Inspect, Diagnose, & Repair Concrete Foundation Cracks

Inspect, Diagnose, & Repair Concrete Foundation Cracks

Cold Pour Joints, Movement, Settlement, Leaks, Exposed Cable Ends, Form Ties

History of cement, concrete, portland cement

Types & Classifications of Mortar

- POST a QUESTION or COMMENT about how to identify cold pour joints in building foundations, how to distinguish a cold pour joint or leak from other types of concrete foundation cracks and leaks, how to assess their impact or importance, and what to do about leaky cold pour joints.

Concrete foundation crack types:

Detection, diagnosis, & repairs for cold pour joints, shrinkage cracks, holes, structural cracks & exposed ends of post tension cables in concrete walls.

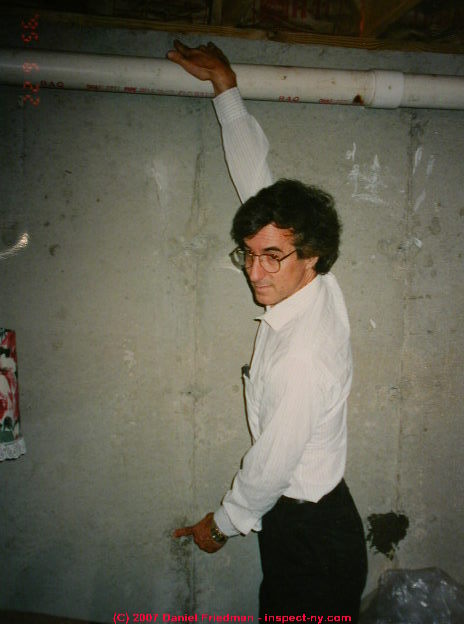

Page top photo shows the author, Daniel Friedman, inspecting a foundation in a New York home in 1985.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Examples of structural & other failures in Poured Concrete Foundations: Cold Pour Joints, Cracks, Leaks, Movement, & Other Defects

This article explains how to identify and diagnose poured concrete foundation walls, movement, settlement, leaks, & other defects involving reinforced or unreinforced concrete foundations and concrete walls, such as damage due to shrinkage, impact, settlement, frost or water damage, and other causes.

This article explains how to identify and diagnose poured concrete foundation walls, movement, settlement, leaks, & other defects involving reinforced or unreinforced concrete foundations and concrete walls, such as damage due to shrinkage, impact, settlement, frost or water damage, and other causes.

Photographs of cold pour joints in foundations and related leaks or damage patterns and types & visual clues of cold pour joints give a history of construction sequence, timing, even concrete delivery location points.

Concrete cold pour joints in a hand-mixed hand-poured concrete wall is shown in this image.

Article Contents

- IDENTIFY COLD POUR JOINTS in CONCRETE WALLS

- IDENTIFY / REPAIR CONCRETE SHRINKAGE CRACKS

- IDENTIFY / REPAIR HOLES in CONCRETE WALLS / FLOORS

- IDENTIFY POST TENSION CABLE ENDS in CONCRETE

- IDENTIFY SETTLEMENT CRACKS in CONCRETE WALLS / FLOORS

- IDENTIFY FORM TIE MARKS & LEAKS in CONCRETE WALLS

- IDENTIFY OTHER TYPES of FOUNDATION CRACKS & DAMAGE

- HISTORY of CONCRETE & PORTLAND CEMENT & CLASSIFICATION of MORTAR TYPES

...

How to Identify Cold Pour Joints in Concrete Foundation Walls

Cold Pour Joints in concrete foundations which leave visible lines in the concrete foundation wall (photo above) are not usually a structural problem but may in some cases form a dry joint which permits water leakage through the foundation wall.Cold pour joints occur because of the time delay between subsequent "pours" into the foundation forms.

An astute inspector, by noting the position, pattern, and slope of the cold pour joint, can probably determine the position from which the concrete was poured into the forms (the high end of the sloping lines) and the extent of delay between pours (evidence of water leaks through the joints indicates that enough time passed for the lower pour to solidify).

Water leaks into buildings at cold pour foundation joints are discussed

at BASEMENT FOUNDATION LEAK POINTS - Leaks at Cold Pour Joints.

