Water Well Bore Alignment & Plumbness

Water Well Bore Alignment & Plumbness

Standards for straightness of Well Bores

- POST a QUESTION or COMMENT about installing, diagnosing, repairing, or replacing all of the components and controls for private well water systems.

Water well bores or drilled well casings need to be straight and more-or-less plumb. A bore that is not straight may not be able to have its pump installed or may cause vibration and failure of some well pump types.

Here we list standards and procedures for assuring a properly straight and sufficiently plumb drilled well bore or casing and we explain why those parameters are important.

These water, well, and water supply equipment articles answer inspection, diagnosis, and repair questions about the building water supply sources and equipment including water testing, water piping, water pumps, water wells, & water tanks.

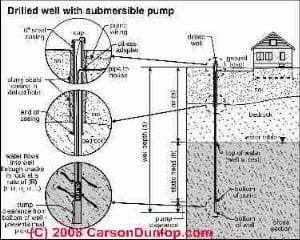

Page top illustration courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing firm.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Water Well Bore Alignment & Plumbness

Question: deep well deviation limit from vertical/plumbline

2020/07/05 Anon by private email said:

What is deep well deviation limit from vertical / plumbline ?

Any material for deviation measurement please share. - Anon, Lahore, Pakistan

[Click to enlarge any image]

Moderator reply: Drift or plumbness vs Alignment of water wells

Ahmed

Thank you for asking a very helpful question; I will add a section to our article above, in which I will list standards for water well bore plumbness and alignment. Meanwhile one of my preferred sources on water well bore or casing alignment and plumbness, because of its clear and direct language is the following:

Drift or plumbness is the amount a given borehole deviates from true vertical. Alignment is the measure of straightness, or conversely the lack of excessive twists or doglegs. A well can be straight but not plumb, but a perfectly plumb well will always be straight.

Alignment is the more important factor in a well, since a pump (particularly turbines) cannot be installed if the well is crooked beyond a certain amount.

Lack of plumbness by itself does not affect pump installation and only at extremes may impact pump life and operation; therefore, insufficient plumbness (or excessive drift) is rarely a problem encountered in modern well construction.

B. STANDARDS.

The AWWA standard allows a drift deviation of two/thirds the well's inside diameter per one hundred feet of depth.

The EPA standard is a deviation from plumbness of one degree per fifty feet of depth (Johnson, Groundwater and Wells 2d. page 333).

It is not uncommon, however, to see requirements as tight as three inches per hundred feet in recent projects.

Note that the problem with each of these standards is that a well which is sufficiently straight to accept the pump may fail the test.

Conversely, a well can meet the drift standard yet still have a tight enough bend in the casing to prevent the installation of the pump.

-source: Indiana State Department of Health cited below.

Reader follow-up:

The AWWA standard allows a drift deviation of two/thirds the well's inside diameter per one hundred feet of depth.

If a well ( 18 inch inner Dia casingis) is 250 ft deep then does it mean according to AWWA standards the allowable deviation is 30 inch??? I have to check 250 ft casing (18 inch) for pump lowering.

Considering 2/3 of inner Dia per hundred ft.

Moderator reply:

I make it .66 x 18 = 11.9 inches spread uniformly over 100 ft.

Do you agree?

Reader follow-up:

Sure I fully agree. Extending the same for 300 ft

Would it be. 66*18*3=36 inch approximately? Almost 2.5 ft. Allowable deviation?

It is a big value ...so I want to ask is this standard valid for 300 ft. ?

Moderator reply: acceptable well bore alignment variation must be distributed over bore depth not concentrated in one spot

Above: long, rigid submersible pumps and well piping, San Miguel de Allende, Guanajuato, Mexico.

[Click to enlarge any image]

The blue submersible pump shown here was bolted to large-diameter galvanized iron pipe and certainly would have jammed if being forced down a drilled well casing that was out of alignment by greater than the recommended standards we discuss here.

I think that's right (keep in mind I'm not a well engineer) - but what's critical is the distribution of the variance.

That deviation, to be acceptable, would have to be spread uniformly over the entire depth of the well casing.

As I understand it, any bend that's sharper would be unacceptable.

You can't sneak in a sharper bend over a shorter distance and then pretend you've averaged it over the whole well depth.

