Refrigerant Piping Insulation

Refrigerant Piping Insulation

installation, inspection, repairs on air conditioners, heat pumps, refrigeration equipment

- POST a QUESTION or COMMENT about installing insulation on refrigerant piping

Guide to proper installation of insulation on refrigerant piping installation, inspection, defects, & repairs. We answer the following questions:

Why is refrigerant piping insulation needed, what problems occur if the insulation is incomplete, missing, crimped, or otherwise improperly installed, and how do we fix these problems?

What types of insulation are used on refrigerant tubing systems & where can the insulation be purchased?

How is the refrigerant piping insulation secured to the refrigerant pipe or tubing?

Is it necessary to insulate refrigerant piping where it runs through ceilings and walls?

Page top photo: gaps in refrigerant tubing insulation or squeezing it too tightly both reduce the effectiveness of the insulation and may add to the operating cost of the system.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Insulation on Air Conditioning & Heat Pump Refrigeration Lines & Condensate Drains

Here we describe defects in refrigerant piping insulation, problems caused by defective refrigerant piping insulation, recommended installation practices for refrigerant tubing insulation in building walls or cavities as well as outdoors where exposed to the weather, and interior leaks on & in wall below a split system air conditioner wall-mounted unit traced to missing insulation.

- Daniel Friedman. Friedman trained as an HVACR service technician and serviced/repaired/installed systems for two decades.

Article Contents

- AVOID GAPS, SPLITS or MISSING REFRIGERANT PIPE INSULATION

- DON'T OVER-COMPRESS REFRIGERANT LINE INSULATION

- CONDENSATION LEAKS at MISSING REFRIGERANT PIPE INSULATION

- WEATHER PROTECTION for REFRIGERANT PIPE INSULATION OUTDOORS

- REFRIGERANT LINE INSULATION BRAND SUBSTITUTION OK?

- REFRIGERANT PIPING INSULATION RESEARCH & SOURCES

...

Avoid gaps and missing insulation along the refrigeration lines

Proper placement and securing of insulation on air conditioner or heat pump refrigeration lines is important to avoid condensation leaks into the building.

Proper placement and securing of insulation on air conditioner or heat pump refrigeration lines is important to avoid condensation leaks into the building.

One, or on some systems both refrigeration lines can be cool or cold under some operating conditions.

The cold copper tubing in contact with warm humid air causes moisture in the air to condense onto and then drip off of the refrigeration lines.

The result can be leaks into the building, as our photo at left illustrates.

Missing or damaged refrigerant line insulation insulation

on the refrigerant lines, particularly on the larger suction line, will cause condensation and drips from the lines in humid areas.

In our photo at above left where refrigerant line insulation is incomplete, the drip stains on the attic floor may well indicate a point at which leak stains or even mold appear on the ceiling below.

In our photo above none of the refrigerant lines are insulated where they emerge from the building wall.

If the lines were also uninsulated within the wall, depending on their location and the wall's dew point properties, a condensation, leak, mold, rot, or insect problem can ensue.

We have seen very costly building damage where lines were not properly insulated indoors: condensate drips wet gypsum board walls, leading to a costly mold remediation project.

Missing refrigerant line insulation also may increase system operating cost or in addition to a condensation worry, uninsulated high pressure refrigerant lines may result in unwanted heat transmission into some building areas..

Just below we illustrate a neat insulation job visible on the outdoor portion of refrigerant piping for a split system ductless air conditioner installation.

According to McQuay International, a large producer of refrigeration equipment,

Suction lines are cold – 40°F (4.4°C) SST – and cause condensation, even in conditioned spaces. In addition, any heat that enters the refrigerant adds to the superheat and reduces system efficiency.

For these reasons, suction lines should be insulated with a vapor proof insulation. This is a requirement of many building codes. Rubatex is the most common form of refrigerant line insulation. - Thanks to professional home inspector Stephen Stanczyk in Washington State (steve@safehaveninspections.com) for editing assistance.

Liquid lines generally are insulated. They are warm to hot (110°F (43.3°C) for air-cooled). If liquid lines pass through a space that is warmer than the refrigerant (i.e. the roof of a building at roof level), or if they could be considered hot enough to pose a safety risk, then insulation should be added.

Discharge lines are generally uninsulated. They may be very hot, in excess of 150°F (66°C), so insulation may be warranted as a safety consideration, or if the heat loss from the discharge gas line would be considered objectionable to the space.