And nearly all cold pour joints will appear as diagonals such as those shown in three of the four photos below.

Details about cold pour joints in concrete are found

...

How to Identify Concrete Shrinkage Cracks in Concrete Foundation Walls

Concrete shrinkage cracks are not usually a structural problem but may permit water leaks through the foundation wall.

Shrinkage cracks are often mistaken by owners and inspectors who, failing to observe the characteristic discontinuous path of the crack and its meandering path, mistake shrinkage cracks for structural damage.

We discuss shrinkage cracks in great detail and provide diagnostic photographs of shrinkage and other types of concrete cracking in poured concrete floors and slabs at

We provide further diagnostic guidance for concrete cracking

at SHRINKAGE vs EXPANSION vs SETTLEMENT.

The repair of shrinkage cracks (if repair is even needed) is discussed

at FOUNDATION REPAIR METHODS for shrinkage cracks .

...

How to Identify Recognize and Repair Holes and Penetrations in Concrete Foundation Walls

Holes and penetrations in concrete foundations such as poorly sealed openings left for piping for water or electrical lines or where form ties were broken off may form points of water entry into the structure but are not normally a structural concern.

The "patched" holes shown in this photograph had been a source of chronic leakage and basement water entry since this home had been constructed about two years before this photograph was taken.

While several unsuccessful attempts had been made to seal and patch this leak point in the concrete foundation wall, none of the repairs had tried using a suitable product sold for that purpose and the wall was still leaking.

Of course, the root problem was that surface water was not being directed away from the building outside.

These holes were high enough on the foundation wall that it would be reasonable (and perhaps preferable) to seal the wall from outside before also regrading to drain surface water away from the building.

...

