HVAC Refrigerant

Diagnostic FAQs

HVAC Refrigerant

Diagnostic FAQs

Questions & answers about air conditioner or heat pump refrigerant or "Freon" charge, leaks, repairs

- POST a QUESTION or COMMENT air conditioning & heat pump refrigerants: refrigerant properties, charges, charge measurements, leaks, repairs

Air conditioner & heat pump refrigerant diagnostic questions & answers:

These HVAC refrigerant pressures, charge quantity, and other diagnostic questions and replies were originally posted in the A/C or heat pump diagnosis and repair articles listed at the end of this page.

Take a look at these questions to find common suction side or low side refrigerant pressures, high side or head pressure side pressures in air conditioners and heat pumps of various types. Here you will find additional diagnosis and repair suggestions for refrigerant charge pressures, leaks, and troubleshooting.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Diagnostic Questions & Answers for HVAC Refrigerant

Charge Measurement, Installation, or Correction & Proper Use of the Refrigeration Charging / Testing Gauge Set

These Q&A about refrigerant gas pressures were posted originally

at REFRIGERANT PRESSURE READINGS & CHARTS - topic home, be sure to check the advice given there.

What Coolant is Used in a Luxair Heat Pump BAUH FO36ab?

Trying to find what kind of coolant is needed for a Luxaire Heat Pump model Bauh fo36ab.

Thank you :) On 2016-03-22 by Kacey

Reply by (mod) - find the refrigerant type on the HVAC equipment data tag

Kacey

The refrigerant needed is almost always included on the compressor/condenser (outdoor unit) data tag for a heat pump.

If your unit doesn't include that data,See the contact information for Luxaire at

LUXAIRE HEATING & AIR CONDITIONING

and armed with the model and serial number of your heat pump, ask for a free copy of the installation and users' manual. That'll specify the refrigerant needed.

Air Isn't Cool and R22 Pressure High & Low are Both at 120 psi

My air condition is not cool enough and the technician said the air flow is not correct.

He used the refrigerant gauge to check the pressure and the high and low pressure both are 120.

The refrigerant type is R22. He said it may be the problem of the condense coil.

I wonder is it true and the AC is more than 20 years. Should I replace a new one or fixed it? On 2016-02-24 by Jan

Reply by (mod) -

Jan,

First , before replacing the system we need an accurate diagnosis of the problem.Some problems are not costly to repair.

If you are facing a repair whose cost is a significant percentage of a new compressor/condenser (for example0 then it would make sense to go to a new unit.

But I certainly am not comfortable with the arm-waving "diagnosis" that you describe.If your outdoor compressor/condenser unit is running and IF the compressor is actually working, then the high and low side pressures would be very different.

Watch out: but IF the technician measured pressures after the system had been OFF for some time, pressures will normally be the same on both high and low sides of the system and that alone would not indicate a problem.

Perhaps a polite call to the company's service manager and a request for a senior technician who an give a reliable diagnosis would be useful.

Porque é que o compressor apresenta alarme insuficiência de gás R410a

Porque é que o compressor apresenta alarme insuficiência de gás R410a enquanto os manometros indicam que a pressão está boa On 2020-01-11 by Narciso

Reply by (mod) -

Narciso

O sistema pode ter pouco refrigerante, mas o compressor ainda produz a alta pressão necessária. Um sintoma pode ser geada na linha de sucção ou temperaturas anormalmente baixas no lado da entrada do compressor.

Why does the refrigerant pressure gauge vibrate?

Sir .if we chek gas . Why sometime vibrate gauge? On 2018-11-09 by Preet -

Reply by (mod) -

Preet

Vibration may be transmitted to your gauge mechanically through equipment vibrations: compressor motor, fans, etc.

Also the pressure in the system is not fixed but will vary both as a response to the compressor motor's output (a piston moving for example) and because of a chatter in the thermostatic expansion valve that is metering refrigerant.

Only if you turn OFF all motors the pressure should not be vibrating, though even then you should seen it changing slowly as system pressures equalise on the high and low pressure sides of the system.

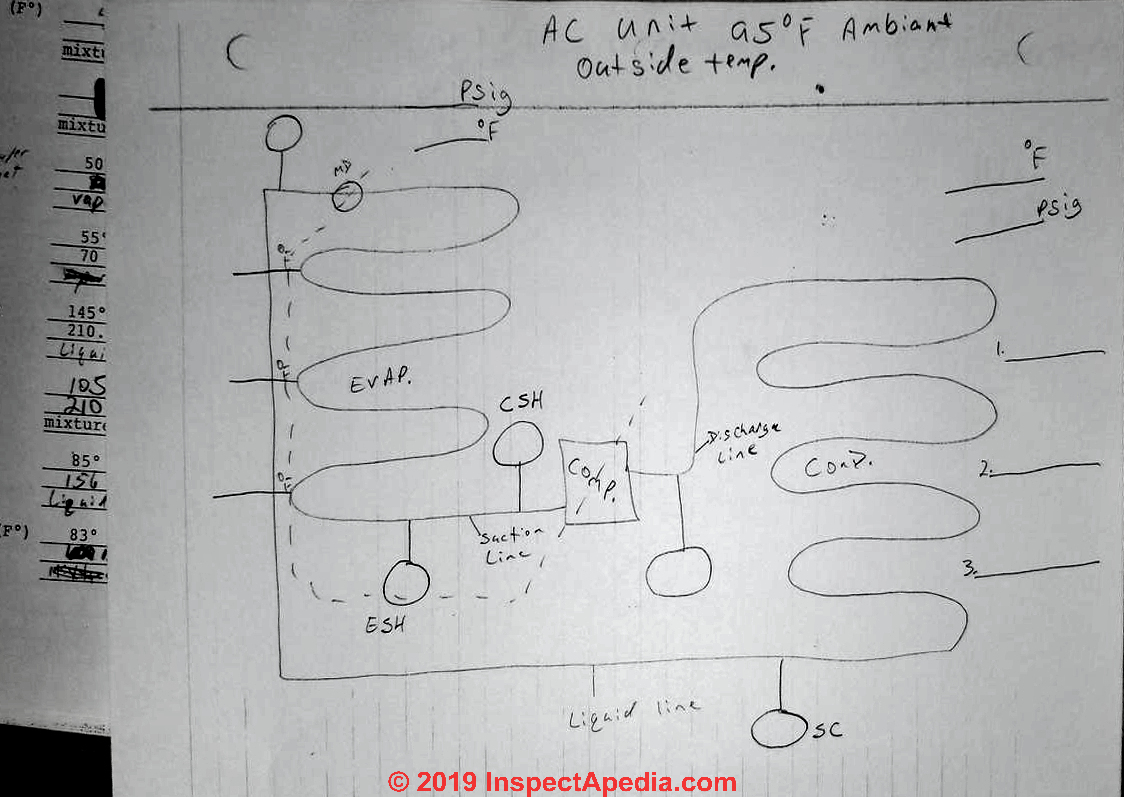

What are the normal pressure and temperature ranges for R22?

I have a class in AC and the teacher has us doing these to learn the system. Just wondering if you could help out with the temp and pressures. R22. Thanks Dennis

On 2019-11-20 by Dennis

Reply by by (mod) -

Of course, Dennis. I took those classes too. AC refrigerant pressures for various refrigerants are given in tables above on this page.

Take a look and then ask any follow up questions that occur to you.

It's important, and will become quickly obvious from the charts, that there is no single "right" answer to "what's the pressure of R22" for example since the pressure will always be affected by

- ambient temperature

- temperature right in the AC equipment

- where the pressure is measured. (For example low-side or inlet the the compressor will be far less than high side pressure measured at the outlet side of the compressor.

What the service tech will often do is pick out the pressure chart for the specific refrigerant she is working with, then measuring temperature at the right spot, will adjust a charge to see the expected pressure; lower pressure means there's not yet enough refrigerant in the system. It's more crude than installing a measured charge but quicker, easier, cheaper (and riskier).

For example, from the R410A chart on this page, measuring on the suction side we might see

45°F at the Evaporator

120° at the evaporator coil

130 psi on the suction side

418 psi on the high side

But change any parameter like temperature and all those data points change too.

Reply by (mod) -

Ask your service tech to check the temperature drop across the cooling coil. If she says that number is normal then the system problem isn't one of refrigerant.

On 2018-07-01 by Luan

My central Air split system is working but i feel it not cool enough then a service man come and add on 5 lbs R-22. I wonder if it is possible when my 2 ton have factory charged 72 oz (4.5 lbs) on original label ? No frozen or icy either before.

