Heating System Low Water Cutoff Safety Switches LWCOs

Heating System Low Water Cutoff Safety Switches LWCOs

Installation, operation, location, repair of LWCOs

- POST a QUESTION or COMMENT about diagnosing & repairing LWCOs low water cutoff switches & controls on heating boilers

Boiler low water cutoff control service or repair: Here we explain Low Water Cutoff Controls: Guide to LWCOs on steam heating and hot water heating systems and we provide a low water cutoff switch Troubleshooting & Repair Guide.

LWCOs are installed on most steam heating boilers and also on many hydronic or "hot water" heating boilers as a safety device to shut down the boiler in the event of loss of water in the system.

This article series answers most questions about central heating systems to aid in troubleshooting, inspection, diagnosis, and repairs.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

A Guide to Inspecting and Flushing Low Water Cutoff Valves on Steam Heating Boilers

What is a low water cutoff valve or LWCO?

What is a low water cutoff valve or LWCO?

In order to avoid a heating boiler explosion or damage from loss of water, the low water cutoff is a device intended to shut down unsafe heating equipment by turning off electrical power to the oil burner or gas burner should the water level or pressure in the heating system fall below a safe level.

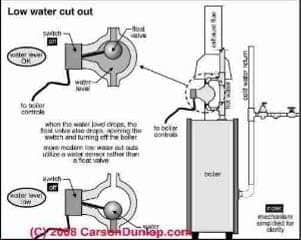

The schematic at left, courtesy of Carson Dunlop Associates, explains how the low water cutoff valve works.

[Click to enlarge any image]

In short, LWCOs are among multiple heating system safety controls that help prevent a boiler explosion or BLEVE

See BLEVE EXPLOSIONS.

Low Water Cutoff - LWCO's On heating boilers: this steam heating boiler safety device contains a mechanical or electronic sensor to monitor water level in the boiler.

LWCOs are installed on many modern residential hydronic (hot water) heating boilers and on virtually all steam boilers.

LWCOs are also installed on all commercial boilers of both types.

Low water cutoff valves are installed on all steam boilers, most commercial heating boilers, and some home heating boilers (hydronic or hot water heating systems).

Low water cutoff valves are installed on all steam boilers, most commercial heating boilers, and some home heating boilers (hydronic or hot water heating systems).

Original LWCO valve designs like the low water cutoff mounted on the face of the boiler shown at left used a mechanical float which operated not unlike the float arm in a toilet tank.

As water level drops the arm moves down and ultimately trips a mechanical switch that operates an electrical contact to turn the heating system off.

Watch out: Mechanical-float LWCOs are subject to jamming due to sludge that forms in the steam boiler as water is lost and mineral debris is left behind.

Electronic LWCOs: Newer LWCO controls replace the mechanical float switch with a sensor, reducing the chances of a cutoff malfunction.

By monitoring boiler water level and turning off the oil or gas or electric heat source to the heating boiler should water level drop too low in the steam boiler, this important safety device prevents damage to the boiler should the system lose its water.

Sediment and Low Water Cutoff Valves - Flushing Needed: how to use the Steam Boiler Blowdown Valve

As we explained above, mechanical-float LWCO's need to be flushed to remove sediment that could prevent the cutoff from working. In the photo at page top you can see that the owner has left a 5-gallon plastic bucket below the low water cutoff drain pipe.

As we explained above, mechanical-float LWCO's need to be flushed to remove sediment that could prevent the cutoff from working. In the photo at page top you can see that the owner has left a 5-gallon plastic bucket below the low water cutoff drain pipe.

That's for flushing out the LWCO valve.

Watch out: if the low water cutoff valve is not flushed often enough, the residue of solid debris (minerals, rust, dirt, also referred to as "TDS" or total dissolved solids) can clog the low water cutoff valve so that it will stop working and could fail to sense an unsafe low-water condition in the heating boiler.

Low boiler water level can lead to costly boiler damage or even a BLEVE explosion.

Ask your heating service technician how often your LWCO needs to be flushed.

In the photo at left you can see that the system has two low water cutoff valves installed, at two different levels on the steam boiler. Perhaps this setup was installed for an extra measure of safety?

Since steam heating systems are constantly using water, losing some of it as water vapor venting at steam radiators, and regaining water as the automatic (or on some systems manual) water feeder replaces water in the system, these systems tend to produce sediment at the boiler.

If sediment collects in the low water cutoff valve it could prevent the valve's internal float from falling as water level in the steam boiler drops, thus preventing the valve from safely shutting down the boiler should water level fall to an unsafe level.

For this reason the low water cutoff valve needs to be flushed regularly, often once a week.

How to Use the Blowdown Valve - Steam Boiler Low Water Cutout Valve Flushing Procedure

Watch out: improper boiler LWCO low water cutoff valve purging or flushing can damage a boiler. Proper purging of the LWCO valve is done by slowly opening the valve's drain line, allowing the flush-water to drain into a bucket that will be dumped appropriately.