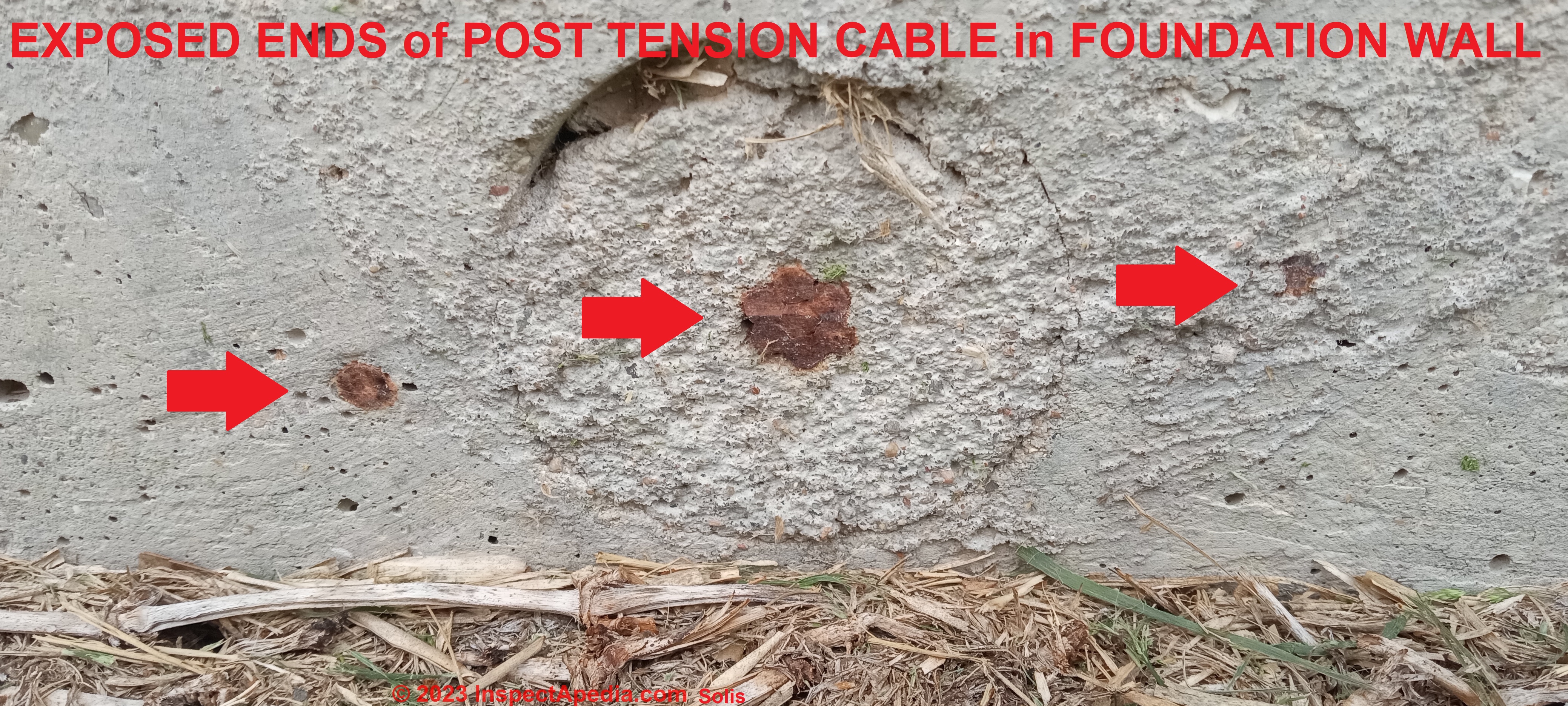

Identify Exposed Post Tension Cable Ends in Concrete Foundation Walls

Reader Question: What do we do about exposed ends of post-tension cables in the foundation of our new home?

I notice that most houses in my area have post tension cables protruding from the foundations and I'd like to know how to fix these correctly.

(Please see photo.) - Anonymous by private email 2023/04/26

Moderator reply: Advice for sealing the exposed ends of foundation post tension cables

Your foundation photo shows what looks like the sliced-off end of a bundled 7-strand cable. You'll want to seal any such exposed cable ends to prevent future rusting. Rusting of post-tension foundation cables can cause exfoliating rust that has enough force to actually damage a foundation wall.

Conventional advice offered is typically to simply seal the exposed post tension cable ends with concrete patch compound.

For a more durable reliable repair, you might want to clean off surface rust and use a foundation repair bonding agent before applying the patch - that will help assure that the "patch" remains on the surface and protects the cable ends against further rust.

These two articles discuss concrete bonding agents and patching/sealing (focused on cracks but working equally well for an exposed post-tension cable end in a concrete foundation wall.)

STUCCO & CONCRETE BONDING AGENTS and

SEAL CRACKS in CONCRETE, HOW TO

Separate from the exposed end of a post tension foundation are similar-looking form ties that you might want to ask your inspector to watch for as well.

Leaks at form ties, a separate issue that is sometimes confused with exposed post tension cable ends in concrete, are illustrated and discussed in our article

CONCRETE FOUNDATION, WALL, SLAB DEFECTS

and in case it helps you, lots of additional photos of form tie marks on concrete foundation walls are in our article

...

How to Identify Settlement Cracks in Concrete Foundation Walls

Definition: Settlement cracks are cracks in a concrete foundation wall that result from downwards movement of the wall or of the soil below the wall's base or footing.

Usually these cracks are either vertical or near-vertical, or occasionally, diagonal, depending on the point at the wall base over which the wall is breaking, and depending further on un-evenness in the settlement of soil below the wall.

The cause of settlement, such as crushing of buried debris under a wall (uncommon but it happens), or excessive water (such as from a downspout that doesn't direct roof runoff away from a building) may be evident by following a settlement crack and looking at outside conditions at the building.

A settlement crack is usually wider at the top of the crack than near the crack bottom.

Here are some details:

Concrete foundation settlement cracking

can result from footing settlement, absence of or poorly prepared footings,

water leading to settlement or actual loss of soils, thus undermining the footings (this can occur and can damage most foundation

types), or movement of the foundation due to nearby blasting or excavation work.

Shrinkage cracks in concrete occur only during curing and will appear mostly in the first 28 days after a wall or floor is poured. If cracks noted and documented after this time continue to increase in length or width, some other cause is at work and further investigation is needed.

The concrete settlement crack shown in our photo above appeared initially in this wall as a hairline fracture of less than 1/16" in width.