Reply by(mod) -

With the compressor running the suction line pressure should be dropping in the high side pressure should be increasing. If you are seeing that in Reverse I suspect that we're talking about a heat pump in heating mode or we've got some Plumbing connections reversed.

On 2018-03-01 by Anonymous

Today I repliced one 2ton a/c out for.after valve open and compressor on.section pressure going up.also section line coming hot why?

Reply by (mod) -

Karen,

If the refrigerant doesn't boil there is no state change and thus no cooling effect.

This sounds a bit like a quiz question. If so, good luck on your test.

On 2017-11-12 by karen

Why must the boiling point of a refrigerant be low enough at atmospheric pressure as to keep the system pressure above 0psig when operating at low temperatures?

Reply by (mod) -

Mohd

Thanks for asking a basic refrigeration question: how does the air conditioning system convert refrigerant R410A from liquid to gas and at what pressures?

The boiling point of R410 is -55.3°F or -48.5°C at atmospheric pressure at sea level. That is 1 ATM or 14.6 psi.

In refrigeration equipment the system is operating under significantly higher pressures. For example at 100 psi +31.2F, at 200 psi + 69.5F, at 300 psi 96.2 psi.

Refrigerant leaves the compressor as a high temperature high pressure gas, then flows through the outdoor condensing coil where it is cooled by movement of outdoor air across the coil (in cooling mode) to condense back to a high temperature liquid.

The liquid refrigerant from that high-pressure side of the system flows onwards to a metering device such as a thermostatic expansion valve TEV that allows refrigerant to escape through the valve at a measured rate across to the low-pressure side of the system and into the cooling coil in the air handler.

That pressure change from high to low causes the refrigerant to convert to a vapor (it boils) and in doing so, that state change absorbs heat, cooling the coil that in turn cools air from the occupied space that blows across the cooling coil.

At 28 psi (a made-up example low side pressure) the boiling point of R410A is -17.9F

On 2017-09-20 by Mohd Faraz Zaidi

R410A refrigerant boiling point temperature is -61°F or -51°C but when I check temperature of gas at Coil region in Air Handling Unit it gives me value of 2-3°C.

If is it so,then How does R410A gets converts from Liquid to Vapor phase?

Comments:

3 Aug 2014 Re-posting comment from PawanY629 without disallowed link to product advertising,

That reader recommends the Robinair 34988 Premium Refrigerant Recovery, Recycling and Recharging Machine

Question: what is a good refrigeration pressure ? What should the refrigerant pressure be in my unit?

Model cxa6 Keeprite air conditioner unit using R-14 refrigeration. What psi pressure it should be good. - Litt 7/26/2011

What are the low and high readings for a 7.5 ton, 220 three phase compressor with two cooling coils and serves two inside units, mod BTA090C300H0, SER W01 195521 - rcannon49@att.net 8/2/11

Reply: R14 refrigerant pressure?

Litt

At we detail, REFRIGERANT PRESSURE READINGS & CHARTS the low or suction side and high or compressor output side pressure of any refrigerant system will measure differently depending on system operating status (running vs. off, and ambient temperature).

R-14 or Freon-14, Tetrafluoromethane has a boiling p;oint at sea level of -198.0°F

At equalization pressure the LOW and HIGH sides will read the same, and as long as there is at least some liquid refrigerant in the system the pressure will be given by a temperature/pressure chart for that specific refrigerant.

If you scroll down to the list of article references below you'll see a link to a refrigeration pressure and temperature chart provided by Reece, an Australian company. That chart is missing R-14 refrigerant but at encyclopedia[dot]airliquide[dot]com[slash]Encyclopedia[dot]asp?GasID=61#VaporPressureGraph you can find that information.

You'll see that at 10 bars of pressure R14 will be at 185K or about -88 C - in other words readily boiling to a vapor at ambient pressures. At 40 bars the temperature will be 230K or -43C. For a working pressure/temperature chart for refrigerants at ambient and typical HVAC pressures I'd go to the unit manufacturer.[dot]airliquide[dot]com[slash]Encyclopedia[dot]asp?GasID=61#VaporPressureGraph you can find that information.

I add that for R14, its Latent heat of vaporization (1.013 bar at boiling point) is 135.7 kJ/kg

One Bar is 0.06895 psiOne kJ/kg = 2.326 British BTUs/Lb

But I THINK that the question you are asking is what pressures will be seen on the HIGH and LOW sides of a refrigeration system using R14 refrigerant.For any refrigerant, you have to consult the individual refrigerant pressure/temperature chart, note the temperature of your system and the measured HVAC-system running stable state suction pressure (LOW SIDE) evaporative data, and of course the running HIGH side for the compressor/condenser condensation pressure data.

Mr. Cannon

You need to consul the manufacturer's technical literature for the refrigerant gas in use and the compressor model in use, and then you'll need to use a table of gases that provides temperature and pressure data in one place, as ambient temperature affects the answer. In sum there is no single precise right number.

There are typical operating ranges of refrigerant pressures, as you can see a REFRIGERANT PRESSURE READINGS & CHARTS.

Did you really mean R-14 refrigerant pressure,. or R-410A.

Also see Freon 142B, Genetron 142B, Isotron 142B - trade names for Chlorodifluroethane - the closest I could come to an "R-14" gas. Chlorodifluroethane or HCFC-142b used as a refrigerant, and is principally employed as a blowing agent in the production of polytstyrene and polyethytlene foam. (Synonyms: 1-chloro-1,1-difluoroethane and CH3CClF2). I'll include Daikin's information about 142b below.

- HCFC-142b REFRIGERANT GAS Product Information [PDF] , DAIKIN AMERICA, INC. 20 Olympic Drive, Orangeburg, NY 10962, USA Phone: +1-845-365-9500 Toll-Free: +1-800-365-9570 Facsimile: +1-845-365-9598 http://www.daikin-america.com,

DAIKIN CHEMICAL EUROPE GmbH Immermannstr. 65D, 40210 Dusseldorf, Germany Phone: +49-211-179225-0 Facsimile: +49-211-1640732 http://www.daikinchem.de

Chemicals Division Umeda Center Bldg., 2-4-12, Nakazaki-Nishi, Kita-ku, Osaka 530-8323, Japan Phone: +81-6-6373-4342 Facsimile: +81-6-6373-4390 http://www.daikin.com/chm

Question: what causes excessive refrigerant pressure?

what cause to much high pressure - Anonymouse

Reply:

Anon: among the reasons for excessively high pressure on the HIGH Side or output side of the compressor/condenser section of an air conditioner or heat pump are a plugged or debris blocked condensing coil, plugged refrigerant line, plugged dryer/filter on the line, or a stuck refrigerant metering device such as a capillary tube or thermostatic expansion valve. There may be other causes of high refrigerant pressure that other readers can add.

How does R410A gets converts from Liquid to Vapor phase?

R410A refrigerant boiling point temperature is -61°F or -51°C but when I check temperature of gas at Coil region in Air Handling Unit it gives me value of 2-3°C.

If is it so,then How does R410A gets converts from Liquid to Vapor phase? On 2017-09-20 by Mohd Faraz ZaidiReply by (mod) - How does the air conditioning system convert refrigerant R410A from liquid to gas and at what pressures?

Mohd

Thanks for asking a basic refrigeration question: how does the air conditioning system convert refrigerant R410A from liquid to gas and at what pressures?

The boiling point of R410 is -55.3°F or -48.5°C at atmospheric pressure at sea level. That is 1 ATM or 14.6 psi.In refrigeration equipment the system is operating under significantly higher pressures. For example

at 100 psi the boiling point of R410 is +31.2°F,

at 200 psi the boiling point of R410 is + 69.5°F,

at 300 psi the boiling point of R410 is +96.2°F

Refrigerant leaves the compressor as a high temperature high pressure gas, then flows through the outdoor condensing coil where it is cooled by movement of outdoor air across the coil (in cooling mode) to condense back to a high temperature liquid.

The liquid refrigerant from that high-pressure side of the system flows onwards to a metering device such as a thermostatic expansion valve TEV that allows refrigerant to escape through the valve at a measured rate across to the low-pressure side of the system and into the cooling coil in the air handler.That pressure change from high to low causes the refrigerant to convert to a vapor (it boils) and in doing so, that state change absorbs heat, cooling the coil that in turn cools air from the occupied space that blows across the cooling coil.

At 28 psi (an example low side pressure) the boiling point of R410A is -17.9°FTables of the boiling point (temperature) of each type of refrigerant at various pressures are published by the refrigerant manufacturers as well as by professional associations such as RSES given below.