Hot gas bypass lines should be insulated, especially if the runs are long or if the piping is exposed to cold temperatures.

Watch out: condensation on the suction line and at the bottom of the compressor could be an indication of excess liquid refrigerant returning to the compressor via the suction line. This liquid slugging of the compressor can damage or destroy the motor. We discuss refrigerant flooding and six common causes of liquid refrigerant slugging the compressor

...

Do Not Compress or Squeeze Insulation on Refrigerant Lines

The same split system air conditioner installer we described above

at A/C CONDENSATE DISPOSAL for Ductless or Split System Air Conditioners

violated the manufacturer's recommendations against compressing the insulation on the refrigerant lines - one more picky issue that we decided to let go since the wall was to be insulated with blown-in foam.

But he made the same mistake on the insulation on the refrigeration lines and condensate drain where they extend outdoors between the building wall and the compressor/condenser unit.

Our photographs illustrate that the importance of not compressing refrigeration line insulation is no joke.

In our photo below, notice those drip stains below the condensate lines at each location where the insulation was compressed by a too-tight plastic tie?

And in the two photos at below, notice the incomplete insulation on the refrigeration line?

It leaves me worried about condensation and water accumulation inside the wall cavity as well. Since I know this installer is not stupid we're left thinking he has a bit of contempt for his customers, or a limited concept of workmanship.

Imagine that same dripping and accumulation of water where the installer made the same mistake in a fiberglass-batt insulated wall or a wall or ceiling inside which the dew point may be reached on the refrigeration lines?

The accumulation of water in a building cavity is asking for a costly mold, insect, or rot damage problem later on.

Missing insulation on the refrigeration lines outdoors is not a catastrophe - at least for a short un such as at this split system compressor/condenser unit.

Perhaps a little loss in efficiency of the system operation in some weather conditions.

On a long refrigeration line run, say between an attic air handler and a ground level compressor/condenser, the effects may be more significant.

We removed the leaky, incomplete, and ugly squashed insulation on the refrigeration lines for this system (above left), replacing the squashed foam insulating tubing with new insulation (shown below)

Below you can see the new refrigerant tubing insulation being installed: we're peeling out the edge tape so that the split foam insulation sides can adhere to one another.

Incidentally, just clipping off the old plastic wire ties to "release" the squashed refrigerant line foam insulation won't work: after a few months the insulating foam remains permanently squashed, as you can see in our photo at left.

We paid particular attention to sealing and insulating the refrigeration line at the exit point from the building wall, reducing the chances of leaks into the wall at that point.

To keep the refrigeration line insulation in place you can still use a plastic tie if you like - just don't tighten it so far as to squash the insulation.

The manufacturer (Sanyo) recommends covering the foam insulation on the refrigeration line with weatherproof tape which we did at the end of this job.

I admit that we "over-designed" the final insulation job shown in our last photo with that extra layer of foam that surrounds both lines, as we used more thickness of insulation than necessary. We did so to end with a neat, weather-protected job that, combined with the application of black weatherproof tape, should last for a long time.

Notice that the aluminum or plastic ties used to hold components in place were left loose - we did not squash the new refrigerant line insulation, and we made sure it was continuous, neat, and protected from the weather.

A neat installation takes what, maybe five minutes longer than a sloppy one, but it took about an hour to buy the replacement refrigerant line insulation, remove the original sloppy installation, and do the job right the second time.

...

Interior Leaks On & In Wall Below a Split System Air Conditioner Wall-Mounted Unit Traced to Missing Insulation

Watch out: The split system air conditioner installer we described

at A/C CONDENSATE DISPOSAL for Ductless or Split System Air Conditioners

violated the manufacturer's recommendations against compressing the insulation on the refrigerant lines not just outside or in the walls, but also inside the wall-mounted unit itself.

During the first season of use of the newly-installed Sanyo split system air conditioner the building occupants noticed water stains and rippled wall paint extending down the wall below the indoor air handler cooling unit.

Our photo (left) shows where the refrigerant lines rise in the wall to enter the wall-mounted half of the split system air conditioner (that larger white area below the left end of the unit) and the blue tape marks where we first saw condensate water dripping from the unit.

On inspection we ran the air conditioner for an hour or so on a hot humid day, then inspected the wall surface for moisture. Simply touching or pressing on the plastic bottom of the wall-mounted cooling unit sent a cascade of water droplets down the building wall interior surface.

