3-Outlet Adapter Wall Tap Short Circuit

3-Outlet Adapter Wall Tap Short Circuit

Arc pitting / burns & dead Short

- POST a QUESTION or COMMENT about wall plug or receptacle electrical device failures

Dead short circuit & arc pitting and burn damage in a 3-outlet adapter wall tap or "plug adapter".

This article describes an internal short circuit in a wall plug adapter that tripped the circuit breaker.

We include photographs of conditions inside of this plug adapter that failed, probably due to bending of internal contacts as a wall plug was inserted into the adapter.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Short Circuit in 3-Outlet Un-Grounded Adapter Wall Tap

attempting to use this old-style multi-plug adapter to permit plugging in three devices at one spot on an un-grounded electrical receptacle in a northern Minnesota home I found that on the instant of plugging in this adapter the circuit breaker tripped.

attempting to use this old-style multi-plug adapter to permit plugging in three devices at one spot on an un-grounded electrical receptacle in a northern Minnesota home I found that on the instant of plugging in this adapter the circuit breaker tripped.

Thinking I'd connected a defective or shorted device to the adapter, I un-plugged everything, leaving the adapter in place.

With the adapter plugged into the wall receptacle the breaker would not reset.

After removing the adapter from the wall receptacle, the circuit breaker could be re-set normally. Inspecting the exterior of the adapter for signs of overheating or arc flash burns I didn't see a thing. [Photo above] [Click to enlarge any image]

So it was time to examine in more detail and then to disassemble this old multi-plug adapter, allowing inspection of its guts to see what happened. These photos tell the story.

Most modern device plugs, plug adapters, and electrical receptacles are manufactured with their respective spade connectors (on wall plugs) or connector slots (on electrical receptacles or on plug adapters) polarized, with the neutral connector being the wider slot or wider spade connector. Shown here is a wall plug adapter that is polarized but lacks a grounding connector. I think this adapter is more than 30 years old.

First let's look at the back of the device where we see that this is a product made by GE (General Electric), rated for 15A, 125V, also bearing a UL symbol.

If you click to enlarge the photo you'll see a bit of scuffing and scratches on the two screws holding the device back-plate but those are new - made by my disassembly. I re-assembled the adapter to take this photo.

Pulling out the two screws and removing the assembly by pulling on the two adapter prongs the entire assembly came out in one piece. That itself is interesting, as the hot and neutral plug spade connectors are originally made as two independent parts.

I set the assembly atop the adapter case to provide a nice view of an obvious and very serious trouble spot in this multi-plug adapter by GE.

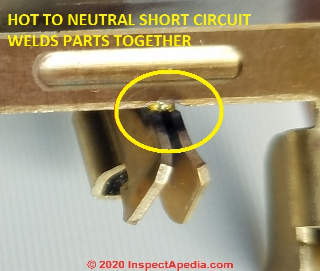

The hot connector and neutral connector copper parts were arc-welded together! Below is a close-up photo of the short circuit found in this plug adapter.

Above: the wider plug-spade connector (neutral side) has come into contact with and has welded itself to the copper bus powering the hot side of the plug adapter.

Below: in addition to the "bent-over" and shorted connection between the neutral plug spade connector and the hot spade connector bus (circled in red), we also see arc flash burn marks on the corresponding neutral spade connector (circled in yellow).

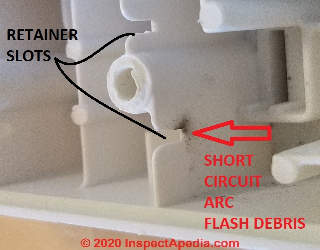

A corresponding over-flash burn and deposit can be observed in the plastic body of the multi-plug adapter - shown below.

Below: a closer second-look at all of the parts of this plug-adapter yields a second bit of information.

Notice the arc burn and melted tip of the hot spade connector of this adapter? This is a completely different location on the device than the welded burned contact point above.

I acknowledge that this burn could have occurred at the time of the original short back inside the adapter. But I pose a second possibility.

My guess is that someone (perhaps I) plugged this adapter into a wall receptacle at least once after its initial internal short and self-welding circus act.

The sequence might be:

The adapter is plugged into a wall receptacle by user No. 1.

A wall plug powering an appliance is plugged into the adapter.

The breaker trips, but User-1 does not imagine that the cause was a failure inside the plug adapter and instead guesses there was a defect in the appliance.

User-1 un-plugs the appliance, leaves the adapter in place and attempts without success to re-set the circuit breaker.

Following speculation, argument, experiment, the User-1 un-plugs the adapter, resets the circuit breaker, and tosses the adapter into the homeowner's garage where it rests for a year or so.

User-2, needing to plug several items in at one wall receptacle finds the adapter, plugs it into the wall, tripping the circuit breaker. User-2 doesn't know the breaker has tripped until observing that the devices plugged into the adapter "don't work." He checks the circuit breaker, finds it won't re-set, and repeats the same experience as user-1.

If not before, this second insertion of the internally-shorted multi-plug adapter into the wall receptacle could certainly have caused the burned hot plug spade tip shown in our photo.

Once the adapter had a hard internal short, any time it was plugged into a wall receptacle there might indeed be an arc and burn at the point of insertion of the adapters hot or neutral spade connector as it was inserted into the receptacle.

What caused this internal short in the multiple plug adapter for wall plugs?

Probably the insertion force of device wall plugs pushed into the adapter - thanks to J. Aronstein for this view.

Possibly - wiggling of wall plugs in the course of inserting or withdrawing them from the adapter.

My photo, above shows the copper components of the wall plug adapter dropped back into their proper place in the plastic adapter body. I had to break apart the welded components to prepare this photo.