- REFRIGERANT PRESSURE CONTROLS & SWITCHES

- REFRIGERANT PRESSURE READINGS & CHARTS

- GAUGE, REFRIGERATION PRESSURE TEST

- REFRIGERANT PRESSURE DIAGNOSTICS

- Prah, Frank, "REFRIGERANT 410A INFORMATION", [PDF] Refrigeration Service Engineers Society, 1666 Rand Road, Des Plains IL 60016, (2001) retrieved 2017/09/20, original source: http://www.rses.org/assets/r410a/r-410a.pdf

How to identify the refrigiration and airconditioning system

How to identify in refrigiration and airconditioning system if there is no specification (gas detail and current ratings) in compressor On 2017-09-13 by Vinoth-

Reply by (mod)

There should be a data tag on the compressor/condenser unit giving the brand, model, serial number.

If the data tag has been lost you at least need to identify the brand.

I charged my compressor but don't understand the low side pressure - it's too low

Helo sir I change my 5 ton three phase compressor and now I can charge the R22 refrigerant after vacume after when I can start the compressor high side pressure is 300 psi and low side niddle show the vacume reading what is the problem please tell me - 2017-07-15 by Rizwan shahid

On 2017-07-15 by (mod) - 5 ton three phase compressor pressures

Rizwan,

I'm not sure, and I'm a bit confused by the question myself. But I think I would include among checks looking for a stuck or defective thermostatic expansion valve

The service tech said we just need to add refrigerant from time to time in some unknown amount

I have a 2010 Payne ac unit. Can a havoc tech says exactly how much puron we are short off. There is a leak in our unit. The tech that came in says we cannot know for sure how much is needed until we fill it.

But other company says they shoiuld be able to tell me how much puron is needed. Please help.. On 2017-06-13 by Kave

Reply by (mod) - Nope

Kave,

In my opinion, no ... well not easily anyway.

When refrigerant has leaked out of an HVACR system we have no idea just how much has been lost on first approach.

To know just how much was lost we'd need to pump out the remaining refrigerant, measure its volume, calculate based on temperatures to adjust the measurement, and compare that with an ASSUMED starting charge volume.

I haven't seen people willing to go to that much trouble.

But its true that for some equipment the only way to put a proper charge in the system is to evacuate it and then install a measured refrigerant charge; this is more critical on small appliances like refrigerators that use a small charge and have no reservoir or receiver of refrigerant.

On larger systems that are leaking I see lots of techs who just "top off" the charge with enough refrigerant that the coolant line temperatures and absence of gas bubbles suggests they've reached the correct minimum chargeI understand the reasonableness of this approach given that finding and fixing a leak is more-costly.

But I find it worrisome that we have some outfits who ultimately develop into a virtual refrigerant delivery service - like the milkman in Richmond when I was a kid. Regrettably they're delivering to leaky systems that are contaminating the environment.

On 2017-05-02 by Aaron

Ive got a 2012 frightliner cascadia im working on. Low side is around 70psi and the high side is only around 50psi. Using a snap on automatic hvac system. Can anyone tell me why the high side isnt building pressure? Call or text 7407012220 asap with a response.

On 2017-01-29 by Bo white

My 410 A heat pump has been running for long periods in 35 degree weather sometimes 30 minutes.And I haven't heard it go into defrost either.The unit is 3 years old . My last heat pump made hissing noise in air handler closet after terminating defrost.

Will unit go into defrost on time or just by temperature below 37(which is temp. set by manufacturer in defrost circuit).?Because outdoor temp. was below 37 and I never heard it defrost.Is this temp. determined by outfoor coil temperature or ambient temp.?

Does 325 hot gas reading and 125 true suction pressure sound good at 55 degree outdoor temp. with 72 indoor temp.?

Does it take longer to reach desired vacuum if system has had refrigerant running

Does it take longer to reach desired vacuum if system has had refrigerant running though it previously? On 2017-01-24 by Gavin

Reply by mod:

NO

What is considered proper high & low side oil pressure for these refrigerants: R22, R410, R134A.

what is the oil pressure high and low side R22, R410, R134A. On 2016-10-10 by Anonymous -

Reply by (mod) - there are not separate "oil pressures" in refrigeration systems.

Anon, there are not separate "oil pressures" in refrigeration systems. Oil is distributed in and along with the refrigerant. You can measure refrigerant pressure using appropriate gauges, and you can look up what the refrigerant pressure will be at various temperatures, but you won't find separate oil pressure readings.

Why does refrigerant pressure drop when I start to charge the system?

central package airconditioning,what is the problem when i start to recharge the unit low side gauge is not going down? whAT WRONG WITH THE UNIT. On 2016-08-17 by Anonymous

Reply by (mod) -

If we have a closed container of refrigerant gas and we add refrigerant to it from an outside source the pressure will increase; as the compressor motor is running at the same time it is reducing pressure on the low side. So when we're low-side charging we might not see a pressure increase.

The pressure I expect to see on the gauge will be affected not just by the suction effect of the compressor, but also the flow rate of refrigerant gas into the low side from the charging canister.

A wild guess: IF the system was not working properly to start with, and if there is a HIGH side blockage (such as a stuck TEV or blocked condensing coil) then if the compressor can't push anything out, its' suction ability will be low to nil.

410a h/p split system & the low side evaporator saturation temperature varies between 32 & 42 degrees Fahrenheit.

I have a 410a h/p split system & the low side evaporator saturation temperature varies between 32 & 42 degrees Fahrenheit. While the high side pressure varies from 350 to 400 psi. Over a time of a few minutes. Both coils are in good condition & clean & blower & condensing fan are functioning properly. What could cause this ? On 2016-07-04 by Bill

Reply by (mod) - Thermostatic expansion valve is oscillating or sticking or debris-clogged.

Bill:

Perhaps the thermostatic expansion valve is oscillating or sticking or debris-clogged.

How do I know if my air conditioner is really leaking just water and not refrigerant?

just to mention that i have an widow ac unit.

my air conditioner is spilling some liquid. how do i know if its spilling refrigerant or just water? On 2016-05-14 by jessica

Reply by (mod) - you will never see liquid refrigerant

Jessica: you will never see liquid refrigerant - if refrigerant escapes from your A/C unit, even if leaking from the high-pressure side where liquid refrigerant is present, at ambient temperatures in and around a building it will immediately evaporate into a gas.

How can we make sure that the charging of refrigerant during night time is sufficient?

how can we make sure that the charging of refrigerant during night time is sufficient? On 2016-05-04 by Anonymous

Reply by (mod) - Proper refrigerant charge does not depend on the time of day

Proper refrigerant charge does not depend on the time of day that the charge is inserted. Night time, or daytime, make no difference.

However charging at night means charging when the outdoor ambient temperature is lower. That might affect the charging pressures. That won't change the proper charge quantity.

Is refrigerant leakage dangerous in any way?

is refrigerant leakage dangerous in any way? - On 2016-03-14 by sarah -

Reply by (mod) - dangers of exposure to refrigerant gas

Sarah

Refrigerant gases are used in a closed-system air conditioner or heat pump. They are not normally "released" nor "consumed" nor are they in the exhaust of an air conditioner unit's compressor/condenser or window cooling unit unless the equipment is damaged and there is a refrigerant leak.

Refrigerant gases are rather inert and non-toxic and thus not directly toxic.

Watch out: however, while refrigerant gases are rather inert and non-toxic, they can replace oxygen.

As a result, if you were in a very small space (like a closet) inside which the concentration or level of refrigerant gas became too high, you might not sense any problem but you could become asphyxiated by lack of oxygen - a condition referred-to as anoxia. Such cases are rare but possible. Below I cite research confirming that what I just explained is not just theory, deaths can really occur.

See GAS EXPOSURE EFFECTS - home

Also

- Thompson, R. J. "Freon, a Refrigerant." Industrial & Engineering Chemistry 24, no. 6 (1932): 620-623.

- Morita, Masahiko, Akemii Miki, Hisashi Kazama, and Masakatsu Sakata. "Case report of deaths caused by freon gas." Forensic science 10, no. 3 (1977): 253-260.

- Glass, Roger I., Richard Ford, Donald T. Allegra, and Harry L. Markel. "Deaths from asphyxia among fishermen." JAMA 244, no. 19 (1980): 2193-2194.

Includes a case of refrigerant asphyxiation. " The third incident was attributed to anoxia caused by a leaking nontoxic refrigerant gas that displaced the oxygen. " - Broussard, Andrea K., David K. Lirette, Larry A. Broussard, and Thomas S. Pittman. "Death due to inhalation of ethyl chloride." Journal of forensic science 45, no. 1 (2000): 223-225.

- Koreeda, Ako, Kosei Yonemitsu, Sohtarou Mimasaka, Yuki Ohtsu, and Shigeyuki Tsunenari. "An accidental death due to Freon 22 (monochlorodifluoromethane) inhalation in a fishing vessel." Forensic science international 168, no. 2 (2007): 208-211.