We gave our A/C installer a call and asked for help. To his credit, the tech came immediately to the job site.

Disassembling and inspecting the indoor cooling unit by removing its plastic cover and then lifting it carefully away from the wall mounting bracket (watch out to avoid bending refrigerant lines and causing a refrigerant leak), he found that there was no insulation whatsoever on the refrigeration lines that ran horizontally along the rear bottom of the unit.

The result was condensation on the refrigeration lines that did not drip into the unit's condensate tray but rather fell into the plastic bottom where water leaked out onto and into the building wall.

The condensate tray in a wall-mounted split system air conditioner or heat pump unit is designed to catch water condensing on the cooling coils, directing it to a drip pan and then to the condensate drain line.

But depending on routing of the refrigerant lines, these may provide another source of condensation that does not fall into the tray.

The "fix" for this condensate leak was the installation of foam insulation along the refrigerant lines inside the unit, from their point of exit from the building interior wall surface to their point of connection to the cooling coil. The leak was stopped.

Is it OK to see No Condensation on Un-Insulated Refrigerant Piping?

Yes, in some circumstances we don't expect to see condensate on exposed lengths of uninsulated refrigerant piping.

- On the high pressure refrigerant line that's normally hot we won't see condensation.

- On heat pump systems where the role of runs of refrigerant tubing swap between high side (high pressure) and low side (suction or negative pressure) we won't see condensate on the refrigerant line that is warm because it's functioning as the "high side" or high pressure line.

...

Protect outdoor refrigerant line insulation from the weather

Manufacturers also recommend wrapping the insulated refrigerant lines exposed to outdoor weather, using an appropriate weatherproof tape.

Weather-resistant refrigerant piping insulation?

Hi-I have a Misubushi HE split system, live on the coast. The insulation on the refrigerant lines is exposed to the elements, runs under the house which is on pilings and deteriorates rapidly, exposing the copper lines. On 2021-04-30 by Chris Robbins -

Are there any recommendations for insulation that might stand up better, ? waterproof?

Thanks

On 2021-04-30 by (mod) - refrigerant line insulation recommendations for coastal or hostile environments

@Chris Robbins,

Absolutely, there are refrigerant tubing insulation products that are more-durable for tough conditions like your coastal area, and thanks for a helpful question that I'd not considered.

1. Coated refrigerant tubing:

Let's start with what you should be using for actual refrigerant tubing, since salt in the air at coastal areas is quite corrosive to copper tubing:

Happily there are polyethylene-coated or plastic-encased copper tubing products that can serve for refrigerant piping and that, through that coating, resist corrosion in coastal or damp or hostile environments.

We also use the same product for oil line piping when the line runs in contact with a concrete floor or masonry foundation.

Shown in our image above is Gas-Tec's 1/2" OD x 50' Coated Copper Refrigeration Tubing Coil (Yellow) that the company describes as follows:

Gas-Tec® is a flexible yellow polyethylene-coated copper tubing that is continuously line-marked for clearer identification and protection of Natural Gas and Liquefied Petroleum Gas installations.The polyethylene coating provides added corrosion protection and enables the tubing to be used for both above and below ground installations. The continuous line markings on the coating indicates tube contents, ASTM specification, size and lot number which enable the tubing to be traced back to the origin of manufacture.

Gas-Tec is flexible and easy to install with no additional training required.

Added Corrosion Protection:

Polyethylene coating protects copper from corrosion - Polyethylene is one of the most inert plastics available, Can Be Used for Both Above & Below Ground

This product is sold by HVACR suppliers including supplyhouse.com where I found this image.

2. Jacketed refrigerant tubing insulation:

Now for refrigerant tubing insulation, the slip-on foam insulating products most HVACR techs use is quite durable except where exposed to lots of sunlight; in that location - even up north where we've worked in NY or MN I see the insulation beginning to crack and crumble after 5-10 years.

Two options include

- using a polyethylene flexible tube-covering sized large enough to fit over the insulation - this is a good add-on image if your pipe inslulation is currently in acceptable condition.

- using a refrigerant tubing insulation product like Armacell's Armaflex insulation that combines foam insulation with a UV-resistant outer jacket - this is a good option for new refrigerant piping installations in environments where there is extra risk of corrosion or exposure to other harsh conditions.