To be clear, the issue isn't that a well casing is not straight or plumb, it's that if it's too out of plumb or too crooked over a too-short distance then the pump or piping will bind.

The Indiana DOH statement makes this objective clear while giving no number at all. But we need a number to make sense of the guideline.

Watch out: also in my OPINION that the risk of binding up a pump in a well casing or bore also depends on the dimensions of the pump itself. As you probably know better than I, some pump models are much longer than others.

2.6 Plumbness and Alignment Each drilled well should be tested for plumbness and alignment.

The bore of the hole should be suciently plumb and straight that the casing will not bind as it is installed.

The casing should be suciently plumb and straight that it will not interfere with installation and operation of the pump.

Water Well Bore or Casing Alignment & Plumbness Standards & Measurement Procedures

- AWWA, A100-15 WATER WELLS STANDARD, (Strawn 2019)

Excerpt: Appendix D: Maximum allowable horizontal distance between the actual well centerline and a straight line representing the proposed pump centerline shall not exceed one-half of the difference between the inside diameter of the casing and the desired maximum outside diameter of the proposed pump to be installed. - AWWA,

A100-90: STANDARD FOR WATER WELLS [PDF] available at: https://www.awwa.org/Store/Product-Details/productId/18417

Description:

This standard covers the construction of water wells ranging in nominal diameter from 8 in. (200 mm) through 30 in. (750 mm). Certain minimum requirements are presented that can be incorporated by reference into the purchaser's specifications.

This standard is intended for large municipal and industrial wells that are constructed using normal well-drilling techniques. Major topics covered are: investigation of geologic/hydrologic conditions and groundwater quality; construction; well casings; well screens; gravel pack; grouting and sealing; plumbness and alignment; well development; performance testing; well disinfection; water quality testing; and abandonment of test holes, partially completed wells, and completed wells.

Appendices cover gravel pack installation methods, grouting and sealing methods of placement; plumbness and alignment procedure for testing; methods of measuring operating parameters during development, water sampling; factors influencing the duration of pumping test; abandonment of test holes, partially completed wells, and completed wells; geophysical bore-hole logs; types of wells; and collapse strength of well casing. - Brooks, Andrew G., and Harry Wilson. "An improved method for computing wellbore position uncertainty and its application to collision and target intersection probability analysis." In European Petroleum Conference. Society of Petroleum Engineers, 1996.

- CGA. Article 400–WATER WELL DRIFT & ALIGNMENT TESTING [PDF] - Adopted by the CGA Board of Directors on April 11, 1992 - California Groundwater Association Website: www.groundh2o.org , retrieved 2020/07/05, original source: groundh2o.org/resources/Documents/article_400.pdf

- DePonty, Jersy D.

, Shane P. DePinto

, Grant S. Kornrumph

, and Marvin F. Glotfelty, WATER WELL PLUMBNESS AND ALIGNMENT STANDARDS –

ANALYSIS AND RECOMMENDATIONS FOR OPERATIONAL APPLICABILITY [PDF] - retrieved 2020/07/05 original source: http://azwwa.org/wp-content/uploads/2013/11/PA-article.pdf

Excerpt:

This study considered two common water well standards to evaluate plumbness and alignment criteria; the American Water Works Association (AWWA) Standard for Water Wells (A100-06) and the standard detailed in the Handbook of Ground Water Development (Roscoe Moss Company, 1990).

The Environmental Protection Agency (EPA) plumbness standard of 1 degree of deviation per 50 feet is also common, but was not included in this study since it is much less stringent than the AWWA or Roscoe Moss standards, and was not applicable to the wells being evaluated.

The AWWA standard is common in the water well industry and is widely used by municipalities, private utilities, industry and consultants.

The Roscoe Moss standard provides the primary basis for the plumbness and alignment requirements used in the current SRP well drilling specification.