As boiler experts note, purging too quickly can cause the LWCO float arm to jerk down suddenly, bending or damaging the float or its linkage. This risk is greater on high-pressure steam boilers than on low-pressure residential steam boilers.

When blowing down a control at pressure, the blow down valves should be opened slowly.

The piping needs to be warmed up and stagant water in the drain piping needs to be pushed out. Suddenly opening a blow down valve causes steam to condense, which may create water hammer.

Damage to components can occur when water hammer occurs due to improper bl ow down piping.

For these reasons, McDonnell & Miller recommends a dual valve blow down system for each control. Blow down the low water cut-off when the water level is at its normal level (pump/valve off) and the burner is on. - McDonnell Miller (2015) cited below.

When we flush a steam boiler or a hydronic heating boiler low water cutoff valve we:

- Place a 5-gallon bucket

under the end of the flush valve drain pipe, being careful not to bang into piping and maybe cause a leak - Open and shut the flush valve several times,

opening it briefly - just a few seconds, then closing it each time. This avoids a large surge of cold water entering (and possibly damaging) a hot steam boiler, and it also seems to help stir up and remove sediment from within the low water cutoff valve. - Watch for clear water:

After flushing the LWCO valve several times, when we see that clear water is coming out of the boiler, the job has been done. But notice: often if you hold the flush valve open longer than just a few seconds, you may see clear water coming from the boiler. - Check for clear flush-water once more:

But if you close the flush valve and open it again you may see new brown sludge water coming out of the valve again!

So when we think we've cleaned out the low water cutoff valve by this flush procedure, we close the valve, wait about 15 or 20 seconds, and then try it once more. If we see that the first water coming out of the valve on this last try is clear too, then we figure we've flushed out the valve successfully. - If an automatic water feed valve is installed:

you'll hear new water flowing into the boiler just after each time you open and flush the LWCO valve.

That's another reason to do this flush procedure gradually - so we don't damage the boiler by filling it with lots of cold water when the boiler is itself very hot. We discuss automatic water feeder valves for steam boilers

at WATER FEEDER VALVE, STEAM - If only a manual water makeup feed valve is installed:

you'll need to add water to the steam boiler, filling it back to the "full" line marked on or behind the sight glass. We discuss manual water feeder valves for steam boilers

at WATER FEEDER VALVE, STEAM.

It's best to add water to the steam boiler slowly to reduce the chances of cracking (more of a risk with cast iron boilers). - Usually the

total volume of water flushed i

s 2-4 gallons. - Dump the flushed boiler water

down a building drain or into another approved outdoor area where some rust and sludge won't contaminate anything, but to not dump hot water into a cold sink or toilet - it may crack.

Safety warning: Be careful, when a steam boiler has been running, water coming out of the low water cutoff flush valve is hot and can scald a bystander.

Watch out: don't confuse water well low-water cutoff controls with heating system low water cutoff controls. The low water cutoff devices that we discuss here are intended for protecting the safe operation of building heating boilers or steam boilers.

Heating low water cutoff devices (LWCO) are distinct from and have nothing to do with the well piping or building water supply cutoff safety devices discussed

If you don't know what kind of heat your building uses, we explain how to figure out the answer

If your heating system is not working properly,

see NO HEAT - BOILER or NO HEAT - FURNACE. Contact us to suggest text changes and additions and, if you wish, to receive online listing and credit for that contribution.

Question: How low should the water go when the low water shutoff works

How low should the water go when the low water shutoff works ? The reading on the sight glass [would be where?]

This question was posted originally

Reply: below the SAFE level marked on the boiler or sight glass

If the boiler or steam boiler water is anywhere BELOW the SAFE LEVEL marked at or behind the sight glass but still visible, that would be a safe LWCO level to shut off the boiler.

That would be consistent with the instructions for LWCO's I've read.

The manufacturer marks a "safe" water level right on the boiler.

That is in fact the point at which the LWCO valve should operate. On some LWCOs such as some McDonnell Miller models there is also a line marked right on the control body too.

Watch out: do not allow a boiler to continue to run if it is too low or has run out of water. LWCOs are among multiple heating system safety controls that help prevent

boiler BLEVE EXPLOSIONS.

For boilers using an automatic water feeder valve, the most-common cause of low boiler water level is failure to properly clean and maintain the water feeder valve, and the most-common cause of failure of the LWCO safety control to function is the same: failure to clean and flush the valve as specified by the manufacturer.

At LOW WATER CUTOFF VALVE NOT WORKING we describe the steps recommended by Hydrolevel if that company's CycleGard LWCO is not responding properly to low water levels in the boiler.

Question: where should the LWCO be mounted?