Here's what the company says:

ArmaFlex Shield - Continuous Coil Pipe Insulation

New ArmaFlex® Shield flexible foam insulation from Armacell is a moisture-resistant and UV-resistant product with a durable protective jacket specially designed for line set, HVAC and refrigeration applications.This tough coating can take the abuse of challenging installations and stands up to the effects of weather and extreme elements like UV, heat and cold, making it a great choice for outdoor applications.

For a durable refrigerant tubing insulation job the company says you ought to seal all of the insulation joints, including the end butt-joints using a suitable adhesive like their ArmaFlex 520 adhesive.That's probably most-important where the material is exposed to the weather, and might be less critical under the floor over a crawl area and where you're also using a polyethylene-coated copper tubing.

- source: https://www.armacell.us/products/armaflexshield/

Above an image of the Amraflex product. There are probably other similar durable-insulation products on the market that will also perform better than the traditional snap-on foam refrigerant line insulation material.

Duct Taped Refrigerant Insulation?

For the record, I tried cleaning up the insulation at this outdoor refrigerant line in New York, taping it with black duct tape. Here's the new installation - it looked great. For a while.

But to set the record straight: less than 10 years later, this is what that attractive duct-taped refrigerant tubing insulation job looked like today.

You may agree with me that duct tape outdoors is not a durable "solution" to making the refrigerant piping insulation weather-resistant.

...

Choosing a Brand or Type of Refrigerant Pipe Insulation

Is it OK for an air conditioner or heat pump installer to substitute the brand of copper refrigerant line insulation?

I’m having a Mitsubishi ductless mini split installed. The contractor uses PMD Gelcopper insulation instead of the Mitsubishi type. Is making the switch a good idea?

I’m having a Mitsubishi ductless mini split installed. The contractor uses PMD Gelcopper insulation instead of the Mitsubishi type. Is making the switch a good idea?

Thanks,M.A. [private email], 2016/03/24

[Click to enlarge any image]

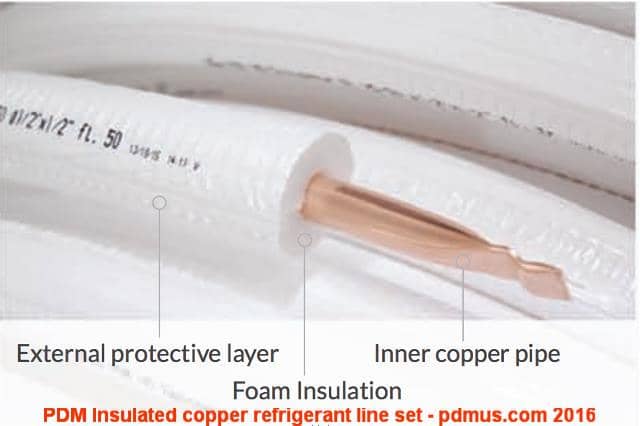

Shown at left: PDM Gelcopper insulated copper refrigerant-tubing line set from PDMUS. This product provides pre-insulated copper refrigerant tubing.

The insulation is polyethylene closed-cell foam on copper tubing. Detailed technical specifications and the ASTM Standards with which this product complies are provided by the manufacturer at the web page we cite below.

Moderator Reply:

Fair question, M.A., I don't know for sure what insulation you are asking about. Insulation on what

? I presume you refer to PDM (not PMD) foam insulation on refrigerant tubing on a split system A/C or heat pump. As long as the insulating properties and weather and damage resistance of the alternative insulation meet the original Mitsubishi specifications I doubt that there is a concern with the change you cite.

You can of course contact Mitsubishi directly to ask if they have an opinion.

PDM Gelcopper is a polyethylene closed-cell foam refrigeration tubing insulation. I'm doubtful that changing the insulation choice affects system operation. Of course depending on where the insulation is installed its life may vary. For example insulation products vary in durability where exposed to sunlight and weather. Here is what the manufacturer says:

R410a approved: Gelcopper can be used in applications where high-pressure gases are used as refrigeration source. UV resistant: Gelcopper is UV resistant Paintable: the insulation can be painted to match the surroundings.

PDM US recommends product installation under plastic duct to protect it from severe weather conditions, accidental damages or theft.