The homeowner monitored the crack and watched it increase in width to nearly 1/2" over the following 12 months, leading to the correct inference that there was structural movement going on.

In this case, we traced the movement to uneven footing settlement which was aggravated by the combination of having placed the footing partly on bedrock, water from roof and surface spillage and runoff causing soil settlement (the contractor had not compacted the backfill under the footings),

and by ongoing foundation blasting at a neighboring lot.

Contrast Settlement Cracks with Two Other Common Concrete Wall Cracks

Don't confuse a vertical or steep diagnoal settlement crack with either of the following:

Concrete foundation damage from horizontal loading, such as by the passage of vehicles too close to the building wall or occasionally by horizontal frost push against the wall, is less commonly seen in concrete walls than in a foundation wall built with unit-construction materials such as brick or masonry block but might occur under unusual conditions.

But key is that these cracks tend to be horizontal rather than vertical or diagonal, and they will be located at the point where the horizontal force against the wall is greatest, usually mid-wall or closer to the wall top (vehicle loading or frost push).

Examples of horizontal loading crack damage are

at HORIZONTAL FOUNDATION CRACKS

where you'll see more diagnostic details discussing the significance of the relative height of the crack in the wall.

Concrete foundation damage from unusual point loads are typically traced to a visible load point or impact point on the structure, can resemble cracks caused by frost heave or exfoliating metal cracking but will occur where the wall is carrying an extra weight or load from above such as a beam or post resting on the wall, or on occasion, an impact to the wall from a vehicle, a falling tree, or similar force.

Examples of point loading damage to a concrete block wall are

...

How to Identify Form Tie Marks and Leak Points in Concrete Foundation Walls

Concrete Foundation Form Tie leaks:

Leaks at the location of concrete form ties used during construction of a poured concrete foundation are not normally a structural problem but they can be blamed for basement water entry.

Form tie leaks occur in a poured concrete foundation wall where the form ties used to construct the foundation have left penetrations in the concrete walls.

Form ties are wire or steel connections between the two vertical sides of the wood or steel concrete form.

Concrete form ties are needed to prevent the forms from separating and bulging from the weight of the concrete poured into the form.

The best solution to concrete wall form tie leaks is to keep water away from the foundation from outside.

...

Other Types of Foundation Damage to Concrete Foundations, Slabs, Walls or Floors

- Leaning concrete foundation walls

or structural walls due to: water, frost, or earth loading, vehicle passage too close to the wall, inadequate footings, soil undermining - Concrete foundation wall cracks:

settlement, shrinkage, cold joints listed at CONCRETE SLAB CRACK EVALUATION - Concrete foundation spalling

due to poor concrete mix, too much water, excessive working of the surface, pouring during cold weather without proper additives, roof runoff rain-splash erosion of the wall surface. - Concrete foundation damage and random pattern cracking due to concrete inclusions

such as iron sulfide mineral (pyrrhotite) .

See FOUNDATION DAMAGE by MATERIAL or INCLUSIONS

Research on Concrete

- Also see the Recommended Articles listed at the end of this article

- Also see References or Citations at the end of this page

- Clarke, Addison Henry. Architect's Hand-book on Cements. WW Clarke & son, 1899. [Available from Google Play as a free eBook] excerpted below and further excerpted

at CONCRETE SHRINKAGE CRACKS

...

History of Portland Cement & Classification of Mortars

(Clarke 1899 pp. 8-14) [With minor editing by InspectApedia.com - Ed.]

The base of all hydraulic mortars is lime or the oxide of the metal calcium.

Various materials have been used as a bond for masonry construction, as mud, asphaltum, and lime. The last is the basis of hydraulic cement, which crystallizes or hardens by the application of mortar. ...

The use of lime as a mortar may be traced back for many hundred years. Volcanic slags, such as Pozzuolana or Tras, have long been employed in Italy and along the shores of the Mediterranean Sea. Improved cements are a comparatively modern discovery.

In 1756, John Smeaton found the need of having a hydraulic cement in building the famous Eddystone lighthouse. He discovered that liimestone was rendered hydraulic by the admixture of a certain proportion of clay. Vicat, the eminent French engineer, made a similar discovery in 1818.