Both of these standards are appropriate for large diameter water production wells, and are applicable to the use of line-shaft vertical turbine pumps. - Drilling Today, "NECESSITY OF PLUMBNESS AND ALIGNMENT OF WATER WELLS" in Drilling Today, Drilling Today House, A-145, Lehri Marg, Shivpuri, Airport Road, Airport Road Sanganer, Jaipur 302011 INDIA 91

Telefax: +91 141 2793166, 2792336 Mobile: +91 9414 219 166, +91 9460 435 474

Visit:www.dthrotarydrilling.com Write us: drillingtoday@yahoo.com retrieved 2020/07/05 original source: https://www.dthrotarydrilling.com/Technical-paper/Alignment-Water-Wells/Necessity-Plumbness-Alignment-Water-Wells.html

Excerpt:

A borehole may be straight but not plumb, if the borehole is plumb it will be straight. In practice some tolerance of deviation is straightness and plumpness is permissible. In a conventional drilling a deviation from plumpness of 2/3rd the wells inside diameter per 100 ft (30.5 mts) of an anticipated pump setting is permissible, considering various difficulties of drilling in different types of formation.

Out of two factors, the straightness of the bore hole is most important, because it gives an idea whether or not particular size of pump can be lowered up to the desired depth of a constructed well. - Hossain, M. M., M. K. Rahman, and S. S. Rahman. "Hydraulic fracture initiation and propagation: roles of wellbore trajectory, perforation and stress regimes." Journal of Petroleum Science and Engineering 27, no. 3-4 (2000): 129-149.

- Indiana State Department of Health, RECOMMENDED STANDARDS for PRIVATE WATER WELLS - Section 2.6 PLUMBNESS & ALIGNMENT [PDF] - Indiana State Department of Health

Environmental Public Health Division

100 N. Senate Ave., N855

Indianapolis, IN 46204 USA

(317) 233-1325 retrieved 2020/07/05 original source: www.in.gov/isdh/23258.htm

Excerpt:

2.6 Plumbness and Alignment Each drilled well should be tested for plumbness and alignment.

The bore of the hole should be suciently plumb and straight that the casing will not bind as it is installed.

The casing should be suciently plumb and straight that it will not interfere with installation and operation of the pump. - Knapp, Seth R. "Method and apparatus for straightening well bore holes." U.S. Patent 2,829,864, issued April 8, 1958.

- Mcneely, Jr Branch M. "Means for controlling directional deviations in a well bore." U.S. Patent 3,043,381, issued July 10, 1962.

- NGWA, NGWA-01-14 Water Well Construction Standard, National Ground Water Association 601 Dempsey Rd. Westerville, OH 43081 USA customerservice@ngwa.org (800) 551-7379 (614) 898-7791

- Proposed NGWA/ANSI WATER WELL CONSTRUCTION STANDARD [PDF] Ground Water Protection Council, Inc. 13308 N MacArthur Blvd Oklahoma City, OK 73142 405-516-4972 , retrieved 2020/07/05 original source: http://www.gwpc.org/sites/default/files/event-sessions/5a_McCray_Kevin_0.pdf

- Rafferty, Kevin. SPECIFICATION of WATER WELLS [PDF] ASHRAE Transactions 107, no. Pt 2 (2001).

Excerpt: For larger wells or those using lineshaft pumps, a more sophisticated test involving a device for measuring deviation of the bore is necessary. - Strawn, Jennifer, "Plumbness and Alignment, Do your wells meet the standard?" in Water Well Journal, January 22, 2019, Email: strawnj2@gmail.com.

Excerpts:

If you’re primarily drilling domestic wells or other small-diameter, shallow wells, it’s not likely a small deviation in plumbness or alignment will cause problems.

However, on deep wells or wells to be equipped with lineshaft turbine pumps, the plumbness, straightness, and alignment of the well is extremely important to the operation of the pumping equipment.

Plumbness is the horizontal deviation of the well centerline from a true vertical centerline. A well can be straight and not plumb.

Alignment refers to horizontal deviation between the actual well centerline and a straight line.

A well that is not plumb or is misaligned (the casing contains bends or “doglegs”) can put excess wear and tear on the pump.

... To test the well for plumbness, you’ll need to complete a plummet test. The plummet test uses a tool constructed of a rigid spindle with two truly round plates or rings at both ends spaced 1.25 times the inside diameter of the casing.

The plates or rings should be ½-inch smaller than the inside diameter of the casing and have holes or some other way for water to pass through it as it is lowered into the well.

The plumb line should be attached exactly in the center of the plummet, and the plummet should weigh enough that the plumb line is kept taut. - Stow, George Raymond Snewin. "Modern Water-well Drilling Techniques In Use In The United Kingdom." Proceedings of the Institution of Civil Engineers 23, no. 1 (1962): 1-14.