- McGee, Michael B., Robert F. Meyer, and Subhash G. Jejurikar. "A death resulting from trichlorotrifluoroethane poisoning." Journal of Forensic Science 35, no. 6 (1990): 1453-1460.

Is a window AC exhaust dangerous?

Also, is it true that refrigerant leakages can be acidic?

i have an window ac,the outlet of which is in my balcony where my childrem sometimes play. should there be any concerns in general?

I have kids playing around at my house. should i be worried about air conditioner refrigerant leakages On 2016-03-16 by sarah

Reply by (mod)

Sorry Sarah,

I can't make a safety inspection of your home from a brief -text. There could be numerous hazards in any home location. Of course at a balcony, you should be particularly concerned about falling hazards and the safety of guard railings.

What blows out of a window AC is normally only indoor air. So whatever is in your indoor air is blowing outdoors onto the balcony.

Your window AC is NOT blowing refrigerant out with the building air (unless there is a refrigerant leak, an abnormal condition).

A properly functioning air conditioner or heat pump is NOT leaking refrigerant at all.

Refrigerant gases are basically inert.

Can I substitute a different expansion valve for a different refrigerant?

please let me know,the high boiling point refrigerant like R13,R14,R23,R50 expansion valves are not easily available in indian market. some refrigerant are available as I mentioned. If you can give me suggestion to substitute with any expansion valve by replacing it for a low temperature application. On 2016-02-09 by suresh babu, Kerala,INDIA

Kindly reply.

Reply by (mod) -

Suresh I'd like to help but am doubtful that I can. Expansion valves are designed for use with specific refrigerants. I'm not sure how we'd calculate or guess at substituting valves based only on the boiling point of the refrigerant being used.

At https://inspectapedia.com/aircond/Refrigerant_Gas_Guide.php - REFRIGERANT GASES & PIPING - we give the boiling points of various refrigerant gases as well as their other properties.

Reply by (mod) - do we need to replace refrigerant lost during connection of equipment?

James: no, not normally

Using proper procedures when connecting HVACR equipment such as test gauges or charging equipment, as I was taught to do it, IF we are about to charge the system,

We first connected the gauge to the refrigerant supply canister

Then we open the canister to purge air out of the refrigerant hoses - that will avoid pushing air ( a contaminant) into the air conditioner, heat pump, or other refrigeration equipment during charging.

Then we close the refrigerant supply

Then we connect the gauge and the pre-charged line to the charging port on the equipment

Then we open the refrigerant supply to supply gas, typically through a measuring device, though many techs use other methods such as a wild guess, watching system temperature on the suction line, watching system pressure, or at the cooling coil, watching the frost line.

If the tech is only measuring, not charging the equipment, she might connect a gauge directly to a high or low pressure port. In this situation the HVACR system pressure pushes a tiny volume of refrigerant out into the test guage hose and to the meter (assuming the hose was not pre-charged). That amount of refrigerant is trivial and is not replaced.

On 2016-02-03 by James D. - refrigerant leakage during testing of HVACR equipment

On a reg. Service call my Tec told me I needed refrigerate(r-10 i believe he told me ) I asked " is their a leak ?" He said , no , it's all the others who tested improperly , allowing it to lose it.

When they connect the Gage on and off you can lose 2,3 even 4 oz. Per test . Times this twice a yr. For 6 yrs. ( Trane 4 tonne unit) of course the salesman/ commission comes to play . So , I had two now tell me this and i have no leak, only lazy service people.

Well , I brought this to the company attention and all these people were lying and do work there anymore. We will send you our senior tec. Without going into detail they messed up and i met a young man who went to school and working here for 2 yrs.

He agreed with losing r-410 through poorly taking the Gage on and off. When asked the amount of loss, no answer. He tells me there is no way to know .

Is this true ? So , I am told i have no leak , yet I need r-10 .when i ask how much I need , they can't tell me .

Then when I say you should replace ehat you lost , they change their tune and tell me I'm fine , I don't need any at all.. I have NO LEAK and what is missing is minimal ? Are you as confused as I am ? I've lost faith and trust.

Reply by (mod) - suction line should be cold and the high pressure refrigerant line maybe anywhere from cool to warm or even hot

Michael

Depending on where we are in the cooling cycle the suction line should be cold and the high pressure refrigerant line maybe anywhere from cool to warm or even hot. Absolute temperature measurements may be made on the suction line as a clue to checking if refrigerant has been lost.

When the system has been off for some time both lines will feel the same.

When the system has begun running and has run for a few minutes the suction line should begin to feel cold.

On 2015-06-16 by MichaelS

Is it possible to determine if a compressor is functioning correctly by feeling the temperature difference between the the high and low line at the back of the unit?

How should they normally feel?

Question: High pressure readings on the low side of my heat pump

I am getting very high pressure readings on the low side of my heat pump. The discharge and return line to the air handler are cool and equal in temp.(showing no refrigerant movement), But my suction line and discharge line leading in to and out of my compressor are very hot. Have open the lines and checked the orifices and they are clear as is the lines to the air handler. Is it possible that the condensing alone can be clogged? I did have a compressor burn out last year. - D. Nix 8/7/11

Reply:

High pressure on the low side sounds to me as if a metering device is stuck wide open; perhaps when your compressor burned up last year it left some debris in the refrigerant lines that has found its way to the TEV and has jammed it. Ask your HVAC tech to check the system again, check the TEV adjustment, and also consider installing a (new) filter/drier on both ends of the refrigerant piping system.

Question: can an R-22 air conditioner or heat pump system be changed to use R-401A? What is involved?

Can an A/C system that uses R-22 be changed to use R-410a? - Anon 6/3/11

What is involved with converting from R-22 to R0417A? My unit was made in 2005. - Bill 6/5/2011

can R-22 CONVERT TO R134A MY UNIT WAS MADE IN 1999. - Jonathan 6/7/11

Reply:

Changing an R-22 refrigerant-based A/C system over to use R-410a is possible but costly since quite likely you cannot simply charge the system with the new refrigerant. It may be possible to continue to use the same compressor/condenser unit and air handler, but significant parts inside each of those components, such as controls and possibly evaporator/condenser coils are going to need to be changed out.

There are "swap-in" substitute refrigerants for R-22, but as you can read above in the Lennox warning, they are not recommended by at least some manufacturers. For this reason, if the R-22 based air conditioner is old and/or if other components are not in pristine condition, you'll want to get a careful price quote that allows comparing conversion of the equipment with replacement.

Question: Where can I buy R-22 freon?

where can I purchase R 22 freon

Reply:

Charles I'd consider converting the refrigeration system equipment to a R-410 -based refrigerant design, as R-22 is no longer recommended. However there are some websites offering R-22 refrigerant - though at astronomical prices for the ones I've seen.

Recent reporting (in 2012) has also noted that due to cost pressures and other market factors, some manufacturers continue to sell replacement HVAC parts that operate on R-22 despite its harmful effects on the atmosphere and environment.

Question: pointing out HVAC equipment operating pressure differences between R22 & R410-a

Regarding your discussions on R22 against R410a.

The pressures are extremely high compared to r22 in the uk we use special gauges with adaptors to fit the equipment operating on r410. Due to the legislation in place you can not work on any system without certification. We strength test our pipe work installs to 623 psi and pressure test to 478 psi.

Retrofitting can be carried out but care has to be taken to ensure that the equipments pipe work can take the higher operating pressures. Additionally we can only purchase recycled r22 and new r22 is not available to us. This is something you will all eventually have to come to terms with. - James 7/12/11

Reply:

James, thank you for making several excellent points; we agree completely. The conversion from R22 to R410 is not trivial;

Question: cost to re-charge a central air conditioning system

How much does it cost to recharge a central air conditioning system (approximately)? - Rick 8/8/2011

Reply:

Rick the cost to re-charge a central air conditioner is basically a service call charge plus extra time and materials and refrigerant - $100 to $200. U.S. IF the tech only adds refrigerant.

Watch out: Since refrigerants should not leak out of an air conditioner or heat pump, if you need to add refrigerant, a good repair would include looking for and fixing the leak. In turn, depending on where the leak occurred, and what repairs are needed, the ultimate cost could therefore be much greater.

See REFRIGERANT LEAK REPAIR article link at page bottom

Question: Is it true that all new appliances are mandated to have chips that operate with wireless transmitter smart meters

Is it true that all new appliances are mandated to have chips that operate with wireless transmitter smart meters (that are being forced on us) ? - Goodsite 9/29/12

Reply:

No

Question: questions about re-charging HVACR equipment using R410-a

Is it normal for new R410a system to have oil come out with refrigerant when detaching gauges.

