Air Conditioner Compressor & Refrigerant Pressure Readings

Air Conditioner Compressor & Refrigerant Pressure Readings

HVAC refrigerant pressures, boiling points, chemical formulas

Global Warming Impact GWP & ODP data

- POST a QUESTION or COMMENT about refrigerant pressure readings in air conditioners, heat pumps, & other refrigeration equipment

Refrigerant charge quantity for air conditioners & heat pumps:

This air conditioning repair article series discusses the the diagnosis and correction of abnormal air conditioner refrigerant line pressures as a means for evaluating the condition of the air conditioner compressor motor, which in turn, is a step in how we evaluate and correct lost or reduced air conditioner cooling capacity.

We explain how overcharging or undercharging of refrigerant in an air conditioner or heat pump is detected and we list the effects of overcharged or undercharged refrigerant.

We discuss how to diagnose refrigerant pressure problems; how to determine the proper refrigerant charge quantity.

Definitions of Heating Ventilation Air Conditioning & Refrigeration (HVACR) "high side" & "low side" pressures; typical refrigerant pressures; effects of overcharged or under-charged refrigerant are found here as well.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

What are the Typical Air Conditioner or Heat Pump System Pressures During Normal Operation

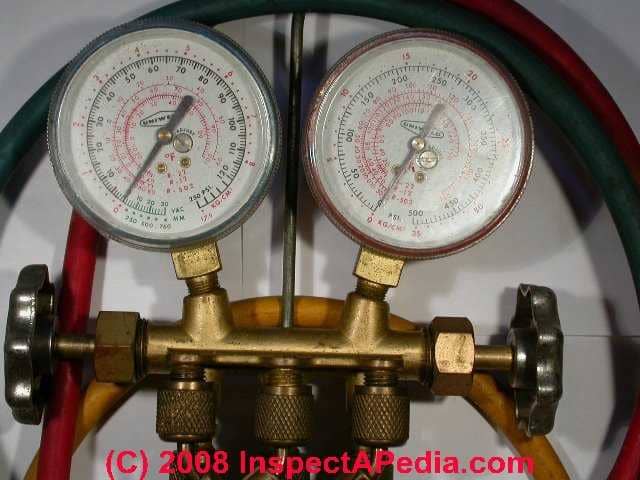

Measuring the refrigerant pressure in air conditioning, heat pump or other refrigerant systems can diagnose a range of operating problems including a refrigerant leak, over charging or under charging.

Measuring the refrigerant pressure in air conditioning, heat pump or other refrigerant systems can diagnose a range of operating problems including a refrigerant leak, over charging or under charging.

Low refrigerant pressures: Refrigerant pressure readings measured at the air conditioning compressor/condenser unit and which are found to be too low on the high pressure side (compressor output) or on the low pressure side (compressor input or suction line) can indicate a problem with the compressor's ability to develop normal operating pressure ranges and thus will affect the cooling capacity of the air conditioning system.

High refrigerant pressures: Abnormally high compressor output pressures are also possible but are less likely.

Both of these conditions are explained here.

Refrigerant Pressures & Pressure Diagnosis

- DEFINITION of HIGH SIDE & LOW SIDE REFRIGERANT PRESSURE MEASUREMENTS

- TYPICAL REFRIGERANT PRESSURES - found in air conditioners, heat pumps, refrigeration equipment for various refrigerant gases

- TYPICAL HVAC COMPRESSOR MOTOR COMPRESSION RATIOS - normal high side vs low side pressure ratio calculation (separate article)

- COMPARISON of REFRIGERANT GAS PROPERTIES - replacements for now-obsolete refrigerants like R22

- COMPARISON of REFIGERANT GAS PRESSURES/TEMPERATURES - refrigerant pressure of various gases at the same temperature?

- DOWNLOAD REFRIGERANT TEMPERATURE - PRESSURE CHARTS - free printable PDF files of refrigerant pressure/temperature tables and charts

- REFRIGERANT TYPES, OVERVIEW

- REFRIGERANT TYPES & ENVIRONMENTAL CONCERNS - UPDATE

Don't Keep Adding Refrigerant: Fix Refrigerant Pressure & Leaks

If after reviewing the refrigerant pressure, temperature, and compression ratio information in this article, you have determined that you have a refrigerant pressure problem or a refrigerant leak, there are procedures to address those issues.

These corrections will include getting the right refrigerant charge by any of several means (weight or volume measurements or some techs monitor refrigerant line temperature).

It also means finding and fixing the refrigerant leak if the problem was simply lost refrigerant.

For help with these corrections,

see our RECOMMENDED ARTICLES list at the bottom of this page.

...

Definition of Air Conditioner High Side and Low Side Pressures

Let's explain "low-side" and "high-side" air conditioner compressor motor pressures and what they mean.