Does it matter on a modulating condensing boiler where the low water cutoff is located? - 2017/08/17

Illustration above showing acceptable locations for the low water cutoff on a hot water heating boiler, adapted from Hydrolevel's Safgard 1150 LWCO instructions cited below. [Click to enlarge any image]

Reply: the height or elevation or position of the low water cutoff sensor has to be correct

John

Watch out: Absolutely, yes, the height or elevation or position of the low water cutoff sensor has to be correct, but the sensor and control does not always have to be mounted right on the boiler itself.

While float type low water cutoffs must be installed on the boiler at an appropriate tapping or sometimes in conjunction with a gauge glass, probe-type LWCOs can be installed either into a side tapping on the boiler or for some equipment, the electronic sensor probe type LWCO can be mounted in a tee on the supply or return piping from and to the boiler.

Basically the LWCO sensor must be at or above the minimum safe water level for the boiler as specified by the boiler manufacturer.

Typically that line is also marked on the boiler itself - for steam boilers, but for a hot water or hydronic boiler you'd you may have to review the manufacturer's instructions. There is often an existing boiler side tapping reserved specifically for such a control.

Appropriate tee fittings can be installed on the supply or return piping for LWCOs to be mounted in those locations.

In some installations the device can work perfectly fine mounted on a tapping on the boiler OR on the water supply line or on its return line (at the right height).

The low water cutoff (LWCO) has a sensor - varying by the LWCO design - that has to be put into the boiler at a location that allows the sensor to detect the fall of boiler water below a "safe" level in the boiler.

On hot wter boilers using a Taco LTA-2 LWCO the control is installed as follows:

1. Install the probe above the minimum safe water level, as determined from the boiler manufacturer's literature. ... NOTE: This may be in a tapping on the boiler or in the boiler supply or return piping.

2. Install the probe to extend into the boiler cavity or piping to make contact with the water.

3. Install the probe so that the exposed portion of the stainless steel is a minimum of 1/4" from any grounding surface inside the boiler (to prevent the probe from shorting).

On hot water boilers using a Hydrolevel company's Safguard 1150 LWCO for hot water boilers are installed thus:

The Safgard 1150 must be installed at or above the minimum safe water level established by the boiler manufacturer.

The 1150 can be installed directly into the boiler if a suitable tapping is available .

The 1150 can also be installed in the boiler piping using a standard 3/4" tee.

On a Peerless hot water boiler such as the hydronic version of the Peerless Series 63/64™ Gas Boiler, the LWCO is installed as follows:

[Click to enlarge any iamge]

Low Water Cut-off Installation on a Hot Water Boiler (Level Control)

a. A hot water boiler installed above radiator level or as required by the authority having jurisdiction must be provided with a low water cut-off device either as part of the boiler or at the time of installation.

b. If a probe-type low water cut-off is used it should be piped into the boiler supply piping as shown in Figure 6.8.

Peerless steam boilers require that the LWCO be installed as follows:

Low Water Cut-off (Level Control):

a. Float Type: Install the float type low water cutoff (if provided) in conjunction with the gauge glass as shown in Figure 6.3.

b. Probe Type: Install the optional probe type low water cut-off into the 3/4" tapping on the right side of the boiler. Refer to Figure 6.2 for tapping location. The supplied control incorporates a 60 second off cycle after a 15 minute on cycle.

This feature allows the water level in the boiler to settle so that the probe can sense a true water level.

Source: PEERLESS Series 63/64 Gas Boilers INSTALLATION & OPERATION MANUAL [PDF] retrieved 2017/08/17, original source: www.peerlessboilers.com

Question: Should I Install a Low Water Cutoff / Water Feeder on my Hydronic (Hot Water) Heat Boiler?

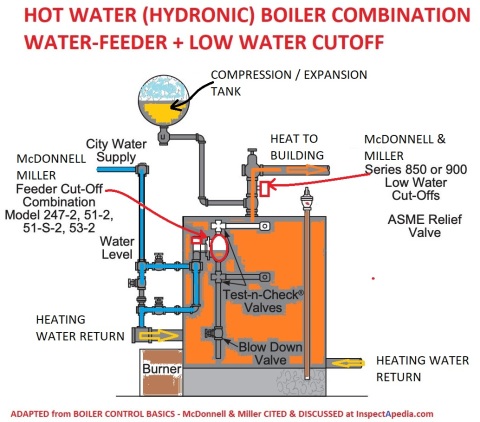

On 2019-11-06 by (mod) - Summarizing: example of LWCO & Water Feeder on a Hydronic (Hot Water) Boiler

For other readers: the pressure/reducer/water-feeder used on residential boilers does not really regulate the boiler pressure except insofar as the feeder will add water to the boiler if the boiler pressure falls below 12 psi (or other settings if the device has been adjusted or modified).

At the other end of boiler pressure, on a residential boiler the temperature/pressure relief valve will open and spill water (and pressure) if boiler pressure exceeds 30 psi.

