Best Practices Guide to Finishes for Wood Floors

Best Practices Guide to Finishes for Wood Floors

- POST a QUESTION or COMMENT about choosing, applying, inspecting or troubleshooting floor finish coatings

This article explains how to choose and apply finishes to wood flooring.

This article series discusses and provides a best construction practices guide to the selection and installation of building interior surface materials, carpeting, doors, drywall, trim, flooring, lighting, plaster, materials, finishes, and sound control materials.

Our page top photo shows a satin polyurethane applied by the editor (D Friedman) over a hand-restored 1850's wide plank floor in Wappingers Falls, NY. No stains were used. Original paint, a mixture of oxblood and milk, had to be stripped by hand. Power floor sanding would have risked grinding the floor to an un-natural flatness.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Wood Floor Finishing Guide

As described in the book, Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) Chapter 5, Interior Finish:

If possible, allow the home’s heating, ventilating, and air conditioning (HVAC) system to run for two weeks after the flooring is installed before sanding and finishing.

The most common site-applied floor finish today is oil-based polyurethane, although waterborne urethanes are rapidly gaining market share due to their fast drying, low level of volatile organic compounds (VOCs), and non yellowing appearance (although “ambering” formulas are now available).

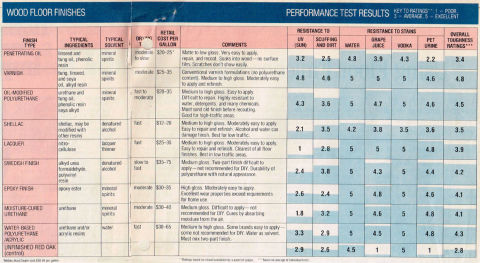

For those seeking a more rustic, lower-gloss appearance and willing to wax and buff periodically, traditional oil sealers and wax remain an option. Finishing options are summarized in Table 5-6.

[Click to enlarge any image]

Penetrating Sealer and Wax Systems Useful for Solid Wood Flooring

These finishes are generally made from mixtures of linseed or tung oil, sometimes with synthetic polymers and additives to improve hardness and drying time. Usually two coats of a penetrating sealer are applied, followed by a coat of wax, providing a low-sheen, rustic appearance. While easy to apply, the finish is fairly high-maintenance, requiring periodic buffing and rewaxing to keep it looking good.

Over time, the wax will become discolored from dirt and grime and will need to be stripped. In its favor, high use areas of the floor are easy to touch up without sanding and refinishing the entire floor.

Surface Finishes for Solid Wood Floors

Most site-applied finishes today are oil-based or water-borne urethanes applied to the surface of the wood in three or more coats. In general, any high quality urethane applied properly will provide a durable, moisture-resistant surface.

While water-borne finishes had some quality problems when first introduced for residential use in the late 1980s, they have continually improved and now offer durability equal or superior to traditional oil-based urethanes. While most floor finishes claim in their marketing to be the toughest, hardest, and longest lasting, moisture-cured urethane is generally considered the toughest site-applied finish.

The most durable finishes, some with warranties of up to 25 years, are available only on factory-finished flooring.

Whatever finish is applied, follow the manufacturer’s instructions closely. The following recommendations apply to most site-applied finishes:

- After sanding, wipe the floor with a lint-free tack cloth and allow to fully dry. Use mineral sprits for oil-based finishes, water for water-borne finishes.

- If you use a stain or penetrating sealer, make sure it is completely dry before applying the top coats.

- Make sure the temperature is right—65°F to 85°F for most finishes. Colder will delay drying; hotter will dry too fast and the finish will not level.

- Keep indoor humidity from 45% to 75%. Higher humidity will delay drying and can harm the finish.

- Provide exhaust ventilation during drying. Poor ventilation can cause a soft or rough finish.

- Allow each coat to fully dry before applying the next coat. Multiple thin coats make the best finish.

- Lightly abrade finish between coats as recommended by manufacturer. (Not required with some water-borne finishes if recoated within 3 to 6 hours—follow manufacturer’s recommendations.)

Prefinished Strip and Plank Flooring.

Many solid wood floor products are now available prefinished in thicknesses from 1/2 to 3\4 inch for roughly twice the price of comparable unfinished wood. In addition to speeding up the installation and eliminating the dust and fumes associated with job-site finishing, these finishes have several other advantages:

- The most durable finishes, such as UV-cured urethane and acrylic impregnation, can only be applied in a factory (see Table 5-6 shown above)

- Finishes are applied in a dust-free, controlled environment.

