely assure our readers that we write and report without bias, we do not sell any products or services, nor do we have any business or financial relationships with any manufacturer or service provider discussed at our website.

...

Continue reading at ELECTRIC MOTOR 3-PHASE TROUBLESHOOTING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- DEFINITION of ELECTRICAL POWER PHASES - Single Phase vs Two vs Three Phase Electrical Power

- ELECTRIC MOTOR DIAGNOSTIC GUIDE - home

- CAPACITOR TYPES, for MOTORS

- ELECTRIC MOTOR 3-PHASE MOTOR SELECTION

- ELECTRIC MOTOR 3-PHASE TROUBLESHOOTING

- ELECTRIC MOTOR CENTRIFUGAL SWITCH or PTC PRD

- ELECTRIC MOTOR DATA TAG

- ELECTRIC MOTOR HORSEPOWER & CIRCUIT WIRE SIZE

- ELECTRIC MOTOR LIFE

- ELECTRIC MOTOR LUBRICATION

- ELECTRIC MOTOR NOISE DIAGNOSIS

- ELECTRIC MOTOR OFF on RESET

- ELECTRIC MOTOR OVERHEATS

- ELECTRIC MOTOR OVERLOAD RESET SWITCH

- ELECTRIC MOTOR RUN DIRECTION - backwards

- ELECTRIC MOTOR START SWITCH

- ELECTRIC MOTOR TESTS

- ELECTRIC MOTOR WIRING DIAGRAMS & GUIDES

- ELECTRIC MOTOR WON'T START / RUN

Suggested citation for this web page

ELECTRIC MOTOR: 3-PHASE MOTOR SELECTION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.