So together those two devices manage the high end and low end pressures of the boiler.

The combination of starting water pressure in the cold boiler and the temperature to which the boiler rises are the main determinants of the actual operating pressure in the system - normally ranging between about 12 psi and under 30 psi. It's the aquastat that controls boiler temperature.

To be clear, in the U.S. ASME does not require that a LWCO (low water cutoff) float type control be installed on residential hydronic (water not steam) boilers; the International Mechanical Code (IMC) does want to see a LWCO on all boilers, both steam and hydronic. You can find LWCOs and water feed devices from various manufacturers including McDonnell & Miller.

The illustration below is adapted from

- McDonnell & Miller's HEATING BOILER BASIC OPERATION [PDF] McDonnell & Miller, retrieved 2019/11/06 original source: controlcomponents.com.au/Open-File/557/Boiler%20control%20basics.pdf

can also be downloaded free from InspectApedia.com - WATER FEEDER VALVE, STEAM illustrates the float controlled valve on a STEAM boiler - less common on residential boilers.

In North America and many other countries a residential hydronic boiler's water supply is controlled simply by an automagic boiler feed valve , and where required an additional backflow preventer to protect the water supply system piping - such as this Watts boiler feed valve (below)

Around our location in Mexico the same solar water heaters as your Costa Rica unit are very widely used.

Watch out: a water pressure-reducer feeder valve is NOT a heating boiler safety device and does not protect against loss of water from the boiler nor from improper boiler pressure conditions caused by other factors. The ONLY job of an automagic water feeder is to set the initial "cold" pressure in the boiler. That's why some codes and some inspectors want a separate LWCO even on residential hydronic boilers, not just on steam boilers.

- Glad to be of help from across our president's wall

On 2019-11-06 by Star - a float-controlled water feed valve is in my future

Thanks so much, really enjoying this!

As for: "won't regulate the temperature properly" - brain fart - meant to type 'pressure' not 'temperature' and missed it on the proof-read! Got the gist.

I repaired a leak in my radiator system on my Jeep Grand Cherokee (1998 5.9 Limited) with White Pepper - made a poultice and spooned it in - lasted for 60,000 miles+ until I sold it!

inspectapedia.com is such an excellent resource - 5 outta 5 on Trip Advisor ok?! Lol, too bad.

So a float-controlled water feed valve is in my future - I have one of those on the Chinese Solar Water Heater that I installed on my roof in Costa Rica :-)

On 2019-11-06 by (mod) -

Star

Well as you know there are "leak stop" products that can be added to a boiler to flow to and "stop" small leaks - though some experts worry that those products can foul other controls on the hydronic system. (My friend Paul poured oatmeal into his car radiator to stop a hot water leak there).

Re-posting your original comments made on the building WATER PRESSURE REGULATOR ADJUSTMENT page

...

Hey, excellent resource - thank you for all your hard work and long hours compiling it for our benefit!

We recently purchased a former commercial building that we are going to renovate and occupy as our home.

It comes with a 1970's hot-water heating system with a boiler (see attached photo). The makeup water valve has always been kept shut off, and the pressure in the 'closed' system drops by about 1lb every couple of days.

The residential zone is two storeys (2 zones to this system) and I've been keeping the pressure between 15psi and 18psi to push against the 12' of head pressure to feed the upstairs radiators.

My questions: does that sound correct so far? And, regarding the pressure regulator just after the makeup water valve - I was told that it's "faulty" and won't control the temperature properly (hence the makeup water cannot be left turned on, I have to bring it up to 18psi and then shut it off again). Do you think if I adjust the pressure regulator that I might get it to do what it is supposed to?

There's obviously a small leak somewhere - and the system has been gone over thoroughly before we purchased looking for leaks (found none that they would admit to ;-) ).

Any input would be appreciated, thanks. We'd like to be able to go away for a couple of months in the winter time but would have to hire someone to come in and tweak the pressure once a week or so as the system stands now.

Moderator further reply:

RE: does that sound correct so far?- I'm not sure which "that" sounds correct but in general losing water isn't generally OK for the reasons we've both cited: convenience and safety and reliability of the system;

If you refer to leaving the makeup water valve OFF - you can do that on a system that's being inspected and manually-fed often enough to keep it safe - but that's not acceptable for most residential heating systems as most homeowners simply won't do it or don't want to or don't know how.

If you refer to the statement that a defective water feeder "won't regulate the temperature properly" - geez I can't make sense out of that. The water feeder/pressure reducer has nothing to do with boiler temperature; its job is to feed water into the boiler at the proper cold-water-pressure level, usually 12 psi when the boiler has been off long enough to be cold.

For tall buildings you might need to boost the cold or starting boiler water pressure

a bit above 12 - which will be OK only if the pressure when the boiler is hot remains low enough so as not to dump the TPR valve. (That would also be unsafe).