- Factory finishes typically carry long-term warranties.

- There are no surprises in the color of the finished floor.

The main disadvantage of this approach is that the installer must take extra care not to mar or scratch the finishes during installation, adding to the installation cost.

Also, most prefinished flooring is chamfered to some degree to hide the inevitable differences in thickness from one board to the next, called overwood, which results from small variations in water absorption, swelling, and shrinking among flooring boards. Debris or irregularities in the subfloor can also cause an uneven surface.

The grooves in deeply beveled flooring tend to trap dirt and can cause problems when it is time to sand and refinish, particularly with stained flooring. Unless the bevels are sanded away, they are hard to strip and difficult to match, leaving dark lines in the refinished floor.

One approach is to refinish before the old finish is completely worn through by just lightly abrading the surface prior to recoating or using one of the no-sand refinishing products.

To address these concerns, most flooring manufacturers now offer prefinished flooring products with no bevel (square edged) or nearly invisible “microbevels” that minimize the effects of a beveled edge.

Maintenance and Reconditioning Procedures for Solid Wood Floors

A sealed and waxed floor typically needs rewaxing no more than once or twice a year to keep it looking good.

With surface coatings, most manufacturers do not recommend waxing. If a surface-coated floor gets lightly scratched over time but has not worn through to bare wood, it can be recoated in most cases without complete re sanding.

After thoroughly cleaning the floor with a non residue cleaner, rough up the old finish with steel wool, light sandpaper, or a sanding screen, then apply a new coat of finish. Many coating manufacturers now offer no-sand refinishing products as well, formulated to bond to the old finish without sanding.

No wood floor should be flooded with water during cleaning. Either use a dry mop or a wet mop that has been squeezed dry. Water can find its way between floor boards and through scratches, swell the wood, and undermine the finish.

- - Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

Resources: Manufacturers, Industry Associations, & Sources of Indoor Flooring & Floor Finishes

Table above: comparing the featutres and costs (1988) of wood floor finish choices, adapted from Rodale's Practical Homeowner, February 1988, p. 82-83 available below as a PDF

[Click to enlarge any image]

Prefinished Wood Flooring Sources

- Alloc Inc. www.alloc.com Snap-together, no-glue long-strip and single-strip laminated flooring

- Anderson Hardwood Floors www.andersonfloors.com Laminated strip, nail, glue, and floating

- Armstrong World Industries www.armstrong.com Bruce, Hartco, and Robbins prefinished plank and engineered strip

- BAMBOO FLOORING

- BHK of America www.bhkuniclic.com Snap-together, no-glue laminated wood flooring

- Columbia Wood Flooring www.columbiaflooring.com Prefinished solid strip

- Duro-Design www.duro-design.com Floating click-lock oak flooring

- Gammapar www.gammapar.com Engineered wood strip with oil, UV-cured urethane, or acrylic-impregnated finish

- Junkers Hardwood www.junkershardwood.com Floating solid strip with metal clip installation

- Kahrs www.kahrs.com Laminated strip with UV-cured acrylic urethane, nail, glue, or floating

- Lauzon www.lauzonltd.com Prefinished strip, laminated strip, and click-lock laminated plank

- Mannington Mills www.mannington.com Laminated strip and plank with polyurethane and aluminum-oxide finish

- Medallion Hardwood Flooring www.medallionhardwood.com Prefinished solid hardwood strip and plank with aluminum-oxide finish

- Tarkett Wood Floors www.harris-tarkett.com Prefinished solid hardwood, laminated, and long-strip flooring

- MercierWood Flooring www.mercierdurable.com Prefinished solid strip and laminated strip with aluminum-oxide finish

- PermaGrain Hardwood Flooring www.permagrain.com Acrylic-impregnated laminated strip and plank

- Zickgraf Hardwood Flooring www.zickgraf.com Prefinished solid strip with UV-cured urethane with diamond and aluminum oxide

- Sloan, David, USING FLOOR FINISHES SAFELY [PDF] Rodale's Practical Homeowner, February 1988, p. 84-86

- CHOOSING a WOOD-FLOOR FINISH [PDF] Rodale's Practical Homeowner, February 1988, p. 78-83

- FLOOR FINISH PERFORMANCE COMPARISON [PDF] Rodale's Practical Homeowner, February 1988, p. 82-83

- - Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

...

Continue reading at FLOOR, WOOD INSTALLATION GUIDE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

Suggested citation for this web page

FLOOR, WOOD FINISHES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING FLOORING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.