Air conditioning service manuals and training refer to:

-

Low-side air conditioner compressor motor pressure:

This is the pressure in the air conditioner's refrigerant suction line (low side pressure during compressor operation) and this will be a relatively low number, often less than 100 psi.

During operation, refrigerant gas is returning to the compressor from the cooling (evaporator) coil in this line.

If we connected the suction line directly to a sealed vacuum test gauge we'd actually find that the compressor could pull an actual vacuum on the line.

The low-side of an air conditioning system is always located inside of the space to be cooled, or inside of an air handler which moves air through the space to be cooled.

By lowering the pressure in the cooling coil located on the "low side" of the air conditioning system, the compressor permits liquid refrigerant to be discharged into the cooling coil where the change of refrigerant state from a liquid to a gas absorbs heat and brings the cooling coil to the proper operating temperature.

The LOW SIDE of a refrigeration system is the low-pressure and low temperature half of the system. Normally this is the indoor air handler - located inside the space that is to be cooled by bringing indoor air to operating temperature. (For a refrigerator this is typically 38 to 45 °F.) - High-side air conditioner compressor pressure:

Output (high side pressure during operation) is the pressure of the compressed refrigerant gas as it leaves the compressor motor. In other words, refrigerant gas returns to the compressor through the suction line from the cooling coil (which is cooling building air).

The low-pressure refrigerant gas is compressed to a high-pressure refrigerant gas inside the compressor motor. This high temperature refrigerant gas is then cooled down to condense into a refrigerant liquid before it is returned indoors to the air handler and evaporator coil to be used to cool building air.

(Thus we get the name "condensing coil" and "condensing unit" or "condenser" for the outside half of an air conditioning system.)

The high side components of an air conditioning system, such as the compressor, condensing coil, and fan unit used to cool the condensing coil are located outside of the conditioned or refrigerated space, and will be immersed in air at ambient outdoor temperature, say 72 °F.

Here is where the magic of air conditioning occurs. As long as the compressor can produce a temperature in the outdoor condensing coil which is above ambient outdoor air temperature, heat will flow from the condensing coil into outdoor air (for example outdoor air blown across the condensing coil by a fan).

If you studied thermodynamics in high school you learned that heat always flows from the warmer to the cooler material. The effect is to transfer heat gathered in the indoor or conditioned space into outdoor air.

The HIGH SIDE of a refrigeration system is at high temperature and higher (refrigerant) pressure and will always be above ambient temperature. So in a cooling system it will be located outside in order to transfer heat to the outdoor air.

A heat pump designed to pump heat into a building will, of course, reverse these roles when in heating mode.

Tricks of the Trade - How to Get a Free or Low-cost HVAC Refrigerant Diagnostic Vacuum Pump

On my own graduation from HVAC school the instructor suggested that since most of the time when people are tossing out an old refrigerator the problem was electrical rather than the compressor, we should look for an old Frigidaire refrigerator and salvage its compressor motor.

Indeed I did just that and for years we used to use an old Frigidaire™ rotary-design compressor motor as our vacuum pump when we needed to get the air out of a refrigeration system prior to charging it with new refrigerant. - Daniel F.

...

Typical HVAC Refrigerant Pressures

Typical residential air conditioning refrigerant pressures vary depending on the model, compressor motor size and design, and the refrigerant used.

The design pressures may be provided on labels attached to the equipment but the actual air conditioner operating pressure will vary in part as a function of the incoming air temperatures.