If you mean "do you think I can get the pressure regulator to do what it's supposed to" - I answered that: yes by servicing it or if that doesn't work, replacing it.

Finally: for a typical two story residential hot water heating system you leave the controls as factory set at 12 psi cold.

Are your pressure calculations for pressure necessary to get hot water heat to the second floor of your building taking into account your elevation above sea level?

In general 1 psi will lift water 2.31 feet. The author's of B&G's nice book

- HOW HYDRONIC [HEATING] SYSTEM COMPONENTS REALLY WORK [PDF] point out on p. 8 that for a boiler located in the basement of a 2 story building you need to lift water from the boiler up a total of about 19 feet.

(19ft. total lift height) / 2.31 lift per ft = 8.23 psi. So 12 psi or even your 10 psi of cold boiler pressure would be fine.

Watch out: There are additional safety concerns with setting the boiler pressure too low including a risk, in a particularly hot boiler, of hot water flashing to steam at the top of the heating system - a dangerous condition as well as one that can make for strange noises in the heating system. So go with the factory settings.

You can get into trouble fooling around trying to fine-tune the starting pressure setting by adjusting the regulator (yours doesn't work anyhow) because when you observe or measure the system pressure you're thrown off by the actual temperature in the system - unless you let the system cool down completely.

Finally: "float operated" water feeders are used on steam boilers and can be installed on residential hydronic boilers too but are not common. Most people find that the pressure/reducer/regulator factory set at 12 psi will keep water in the boiler just fine for decades until that valve clogs up.

On 2019-11-06 1 by Star - how much pressure to get heating water to the second floor

As a retired JM Boilermaker/JM Boilermaker Welder (36 years) I'm still learning! This is small stuff compared to what I'm used to in my trade (ie 10" water feed piping, 72" gate valves, etc) but it's all working under the same principles of course. Back to my own personal house boiler.

Regarding the leak - don't believe I'll find it so I'm going to carry on as is. The tradesmen searching for the leak previously removed nearly all the insulation from the piping which is very unfortunate - and there is evidence of scale and deposits buildup at multiple locations, but nothing wet. The town we live in switched to a full R/O system about 10 years ago so the scale issue is done at least (particularly for build-up inside the pressure regulator on the screen).

From the calculations in my original comment (below, originally posted at PRESSURE REDUCING VALVE WATER FEEDER INSTALLATION) (multiply feet of rise by 0.43 and add 3#)

I have determined that I should only need about 10# pressure to feed the 2nd floor radiators. I'm going to let the pressure drop now until the radiators are cold on the 2nd floor and I'll know where the "sweet" spot is for certain.

Any danger in this? Is a vacuum created when the pressure drops too low?

You said: "While the manufacturers are careful to say that the pressure/reducer/regulator should not be used as an automatic water feeder, that's what almost everyone relies on in residential hot water heating systems." This page states: "a properly-installed float-operated water feed valve should all be installed." I take it to mean this is the proper alternative. I have been discussing the installation of such a device with my local plumber.

Thanks again for you time and trouble - please take a moment to answer my two questions above.

On 2019-11-06 by (mod) - can't find leak in hot water heating boiler ... now what?

Star

Star

I see a hydronic (hot water) heating boiler with at least 2 circulator pumps, and with what looks like asbestos lagging coating the boiler top and sides (if so, hazardous, do not disturb it).

You are right that a hydronic heating system should not be consuming water; there is a leak somewhere; often a small boiler leak seeps out on a hot component of the boiler, piping, or radiator/baseboard where the water evaporates; therefore you may not find a puddle or obvious leak point.

However there will in such cases always be a build-up of crud and corrosion and deposits of salts left behind as the water evaporates, so a careful and thorough inspection can find such leaks unless the leak is where piping or components are in an inaccessible area such as a wall or ceiling cavity.

While the manufacturers are careful to say that the pressure/reducer/regulator should not be used as an automatic water feeder, that's what almost everyone relies on in residential hot water heating systems.

Sometimes the regulator can be cleaned - there's a screen that clogs - to get it working again; most techs don't bother, they just replace it. Your system is, in a subtle way, unsafe if its water feed system isn't working since when no one is around the system loses water and can thus be damaged or could overheat.

Your comments are on a page for BUILDING water pressure regulators.

To read about the most-common type of pressure-reducer / regulator used on hot water heating systems please see

PRESSURE REDUCING VALVE WATER FEEDER INSTALLATION

On 2019-11-06 by Star

Hey, excellent resource - thank you for all your hard work and long hours compiling it for our benefit!

We recently purchased a former commercial building that we are going to renovate and occupy as our home. It comes with a 1970's hot-water heating system with a boiler (see attached photo). The makeup water valve has always been kept shut off, and the pressure in the 'closed' system drops by about 1lb every couple of days.

