Types of Water Supply Piping

Types of Water Supply Piping

Chapter 13 of How to Build Your Dream Home © 2020 InspectApedia.com

- POST a QUESTION or COMMENT about how to identify the architectural style of buildings and building components

This article series provides an updated version of Hubbard Cobb's Your Dream Home, illustrated by Sigman-Ward, first published by Wm. H. Wise & Co. New York, 1950.

From site selection and obtaining financing through each step in construction of a single family home the simple procedures and drawings in this book are still useful for anyone building or repairing a home or other small structure.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Types of Water Supply Piping

This is a section of Chapter 13 of BUILD YOUR DREAM HOME at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

This is a section of Chapter 13 of BUILD YOUR DREAM HOME at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Once you have the rough shell of the house completed, the job of roughing in the plumbing system should be done. This will consist of installing all the pipes through the walls and ceiling for the fresh-water supply and the drainage system as well as installing the various outlets for the plumbing fixtures.

The fixtures themselves will be installed after the interior walls have been finished.

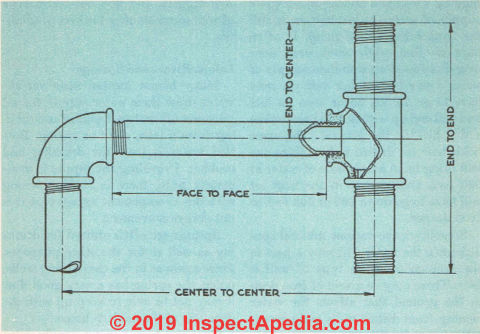

Fig. 3. When cutting and measuring iron pipe, be sure to take into account the fact that the pipe will extend some distance into the fitting.

[Click to enlarge any image]

In spite of what you may hear, be told or read, there is no one metal used for water pipes that is suitable for every water condition that you might run into. To be sure, certain types of pipe have definite advantages over others.

but in so far as the pipe’s ability to withstand the corrosive action of certain kinds of water goes, it is impossible to generalize.

Practically any water taken from the ground will have certain corrosive characteristics. In the case of iron pipe, the corrosive quality of the water will cause rust.

If the water is very corrosive, the rust inside the pipe will in time become so great as to completely clog up the lines and prevent water from flowing through. It will also cause the pipes to fail in time—usually at the joints, for here the metal is at its thinnest.

In the case of yellow brass pipe, water containing certain specific corrosive elements will dissolve the zinc from the copper-and-zinc alloy and cause the pipe to fail. Red brass and copper are highly resistant to corrosion, but even they can be damaged by certain types of water.

Hard water, that is, water containing a high percentage of mineral salts, is usually less corrosive than soft water. On the other hand, these minerals in the water will attach themselves to the sides of the pipe, thus reducing the flow of water. This is more apt to happen in the hot-water system than in the cold supply because as the water is heated, it tends to release these minerals more readily than when cold.

See details about water softeners to remove minerals (calcium and magnesium and some iron) found in hard water by reading at WATER SOFTENERS & CONDITIONERS - home

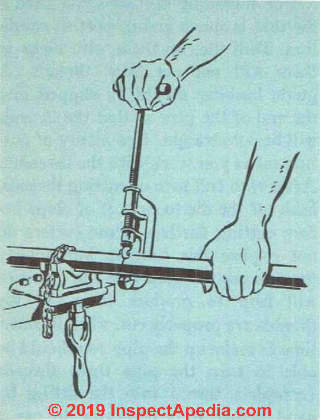

Fig. 4. You will need a pipe vise and cutter if you use galvanized-iron pipe for the plumbing system.

Once you know what minerals and chemicals are contained in the water, select the pipe that will give the longest service. Even if this should be the most expensive type of pipe on the market, it will still be cheaper in the long run than having to replace the plumbing system in a few years. On the other hand, when an inexpensive type will give as good service as the expensive, it is sensible to select the cheaper.

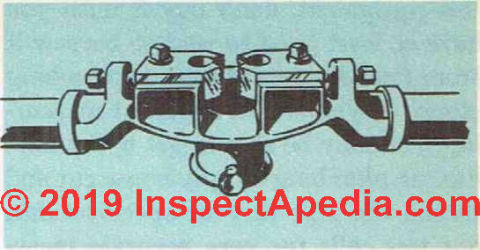

Fig. 5. Stock and die used for cutting threads on iron pipe.

Fresh-Water Supply Pipe Choices

In the 1950s, the three most popular pipes used for the house fresh-water supply—and this includes the hot as well as the cold system—were galvanized steel, brass pipe and copper tubing.