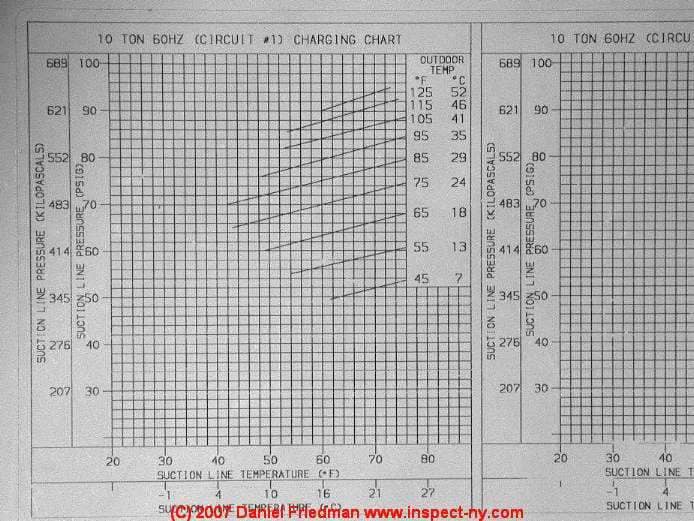

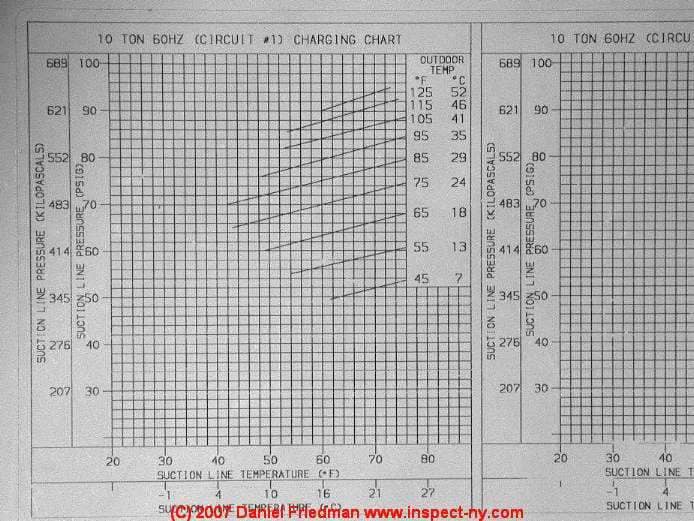

"Charging Charts" (such as the commercial unit charging chart shown here) are provided in service manuals to determine the target suction vacuum (negative) pressure and output (positive) pressure for a given compressor motor.

Use of the charging chart for the specific compressor is the correct way to service it.

The following example refrigerant pressures are based on "rules of thumb" that get you in the right "ballpark" if no charging chart is at hand.

Example of actual air conditioner compressor high side output pressure:

Using R-22 refrigerant and assuming an outside air temperature of 85 °F called for 120 °F inside the compressor (add 35 °F to incoming air temperature) and an output high-side compressor pressure of about 260 psi.

Example of actual air conditioner low side input or suction line pressure during operation:

Low-side pressure during normal operation of the same compressor model and refrigerant and the same outdoor air temperature of 85 °F called for 45 °F temperature entering the compressor (subtract 40 °F from incoming air temperature) which on the service chart indicates that the incoming or suction line pressure would be about 75 psi.

Example of a more theoretical air conditioner or heat pump pressure and temperature at the compressor and at the cap tube or thermostatic expansion valve:

During normal operation: at an outdoor temperature of 72 °F, liquid refrigerant (R12 for example) leaving the outdoor condensing coil and entering the cap tube or TEV might be at 100 psi and 95 °F.

These numbers vary by changes in ambient temperature, compressor model, and refrigerant gas used.

On the low side of the TEV or cap tube (in the cooling coil in the air handler) where the liquid refrigerant is changing state to a gas, it may be cooled down to 10 °F. and by the time the refrigerant leaves the cooling coil (evaporator coil) and gets back to the compressor motor it will be all vapor and may be at just 15 psi.

[R12 refrigerant changes from liquid to vapor at 14.6 psi at 10 °F.]

Meaning of Abnormal Refrigerant Pressure Readings

What do "High" or "Low" Refrigerant Pressures Mean? |

|||

| Low Side Pressure Reading | High Side Pressure Reading | Compression Ratio | What to Do |

| Normal Range | Normal Range | HVAC: 2.3:1 to 3.5:1 Coolers: 3.0:1 to 5.5:1 Freezers: 6.0:1 - 13.0:1 |

Proper Operation No Action Needed |

| Low | Low | Refrigerant Lost |

|

| Low | High | Check for blocked TEV or capillary tube | |

| High | Low | Check compressor operation Check TEV operation |

|

| High | High | Check/Correct refrigerant charge (probably over-charged) | |

Notes to the table above

- The "Range" of refrigerant pressure numbers depends on the specific refrigerant gas involved and on the ambient temperatures so you will need to get the right chart for your system

See DETAILED REFRIGERANT TEMPERATURE - PRESSURE CHARTS - More causes of abnormal refrigerant pressures, both too high or too low, are given below on this page.

Air Conditioner or Heat Pump Refrigerant Equalization Pressure - System-OFF refrigerant pressures

When you measure heat pump or cooling system pressures makes as much difference as where you measure it.

When an air conditioning or heat pump system has turned off and been off for some time (30 minutes or more) pressures equalize throughout the system between the high and low sides.

At that point the refrigerant pressure in both the high side and low side of the air conditioner or heat pump system will be in accordance with the ambient air temperature and the properties of the particular refrigerant gas present.

The static or equalized system refrigerant pressure will be defined by the refrigerant gas type (which defines its boiling point and pressure at various temperatures).

For example with that cute old R12 refrigerant, as long as there is just about any refrigerant in the system - enough so that there is some liquid refrigerant, i.e. it's not all just gas) then in equalized condition at 70 psi ambient temperature the refrigerant pressure will be 70 psi.