- PMD US, 640 Celriver Road, Rock Hill SC 29730, USA, Website: pmdus.com, Tel: 803-909-8100, Email: info@pmdus.com Retrieved 2016/03/24, original source: http://pdmus.com/wp-content/uploads/2014/01/PDMUS_GelCopper_LineSets.pdf

What Insulation Should I Add to Stope Condensation Dripping on This Pipe Elbow?

I have a question on how to insulate the pipe shown, it is getting condensation from the cold water in the condensate drain from the A/C unit in the floor above and was dripping through the drywall in the ceiling below - On 2023-03-03 by Shawn

Reply by InspectApedia Editor - Other Insulation Options to Avoid Condensation

@Shawn,

Sure, glad to help. One thing to keep in mind that will always encourage us when solving an unfamiliar building problem is that it's pretty likely that anything we run up against has occurred before and that someone has probably already figured out a good solution. The work is in the looking.

In this case, there are various reasons that we have to insulate P-traps like the one shown in your photo - to reduce the risk of freezing is the main one.

Below we show a pre-fabricated P-trap insulation system provided by Proto Corporation, a provider of PVC covers and insulation for P-traps.

In addition to pre-fabricated add-on P-trap insulating covers - almost certainly available at your local plumbing supplier and maybe at a big-box store building suppliers, other plumbing and other insulating product manufacturers, such as Nomaco Insulation,. describe as an alternative, simply using flexible closed-cell pipe insulation of a proper size, cut and fit into place on the job.

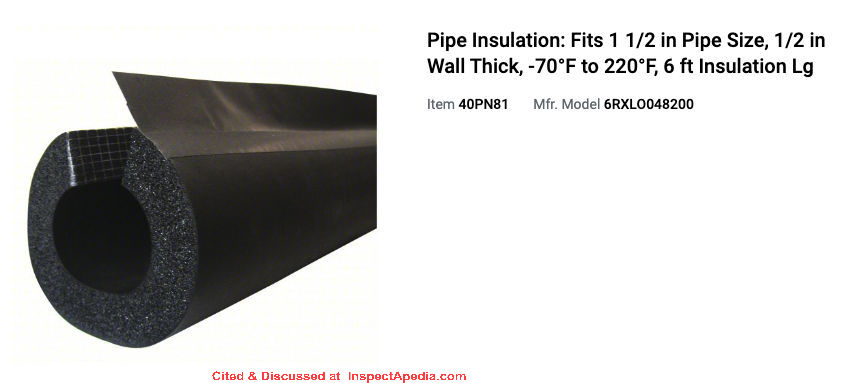

So if your P-trap is 1 1/2" in outside diameter, you'd buy flexible closed cell foam pipe inslulation (we'll show an example below) that can be cut, including cutting some ends at a 45 degree mitre to fit nicely around that P-trap.

Take a look at

P-TRAP INSULATION, STANDARD SIZING CHART [PDF] Proto Corporation, protocorporation.com - retrieved 2023/03/05, original source: PVCproducts-page/specialty-fitting-covers/standard-p-trap/

For a description of using flexible snap-on or slide-over closed cell foam pipe insulation to insulate a P-trap, take a look at this advice from Nomaco

P-TRAP INSULATION PROCEDURE for BENDS & TRAPS [PDF} Nomaco Insulation, - retrieved 2023/03/05 original source: www.nomacoinsulation.com/pdf/installation%20guidelines/TA03%200909.pdf

Illustration below: pipe insulation such as we just described, from Grainger (grainger.com)

...

HVAC & Refrigerant Piping / Tubing Insulation Guides, Manuals, Research

- Alzoubi, M. Development of a high-performance compact refrigeration cooling prototype [PDF] Master thesis, Masdar Institute of Science and Technology (2014).

- Deshmukh, Gajanan, Preeti Birwal, Rupesh Datir, and Saurabh Patel. "Thermal insulation materials: A tool for energy conservation." J. Food Process. Technol 8, no. 04 (2017): 8-11.

- discusses alternative thermal insulation materials, propeties, benefits. - Kapp, Sean, Jun-Ki Choi, and Kelly Kissock. "Toward energy-efficient industrial thermal systems for regional manufacturing facilities." Energy Reports 8 (2022): 1377-1387.

- Kayfeci, Muhammet. DETERMINATION OF ENERGY SAVING AND OPTIMUM INSULATION THICKNESSES OF THE HEATING PIPING SYSTEMS FOR DIFFERENT INSULATION MATERIALS [PDF] Energy and buildings 69 (2014): 278-284.