It appears that the slotted plastic partitions intended to hold the copper components in place to prevent accidental shorts from neutral to hot were not adequate to prevent a device failure and short circuit.

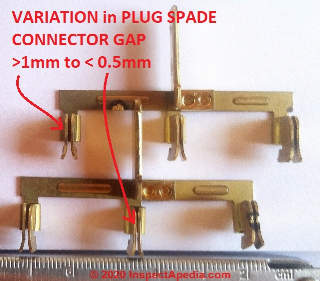

It is also interesting to note the variation in gaps among the six plug spade connectors (photo below), in my opinion, most-likely an effect of usage rather than a manufacturing variance.

Is this bending-apart of the plug spade connectors due to variation in thickness of wall plug spades inserted into the adapter, due to repeated usage, due to wiggling of connectors or something else?

Was the bending-over of the shorted plug spade connector caused by insertion of a thick spaded wall plug into tight plug spade connectors, combined with the inability of the plastic carrier to prevent bending-over of the connector to make direct contact between hot and neutral components, thus causing a short circuit?

Below: 3-Outlet Adapters or "Wall Taps" are still manufactured and distributed bearing the GE-Logo as you can see with this GE 3 Outlet Adapter, but the current model is designed to accept grounded plugs.

Special thanks to Dr. Jess Aronstein for discussing this electrical failure and its probable cause.

- Dr. Jess Aronstein, protune@aol.com is a research consultant and an electrical engineer in Schenectady, NY. Dr. Aronstein provides forensic engineering services and independent laboratory testing for various agencies. Dr. Aronstein has published widely on and has designed and conducted tests on aluminum wiring failures, Federal Pacific Stab-Lok electrical equipment, and numerous electrical products and hazards.

Contact: J. Aronstein Consulting Engineer Bme, Msme, Ph.D., NYS. P.E. Lic. No. 39860, 909 Londonderry Ct., Schenectady, NY 12309 USA, Tel: (845) 462-6452 Email: AronsteinJesse@ieee.org

See ALUMINUM WIRING BIBLIOGRAPHY and FPE HAZARD REPORT - 2017 [PDF] independent research article by Jess Aronstein, supercedes older FPE hazard reports by this author.

Information for Homeowners, Inspectors, and Electricians (Updated November 10, 2017), FEDERAL PIONEER PANEL SAFETY and FPE HAZARD ARTICLES, STUDIES, and BACK-WIRED ELECTRICAL DEVICES also CIRCUIT BREAKER FAILURE RATES and UBI FPE CIRCUIT BREAKER TEST RESULTS also ZINSCO FAILURE REPORTS for examples.

...

Continue reading at ELECTRICAL RECEPTACLE ARC PITTING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ELECTRICAL CIRCUITS, SHORTS

- ELECTRICAL OUTLET, HOW TO ADD & WIRE - home

- ELECTRICAL OUTLET ADAPTER SHORT CIRCUIT

- ELECTRICAL RECEPTACLE ARC PITTING

- ELECTRICAL RECEPTACLE CONNECTION DETAILS

- 2-WIRE RECEPTACLE CONNECTIONS

- WHICH SCREWS GET the BLACK, WHITE & GROUND WIRES ?

- WHICH WIRES GO to LINE or LOAD CONNECTIONS?

- HOW to CONNECT WIRES to a RECEPTACLE or SWITCH

- GROUND WIRE CONNECTION SUMMARY

- NUMBER of WIRES NEEDED: 2-WIRE, 3-WIRE, 2 or 3 WITH GROUND?

- ELECTRICAL DUPLEX RECEPTACLE WIRING

- ELECTRICAL OUTLET, HOW TO ADD in OLDER HOME

- ELECTRICAL RECEPTACLE WIRING SERIES vs PARALLEL

- ELECTRICAL SPLIT RECEPTACLE WIRING

- WIRES TOO SHORT TO CONNECT, REPAIR FOR

- ELECTRICITY TURN ON AFTER BREAKER TRIP

- GROUND WIRE CONNECTIONS

- LIGHTNING DAMAGE to ELECTRICAL SYSTEM

Suggested citation for this web page

ELECTRICAL OUTLET ADAPTER SHORT CIRCUIT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Dr. Jess Aronstein, protune@aol.com is a research consultant and an electrical engineer in Schenectady, NY. Dr. Aronstein provides forensic engineering services and independent laboratory testing for various agencies. Dr. Aronstein has published widely on and has designed and conducted tests on aluminum wiring failures, Federal Pacific Stab-Lok electrical equipment, and numerous electrical products and hazards.

Contact: J. Aronstein Consulting Engineer Bme, Msme, Ph.D., NYS. P.E. Lic. No. 39860, 909 Londonderry Ct., Schenectady, NY 12309 USA, Tel: (845) 462-6452 Email: AronsteinJesse@ieee.org

See ALUMINUM WIRING BIBLIOGRAPHY and FPE HAZARD REPORT - 2017 [PDF] independent research article by Jess Aronstein, supercedes older FPE hazard reports by this author. Information for Homeowners, Inspectors, and Electricians (Updated November 10, 2017), FEDERAL PIONEER PANEL SAFETY and FPE HAZARD ARTICLES, STUDIES, and BACK-WIRED ELECTRICAL DEVICES also CIRCUIT BREAKER FAILURE RATES and UBI FPE CIRCUIT BREAKER TEST RESULTS also ZINSCO FAILURE REPORTS for examples. - "Evaluating Wiring in Older Minnesota Homes," Agricultural Extension Service, University of Minnesota, St. Paul, Minnesota 55108.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.