- US EPA, MANUAL of WATER WELL CONSTRUCTION PRACTICES [PDF] U.S. Environmental Protection Agency,

- USFGS, POTABLE WATER SUPPLY WELLS [PDF] see 3.2.3.2 Test for Plumbness and Alignment,

- Wong, J., Han, L., Stewart, R.R., Bentley, L. and Bancroft, J., 2009. Geophysical well logs from a shallow test well and automatic determination of formation velocities from full-waveform sonic logs. CSEG Rec, 34, pp.21-30.

Excerpt:

The geophysical well logs presented in this study gave useful information regarding the near-surface geological and hydrogeological characteristics of the Paskapoo Formation at the Rothney Observatory site near Priddis, Alberta

...

Continue reading at DRILLED WELLS, STEEL CASINGS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- DRILLED WELLS, STEEL CASINGS

- PITLESS ADAPTERS - Definition & use of a pitless adapter at water wells

- WATER PUMPS, TANKS, TESTS, WELLS, REPAIRS - home

- WELL BORE ALIGNMENT PLUMBNESS STRAIGHTNESS - standards, test procedures, why well bore alignment is important

- WELL CAPS & COVERS for well casing cap sealing & venting requirements

- WELL CASING DIAMETER CHOICE - the effects of larger diameter well casings on the static head in a well

- WELL CASING LEAK REPAIRS

- WELL CLEARANCE DISTANCES how far should the well be from the septic, road, property borders, buildings

- WELL FLOW RATE how do we find out well water quantity - well flow rates or draw down tests

- WELL FLOW TEST PROCEDURE how can a homeowner or home buyer make a simple well water quantity test

- WELL PIPING LEAK DIAGNOSIS - a leak in the water piping anywhere between the well bottom and the building can wreak havoc

- WELL YIELD IMPROVEMENT how to improve well water yield - steps to try before drilling a new well

Suggested citation for this web page

WELL BORE ALIGNMENT PLUMBNESS STRAIGHTNESS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Drinking Water from Household Wells - PDF, U.S. EPA, Original source last retrieved 2/13/2013, original source: http://www.epa.gov/privatewells/pdfs/household_wells.pdf

- [2] Salzman, James, Drinking Water: A History, Overlook (2012), ISBN-10: 1590207203, ISBN-13: 978-1590207208, Quoting product description:

In Drinking Water, Duke University professor and environmental policy expert James Salzman shows how drinking water highlights the most pressing issues of our time--from globalization and social justice to terrorism and climate change--and how humans have been wrestling with these problems for centuries. From the aqueducts of Rome to the revolutionary sewer system in nineteenth-century London to today’s state-of-the-art desalination plants, safety and scarcity of water have always been one of society’s most important functions. - [3] Soll, David, Empire of Water: An Environmental and Political History of the New York City Water Supply, Cornell University Press, (2013), ISBN-10: 0801449901, ISBN-13: 978-0801449901, Quoting: product review

"Empire of Water chronicles the fascinating story of New York City's water supply, which comes mostly from reservoirs in the Catskills and, remarkably, is unfiltered. That's because the city has spent billions of dollars and decades of effort working with residents, businesses, and governments in the Catskills to protect the reservoirs from pollution caused by runoff from roads, farms, and dairies. This meticulously researched and persuasively reasoned history explores the change in New York City’s attitude toward water, from indifference to profligate water waste and environmental pollution to stalwart champion of water conservation and protection. The best histories shed light on the past as they illuminate the present. Empire of Water is in this category. By protecting the ecosystem services provided by a pristine watershed in northern New York, the city avoided having to spend $8 billion to build a treatment plant. As we confront water shortages in the United States and across the world, Empire of Water teaches that business as usual—looking for new oases and relying on massive engineering solutions—no longer makes sense. We must acknowledge nature’s limits and work within them to secure a sustainable future for coming generations."—Robert Glennon, Regents’ Professor and Morris K. Udall Professor of Law and Public Policy, University of Arizona, author of Unquenchable: America's Water Crisis and What To Do About It - [4] Mithen, Steven, Thirst: Water and Power in the Ancient World, Harvard University Press (2012), ASIN: B00EDZ5OHC. Quoting product review at Amazon:

Water is an endangered resource, imperiled by population growth, mega-urbanization, and climate change. Scientists project that by 2050, freshwater shortages will affect 75 percent of the global population. Steven Mithen puts our current crisis in historical context by exploring 10,000 years of humankind’s management of water. Thirst offers cautionary tales of civilizations defeated by the challenges of water control, as well as inspirational stories about how technological ingenuity has sustained communities in hostile environments.