Parker's "Roman" cement was discovered in 1796 on the Island of Sheppey off the coast of England.

J.C. Aspdin, a brickmaker of Leeds, England, took out a patent in 1824 for what he called Portland Cement, owing to its resemblance to the Oolithic limestone quarried on the "Isle of Portland". Westminster Abbey is built of this Portland Stone.

In tis country, Natural Rock Cement was discovered during the building of the Erie Canal in 1829.

A somewhat similar cement was discovered in 1823 near the town of Rosendale, in Ulster County, New York, during the building of the Delaware and Hudson Canal.

...

It was not until about 1848 that Portland cement began to be well known in the London Market. At this time Mr. I.C. Johnson discovered the proper mixture of lime and clay to make Portlan Cement, and also the secret of burning the clinker to the point of vitrification to secure the best results.

- Quick Lime

contains 44 parts by weight of carbon dioxide and 56 parts oxide of calcium. In slaking, 18 parts by weight of water unite with 56 parts quick lime, making 74 parts calci hydrate. The process of slaking is greatly facilitated by the heat that is generated. - Hydraulic Lime

contains 10 20 25 pecent alumina. It differes from Quick Lime in that it hardens in water. It is either argillaceous or siliceous. - Natural Rock Cement

is made from argillo-magnesian limestones, the principal ingredients being carbonates of lime and magnesia, silica and aluina. The quarried rock is burnt in kilns, crushe and ground to powder.

This cement differs from Portland Cement in chemical analysis, specific gravity and temperature at which it is burnt. ... The color of natural rock cement is due to varying proportions of oxide of iron and impurities, but bears little relation to its ultimate strength.

[Watch out: also see PYRRHOTITE INCLUSION CRACKING - Ed. ] - Pozzuolana Cement

is so called from the town of Pozzuoli in Italy, near which place the ingredients were found from which it was first made. This cement is rendered hydraulic by the addition of proper proportion of quick lime. - Artificial Pozzuolana

is made from blast furnace slag, and also from the scales from the blacksmith's forge. - Tasrras or Tras

is a volcanic substance quite similar to Pozzuolana and found at Andernach in the department of the Rhine. - Roman Cement

originally called Parker's Cement, is made from nodules found in certain places on the English coast. The composition of this rock is quite similar to that from which Natural Rock Cement is made in the United States. (p. 12)

...

Parker's "Roman" Cement was discovered in 1796 (p. 8)

...

It was not until about 1848 that Portland cement begasn to be well known in the London market. At this time Mr. I. C. Johnson discovered the proper mixture of lime and clay to make Portland Cement, and also the secret of burning the clinker to the point of vitrification to secure the best results. ...

The United Stats was late in the field. Portland Cement began to be importted into this country about the year 1865, when it was sold at from $5 to $7 perbarrel.

It was not until the year 1872 that Mr. David O. Saylor succeeded in producting a Portland Cement from argillaceous limestone that he had been employing in the manufacture of Natural Rock Cement. - Portland Cement

is made dfrom various substances in combination, which in themselves posess no hydraulic energy, then burning to the melting point and grinding the clinker to an impalpable powder, having an average chemical analysis [paraphrasing-Ed] [combining carbonate of lime 62%, silica 22%, and smaller amounts of alumina, oxide of iron, magnesia, and sulphuric acid.

Portland cement is further dividied into four groups depending on the sue of chalk, clay, marl, limestone rock, blast furnace slag. - Magnesian Cement

is made from finely-ground magnesium oxide and a solution of magnesium chloride. It sets quickly, becoming harder than marble, having an estimated crushing rsistance of over 1000 tons per squre foot, being by far the strongest cement known. - Silica-Portland Cement

is a mixtuer of portland cement and siliceous sand groudn together into an impalpable power in a tube mill. - Slag-Cement,

after many and repeated failures in this country and Europe, ... has finally been demonstrated ... [as possible] to make a safe and durable hydraulic cement from the slag from blast furnaces. ... Slag cement is quite slow setting and requries more moisture in crystallizing than other cements to obtsain the best results.

...

...