Of these three, in the 1950s galvanized steel was the least expensive and has been used for years in domestic plumbing systems. A somewhat similar type of pipe but one that is more expensive and more resistant to corrosion is genuine wrought-iron pipe.

In most parts of the world, by the 1970s copper pipe was widely used for water supply piping and sometimes for waste pipes as well. Compared with galvanized iron pipe, copper is considerably easier to cut and join using soldered fittings or in some cases flare fittings.

Modern water supply piping in many parts of the world uses plastic piping such as PEX, joined by special fittings. Flexible plastic supply pipes reduce the number of joints needed and is quick and easy to install.

See details about types of plastic water supply piping at PLASTIC PIPING ABS CPVC PB PEX PVC - home

Galvanized Steel (Iron) Water Pipe Installation

Fig. 3. When cutting and measuring iron pipe, be sure to take into account the fact that the pipe will extend some distance into the fitting.

Making Joints in Galvanized Steel Pipe

Galvanized steel pipe comes in lengths of 20 feet. Sections of pipe are joined together with threaded fittings. These threads will extend a certain distance into the fittings or couplings and this fact must be taken into consideration when measuring and cutting the pipe.

To allow for the distance that the pipe extends into the fittings at each end, the pipe must be cut a little longer than the actual distance between the fittings. See Fig. 3.

Allow about 1/2" for fittings such as valves, couplings and elbows at each end of 1/2-inch pipe.

Allow 9/16" for 1-inch pipe.

Allow 11/16" for the 2-inch pipe used in the drainage system.

To work with galvanized steel pipe you are going to need a pipe vice, a pipe cutter, (Fig. 4) a reamer, a die for cutting the pipe threads and two pipe wrenches for making up the pipe. See Fig. 5.

If you do not have any of this equipment, don’t buy it until you have at least tried to rent or borrow it from friends or hardware or plumbing stores. If you are an expert at measuring, you may be able to get by by having the plumbing-supply house cut and thread the pipe to your specifications, but this calls for very accurate measurement.

Much of the trouble found in plumbing systems with galvanized steel pipe is due to the fact that the pipes were not properly cut and threaded.

Poor threads are almost sure to cause leaks at the joints. Unless the pipe is properly threaded, a good joint cannot be obtained, and unless the pipe is cut right, it is impossible to get it properly threaded.

The tool used for cutting galvanized steel pipe must have a good sharp cutting wheel. Be sure that the cutter is properly centered and that the cut is made at the exact point marked on the pipe. The first cut must be square. If it is not, then make a fresh start.

The tool used for cutting galvanized steel pipe must have a good sharp cutting wheel. Be sure that the cutter is properly centered and that the cut is made at the exact point marked on the pipe. The first cut must be square. If it is not, then make a fresh start.

After the pipe has been cut, ream it out to remove the burr left by the cutting. This is an important step because if these little burrs are left inside the pipe, they will collect sediment and this may in time cause a serious stoppage.

For threading the pipe you need a die that is sharp and in perfect condition. Dull dies or those with nicks in them will not cut good threads. A guide bushing should be slipped into the end of the pipe so that the threads will be cut straight.

Use plenty of cutting oil as you work with the threader. After each full turn of cutting threads, back off the die to clear it of chips before cutting further. Some cutters do not require this caution, but quality threads are the goal and this practice will help to produce them.

If the threads are properly cut, when it comes time to make up the pipe you should be able to turn the pipe three threads (complete turns) into the fitting by hand before it is necessary to use a wrench. The explanation of this is that pipe threads are tapered so that the deeper the threads extend into the fitting the tighter the joint becomes.

Actually, a well-cut threaded joint should be absolutely water tight by itself, but to take care of any small irregularities in the threads, it is wise to use pipe dope or pipe compound over the external pipe threads. Do not get any of this compound on the internal threads or it may cause an obstruction in the line.

See details about galvanized iron or galvanized steel water pipes at GALVANIZED STEEL WATER PIPING - home

Brass Water Supply Pipe Installation

Fig. 3. When cutting and measuring brass water pipe, as with galvanized pipe, be sure to take into account the fact that the pipe will extend some distance into the fitting.

Brass water pipe is more expensive than galvanized steel pipe and except for special applications is not normally used in new construction in modern homes (2019).

1950s advice: on the other hand, you could use brass pipe one nominal pipe size smaller and still get the same volume of water as with the larger galvanized steel pipe. This is because the inside of brass pipe is smooth while the interior of galvanized steel is rough.