With a temperature correction chart you can read the static or equalized refrigerant pressure for any refrigerant gas and the actual ambient temperature.

Reminder: this refrigerant gas behavior means that if you use pressure test gauges to measure the refrigerant pressure in the static or equalized air conditioning or heat pump system, the gauges only tell you the refrigerant pressure, not the quantity of refrigerant that is present in the system.

...

Typical HVAC Compressor Motor Compression Ratios

Information and tables on normal and abnormal HVAC compression ratios are now found

...

Comparison Table of Refrigerant Gas Properties

Comparison of Refrigerant Gas Properties |

||||||||

| Refrigerant Gas | Properties | Refrigerant Type14 |

Replaces Substitutes20 |

Replaced By20 |

GWP1 | ODP1 | Com- |

Pressure Charts & Details |

| R11 | Trichlorofluoromethane CFC-11 = Freon-11 = R-11. Banned-1996 Montreal Protocol |

CFC | 4000 | 1.0 | Y | Basis for ODP comparisons | ||

| R12 | Dichlorodifluoromethane Freon No remaining life Banned-1996 Montreal Protocol |

CFC HFC |

R124 R134a R401a R401b |

2400 | 1.0 | N | n/a | |

| R12 B1 | CFC | R124, R142b | N | |||||

| R13 B1 | Bromotrifluoromethane Halon 1301 or BTM CBrF3 |

CFC Halon |

R410A, ISCEON® MO89 R402B? |

10 | N | |||

| R22 | Chlorodifluoromethane No remaining life Do not go to R-410A |

HFC HCFC |

R404A | R407c ? | 1700 | 0.05 | Y | R22 REFRIGERANT PRESSURES R22 pressure chart, high & low side |

| R23 | Additions banned 1 Jan 2020 Reclaimed use permitted to end of 2029 |

HFC | R13, R503 Halon 131 |

18,400 | 0 | N | ||

| R32 | Difluoromethane, CH2F2 Use in new equipment |

HFC | R134A ? R410A ? |

N ? | R32 REFRIGERANT PRESSURES | |||

| Eco 32 | Blend: Propane R290 + Ethane R170 reduced-GWP |

HC |

R32, R410a | ? | ? | Y | Eco-32 REFRIGERANT PRESSURES [PDF] 17 | |

| R32 | Difluoromethane R 410A replacement in new equipment Not to be used as a retrofit |

HFC | R410A | 650 | 77119 | 0 | Y | R32 REFRIGERANT PRESSURES |

| R113 | Trichlorotrifluoroethane |

CFC | 4800 | 0.8 | ||||

| R114 | Dichlorotetrafluoroethane Banned-1996 Montreal Protocol |

CFC | R124, R142b | 3.9 | 1.0 | |||

| R123 | Dichlorotrifluoroethane | HCFC | R11 | 0.02 | 0.02 | |||

| R1234YF | Automotive AC 2,3,3,3-Tetrafluoropropene |

HFO | R134A | 4 | Y | R1234YF PRESSURE CHART [PDF] 10 | ||

| R1234ZW | [citation needed] | |||||||

| R124 | Chlorotetrafluoroethane | HCFC | R12, R114 | 620 | 002 | |||

| R125 | Pentafluoroethane | 3400 | 0 | |||||

| R134A | Tetrafluoroethane |

HFC | R12 |

1234yf R-152a R-744 |

1300- 1430 |

0 | N | R134 REFRIGERANT PRESSURE CHART |

| R143A | Trifluoroethane | 4300 | 0 | |||||

| R152A | Difluoroethane | 120 | 0 | Y | ||||

| R245A | Pentafluoropropane | ? | 0 | N | Flammable under pressure | |||

| R290 | Pure HC Propane, CARE® 40 | HC | R12, R22, R502 ? |

3 | ? | Y | R290 PRESSURE CHART [PDF] 3 | |

| R401A | Blend 53% R-22, 34% R-124, 13% R-152a |

HCFC | R12, R500? | 1100 | 0.037 | N | ||

| R401B | Blend 61% R-22, 28% R-124, 11% R-152a |

HCFC | 1200 | 0.04 | N | |||

| R402A / HP80 | Blend of R-22 & R-125 w/ hydrocarbon R-290 (propane) 38% R-22, 60% R-125, 2% R-290 |

HCFC | R502 | 2600 | 0.02 | N | R402A PRESSURE CHART [PDF] 13 | |

| R402B | Blend of R-22 and R-218 w/ R-290 (propane) |

HCFC | R502 R-13B1? |

N | ||||

| R403B | Blend of R-22 and R-218 w/ R-290 (propane) |

HCFC | R502 | N | ||||

| R404A | Blend, replaces R502 & R22 Short remaining life2 44% R-125, 52% R-143a, R-134a |