What can cause a system to have oil come out with refrigerant? - Tim 5/23/12

Reply:

Tiny amounts, may be common; significant amounts more than enough to wet the port suggest to me something is wrong with the oil distribution & charge procedure.

In commercial and most other refrigeration systems, the refrigerant delivers lubricant oils to the compressor's moving parts. If there is a refrigerant leak, the oil carried in the liquid refrigerant may be left behind and show up as a dusty dirty oily coating in the areas near the leak point.

Question: can we change refrigerants without changing the thermostatic expansion valve?

Thermostatic expansion valves IS OKY USE 410 IN E22 O R22 - 6/16/2012

Reply:

It depends. The answer is no if the new refrigerant has different operating properties, density, pressures, operating range. The answer is yes if the new refrigerant is rated as a drop-in substitute for R-22, but watch out as at least some manufacturers do not recommend that approach.

Question: my heat pump was found to be low on refrigerant and now I notice my grandson has a chronic cough - could that be from the freon leak?

My heat pump system was recently serviced and found to need low about 4 lbs of refrigerant. I noticed that my small grandchildren who live with me start having a chronic cough about a month before i had the service accomplished. Now that we had it serviced both their mom and myself have developed a cough we can't get rid of. Could this possibly be from a freon leak in my system possible releasing gas inside my home? - Manuel Ortiz 6/22/12

Reply:

Manuel, the refrigerants used inside of HVAC equipment are encapsulated and besides, chemically pretty inert - freon is not likely to directly explain the cough or IAQ complaint you describe.

BUT indirectly, a malfunctioning air conditioning system can include moisture, water, or even ice formation in the air handler at the cooling coil - in a few cases we've seen that lead to problematic mold contamination in the duct system.

Similarly, failure to properly maintain and clean the system, such as leaving dirty filters in place, or no air filters at all, can be a source of complaints.

Finally, picking up return air for the system at a location that picks up and transports any airborne contaminant can redistribute it through the building - more or less depending on the quality of filtration.

Question: Ice on the refrigerant equipment & piping lines, refrigerant leak can't be traced until the ice melts - which will take 3 days?

MY A/C unit was not cooling my house as much as it was a week ago. A technician examined my outside fan and basement A/C, noted ice on both units and on tubing lines. He and stated it would not be possible to determine the exact source of the leak until the ice melted, which will probably take 3 days. If my children and I stay in the house during the next 3 days is there any danger that we may inhale a carcinogenic gas or be exposed to any other health risks? Thank you! - Richard Wilson 6/25/2012

Reply:

Richard, I think the tech was saying that a refrigerant leak can lower the pressure in the system and cause icing on the cooling coil as well as on the refrigerant lines. (Missing insulation can also cause line icing). 3 Days? Gee that's odd. Typically if you shut off the system, in an hour or less the ice is long gone - especially in hot weather.

A/C refrigerants that use modern refrigerant gases are rather inert and are not carcinogens. Where did that worry arise? The hazards of breathing refrigeration gases occur when the gas, which is odorless, is released at sufficient quantity in an enclosed room - replacing oxygen and risking asphyxiating occupants. In a private home that sounds rather far fetched but it has occurred in industry. To read of a similar example search InspectApedia for "Toxicity of Carbon Dioxide Gas Exposure, CO2 Poisoning "

Question: refrigerant leaks out of our equipment - local custodian is releasing gas to the atmosphere

I work in a school, and my air conditioning unit is broken twice a year-- fall and spring (actually it has never been fixed)! I hear that a part has been replaced, and the refrigerant leaks out sometime after it is recharged again in the fall.

This refrigerant goes into a large air unit (the length of one wall of my classroom) that is INSIDE the classroom, so I have a couple of questions here: First, when our custodian recharges the unit, I see him undo the hose, and I see the gas come out into my classroom for about a minute or so-- then the custodian shuts it off.

He thinks it will be safe to hold class in there twelve hours later. What do you think? I'm not sure what type of refrigerant is used, but I've been told that these air conditioners are about 20 years old, and the gas seems to be odorless and you can't see it except when it is spilling out of the hose. Second, if my a/c is leaking, my guess is that it's leaking INTO my classroom.

As I said, it is all gone by the time the warm weather rolls back around in the spring. Do you have any idea if this would be a danger? I am in the class all day and am trying to conceive. I don't want anything hurting my students or myself. Please, any answers would be appreciated. - Jennifer Fischer 8/16/2012

Reply:

Jennifer,

The hazards from freon-type refrigerants are not as poisons but as replacements for oxygen if they are released at high concentrations in an enclosed space.

But it is illegal and a bad practice to just dump refrigerants into the atmosphere at any time.

Question: can a refrigerant gas leak be fixed or does the whole compressor need replacement?

I need to know whether a leak form one of the compressor tubes is fixable or not. My technician said that the whole compressor would need to be replaced. - Ehab 8/176/11

Reply:

Ehab refrigerant leaks can be repaired by various patch methods. But if the leak is discovered to be a symptom of more extensive corrosion, such as at a cooling coil, it's a much bigger repair than just a patch. I'm not sure why, if the compressor was working normally,

you'd need to replace all the equipment- perhaps the tech is referring to the issue that s/he cannot any longer recharge with R12 or R22 - used in older compressors, but there are alternative refrigerants that can often work with some adjustments.

Question: Comment on refrigerant gauge set hose color coding; How do I know if the HVAC Tech Put In Enough Refrigerant?

Blue line goes to bigger line in compressor and red on little line

For high side - Anon 10/6/11

Hello, For a typical home split air conditioner, how to make sure that the technician has filled in enough gas in the out door compressor unit? - Sanjay 7/21/2012

Reply:

Sanjay, without evacuating the air conditioner completely and putting in a precisely measured charge using gauges and metering equipment, you cannot know yourself exactly how much refrigerant is in the system. But there are indications of the refrigerant charge being too much or too little that can show up without sophisticated instruments. For example:

- if you hear a bubbling sound in the liquid line the charge may be low

- if you see bubbles in the sight glass (usually only found on commercial refrigeration equipment and on some residential air conditioner or heat pump systems) the charge may be low

- if the cooling coil is frosting over one of the causes is low refrigerant charge

- if the compressor makes a horrible clanking sound and then stops dead, one of the possible causes is overcharging or another problem (such as a failed TEV or other refrigerant metering control) that has caused liquid slugging of the compressor on the suction side.

Beyond these observations, you need to be able to trust your HVAC technician. While mistakes are of course possible, no service tech any credible motive for placing an improper refrigerant charge into the system. Doing so just makes more work and trouble for everyone.

Question: why do refrigerant pressures keep jumping up and down?

low side pressure jumping up and down (Sept 5, 2012) joe said:

Reply:

Joe, a sticky TEV can cause odd pressure variations but if you are just seeing the gauge needle vibrate over a small range I suspect that's just an artifact of the compressor motor itself.

Question: how do you know if you got air into the refrigeration system?

How would you know if you introduced air into an R22 system when charging?Would the low side guage fluctuate or would the reading on the low side bounce up and down?I charged my heat pump and the low side guage is reading a steady 70psi with no bouncing movements on the needle. Do you think I'm ok? (Oct 25, 2012) Bob W.

Reply:

Bob,

Air in the refrigerant system won't cause pressure gauge needle bounce, more likely that's an artifact of vibration or compressor operation. Too much air contamination would change refrigerant operating properties and accompanying moisture might freeze up an expansion valve or cap tube. The fix for that problme is ugly: evacuate the system and reinstall the proper charge - something you dont' want to do if it's not necessary.You're probably OK.

Daniel F

Question: Rheem 15 seer 4 ton heat pump split system refrigerant connections

why the compressor keep in operation while removing the compound gauge in closing for the system? (Jan 20, 2013) Spongebert11

a rheem 15 seer 4 ton heat pump split system. the new condenser has 3 freon connections. the old lennox was only a normal air conditioner system and it had 2 freon connections. i am familiar with liquid and vapor lines and connections, but the 3rd connection appears to be another liquid line. can you tell me what it is. the connection has a cap and a schrader valve, but no shut off valve. can you tell me what that 3rd connection is for. (Mar 25, 2013) HomeOwnerCharlie

Reply:

Sponger:

(Jan 25, 2014) humphrey said:

you keep the HVAC compressor running when disconnecting the gauges to maintain the differences in pressureHomeowner Charlie,

Come compressor units are ab

Question: pressure readings 75 psi low 240 to 280 on the high side - yes it bounces

(June 18, 2014) Brian said:

my 2006 house 3 ton unit- little to no condensation inside- pressure readings 75 psi low 240 to 280 on the high side - yes it bounces. House cools. 74F inlet temp, 54 supply temp. 90F outside temp. should I be concerned about by metering valve that might be causing my bounce?