The residential zone is two storeys (2 zones to this system) and I've been keeping the pressure between 15psi and 18psi to push against the 12' of head pressure to feed the upstairs radiators.

My questions: does that sound correct so far? And, regarding the pressure regulator just after the makeup water valve - I was told that it's "faulty" and won't control the temperature properly (hence the makeup water cannot be left turned on, I have to bring it up to 18psi and then shut it off again).

Do you think if I adjust the pressure regulator that I might get it to do what it is supposed to?

There's obviously a small leak somewhere - and the system has been gone over thoroughly before we purchased looking for leaks (found none that they would admit to ;-) ).

Any input would be appreciated, thanks. We'd like to be able to go away for a couple of months in the winter time but would have to hire someone to come in and tweak the pressure once a week or so as the system stands now.

This discussion began at WATER PRESSURE REGULATOR ADJUSTMENT

LWCO Low Water Cutoff Valve Manuals & Instructions

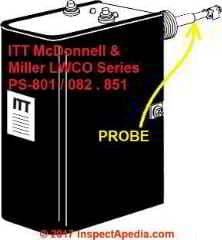

Illustration: A McDonnell & Miller LWCO PS-801-802 851 series probe type low water cutoff control. [Click to enlarge any image]

Illustration: A McDonnell & Miller LWCO PS-801-802 851 series probe type low water cutoff control. [Click to enlarge any image]

- Bell & Gossett HOW HYDRONIC [HEATING] SYSTEM COMPONENTS REALLY WORK [PDF] (2012) CounterPoint from B&G, Bell & Gossett (a Xylem brand), Xylem Inc. 8200 N. Austin Avenue Morton Grove, Illinois 60053 Phone: (847) 966-3700 Fax: (847) 965-8379 www.xyleminc.com/brands/bellgossett retrieved 2019/11/06 original souirce:

- Hydrolevel Safgard™ 400 Series Steam LWCO [PDF], Hydrolevel Company, 126 Bailey Road, North Haven, CT 06473 USA, Tel: (203) 776-0473 Website: www.hydrolevel.com Retrieved 2017/04/06, original source: http://hydrolevel.com/safgard-400-series-steam/

- Hydrolevel Safgard™ 450 Series Steam LWCO [PDF], retrieved 2017/04/06, original source: http://hydrolevel.com/safgard-400-series-steam/

- HYDROLEVEL SafGard Model 550/650/750 Low Water Cutoffs [PDF] retrieved 2017/04/06, original source: http://www.bryanboilers.com/pdfs/Vendor_Com/HydroLevel/550_650_750_opt.pdf

- HYDROLEVEL SafGard™ Model 1150 Low Water Cutoff for Residential Hot Water Boilers [PDF] retrieved 2017/08/17, original source: http://hydrolevel.com/wp-content/uploads/2015/12/Safgard-1150-LWCO-Installation-Sheet.pdf

- ITT McDonnell & Miller GUARDDOG® Model RB-24E Conductance Type Low Water Cutoff for Residential 24VAC Hot Water Boilers [PDF], (2009)ITT 8200 N. Austin Ave., Morton Grove IL 60053 USA, Tel: 847-966-3700 retrieved 2017/08/17, original source: https://www.torrco.com/ASSETS/DOCUMENTS/CMS/EN/83260_PROD_FILE.pdf

- McDonnell & Miller ITT Series 47 & 247 Mechanical Water Feeders, Series 47-2 & 247-2 Combination Mechanical Water Feeder & Low Water Cut-Off Installation & Maintenance Instructions [PDF], retrieved 4/23/2017, original source: http://s3.supplyhouse.com/manuals/1350993347279/84563_PROD_FILE.pdf

- McDonnell & Miller ITT Models 51, 51-2 & 53 Water Feeders & Models 51-2, 51-S-2 & 53-2 Feeder Cut-OffCombination Instruction Manual, [PDF] retrieved 4/23/2017, original source: https://www.nationalpumpsupply.com/content/pdf/mcdonnell-&-miller-series-51-51s-53-instruction-manual.pdf

- McDonnell & Miller SERIES 69 LOW WATER CUTOFF INSTRUCTION MANUAL [PDF] Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

USA Tel: (847) 966-3700

Website: www.mcdonnellmiller.com Retrieved 2019/02/15

Example LWCO MAINTENANCE SCHEDULE:

Blow down weekly (at least once) when the boiler is in operation.

Disassemble and inspect annually. Replace the low water cut-off if it is worn, corroded, or if components no longer operate properly.

Inspect the shield, float and bellows annually. Remove all sediment and debris.

We recommend replacement when the switch no longer operates properly.

If you choose to replace the switch, order the McDonnell & Miller replacement switch and follow the Repair Procedure provided.

Replace the low water cut-off every 10 years.