HFC | R502, R22 | 3300 3922 ? |

0 | N | R404A PRESSURE CHART [PDF] 4 Flammable under pressure |

|

| R407A | Blend 20% R-32, 40% R-125, 40% R-134a |

HFC | R22 | 2000 | 0 | N | ||

| R407C | Blend 23% R-32, 25% R-125, 52% R-134a |

HFC | R22 | 1600 | 0 | N | ||

| R407H | Mixture of R32, R125, R134A, not ozone resistant |

HFC | R22, R-404A?, |

1490 1495 |

- | N | R407H PRESSURE CHART [PDF] 5 16 |

|

| R408A / FX10 | Blend, Forane® | HCFC | R502 | 3152 | 0.024 | N | R408A PRESSURE CHART [PDF] 13 | |

| R409A | Blend of R-22, R-142b | HCFC | R12 | N | ||||

| R410A | Domestic HVAC |

R-22 | R-32 Eco-32 |

2088 | N | R410A REFRIGERANT PRESSURE CHART | ||

| R414B | Blend of R-22, R-124, R-142b w/hydrocarbon R-600a (isobutane) |

HCFC | R12 |

N | ||||

| R448A | Blend R32, R125, R134A, R1234YF, R1234ZW |

HFC HFO |

R404A or R507 | 1273 | N | R448A / N40 PRESSURE CHART [PDF] 6 | ||

| R449A | Blend | HFC HFO |

R404A | 1282 | N | R449A PRESSURE CHART [PDF] 7 | ||

| R452A | Blend | HFC HFO |

R404A, R507 | 1945 | N | R452A PRESSURE CHART [PDF] 8 | ||

| R452B | Blend blend R32 + R125+ R1234yf? |

HFC HFO |

R410A | Y | ||||

| R454B | Blend | HFO | R410A | Y | ||||

| R500 | Blend R-12 / R-152a Banned-1996 Montreal Protocol |

CFC | R12 | N | ||||

| R502 | Freon |

CFC | R-22 / R115 | R404A | 4.1 | 0.283 | N | R502 PRESSURE CHART [PDF] 12 Becomes flammable under pressure |

| R507 | Blend 50%-50% R-125 & R-143A - or 45% R-125, 55% R-143 |

HFC | R22, R502 | 3300 | 0 | N | R507 PRESSURE CHART [PDF] 11 Becomes flammable under pressure |

|

| R600A | Iso-butane | R12, R134 | 3 | Y | R600A PRESSURE CHART [PDF] 9 | |||

| R717 | Ammonia - NH3 Among oldest refrigerants |

R134A-? R32-? |

0 | 0 | Y | Flammable at high temp. | ||

| R718 | Water - H20 | 0 | N | |||||

| R729 | Air | 0 | N | |||||

| R744 | Carbon Dioxide - CO2 GWP REFERENCE GAS |

1 | 0 | N | ||||

Notes to the table above

- GWP = Global Warming Potential, relative contribution to global warming by contributing to greenhouse gases that trap heat in the earth's atmosphere. CO2 (Carbon dioxide) has a GWP of 1.0.

By 2025, high Global Warming Potential (GWP) refrigerants with a GWP of over 750, will be banned together along with HVACR equipment that uses that gas. Note that GWP ratings are controversial.

ODP = Ozone Depletion Potential - relative damage to the earth's ozone layer.

ODP is defined as the total amount of ozone destroyed by that substance compared with the amount of ozone that would be destroyed by the same mass of CFC-11 = Freon-11 = R-11.

Combustible or flammable: refrigerants are rated as

1 - not flammable,

2L - very low flammability,

2 - low flammability,

3 - high flammability

- Source:

ASHRAE: ASHRAE Standard 34 describes a shorthand way of naming refrigerants and assigns safety classifications based on toxicity and flammability data

ASHRAE Standard 15 establishes procedures for operating equipment and systems when using those refrigerants.

- R404A, commercial use banned after 2020 is replaced by R448A, R449A, R452A, R407H.