Reply:

Brian I think it's worth looking-at. Look for dirt, contamianation, or frosting / icing.

Question: why do we use hoses with knurled connectors on refrigeration gauges

(Sept 14, 2014) rash said:

hi.what is the reason for fitting a gauge hose ends with brass knurled nuts?

Reply:

Rash the knurling permits the technician to attach and detach the fittings by hand without using tools.

Question: breathing sound from AC compressor

i see grafts and what ever, but not a HIGH (?100-125) LOW (?25) i said the new unit sounded like it was working to hard (breathing) they said the freon was too high and let some out. i can't make heads or tails of what i've read so far in reguard to high/low (Feb 6, 2015) Ben

Reply:

Ben

I'm a bit confused by your question too, but it's fair to gripe if you're not finding the info you need here.

I'll review the article above to see what I can add about specific example HI and LO pressures. Understand that the actual reading of refrigerant pressure MUST be understood or interpreted along with a table giving the specific refrigerant as well as ambient and system temperatures.

Since the cooling system cannot manufacture its own refrigerant, if the refrigerant charge was too high according to your service tech, then the system was previously over-charged during service. Quite possibly the problem is elsewhere.

Question: refrigerant volume changes in cooling vs heating mode for a heat pump?

(Feb 19, 2014) tommy

Does the volume of the Freon charge within a heat pump system need to be increased when it is heating a house vs. cooling the house. My HVAC contractor has told me that the system needs a larger volume of Freon when heating the house. He recently added two additional pounds over what was deemed a normal operating refrigerant charge condition during the summer months(cooling the house). This seems a bit fishy to me. I would appreciate some feedback on this tTommy,

Reply:

Nice question. The answer is no. The refrigerant charge in an HVAC system does not change (unless there is a leak). In heating mode rather than cooling mode basically the same system is operating with the same components and refrigerant, but it runs backwards: moving heat from outdoors to indoors when in heating mode, and moving heat from indoors to outdoors in cooling mode. The same refrigerant and refrigerant quantities are used.

Your contractor may have been thinking of something else, or may be arm-waving, or we may have misunderstood. For example, s/he MIGHT have been trying to say that the total capacity of your heat pump was adequate for cooling but not for heating in your climate.

But by NO means would that problem be fixed by changing the refrigerant charge in the system. Instead you' need a different (greater capacity) heat pump system installed.

Technical note: unlike water whose volume changes only a small amount as a function of temperature, most refrigerant liquids change more significantly in volume. That's why on an old refrigerant charging cylinder you'd see that volume gauge printed right on the cylinder side giving different charge volumes at different temperatures.

To understand the relationships between pressure and volume of gases, such as refrigerant gas, take a look aty our discussion of Boyle's Law (P1V1 = P2V2) at WATER TANK PRESSURE CALCULATIONS and also at OIL TANK PRESSURE

Question: Trane A/C unit pressures

(Mar 8, 2014) maryjo

hi, my trane air conditioner has pressure readings of 75 and 135 respectively. the a/c people that came out said that the unit was failing and should be replaced. Are these pressures ok?, and will it fail?. 1 month prior, a service guy came out to do the annual and said the unit was fine?....any suggestions?

Reply:

Maryjo I'm sorry but I'm not sure how to interpret pressures without knowing where they were measured and what was the status of the equipment at the time. In general, if in an HVAC system that has the proper refrigerant charge quantity the compressor is unable to reach the proper high and low side pressures that something is wrong. The problem could be a costly - one: need a new compressor motor, or a less costly one such as a failing refrigerant metering valve (TEV or "thermal expansion valve"). I would listen to the tech's description of what she or he checked and found to get an idea of the scope of investigation that was made.

Luis Castro owner of castro mechanical

Hey Mary no after reading all these comments it sounds like this tech was trying to make some extra money or cover his Ass in some sense your head pressure should be a little higher if this is r22 also depending on tonnage of your unit

I'm having a feeling u need to check out ure full efficiency of your compressor,hear the windings and pumping check full load of amps on your compressor,and check further on ure filter drier and tev on your evaporated coil ,and after u determine what's wrong I would put a can of leak seal

I have done over thirty jobs with this seal and have been have been very successful with my customers that will call me every e Ryan year for a shot I have been mentioning the leak seal and I was able to build my customers trust if you have any further questions you can call me

Luis castro

Castro mechanical

(516)547-5509

Question: where do the red, green and yellow hoses on the AC refrigerant test gauge set get connected?

5/13/14 Anonymous said

Where must the low pressure (green-hose) and the high pressure (red hose) on the refrigerator be connected because the yellow hose must be connected on the refrigerant ?

Reply:

Anon, although the HVAC system you are looking at may not show the high and low side connector ports or just one of them, this sounds as if you ought to be asking for an on-site trained HVAC technician.

Question: The refrigerant gauge said I was in good range after I added one can of refrigerant but the pressure didn't change

(May 15, 2014) Chris

When I connected the refrigerant gauge to the low port the reading was in a good range (green on the gauge). When I pulled the trigger the gauge goes to zero. I put one can in and the air did get much cooler, but the reading really did not change. Is this a indication the compressor is bad if the pressure is fine, but no cold air.

Reply:

Chris I can't say, not knowing the system type, but it sounds as if you might want to check to see what is the proper charge for the system in the first place.

I am guessing you're talking about an automotive air conditioning system. If so, the refrigerant system includes a reservoir space, so your gauge, particularly the little gauge that you find on do-it-yourself car, truck or RV air conditioning recharge kits is not going to give a precise reading in pressure.

Question: low side says 10 psig and high is 100 psig. What's wrong?

(May 17, 2014) zee

When I connected the gauge to my ac unit the low side read 10psig and high side read 100psig. What wrong with the unit? low freon, TEV block, air in the system, or bad compressor?

Reply:

Sounds like a bad compressor in that you're not seeing much high side pressure, but a very low total refrigerant charge could also explain the problem so I'd start by evacuating the system and installing a proper charge quantity.

Question: shouldn't I see high pressure in the AC compressor even if it has been turned off for a while?

(May 23, 2014) Anonymous

shouldn't there be considerable pressure on a unit, even if it hasn't been run for a while?

Reply:

No Anon. When the compressor is off the system PRESURE on typical residential cooling systems or heat pumps drops to the normal pressure for a refrigerant at that temperature. When the compressor motor has been off for 15-30 minutes or longer, the high side and low side pressures on most equipment will be the same. It's the compressor that creates the high pressures when it's running.

(May 27, 2014) Anonymous

yes, the system was running the low side read 10psig and high side read 100psig.

Question: suction line (low side) pressure is 120 psi, head pressure (high side) is 220 psi.

(June 7, 2014) Tim

System has capillary tubes and scroll compressor. AC cooling by -10 degrees (dry supply - dry return) and no cooling when measuring: (dry supply - wet return = 0).

The suction line is at 120PSI. Head pressure @ 220PSI. Ambient 95 degrees. Compressor drawing lower amps. When turned off, pressures equalize to around ambient temperature within 5mins.

AC works perfectly sometimes giving 15-20 DT, something like once in 2 weeks (ruling out under/over charge).

What could be the problem. My understanding is that neither capillary tubes nor scroll compressor can partially malfunction. They either run or breakdown completely.

Appreciate your feedback and thanks for the great post.

Reply:

Tim that's a rather high pressure on the suction line, suggesting a refrigerant metering problem.

Question: charging a R410 A 3-ton unit from the low side.

(June 9, 2014) Priyam

Hi!

I've been charging a R410A 3 ton heat pump system from the low pressure side. I've charged it to 40% but the low side pressure still hasn't increased, and this causes the compressor to go off because of maybe a low pressure cut out. I'm worried because I'm not seeing any bubbles in the site glass with a 60% undercharged system.

I

wanted to check if this is normal before I go on charging the system. Could the expansion valve be seeing pure vapor? Is there some reason there's no condensation happening at all?

(The system is in a laboratory, and is used for testing)

On a different note, great information on the website! Very useful.

Reply:

Priyam, check the adjustment of the TEV itself.

Question: heat pump won't cool at high temperatures

(June 30, 2014) Rich English

Heat pump will not cool at high outside temps. I read your site (very nice job guys) and I will list what the problem isn't

1) R22 gas charged to optimum level (there is a small leak in the system)

2)AC filter new

3)Condenser and evaporator coil clean

4)Pump pressure looks good low about 55 psi and high side about 200 psi on a normal day in north texas.