... Mithen blends archaeology, current science, and ancient literature to give us a rich new picture of how our ancestors lived. Since the Neolithic Revolution, people have recognized water as a commodity and source of economic power and have manipulated its flow. History abounds with examples of ambitious water management projects and hydraulic engineering—from the Sumerians, whose mastery of canal building and irrigation led to their status as the first civilization, to the Nabataeans, who created a watery paradise in the desert city of Petra, to the Khmer, who built a massive inland sea at Angkor, visible from space.

As we search for modern solutions to today’s water crises, from the American Southwest to China, Mithen also looks for lessons in the past. He suggests that we follow one of the most unheeded pieces of advice to come down from ancient times. In the words of Li Bing, whose waterworks have irrigated the Sichuan Basin since 256 bc, “Work with nature, not against it.” - [5] Pabich, Wendy J., Taking on Water: How One Water Expert Challenged Her Inner Hypocrite, Reduced Her Water Footprint (Without Sacrificing a Toasty Shower), and Found Nirvana, Sasquatch Books (2012), ASIN: B00EB0JTB6, Quoting Amazon product review:

When Wendy Pabich received a monthly water bill for 30,000 gallons (for a household of two people and one dog), she was chagrined. After all, she is an expert on sustainable water use. So she set out to make a change. Taking on Water is the story of the author's personal quest to extract and implement, from a dizzying soup of data and analysis, day-to-day solutions to reduce water use in her life. She sets out to examine the water footprint of the products she consumes, process her own wastewater onsite, revamp the water and energy systems in her home, and make appropriate choices in order to swim the swim. Part memoir, part investigation, part solution manual, the book is filled with ruminations on philosophy, science, facts, figures, and personal behavioral insights; metrics, both serious and humorous, to track progress; and guidelines for the general public for making small (or perhaps monumental) but important changes in their own lives. - [5] Pabich, Wendy J., Taking on Water: How One Water Expert Challenged Her Inner Hypocrite, Reduced Her Water Footprint (Without Sacrificing a Toasty Shower), and Found Nirvana, Sasquatch Books (2012), ASIN: B00EB0JTB6, Quoting Amazon product review:

When Wendy Pabich received a monthly water bill for 30,000 gallons (for a household of two people and one dog), she was chagrined. After all, she is an expert on sustainable water use. So she set out to make a change. Taking on Water is the story of the author's personal quest to extract and implement, from a dizzying soup of data and analysis, day-to-day solutions to reduce water use in her life. She sets out to examine the water footprint of the products she consumes, process her own wastewater onsite, revamp the water and energy systems in her home, and make appropriate choices in order to swim the swim. Part memoir, part investigation, part solution manual, the book is filled with ruminations on philosophy, science, facts, figures, and personal behavioral insights; metrics, both serious and humorous, to track progress; and guidelines for the general public for making small (or perhaps monumental) but important changes in their own lives. - 1-Bromo-3-chloro-5,5-dimethylhydantoin (C5H6BrClN2O2) is produced world-wide and is also used in cleaners and bathroom disinfectants and deodorizers. Here is an example MSDS for this product, provided by Leisure Time

- "Bacteria in Drinking Water" - "Chlorine," Karen Mancl, water quality specialist, Agricultural Engineering, Ohio State University Extension. Mancl explains factors affecting the effectiveness of chlorine in water as a means to destroy bacteria and other microorganisms. OSU reports as follows:

- Chlorine kills bacteria, including disease-causing organisms and the nuisance organism, iron bacteria. However, low levels of chlorine, normally used to disinfect water, are not an effective treatment for giardia cysts. A chlorine level of over 10 mg/1 must be maintained for at least 30 minutes to kill giardia cysts. -- http://ohioline.osu.edu/b795/index.html is the front page of this bulletin