More frequent replacement may be required when severe conditions exist such as rapid switch cycling, surging water levels, and use of water treatment chemicals. - McDonnell & Miller PS-801 & PS-802 Low Water Cut-Offs PRODUCT SPECIFICATIONS [PDF], electronic operating probe-type LWCO control

- McDonnell & Miller PS-801 Low Water Cut-Off INSTALLATION & MAINTENANCE INSTRUCTIONS [PDF], electronic operating probe-type LWCO control

- McDonnell & Miller Low Water Cutoff LWCO Probe Type Series PS-801 Steam Boiler LWCO & Series PS-851 GuardDog Hot Water Boiler LWCOInstallation & Maintenance Manual [PDF], (2007) ITT, 8200 N. Austin Ave., Morton Grove IL 60053, Tel: 847-966-3700, Website: www.mcdonnellmiller.com

- McDonnell Miller Series 1575 Low Water Cutoff for Steam Boiler INSTRUCTIONS, mechanical unit, [PDF] (2015) Xylem Inc. 8200 N. Austin Avenue Morton Grove, Illinois 60053 Phone: (847) 966-3700 Fax: (847) 965-8379 www.mcdonnellmiller.com, retrieved 2017/04/06, original source: http://documentlibrary.xylemappliedwater.com/wp-content/blogs.dir/22/files/2013/10/MM-286C.pdf

- McDonnell & Miller ITT Series 150S & 157S Low Water Cut-Off Pump Controllers for Steam Boilers [PDF], retrieved 2017/04/06, original source: http://dominion.com.mx/fichas/control-de-nivel-mcdonnell-miller-259.pdf

- McDonnell & MIller, HEATING BOILER BASIC OPERATION [PDF] McDonnell & Miller, retrieved 2019/11/06 original source: www.controlcomponents.com.au/Open-File/557/Boiler%20control%20basics.pdf

- Safgard Low Water Cutoffs 550/650/750 Series 120VAC LWCO Manual from Bryan Boilers [PDF], retrieved 2017/04/06, original source: http://hydrolevel.com/wp-content/uploads/2015/12/Safgard-LWCO-550-650-750-Instructions-final-1.pdf

- Taco LF-Series Foam Compensating LOW WATER CUTOFF with Test Button & Dual Vision [PDF] (2009) retrieved 2017/04/06, original source: http://www.taco-hvac.com/uploads/FileLibrary/102-207.pdf

The probe of this device is installed "above" the manufacturer's minimum safe water level. - Taco LN-Series LWCO Instruction Sheet [PDF], op. cit.

- Taco LT-Series LWCO Instruction Sheet [PDF], op. cit.

- TACO® Comfort Solutions™ LTA-2 LOW WATER CUTOFF for HOT WATER BOILERS [PDF] (2009), retrieved 2017/08/17, original source: http://www.taco-hvac.com/uploads/FileLibrary/102-350.pdf

- Taco LTR Series LWCO for Hot Water Boilers [PDF], op. cit.

- Also see MANUALS for HEATING & A/C SYSTEM CONTROLS

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2023-08-27 by InspectApedia Publisher

@David Geer,

Essentially ALL Steam boilers would be expected to have a low water cut-off (LWCO).

While it's good practice, few residential hot water heating boilers (hydronic heat) have LWCOs, and fewer of those installed 40+ years ago.

The FIRST order of business for your boiler's safety is that it has a properly sized, installed, and tested pressure/temperature relief valve. (Search InspecdtApedia for "relief valves" to read details.

The second order of business for your boiler's safety is that its fuel supply and burner, combustion air, and combustion gas exhaust venting are all properly installed, set-up, and working.

So start by having your boiler inspected, cleaned, adjusted by an experienced heating service technician. Ask her to add to the basic procedure that she might use, additional steps to test the relief valve and to check and report to you on draft, CO detection, etc.

The third order of safety for your boiler is to be sure that you have working, properly located, installed, tested, smoke and fire and CO2 detectors.

Before going to the expense of adding a LWCO to your boiler make absolutely sure that the steps in the article above have been addressed.

or at a

heating boiler safety controls article like

FIRE SAFETY CONTROLS (if yours is an oil fired boiler)

Did you try the search box found at the top or bottom of our pages? Was our information hard to find or confusing?

Now PLEASE HELP US manage InspectApedia to keep it most useful and helpful buy telling me why you posted this question here on our Contact Us page rather than on one of the topic pages that address your question such as

On 2023-08-26 by David Geer

Were most hot water boilers made in the late 80s equipped with low water cut-offs? Mine is for baseboard heating. I can't afford a new boiler, but I want to at least ensure that it is unlikely to explode.

This reader's Q&A were originally posted at HOW TO CONTACT InspectApedia.com

On 2020-09-30 - by (mod) - Fulton steam Boiler - contact information

Scott:

I'm not clear if the issue is with surging, with a control improperly set, or with a clogged condensate return system.