Continue reading at CONCRETE SLAB CRACK EVALUATION which discusses in detail the process of evaluating cracks, settlement, leaks, shrinkage, or other damage in poured concrete slabs, monolithic slab foundations, and concrete floors, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Also see these

Recommended Articles

- CONCRETE COLD POUR JOINTS

- CONCRETE CORROSION DUE TO HYDROGEN SULFIDE

- CONCRETE DELIVERY & MIXING

- CONCRETE FOUNDATION, WALL, SLAB DEFECTS

- CONCRETE REINFORCEMENT, FIBER

- CONCRETE SHRINKAGE CRACKS

- CONCRETE SLAB CRACK EVALUATION

- CONTROL JOINT CRACKS in CONCRETE

- FREEZING & WATER DAMAGED SLABS

- FROST HEAVE / EXPANSIVE SOIL CRACKS in SLABS

- SETTLEMENT CRACKS in SLABS

- SETTLEMENT vs. FROST HEAVE CRACKS

- SETTLEMENT vs. SHRINKAGE CRACKS

- SHRINKAGE CRACKS in SLABS

- SHRINKAGE CRACKS at FOUNDATION WALLS

- TEMPERATURE EFFECT on CONCRETE POUR

- CONCRETE SLAB CRACK REPAIR

- FOUNDATION CRACK DICTIONARY discusses evaluating foundation damage by examining concrete crack size, shape, pattern, and location.

- FOUNDATION CRACKS & DAMAGE GUIDE

- FOUNDATION DAMAGE by MATERIAL or INCLUSIONS

- POST TENSION CABLE END EXPOSED - REPAIR

- PYRRHOTITE INCLUSION CRACKING

- SOIL PROPERTIES & BUILDING FAILURES

Suggested citation for this web page

CONCRETE FOUNDATION, WALL, SLAB DEFECTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about how to identify cold pour joints in building foundations, how to distinguish a cold pour joint or leak from other types of concrete foundation cracks and leaks, how to assess their impact or importance, and what to do about leaky cold pour joints..

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- Paul Galow [Website galowconsulting.com ] - technical consultant on networking, LAN design, applications support. Galow Consulting Services [Website galowconsulting.com ] , 914-204-1749, email: paulgalow@galowconsulting.com

- "Concrete Slab Finishes and the Use of the F-number System", Matthew Stuart, P.E., S.E., F.ASCE, online course at www.pdhonline.org/courses/s130/s130.htm

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- "Concrete Slab Finishes and the Use of the F-number System", Matthew Stuart, P.E., S.E., F.ASCE, online course at www.pdhonline.org/courses/s130/s130.htm

- Sal Alfano - Editor, Journal of Light Construction*

- Thanks to Alan Carson, Carson Dunlop, Associates, Toronto, for technical critique and some of the foundation inspection photographs cited in these articles

- Terry Carson - ASHI

- Mark Cramer - ASHI

- JD Grewell, ASHI

- Duncan Hannay - ASHI, P.E. *

- Bob Klewitz, M.S.C.E., P.E. - ASHI

- Ken Kruger, P.E., AIA - ASHI

- Aaron Kuertz aaronk@appliedtechnologies.com, with Applied Technologies regarding polyurethane foam sealant as other foundation crack repair product - 05/30/2007

- Bob Peterson, Magnum Piering - 800-771-7437 - FL*

- Arlene Puentes, ASHI, October Home Inspections - (845) 216-7833 - Kingston NY

- Greg Robi, Magnum Piering - 800-822-7437 - National*

- Dave Rathbun, P.E. - Geotech Engineering - 904-622-2424 FL*

- Ed Seaquist, P.E., SIE Assoc. - 301-269-1450 - National

- Dave Wickersheimer, P.E. R.A. - IL, professor, school of structures division, UIUC - University of Illinois at Urbana-Champaign School of Architecture. Professor Wickersheimer specializes in structural failure investigation and repair for wood and masonry construction. * Mr. Wickersheimer's engineering consulting service can be contacted at HDC Wickersheimer Engineering Services. (3/2010)

- *These reviewers have not returned comment 6/95

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- The Journal of Light Construction has generously given reprint permission to InspectAPedia.com for certain articles found at this website. All rights and contents to those materials are ©Journal of Light Construction and may not be reproduced in any form.