- "Chemicals and Our Health", Nicholas D. Kristof, New York Times, 16 July 2009, p. 27. This outstanding editorial calls for improvements in public health policy to address phthalates and other environmental contaminants from common chemicals and products in everyday use. - DJ Friedman

- Crystal Clear Supply provides portable ceramic water filter purifiers and portable reverse osmosis water treatment equipment - see http://www.crystalclearsupply.com/category_s/7.htm

- Endocrine Disruptor Exchange, Dr. theo Colborn (also see Our Stolen Future). From that website: The Endocrine Disruption Exchange, Inc. is the only organization that focuses primarily on the human health and environmental problems caused by low-dose and/or ambient exposure to chemicals that interfere with development and function, called endocrine disruptors. ... TEDX's work focuses on the endocrine system, which is the exquisitely balanced system of glands and hormones that regulates such vital functions as body growth, response to stress, sexual development and behavior, production and utilization of insulin, rate of metabolism, intelligence and behavior. Hormones are chemicals such as insulin, thyroxin, estrogen, and testosterone that interact with specific target cells. The interactions occur through a number of mechanisms, the easiest of which to conceptualize is through a lock and key arrangement.

- Giardia exposure limits for drinking water: see www.mass.gov/dep/water/drinking/standards/giardia.htm is the current regulatory exposure limit (your minimum target for sterilization)

- Health Effects of Chemical Contaminants in Drinking Water, US Environmental Protection Agency,

- Hydrogen peroxide: Wikipedia on history of use of hydrogen peroxide: Information on Hydrogen peroxide as a sterilant is in Wikipedia at en.wikipedia.org/wiki/Sterilization_(microbiology) HO2 has been used for a long time, including by vaporization for sterilizing freeze dryers.

- Hydrogen Peroxide warning: US FDA Warning about drinking hydrogen peroxide: www.truthorfiction.com/rumors/h/hydrogen-peroxide.htm This article cites a 2003 entry in Journal of Food and Science on using Hy.Perox to sterilize vegetables, referring to E.coli - NOT to Giardia.

- Iodine: "Do Iodine Water Purification Tablets Provide an Effective Barrier against Cryptosporidium parvum?", Starke, Jeffrey A., Bowman, Dwight D., Labare, Michael, Fogarty, Elizabeth A., and others, Military Medicine, 25 October 2001 [possibly a later version of this article appeared in 2005 -DF] http://www.amsus.org/military medicine/milmed.htm

- Ohio State University article on the concentration of chlorine necessary to act as an effective disinfectant, and the effects of the water's pH and temperature: See http://ohioline.osu.edu/b795/b795_7.html for details.

- Our Stolen Future: Are We Threatening Our Fertility, Intelligence, and Survival?--A Scientific Detective Story, Theo Colborn, Dianne Dumanoski, John Peter Meyers. Plume-Penguin Publishing, 1997, ISBN 0-452-27414-1., ISBN13: 9780452274143. This book is a seminal work on endocrine disruptors (chemical contaminants having impact at extremely low levels in the environment).

Recommended by Daniel Friedman, this book is a critical update to the landmark Silent Spring by Rachel Carson and discusses the effects of minute trace amounts of chemical contaminants in the environment. The text "Identifies the various ways in which chemical pollutants in the environment are disrupting human reproductive patterns and causing such problems as birth defects, sexual abnormalities, and reproductive failure. Reprint. Tour. NYT."

Amazon.com Review: By O T (Ontario, BC) - 'Our Stolen Future' is a great introduction to one of the most important scientific discoveries in our time. Having recently completed a thesis project at university on Endocrine Disruptors, I have reviewed hundreds of papers on the subject. This book is a good clear overview of the scientific literature on EDs. The authors are experts - Theo Colborn is largely responsible for creating the field by bringing together diverse researchers so they could see the big picture of their work. Many of the principle investigators are interviewed and quoted at length on the way chemicals participate in and interfere with delicate hormonal systems in animals (including humans). The major accomplishment of the book is to make an easy-to-follow story out of complex research. Many resources are available to help you assess the reliability of this story, and the best thing to do if you have any doubts is read review articles in scientific journals (which are easier to understand than technical papers). The Physicians for Social Responsibility (PSR) have a guidebook for health-care professionals on Endocrine Disruptors, and the US EPA has many reports on the matter. Beware of people or websites who try to 'debunk' this book (or the science behind it) by simply declaring it false, flawed or disproven. There is far too much supporting research for so simple a refutation.