If your local service technician hasn't sorted this out I'd contact the manufactuer's technical support:

Fulton has offices and sales in Canada, The U.S., Great Britain and China.

Fulton Boiler Works

3981 Fulton St.,

Pulaski NY 13142 USA

or

Fulton Thermal COrporation / Fulton Steam Solutions Inc. / Fulton Service Solutions Inc.,

972 Centerville Rd., Pulaski NY 13142 USA

Telephone: (315) 298-5121

For emergency assistance outside of normal business hours, you can reach a technician by calling (315) 298-5121 and following the prompts.

For other readers: Fulton produces both hydronic (hot water) and steam boilers;

the Fulton 15HP boiler is a small steam boiler like this recently-sold by firstechservices.com

On 2020-09-30 by Scott - Burks pump water level drop

Fulton 15 hp boiler. When Burks pump comes on water level drops low enough for low water shutdown to activate. Please help. New pump will put up 200psi approximately. Two new one way valves on supply line to boiler. All water level probes cleaned and inspected.

On 2019-01-26 - by (mod) -

Try flushing the control first, following the instructions for your particular brand and model.

ALso take a look at the steam boiler sight glass (assuming yours is steam heat) - to see if the boiler is surging.

On 2019-01-25 by jessica

lwco making rattling noise - what could cause this. On New Yorker boiler

On 2019-01-18 - by (mod) -

I don't understand the part about two out of four switches burned out.

Nor am I quite clear on which controls and bells we were discussing.

It sounds as if we a're talking about a safety device. All of its components need to work.

It sounds to me as though even though you've had a sort of Cloudy explanation you need a new low water cutoff valve or water feeder.

Ask your heating Service Company to send you an experienced service tech. Explain the system to you and to decide what Replacements are needed for safety.

On 2019-01-17 by Tracey

I had a water feeder installed. The plumber emptied the water byway of the low water valve. He began to bang on it quit hard with a wrench to release any rustication inside.

After installing the water feeder which never worked ,I now had to feed the boiler more often then before(every 2 days). The plumber's explanation was 2 out of the 4 switches in the low water valve have burnt out. Is this a possibility or could the banging on the valve have damaged it? The system is pretty old but was working fine until I had him install a water feeder.. I need your help please.

Thanks & Happy New Year

Tracey

On 2018-10-29 - by (mod) -

Check for voltage

On 2018-10-29 by Rosanna Raziah Mohamed

on my low water cut out ,every thing is working perfect but on the controls 'B' is not pulling in the gas valve

...

Continue reading at WATER FEEDER VALVE, STEAM or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see LOW WATER CUTOFF VALVE FAQs - questions and answers posted originally on this page

Or see these

Boiler Water Control Articles

- BOILER CLEANER CHEMICALS / TREATMENTS

- BOILER OPERATING PROBLEMS

- LOW WATER CUTOFF VALVE, BOILER

- LOW WATER CUTOFF VALVE NOT WORKING

- PRESSURE REDUCING VALVES

- MANUAL WATER FEEDER VALVES ON HOT WATER BOILERS

- AUTOMATIC WATER FEEDER VALVES ON HOT WATER BOILERS

- AUTOMATIC HEATING SYSTEM AUTOMATIC WATER FEEDER BUILT-IN BACKFLOW PREVENTER

- IS THE B&G PRESSURE REDUCER AN AUTOMATIC WATER FEED VALVE

- ADD A LOW WATER CUTOFF SAFETY VALVE?

- MAKEUP WATER REQUIREMENTS - HYDRONIC HEAT VERSUS STEAM HEATING BOILERS

- PRESSURE REDUCING VALVE (AUTOMATIC WATER FEEDER) HAS TWO ADDITIONAL FEATURES

- PHOTO GUIDE TO HEATING BOILER PRESSURE REDUCING VALVES

- WATER PRESSURE SETTING FOR A PRESSURE-REDUCING VALVE OR WATER FEEDER ON A HOT WATER HEATING SYSTEM

- AUTOMATIC WATER FEEDERS BUILT-INTO EXPANSION TANKS

- PRESSURE REDUCING VALVE TROUBLESHOOTING, INSPECTION, SERVICE & REPAIR PROCEDURE

- PRESSURE REDUCING VALVE WATER FEEDER INSTALLATION

- SIGHT GLASS, STEAM BOILER

- STEAM BOILER FLOODING / SURGING REPAIR

- STEAM HEATING SYSTEMS & CONTROLS - home

- WATER FEEDER VALVE, HYDRONIC BOILER

- WATER FEEDER VALVE, STEAM

Suggested citation for this web page

LOW WATER CUTOFF VALVE, BOILER at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to STEAM BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about diagnosing & repairing LWCOs low water cutoff switches & controls on heating boilers

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.