- R290 PT Chart, A-Gas, Units 7 & 8 Gordano Court

Serbert Close

Portishead, Bristol BS20 7FS

UK, +44 1275 376600

Offices world wide, Website: www.agas.com, retrieved 2020/02/10 original source: https://www.agas.com/media/2422/r290-propane-pt-chart.pdf

Linde, R290 REFRIGERANT GRADE PROPANE [PDF] Linde AG Linde Gases Division, Seitnerstrasse 70, 82049 Pullach, Germany Phone +49.89.7446-0, Fax +49.89.7446-1230, www.linde-gas.com/refrigerants, refrigerants@lindegas.com retrieved 2021/12/22 original source: http://hydrocarbons21.com/files/refrigeration_R290.pdf

Excerpt:

R290 is the common name for high purity propane (C3H8) suitable for use in the refrigeration and air conditioning industry. It is also known as CARE® 40. - R490 PT Chart, A-Gas, op. cit. retrieved 2020/02/10 original source: https://www.agas.com/media/2405/r404a-pt-chart.pdf

- R407 Data, Daikin Chemical Europe GmbH

Am Wehrhahn 50

40211 Düsseldorf, Germany

Phone: +49 211-179225-0

Fax: +49 211-179225-39

daikinchem.de, retrieved 2020/02/10 original source: https://www.daikinchem.de/sites/default/files/pdf/Refrigerants/Daikin_R407H_Handling_Brochure_EN.pdf

R407H: zeotropic mixture of 32.5 weight% R32, 15 % R125, and 52.5% R134a. It is a drop-In refrigerant for R404A / R507 and a retrofit refrigerant for R22. - R448A Data, (N40) Pressure & Temperature, FSW op. cit. retrieved 2020/02/10 original source: https://www.fsw.uk.com/sites/www.fsw.uk.com/files/r448a-n40-pt-chart.pdf

Alternative Chart: R448A Data Honeywell's Solstice® N40 = R448A [PDF] Honeywell Advanced Materials 115 Tabor Road Morris Plains, NJ 07950 honeywell-refrigerants.com retrieved 2020/02/10 original source: https://www.fluorineproducts-honeywell.com/refrigerants/wp-content/uploads/2018/02/SPM-FLP-00643-PT-Chart-Solstice-N40_3x5_LR.pdf - R449A / XP40 Data, FSW Cannock Delta House,Fairway, Bridgtown, Cannock, Staffordshire, WS11 0DJ Email Sales@fsw.uk.com Tel: 01543 437 010 retrieved 2020/02/10 original source: https://www.fsw.uk.com/sites/www.fsw.uk.com/files/r449a-xp40-pt-chart.pdf

- R452 Data, FSW, Op. Cit., retrieved 2020/02/10 original source: https://www.fsw.uk.com/sites/www.fsw.uk.com/files/r452a-xp44-pt-chart_0.pdf

- R600A Data, Iso-Butane, A-Gas, op. cit. retrieved 2020/02/10 original source: https://www.agas.com/media/2423/r600a-iso-butane-pt-chart.pdf

- R600A Data, Iso-Butane, A-Gas, op. cit. retrieved 2020/02/10 original source: https://www.agas.com/media/6742/r1234yf-pt-chart-2.pdf

- R507 Data, Agas, Op. Cit., https://www.agas.com/media/2421/r507-pt-chart.pdf

- R502 Datra, R502 is replaced by R402A / R-408A, retrieved 2020/02/10 original source: http://www.pchetz.com/_Uploads/dbsAttachedFiles/R502PressureEnthalpy.pdf

- R402A Data, REFRIGERANT CHANGEOVER

GUIDELINES

R-502 TO R-402A/R-408A [PDF] (2005) Copeland / Emerson Climate Technologies, 1675 W. Campbell Road

Sidney, OH 45365-0669

(937) 498-3011

copeland-corp.com

Excerpts: Copeland does not advocate the wholesale changeover of CFC refrigerants to HCFCs or HFCs. If a system is not leaking refrigerant to the atmosphere, and is operating properly, there is no technical reason to replace the CFC refrigerant.

In fact, changing the refrigerant may void the U.L. listing of the unit. However, once the decision has been made to make the change from R-502 to the interim R-402A or R-408A, the following guidelines are recommended.

R-402A/R-408A should be used only in systems that currently use R-502. It should not be mixed with R-502 or any other refrigerant nor should it be used to replace CFC-12 or HCFC-22 - R408A Data, see #13 above.

- Daikin, R407H PROPERTIES, USE & HANDLING [PDF] Daikin Chemical Europe GmbH

Am Wehrhahn 50

40211 Düsseldorf, Germany

Phone: +49 211-179225-0

Fax: +49 211-179225-39

daikinchem.de

Excerpt:

R407H can be used as a Drop-In refrigerant in R404A / R507 systems. A Drop-In is the easiest way to convert a refrigeration system to another refrigerant. It is linked with minor changes and it usually uses the same oil type. - Eco Freeze, E.F. International bvba Boombekelaan 11E B-2660 Hoboken (Antwerp) Belgium + 32 498 648 933 – Arya Mohadjerin arya@eco-freeze.com source of our Eco-32 pressure chart given in the table above, retrieved 2021/12/22 original source: https://eco-freeze.com/resources/#32chart

- Engineering Toolbox, "Refrigerants - Environmental Properties,

Refrigerants - Ozone Depletion (ODP) and Global Warming Potential (GWP)", retrieved 2021/12/22 original source: https://www.engineeringtoolbox.com/Refrigerants-Environment-Properties-d_1220.html

This article provided data for some of the gas properties entered in the table above. - The GWP of R32 was increased from 675 to 771 in August, 2021 by the Intergovernmental Panel on Climate Change (IPCC), sixth assessment report “Climate Change 2021 – The Physical Science Basis.”