A rough interior causes a certain amount volume of of friction as the water flows through and therefore produces a slow-down. Brass pipe is cut and threaded in the same manner as galvanized steel pipe.

While it is possible to use the same cutter and dies for brass as for steel, special equipment is available that is intended only for work with brass and this should be used when possible. These cutters and dies, because they are made for work in brass which is a soft metal, should not be used on galvanized steel pipe.

Ordinary pipe wrenches can be used to assemble brass pipe but they will leave burrs on the outer surface, which are a sign of less than perfect workmanship.

For a first-class job, special friction vices and wrenches should be used with brass pipe so that the surface is not damaged.

In making up joints, use wicking as well as pipe compound. The wicking should be twisted around the external threads in the same direction that the threads are turned into the fitting.

See details about brass water pipes at BRASS WATER PIPES - home

Copper Water Pipe

Copper tubing has one great advantage over either brass or galvanized iron and that is the ease with which it can be installed. See Fig. 6.

Copper tubing has one great advantage over either brass or galvanized iron and that is the ease with which it can be installed. See Fig. 6.

Flexible copper tubing comes in long rolls up to 100 feet in length. See Fig. 7. The tubing is strong enough to withstand handling but it is also soft enough so that it can be bent around obstructions, saving both time and the cost of various fittings. This is

a great help for the amateur plumber because with rigid pipes it is necessary to have the exact measurements for a run of pipe between two fittings, but with copper the tube can be cut a little too long and then be bent slightly until it is just the right length.

Copper tubing, like red brass, will withstand very well the corrosive elements found in most water.

Copper tubing (above) has a great advantage over rigid pipe (below) in that the copper tubing can be installed with a minimum of fittings.

Fig. 7. Copper tubing comes in rolls up to 100 feet in length.

One common mistake made about copper tubing, however, is the belief in its ability to withstand freezing. It is true that water inside soft-drawn copper tubing can be frozen several times before the tube itself is damaged, but repeated freezings will burst it eventually. Hard-drawn tubes will be damaged by freezing just like other types of rigid pipe.

Types of Copper Pipe: Type K, Type L

Copper tubing is either hard drawn or soft drawn. There are also two wall thicknesses, type K copper pipe for the heavy and type L copper pipe for the light. Type L can be used in most instances, unless the water happens to be extremely corrosive, in which case the heavier type K should be used. Tubing comes in sizes from 1/8" to 2".

Copper tubing can be used for the entire plumbing water supply system, including the service entrance. In fact, if you had difficulty in digging a trench from the house to the source of water because of large rocks and it is impossible to get a straight trench, copper tubing is about the only thing you can use unless you want to spend many extra hours trying to fit rigid pipe into the trench.

Another advantage that copper tubing has over galvanized steel or brass is that while brass and steel are both weakened at the joints because it is necessary to cut into the pipe to make threads, in copper tubing the joints are stronger than any other part. This is due to the type of fittings used with copper.

See details of copper pipe installation at

Plumbing Pipe Size Selection

The size of pipe necessary for house plumbing is discussed

This entire chapter is also available as PLUMBING SYSTEM INSTALLATION [eBook], or as a PDF image at THE HOUSE PLUMBING SYSTEM [PDF] original page images.

...

Continue reading at XCOPPER PIPE INSTALLATION - next section of this chapter, or go to book contents at BUILD YOUR DREAM HOME, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these sections of Chapter 13 - PLUMBING SYSTEM INSTALLATION

- PROPER PLUMBING WORK is IMPORTANT

- WATER SUPPLY SOURCES

- TYPES of PIPING MATERIALS

- COPPER PIPE INSTALLATION

- COPPER FLARE CONNECTIONS

- PIPE SIZE SELECTION

- CAST IRON PIPE INSTALLATION

- PLUMBING SYSTEM LAYOUT PLAN

- PLUMBING FIXTURE INSTALLATION BATH KITCHEN

- WATER HEATERS & TANKS

- PLUMBING SYSTEM PRESSURE TESTS

- SEPTIC TANK, DRAINFIELD INSTALLATION

- PLUMBING MATERIALS LIST for the basic house

Or see these

Recommended Articles

- ABS PLASTIC PIPE

- BUILD YOUR DREAM HOME

- CAST IRON DRAIN PIPING

- PLUMBING SYSTEM INSPECT DIAGNOSE REPAIR - home

- PLUMBING VENT DISTANCES & ROUTING

- SUPPLY PIPING - home

- WATER SUPPLY & DRAIN PIPING - home

Suggested citation for this web page

TYPES of PIPING MATERIALS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about how to identify the architectural style of buildings and building components

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.