Problem when out side temp hits 90F the system starts to cool less. Below 90 degrees I see a differential inside temp of about 18-22 degrees. at 90F the differential drops to about 15 degrees. at 95F outside we go down to about 12 degrees and at 98 degrees it drops to about 8-9 degrees making the system runs all day in the Texas summer.

Unit is 20 years old and I'm wondering what part or parts could cause this strange problem. Please help as the ac guys have all failed to figure this out. I call them gas men as they seem to think playing with the refrigerant level will solve it.

A few more comments...

Electrical looks good

Air handler sealed up from leaks

extra insulation added to reduce cooling load

Plenty of inside and outside airflow

I tried to cool off the outside unit with a spray of hose water and the system did not cool any better at high outside temps!Reply:

A couple of things to check first:

1. check the air temperature drop across the cooling coil.

2. check for partial frosting at the AC coil - a small refrigerant leak drops pressure and can cause that problem.

Question: R-22 heat pump pressures

(July 18, 2014) Larry

I purchased a slightly used 2.5 ton R-22 heat pump to replace my 10 yr old a/c condenser unit. The "new" unit is pressurized but I don't know if the R-22 was pumped down into the condenser or was reclaimed and filled with inert gas. Is there a way to determine without losing the R-22?

Would a non operating condenser filled with some amount of R-22 show about 120 psi at 78 degrees F? I have tried locating the original installer but have had no success. Worst case, I will recycle whatever is in it and refill with virgin R-22.

Question: Scroll compressor suction side and head pressures

(June 7, 2014) Tim said:

System has capillary tubes and scroll compressor. AC cooling by -10 degrees (dry supply - dry return) and no cooling when measuring: (dry supply - wet return = 0).

The suction line is at 120PSI.

Head pressure @ 220PSI. Ambient 95 degrees. Compressor drawing lower amps. When turned off, pressures equalize to around ambient temperature within 5mins.

AC works perfectly sometimes giving 15-20 DT, something like once in 2 weeks (ruling out under/over charge).

What could be the problem. My understanding is that neither capillary tubes nor scroll compressor can partially malfunction. They either run or breakdown completely.

Appreciate your feedback and thanks for the great post.

Comment: kudos for this article

Very interesting and informative article. I've recently had "added" to my responsibilities a lot of A/C kit. Although an engineer I haven't any qualifications in A/C but would like to be aware of what's happening (or isn't) when these guys visit the site. So I bought books on the subject and read up on it.

Question: oudoor temperatures compared with air coming from air conditioning vents and suction line pressures

(July 25, 2014) Anonymous said:

I have a 1 1/2 ton r-22 trane xb 1000 ac unit. in the morning the outside temp is 75 and the suction pressure is 70 with the temp coming out of the inside vents is 54. in the afternoon when the temp outside is 96 the suction line pressure goes up to 90 psi and the temp coming out of the vents is 66 and the thermostat will not get below 76 what may be causing this

Reply:

Sounds like the TEV is feeding in refrigerant faster at the higher temps but perhaps the compressor / condenser is not able to keep up. Check the TEV first. Then refrigerant charge. Could there be gas on the liquid side you'd see this problem. Try spraying the hot condensing coil with water. (not the electrics)

Question: Bard-type wall mounted air conditioner - 300 psi high side and low on Freon

(Aug 3, 2014) Anonymous said:

I have a 30 plus year old Bard-type outside wall mounted a/c unit that i thought wasn't cooling enough when i came in from a 2 month absence from my condo. It was left on 82 degrees while gone, I turned it down to 77 as usual, but it would never register below 81 after a few hours. and it was quite warm outside, say 88-90 degrees. I turned it off for 4 hours, came back, turned it on, but turned it to 72 degrees

. It went down to 74 slowly and stayed cool all night & seemed fine. I had called an a/c repair service who came out the next day to check it out. Repair tech said it was registering fine & cool by his inside readings, but outside the pressure was 300psi (high) and the Freon gas was low.

He was afraid if he added Freon it would raise the temp up higher and shut down the compressor totally. H e said the unit should be replaced. He said it was using the old gas, not the new one. Should I replace it since it seems fine and cool now or wait? How long should it last under these conditions? Susan

Reply:

Anon

Certainly I would not replace a compressor only because it was using an older type of refrigerant.

That high pressure on the "high" side of the system may indicate that a metering device such as a capillary tube or expansion valve is clogging.

I would agree with a tech who advised that IF you were facing an expensive repair - such as a compressor replacement - it would make more sense to replace the entire unit.

Question: is it possible to repair a leaky evaporator coil and then replace the refrigerant?

(Sept 30, 2014) p. choate said:

Repairman said there was a leak in evaporator. Can it be replaced and freon replaced.

Reply:

P. C.

IF the evaporator is corroded, patching it is a short term band-aid repair. More likely in that case it'd need replacement and then of course refrigerant replaced/recharged. Install a new filter drier too.

Question: Repeated re-filling of refrigerant - nobody fixes the leak. Should I replace the coil?

(July 25, 2011) Marie

We have been out of A/C for a week now and I have a 20 month baby at home and pets. My husband got a window unit so we can live and sleep in the living room keeping the other rooms closed and hot (82). We have to go through AHS. Already the unit had a problem last year and got filled 3 times despite being 'diagnosed' with a leak.

Now because we asked to replace the whole unit, the second opinion experts AHS pay say they have to replace the evaporator coil.

But since my unit is old (18y.o) they have to adapt it on it requiring I guess more welding work. I dont know what to ask or say because I think they should have done this last year already and the leak could be from anywhere not just the coil correct?

What should I do? I am past over a week now w/o AC and temperatures have been reaching 100 (I live in TN). Should I insist to get a whole new unit or just let them replace the coil and make a 'custom' job?

15 July 2015 Luke Ducote

I've been having problems with a Freon leak for a couple of years now on an R22 system. A charge usually lasts several months, however the last charge only went a month before I was having problems again. Upon placing my gauges on the unit, I noticed the pressures were normal (75/210).

Although the condenser coils did not appear real dirty I cleaned them anyway. Both pressures dropped considerably so I added Freon. Then unit began running better/colder but is still having problems keeping up. I added a little more Freon (up to 85 psi) on the low side, however the high side is not getting any higher.

Did I put too much Freon? Could there be air in the system? I'm wondering if the compressor has been damaged but would rather not replace it as a means of troubleshooting. Any suggestions?

This question was posted originally

at DIAGNOSTIC GUIDE A/C or HEAT PUMP

Reply:

Marie:

If the leaky component is the evaporator coil it may be so corroded as to be beyond repair. Changing out the coil in an old system runs into lots of trouble including a possible need to change the refrigerant gas type (older R12 and R22 your system could have used are no longer permitted), as well as needing to match the coil size to the air handler.

You're right that there could be more than one leak in the system. What people do is scan all accessible components for evidence of a leak, fix leaks detected, and then pressure test the system before continuing with the repair job.

So if the techs can replace the coil and that fixes your leak problem without a full system replacement, it's worth doing; just ask the results of the pressure test (or vacuum test) that was done before the system was recharged.

Question: Technician used a $500 additive to "fix" aan air conditioner coil leak - guaranteed for a year, lasted 6 weeks!

(Aug 26, 2011) maria holt

my technician told us we had a leak in the coil and after he added refrigerant he used something that cost us $465.00 and designed to seal the leak for at least a year. It worked for not even six weeks. Is that ethical? Is the product useful?

Reply:

Maria,

I'd sure like to know what product your technician used as a magic refrigerant leak fix. The methods I'm familiar with all involve soldering or brazing. There may be other products and approaches, and if so they might "work" if applied exactly as the manufacturer instructs.

A repair of a refrigerant leak that works should "stay" sealed and continue to work for the life of the equipment, with these exceptions (HVAC techs may have more to add)

- if the HVACR system piping or coils are corroded then no leak repair will be durable as we're facing ever thinning, fragile materials

- if the leak was caused by vibration or repetitive movement of parts that rubs and wears through then the problem may recur

- if the leak is a a fitting such as a service valve or (used in some areas) a flare fitting, then more likely that valve or fitting needs to be replaced or the connection re-made to seal the leak.

I'm reluctant to judge on ethics without more information, but surely it'd be reasonable for you to expect the technician to return and fix the problem (provided it's the same problem not a new one) given that you were promised a year and didn't make even six weeks of no-leaking. It sounds more as if the guarantee should have been ... "... until my truck reaches the end of your driveway"

Question: what causes frost on the refrigerant high side tubing?