- US EPA UNACCEPTABLE SUBSTITUTE REFRIGERANTS [PDF] U.S. EPA, retrieved 2021/12/22 original source: https://www.epa.gov/snap/unacceptable-substitute-refrigerants

...

Comparison of Ambient Pressure/Temperature for Refrigerants

These refrigerant line pressures are the natural pressure at which each refrigerant gas would be found at ambient temperature. If your HVAC equipment has been off long enough for all of its components to reach ambient temperature and thus its high side and low side pressures have had time to equalize, then at our example temperature of at 30°C / 86°F Ambient Temperature you will see the gauge pressures given in our table below.

Comparison of Refrigerant Pressures at 30°C / 86°F Ambient Temperature |

|||

| Refrigerant Gas | Gauge Pressure - BAR | Gauge Pressure - PSIG | Pressure Charts & Details |

| R22 | 10.9 | 158.2 | R22 REFRIGERANT PRESSURE / TEMPERATURE CHARTS - and rules of thumb |

| R32 | 18.26 | 264.80 | |

| R134A | 6.69 | 96.00 | |

| R290 | 9.78 | 141.77 | R290 PRESSURE CHART [PDF]3 |

| R404A | 13.3 | 190.40 | R404A PRESSURE CHART [PDF]4 |

| R407H | see R404A / R507 | R407H PRESSURE CHART [PDF]5 | |

| R410A | 17.82 | 258.42 | |

| R448A | 11.18 | 162.07 | R448A / N40 PRESSURE CHART [PDF] 6 |

| R449A | 10.83 | 157.02 | R449A PRESSURE CHART [PDF] 7 |

| R452A | 12.00 | 173.97 | R452A PRESSURE CHART [PDF] 8 |

| R502 | 12.00 | 173.97 | R502 PRESSURE CHART [PDF] 12 |

| R507 | 13.57 | 196.82 | R507 PRESSURE CHART [PDF] 11 |

| R600A | 3.03 | 44.00 | R600A PRESSURE CHART [PDF] 9 |

| R1234YF | 6.82 | 98.92 | R1234YF PRESSURE CHART [PDF] 10 |

| R1234ZW | |||

Notes to the table above

- These are vapour pressures unless stated otherwise

- Watch out: at other ambient temperatures above or below 30°C / 86°F Ambient Temperature you will see the gauge pressures will differ.

- Watch out: when the HVAC equipment is actually running to produce different high and low pressures on those lines respectively, depending on the ambient temperatures you'll see different gauge pressure.

For example, the system pressure sin an R-1234YF refrigerant system at 95°F that is running normally will be about:

Low side: 49-59 psi and

High side: 266-289 psi. (at 95°F)

That's why you need to both measure the ambient temperature and use the proper refrigerant pressure chart for the specific kind of refrigerant in your system. - [6] Alternative Chart for R448A (N40) Pressure & Temperature, FSW op. cit. retrieved 2020/02/10 original source: https://www.fsw.uk.com/sites/www.fsw.uk.com/files/r448a-n40-pt-chart.pdf

...

Refrigerant Pressure / Temperature Chart & Table Downloads

Here is a list of pages where you can download free refrigerant pressure/temperature charts, provided courtesy of various HVACR manufacturers that we cite.

- REFRIGERANT PRESSURE / TEMPERATURE CHARTS for R-11, R-113, R-123, R-12, R-13, R-134A, R-114, R-14 or Freon-14, Tetrafluoromethane,R-22, R-23, R-410A, R-409A, R-416A, R-500, R-503, R-507, R-503 [PDF]

Airgas Refrigerants, Inc., Headquarter Office 2530 Sever Road, Suite 300, Lawrenceville, GA 30043 Tel: 1-800-473-3766, Website: www.airgasrefrigerants.com Email: ARF-Contact.us@airgas.com - R22 REFRIGERANT PRESSURE / TEMPERATURE CHARTS [Web Article and PDFs] Troubleshooting, repairing, + R22 chart downloads + R22 refrigerant rule of thumb

- REFRIGERANT PRESSURE / TEMPERATURE CHARTS for R-22, R-410A, R-134A, R-404A REFRIGERANTS [PDF] Advantage Engineering, Inc. 525 East Stop 18 Road Greenwood, IN 46142USA, Tel: 317-887-0729 Web site: www.AdvantageEngineering.com Email: sales@AdvantageEngineering.com