- Appliances and Home Electronics, - energy savings, U.S. Department of Energy

- Avongard FOUNDATION CRACK PROGRESS CHART [PDF] - structural crack monitoring

- Building Pathology, Deterioration, Diagnostics, and Intervention, Samuel Y. Harris, P.E., AIA, Esq., ISBN 0-471-33172-4, John Wiley & Sons, 2001 [General building science-DF] ISBN-10: 0471331724 ISBN-13: 978-0471331728

- Building Pathology: Principles and Practice, David Watt, Wiley-Blackwell; 2 edition (March 7, 2008) ISBN-10: 1405161035 ISBN-13: 978-1405161039

- Construction Drawings and Details, Rosemary Kilmer

- Diagnosing & Repairing House Structure Problems, Edgar O. Seaquist, McGraw Hill, 1980 ISBN 0-07-056013-7 (obsolete, incomplete, missing most diagnosis steps, but very good reading; out of print but used copies are available at Amazon.com, and reprints are available from some inspection tool suppliers). Ed Seaquist was among the first speakers invited to a series of educational conferences organized by D Friedman for ASHI, the American Society of Home Inspectors, where the topic of inspecting the in-service condition of building structures was first addressed.

- Design of Wood Structures - ASD, Donald E. Breyer, Kenneth Fridley, Kelly Cobeen, David Pollock, McGraw Hill, 2003, ISBN-10: 0071379320, ISBN-13: 978-0071379328

This book is an update of a long-established text dating from at least 1988 (DJF); Quoting:

This book is gives a good grasp of seismic design for wood structures. Many of the examples especially near the end are good practice for the California PE Special Seismic Exam design questions. It gives a good grasp of how seismic forces move through a building and how to calculate those forces at various locations. THE CLASSIC TEXT ON WOOD DESIGN UPDATED TO INCLUDE THE LATEST CODES AND DATA. Reflects the most recent provisions of the 2003 International Building Code and 2001 National Design Specification for Wood Construction. Continuing the sterling standard set by earlier editions, this indispensable reference clearly explains the best wood design techniques for the safe handling of gravity and lateral loads. Carefully revised and updated to include the new 2003 International Building Code, ASCE 7-02 Minimum Design Loads for Buildings and Other Structures, the 2001 National Design Specification for Wood Construction, and the most recent Allowable Stress Design. - Building Failures, Diagnosis & Avoidance, 2d Ed., W.H. Ransom, E.& F. Spon, New York, 1987 ISBN 0-419-14270-3

- Domestic Building Surveys, Andrew R. Williams, Kindle book, Amazon.com

- Defects and Deterioration in Buildings: A Practical Guide to the Science and Technology of Material Failure, Barry Richardson, Spon Press; 2d Ed (2001), ISBN-10: 041925210X, ISBN-13: 978-0419252108. Quoting:

A professional reference designed to assist surveyors, engineers, architects and contractors in diagnosing existing problems and avoiding them in new buildings. Fully revised and updated, this edition, in new clearer format, covers developments in building defects, and problems such as sick building syndrome. Well liked for its mixture of theory and practice the new edition will complement Hinks and Cook's student textbook on defects at the practitioner level. - Guide to Domestic Building Surveys, Jack Bower, Butterworth Architecture, London, 1988, ISBN 0-408-50000 X

- "Avoiding Foundation Failures," Robert Marshall, Journal of Light Construction, July, 1996 (Highly recommend this article-DF)

- "A Foundation for Unstable Soils," Harris Hyman, P.E., Journal of Light Construction, May 1995

- "Backfilling Basics," Buck Bartley, Journal of Light Construction, October 1994

- "Inspecting Block Foundations," Donald V. Cohen, P.E., ASHI Reporter, December 1998. This article in turn cites the Fine Homebuilding article noted below.

- "When Block Foundations go Bad," Fine Homebuilding, June/July 1998

- Quality Standards for the Professional Remodeler, N.U. Ahmed, # Home Builder Pr (February 1991), ISBN-10: 0867183594, ISBN-13: 978-0867183597

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.