(July 16, 2012) Anonymous

frost on high side tubing

Reply:

Anon I've seen this question once before and am sure we don't have all the answers but look for a TEV stuck wide open or a heat pump stuck in heating mode

Shelly think about low refrigerant and pressure equalizing after shutdown

Question: how to evacuate a common home HVAC (refrigerant-based) system

(Aug 1, 2011) Brian

what is procedure to evacuate most common home hvac system

Reply:

Current regulations in Northamerica require that refrigeration systems that are going to be evacuated are first emptied of whatever refrigerant remains in the system - but that refrigerant is NOT vented to the atmosphere. It must be collected into a retrieval canister. There are two ways this is done.

Traditionally a vacuum pump is connected to a service port on the HVAC system and the output of the pump is connected to a receiving canister. The pump is run until there is a vacuum on the HVAC system for some specified interval then the receiving canister is closed and the pump shut off.

Currently there are also refrigerant receiving canisters that are sold already having been pumped to a vacuum.

The canister can be connected to the service port on the HVAC system.

In either case a gauge set with appropriate connecting hoses and control valves would be used to make the connections between the HVAC system service port(s) and the receiving canister.

Following removal of refrigerant from the system, depending on the HVAC system size, a vacuum pump may be left on and running for minutes to hours to attempt to clean the system as thoroughly as possible of refrigerant, moisture, and debris. The reason we need to allow some time to pass is that the initial "vacuum" is incomplete.

Some moisture may remain in the refrigeration system that can convert to gaseous form as the system warms up, thus allowing still more moisture to be removed in vapor state. On a home system this may be just an hour or three; on a commercial HVAC or other refrigeration system we might leave the vacuum running for 24 hours.

Finally, when the system is to recharged, the HVAC tech will normally also install a dryer/filter to help remove any remaining moisture or debris.

Question: Does the level and amount of gas in the system vary in cool weather vs hot weather?

(Sept 29, 2012) Edrotman@aol.com

In measuring the level of r-22 in a central Ac, Does the level and amount of gas in the system vary in cool weather vs hot weather? I had a service technician tell me my system needed 4 pounds but when I asked another technician he said it showed low because it was too cool to get a proper reading. Whose right?

(Mar 21, 2013) Anonymous

what is the pressure when we put refirgerant in the system?

Reply: the refrigerant gas pressure in a closed container will be affected by ambient temperature

Anon

At the article links near page top click on

REFRIGERANT PRESSURE READINGS - separate article

Question: transferring refrigerant when moving equipment

transfering refrigerant in a condensing unit in a split system ac when moving house in a fully installed unit

Reply:

Gaudy

If you are asking about preserving refrigerant when disconnecting and moving HVAC equipment, I am doubtful. IN a conventional split system cut, move, and reinstall, the tech will need to pull a vacuum, clean the system piping and equipment after it's reconnected in the new location, then install refrigerant.

Question:

(Nov 2, 2012) sandesh

What should be pressure when system is stop & run respectively?

Question:

(Nov 3, 2012) flavia labita

when charging a freon n a 9cu.ft refregerator how many current amperes to be use....thanks

Reply:

Flavia, your question is basically incorrect unless you are "guessing" at refrigerant charge by measuring the current draw of the compressor.

Rather than measuring refrigerant charging in current nor amperes we measure in system pressures adjusted for temperature, dispensing a volume of refrigerant required by the manufacturer with additional allowance for the volume of system piping.

Question:

(Mar 12, 2014) Anonymous

All automotive gas R134a charge Chart please

Bill Torres

What would be a normal low pressure reading for R410 on gauge manifold and a normal high pressure reading.

Reply:

Anon,

R-134a pressure/temperature charts are widely available here and at other websites by simple search.

There is a very detailed R-134a Air Conditioner Filling Chart provided by NRF and found at http://www.nrf.eu/uploads/files/nrf_ac_70x100_zs_def_lr.pdf

Bill,

You'll want to pick up a refrigerant pressure/temperature chart for R410 since pressures vary as a function of temperature.

Giving a single example from a common chart for R410A

At 70F R410A will be at about 201.5 psi.

At 120F R410A will be at about 416.4 psi.

On the suction side, the pressure will depend on the compressor.

Properties for R410A are at

inspectapedia.com/aircond/Refrigerant_Gas_Guide.php#Puronand there you will find a 410 Pressure/temperature chart.

Question: normal low pressure readings for R410A

(July 22, 2014) Bill Torres said:

What would be a normal low pressure reading for R410 on gauge manifold and a normal high pressure reading.Reply:

Bill,

You'll want to pick up a refrigerant pressure/temperature chart for R410 since pressures vary as a function of temperature.

Giving a single example from a common chart for R410AAt 70F R410A will be at about 201.5 psi.

At 120F R410A will be at about 416.4 psi.

On the suction side, the pressure will depend on the compressor.

Properties for R410A are at

inspectapedia.com/aircond/Refrigerant_Gas_Guide.php#Puronand there I'll add a 410 Pressure/temperature chart.

Question: how to find out how much refrigerant to charge

(Nov 3, 2014) Mad said:

I have a heat pump unit, there isn't any information on the compressor to know the capacity of it or amount of refrigerant must be charge.

I wish to fill my device how I know the capacity of the compressor and amount of refrigerant must I charge it

Reply:

Mad

The data tag will be on the compressor/condenser uni cabinet, not on the motor itself.

Question: air conditioner motor not working

(Aug 6, 2011) tungnguyen said:

air conditioning motor no work

Reply:

Nguyen, I'd start diagnosis at LOST COOLING CAPACITY

Question: epoxy repair for leaky air conditioner coil?

(Mar 27, 2014) Mike said:

My air conditioner is 8 years old. The system is leaking refridgerant at a slow level and the hole is midway through coil. Should I try to fix the coil or opt for a new unit?

Reply:

Ugh. Some AC coils can be repaired using epoxy but I am not optimistic about this approach. Here are some considerations:

If the coil leak was caused by an accident, like a mechanical puncture, repairing it might yield a durable remaining life for the system provided we don't contaminate (or contaminate and fail to clean) the refrigerant piping system in the process.

If the AC coil leak was caused by vibration and rubbing or by corrosion I fear that fixing the leak in one place is a band-aid repair that won't give a durable repair since other leaks are coming soon. It's the beginning of the end.

If the HVAC system is relatively new so that it uses modern contemporary refrigerants, then replacing the coil is a plausible repair and the recommended one. The system will have to be evacuated, cleaned, new refrigerant installed along with appropriate refrigerant dryer/filters.

If the HVAC system were old enough (probably not your case) that it still uses R22, repair people either take another band-aid approach by replacing the ruined coil with an R-22-rated coil and R22 refrigerant (no longer a proper repair as this refrigerant has been phased out of use) OR the technician may be tempted to install a new coil rated to use a new refrigerant.

But that last approach leads to more costs: a coil mis-matched to the rest of the equipment will operate very poorly, as demonstrated by www.racca-florida.org/AlabamaStudy.pdf

and when we change refrigerant we may need to change additional controls (TEVs for example) increasing the job cost until it begins to look as if a complete outdoor compressor/condenser unit replacement or even a whole system replacement would have been a smarter change.

(Mar 27, 2014) Mike said:

Thanks. A new system it is. After 8 years I guess that isn't so bad.Reply:

Actually Mike it's disappointing - I'd have expected a recent A/C unit to last more than 8 years. Why not start by giving the manufacturer a call to ask the status of your warranty.

Question: compressor won't start but fan is on

(June 5, 2014) kevin mudong said:

I have come across problem on my ac I switch it on the outside unit the compressor did not start but the fan is on I need assistance I have checked for continuity on the common to start is ok common to run ok run to start ok now I stock so if need help

Re-Posting reader comment (remember to include a space after periods - else the security software thinks you're posting a link and won't automatically accept your comment or question - Daniel

AUTHOR:rod128 (no email)

COMMENT:I've had a terrible technician that came by to recharge my unit. He told me I needed a new compressor and it had a leak outside. He convinced me to get a new outdoor unit. So four hours after the install I noticed the unit wasn't as cool as it should be. So I opened the furnace and noticed the pipes were frozen.

So I called the tech again and he check the inside and found two leaks but offered to put sealant in the unit and recharged it. It cooled for a few hours and then I noticed - water all over the floor coming out of the inside unit and no more cooling. What I'm at wits end and about to go purchase window units.

Reply:

Rod

I suggest that you try calling back the HVAC company you used, speak calmly with the service manager, and ask them to send a senior, experienced technician to your home to repair the system properly.

Question: can vacuum testing cause the evaporator coil to fail?

(Aug 18, 2015) Kay said:

Can either vacuum testing or overfilling of refrigerant cause an evaporator failure in a home A/C unit?

Reply:

Kay