HCFC-142b REFRIGERANT GAS Product Information [PDF] Op. Cit. - R32 REFRIGERANT PRESSURES [Web Article] includes downloadable PDFs of R-32 pressure/temperature charts

- R32 PRESSURE / TEMPERATURE CHART [PDF] Agas, Op. Cit., retrieved 2020/02/10 original source: https://www.agas.com/media/2427/r32-pt-chart.pdf

- R134 REFRIGERANT PRESSURE / TEMPERATURE CHARTS [Web Article] + additional data on & downloads for R-134

- HFC R-134A PRESSURE TEMPERATURE CHART [PDF], Pacific Sea Breeze Marine Products, 100 Grace Way, Scotts Valley, CA 95066 USA, Tel: 831-600-7878 Website: http://pacificseabreeze.com/technical_library

- R134A REFRIGERANT PT CHART [PDF] Agas, Op, Cit. retrieved 2020/02/10 original source: agas.com/media/2404/r134a-pt-chart.pdf

- HCFC-142b REFRIGERANT GAS Product Information [PDF], DAIKIN AMERICA, INC. 20 Olympic Drive, Orangeburg, NY 10962, USA Phone: +1-845-365-9500 Toll-Free: +1-800-365-9570 Facsimile: +1-845-365-9598 http://www.daikin-america.com,

DAIKIN CHEMICAL EUROPE GmbH Immermannstr. 65D, 40210 Dusseldorf, Germany Phone: +49-211-179225-0 Facsimile: +49-211-1640732 http://www.daikinchem.de

Chemicals Division Umeda Center Bldg., 2-4-12, Nakazaki-Nishi, Kita-ku, Osaka 530-8323, Japan Phone: +81-6-6373-4342 Facsimile: +81-6-6373-4390 http://www.daikin.com/chm - HCFC R-142b REFRIGERANT GAS MSDS [PDF], National Refrigerants, Inc., 661 Kenyon Ave., Bridgeton NJ 08302, USA

- R290 PRESSURE CHART [PDF]

- R410A REFRIGERANT PRESSURE / TEMPERATURE CHARTS [Web Article] Troubleshooting, repairing, + R-410a refrigerant pressure chart downloads.

- REFRIGERANT TEMPERATURE / PRESSURE CHARTS for R-407, R-22, R410a, R-407c, R-134a, R404a, [PDF], Op. Cit.,

- R448A / N40 PRESSURE CHART [PDF]

- R449A PRESSURE CHART [PDF]

- R452A PRESSURE CHART [PDF]

- R502 PRESSURE CHART [PDF]

- R507 PRESSURE CHART [PDF]

- R600A PRESSURE CHART [PDF]

...

Overview of Refrigerant Types - past and current

Information on different types of refrigerants can now be found

...

Refrigerant Type & Environmental Concerns Update

More about environmental concerns among refrigerants and the move towards refrigerants that offer less contribution to global warming and its costs is now found

...

...

Continue reading at REFRIGERANT PRESSURE DIAGNOSIS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see REFRIGERANT PRESSURE READING & CHART FAQs - questions & answers posted originally at this page.

Or see these

Recommended Articles

- AIR CONDITIONING & HEAT PUMP SYSTEMS - home

- PRESSURE CONTROLS & SAFETY SWITCHES

- REFRIGERANT GASES & PIPING - home

- GAUGE, REFRIGERATION PRESSURE TEST

- HVAC COMPRESSION RATIOS

- REFRIGERANT CHARGING PROCEDURE

- REFRIGERANT DRIERS & FILTERS

- REFRIGERANT FLOODBACK, LIQUID SLUGGING

- REFRIGERANT LEAK DETECTION

- REFRIGERANT LEAK REPAIR

- REFRIGERANT LINE FROST or ICE

- REFRIGERANT METERING DEVICES TEVs & EEVs

- REFRIGERANT METERING CAPILLARY TUBES

- REFRIGERANT OVERCHARGE EFFECTS

- REFRIGERANT PRESSURE DIAGNOSTICS

- REFRIGERANT PRESSURE READINGS & CHARTS

- REFRIGERANT PROBLEM TYPES

- REFRIGERANT TYPES

- REFRIGERANT UNDERCHARGE EFFECTS

- REFRIGERANT SIGHT GLASS

- REPAIR GUIDE for AIR CONDITIONERS - If your air conditioning or heat pump system has lost its cooling capacity or won't start

- SPLIT SYSTEM AC / HEAT PUMP REPAIRS

Suggested citation for this web page

REFRIGERANT PRESSURE READINGS & CHARTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.