OPINION: Significant and discussed in this book is the observation that at certain critical points in the development of animals, presumably including humans, exposure to extremely low levels of endocrine disruptor chemicals (EDC's) BPA - Bisphenol-A or BPA, Diethylstilbestrol - DES, dioxins, PCBs, and chemicals used in the production of certain cleansers, dyes, flame retardants, plastics, pesticides, white papers ) perhaps just a few molecules, or in the parts per trillion, is sufficient to cause disruption of the animal's development, including proper sex differentiation, or the lack of it that produced androgynous ducks unable to reproduce under such conditions.

A endocrine disruptor is a synthetic chemical compound that mimics natural hormones when it is taken into the body of a human or other animal. It "disrupts" the endocrine system by turning on or off normal chemical signals that in turn can affect normal hormone levels, bodily functions, and significantly, the development of embryos. Further, unlike naturally occurring hormones ingested, for example from plants (phytoestrogens), synthetically-generated hormones accumulate in the body and can have a half-life of decades or longer.

One significance of this finding includes the observation that an important medical effect that occurs with exposure to chemicals in extremely low concentrations means that experiments to test for correlations between chemical exposure and subsequent serious medical problems will be deeply flawed if, for example, the experimental design does not include testing for the presence of the chemical at extremely low levels. A related concern is that even if harmful effects from exposure to extremely low concentrations of an endocrine disruptor are occurring, teasing out and proving that relationship can be also extremely difficult. - Potable Aqua® emergency drinking water germicidal tablets are produced by the Wisconsin Pharmacal Co., Jackson WI 53037. 800-558-6614 pharmacalway.com

- [20] SCALE FORMATION in WATER HEATERS and METHODS of PREVENTION free download as [PDF] Krappe,

Justus Maximilian, Engineering experiment station. Gas engineering bulletin; no. 6; Research series; no. 74; On cover: Engineering bulletin, Purdue university. Vol. xxiv, no. 3a. June, 1940 (Layfayette Indiana) commonly referred to in some references as "Purdue University Bulletin No. 74" - thanks to researcher Robyn Goldstein for the full citation. LCCN: 40028844 & OCLC: 1038544 - Water analysis, water softening, hot-water supply. 27pages.

You can also obtain this document through your local library. (full copy file at InspectAPedia 3/31/2010) Purdue B074 can be hard to locate online.

Also Bradford White Corporation (a manufacturer of water heaters) previously published

SCALE FORMATION in WATER HEATERS - EXCERPTS [PDF] from that document made available by Purdue University. - Silent Spring, Rachael Carson, Mariner Books; Anv edition (October 22, 2002), ISBN-13: 978-061824906.

Amazon.com Review: Silent Spring, released in 1962, offered the first shattering look at widespread ecological degradation and touched off an environmental awareness that still exists. Rachel Carson's book focused on the poisons from insecticides, weed killers, and other common products as well as the use of sprays in agriculture, a practice that led to dangerous chemicals to the food source. Carson argued that those chemicals were more dangerous than radiation and that for the first time in history, humans were exposed to chemicals that stayed in their systems from birth to death. Presented with thorough documentation, the book opened more than a few eyes about the dangers of the modern world and stands today as a landmark work. - Shock or Chlorinate a Well, When, How-to - Procedure for Shocking a Well to (temporarily or maybe longer) "Correct" Bacterial Contamination

- UNESCO: World Water Assessment Programme [ copy on file as /water/Water_Assessment_UNESCO_129556e.pdf ] - , Executive Summary, UNESCO Publishing, Secretariat: C/O UNESCO/Division of Water Sciences, 1 Rue Miollis, F-75732 Paris Cedex 15, Tel: +33.1.45.68.39.28, Email: wwap@unesco.org, websearch 09/10/2010 original source: http://unesdoc.unesco.org/images/0012/001295/129556e.pdf - Quoting:

This report is organized in six main sections: a background, an evaluation of the world’s water resources, an examination of the needs for, the uses of and the demands on water (‘Challenges to Life and Well-Being’), a scrutiny of water management (‘Management Challenges’), seven representative case studies highlighting different water scenarios, and conclusions and annexes. - US EPA: list of drinking water contaminants: see http://www.epa.gov/safewater/contaminants/index.html

- UV light: This patent application for UV light sterilization www.patentstorm.us/patents/6565803.html Lists good references on water purification for Giardia et als

- Access Water Energy, PO Box 2061, Moorabbin, VIC 3189, Australia, Tel: 1300 797 758, email: sales@accesswater.com.au Website: http://www.accesswater.com.au/

Moorabbin Office: Kingston Trade Centre, 100 Cochranes Rd, Moorabbin, VIC 3189

Australian supplier of: Greywater systems, Solar power to grid packages, Edwards solar systems, Vulcan compact solar systems, water & solar system pumps & controls, and a wide rage of above ground & under ground water storage tanks: concrete, steel, plastic, modular, and bladder storage tanks. - Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Crystal Clear Supply provides portable ceramic water filter purifiers and portable reverse osmosis water treatment equipment - see http://www.crystalclearsupply.com/category_s/7.htm

- Handbook of Disinfectants and Antiseptics, Joseph M. Ascenzi (Editor), CRC, 1995, ISBN-10: 0824795245 ISBN-13: 978-0824795245 "The evaluation of chemical germicides predates the golden age of microbiology..." -

This well-focused, up-to-date reference details the current medical uses of antiseptics and disinfectants -- particularly in the control of hospital-acquired infections -- presenting methods for evaluating products to obtain regulatory approval and examining chemical, physical, and microbiological properties as well as the toxicology of the most widely used commercial chemicals. - Potable Aqua® emergency drinking water germicidal tablets are produced by the Wisconsin Pharmacal Co., Jackson WI 53037. 800-558-6614 pharmacalway.com

- Principles and Practice of Disinfection, Preservation and Sterilization (Hardcover)

by A. D. Russell (Editor), W. B. Hugo (Editor), G. A. J. Ayliffe (Editor), Blackwell Science, 2004. ISBN-10: 1405101997, ISBN-13: 978-1405101998.

"This superb book is the best of its kind available and one that will undoubtedly be useful, if not essential, to workers in a variety of industries. Thirty-one distinguished specialists deal comprehensively with the subject matter indicated by the title ... The book is produced with care, is very readable with useful selected references at the end of each chapter and an excellent index. It is an essential source book for everyone interested in this field. For pharmacy undergraduates, it will complement the excellent text on pharmaceutical microbiology by two of the present editors."

The Pharmaceutical Journal: "This is an excellent book. It deals comprehensively and authoritatively with its subject with contributions from 31 distinguished specialists. There is a great deal to interest all those involved in hospital infection ... This book is exceptionally well laid out. There are well chosen references for each chapter and an excellent index. It is highly recommended." The Journal of Hospital Infection.: "The editors and authors must be congratulated for this excellent treatise on nonantibiotic antimicrobial measures in hospitals and industry ... The publication is highly recommended to hospital and research personnel, especially to clinical microbiologists, infection-control and environmental-safety specialists, pharmacists, and dieticians."

New England Journal of Medicine: City Hospital, Birmingham, UK. Covers the many methods of the elimination or prevention of microbial growth. Provides an historical overview, descriptions of the types of antimicrobial agents, factors affecting efficacy, evaluation methods, and types of resistance. Features sterilization methods, and more. Previous edition: c1999. DNLM: Sterilization--methods. - U.S. Army Field Manual 21-10, Field Hygiene and Sanitation, 1988, web search 07/02/2010, original source: http://www.enlisted.info/field-manuals/fm-21-10-field-hygiene-and-sanitation.shtml

The purpose of this manual is to assist individual soldiers, unit commanders, leaders and field sanitation teams in preventing disease and environmental injuries. The manual provides information on preventive medicine measures (PMM) to the individual soldier as well as essential information for the unit commander, unit leaders, and the unit field sanitation team on applying unit level PMM. - When Technology Fails, Matthew Stein, Chelsea Green Publisher, 2008,493 pages. ISBN-10: 1933392452 ISBN-13: 978-1933392455, "... how to find and sterilize water in the face of utility failure, as well as practical information for dealing with water-quality issues

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.