Note that this is for heating, not cooling, piping, possibly aconsideration also in heat pump systems depending on the auxiliary or backup heat system type.

- McIrwin, Oliver, Mark Fraser, David Ashby, and José Terán. "GMT refrigerant-based cooling system and design considerations." In Ground-based and Airborne Telescopes VII, vol. 10700, pp. 879-899. SPIE, 2018.

- Trane Guide to INSTALLING REFRIGERANT PIPING [PDF] (2011) as part of its training series, Trane Corporation, website: www.trane.com/, retrieved 2021/03/23 original source: .tranebelgium.com/files/book-doc/20/en/20.aqerykdx.pdf The company has offices world-wide.

- Yildiz, Abdullah, and Mustafa Ali Ersöz. DETERMINATION OF THE ECONOMICAL OPTIMUM INSULATION THICKNESS FOR VRF (VARIABLE REFRIGERANT FLOW) SYSTEMS [PDF] Energy 89 (2015): 835-844.

Abstract

This study deals with the investigation into optimum insulation thickness of installed inside building pipe network of VRF (variable refrigerant flow) systems.

Optimum insulation thickness, energy savings over a lifetime of 10 years and payback periods are determined for high pressure gas pipelines, low pressure gas pipelines and low pressure liquid pipelines under the heating-only and cooling-only modes of the three-pipe VRF system using R-410A as refrigerant.

By using the P1–P2 method, the value of the amount of the net energy savings is calculated. Under heating mode of VRF system, while the optimum insulation thickness varies between 16 and 20 mm depending on the pipe sections of high pressure gas pipeline, it varies from 11 to 13 mm for the pipe sections of low pressure liquid pipeline.

Under cooling mode of VRF system, the optimum insulation thickness varies between 7 and 8 mm for pipe sections of low pressure gas pipeline and low pressure liquid pipeline.

A principal reason that people add insulation on the suction line is to avoid problems with condensation along the piping and its route. - [6] REFRIGERANT PIPING GUIDE [PDF] , Application Guide AG-31-011, McQuay Air Conditioning, Daikin McQuay International Equipment, 13600 Industrial Park Blvd., Minneapolis, Minnesota 55441 USA Tel: 800-432-1342 (Toll Free), Website: http://www.daikinmcquay.com/, [Copy on file as https://inspectapedia.com/aircond/AC_Guide_McQuay.pdf ]

...

...

Continue reading at REFRIGERANT PIPING INSTALLATION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see REFRIGERANT PIPING INSULATION FAQs - questions and answers about insulation on refrigerant pipes or tubing, posted originally at the end of this page.

Or see these

Recommended Articles

- CONDENSATION or SWEATING PIPES, TANKS

- REFRIGERANT GASES & PIPING - home

- REFRIGERANT PIPING INSTALLATION

- REFRIGERANT PIPING DAMAGE & LEAKS

- REFRIGERANT PIPING GURGLING

- REFRIGERANT PIPING INSULATION

- REFRIGERANT LINE MOUNTING

- REFRIGERANT LINE NAIL PROTECTION

- REFRIGERANT PIPING LENGTH vs DIAMETER

- REFRIGERANT TUBING BRAZING & SOLDERING

- REFRIGERANT TUBING FLARE CONNECTIONS

- REFRIGERANT TUBING ECONOMIZER & HEATING TRICKS

- REFRIGERANT PIPING UNDERGROUND, BURIED

- REFRIGERANT PIPING CODES & STANDARDS

Suggested citation for this web page

REFRIGERANT PIPING INSULATION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Stephen Stanczyk, Washington State Licensed Home Inspector #221, Safe Haven Inspections, Email: steve@safehaveninspections.com

- [2] Modern Refrigeration and Air Conditioning, A. D. Althouse, C.H. Turnquist, A. Bracciano, Goodheart-Willcox Co., 1982

- [3] Principles of Refrigeration, R. Warren Marsh, C. Thomas Olivo, Delmar Publishers, 1979

- [4] "Air Conditioning & Refrigeration I & II", BOCES Education, Warren Hilliard (instructor), Poughkeepsie, New York, May - July 1982, [classroom notes from air conditioning andRefrigeration and Air Conditioning Technology, 5th Ed., William C. Whitman, William M. Johnson, John Tomczyk, Cengage Learning, 2005, ISBN 1401837654, 9781401837655 1324 pages

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.