Concrete Crack & Damage by Temperature

Concrete Crack & Damage by Temperature

Concrete Curing at High or Low Temperature: Cracks, Spalling, Damage

- POST a QUESTION or COMMENT about cracked concrete slabs and floors

What are the temperature limits to avoid damage to concrete during placement, pour, set, curing?

This article discusses reader questions about shrinkage cracks, spalling, and other damage to concrete slabs, floors, or structures that may be caused or aggravated by high or low temperatures at the site during concrete placement and curing.

Are shrinkage cracks only a cosmetic concern? Are there hot and cold temperature limits for placing concrete? What is the role and what are the limits of additives in concrete pour during hot or cold weather?

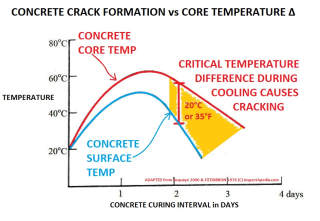

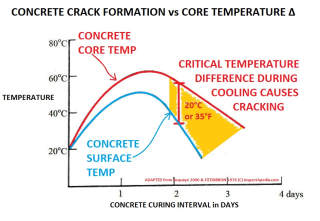

Our page top graph showing the critical temperature difference gap between the concrete surface and concrete core temperature illustrates the conditions under which cracking in new concrete is likely. Adapted from Acquaye 2006 and Fitzgibbon 1976 cited in this article.

This article series describes the types of cracks that occur in poured concrete slabs or floors and explains the risks associated with each, thus assisting in deciding what types of repair may be needed. This series also describes how to recognize and diagnose various types of foundation failure or damage, such as foundation cracks, masonry foundation crack patterns, and moving, leaning, bulging, or bowing building foundation walls.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Effects of Curing Temperature on Concrete: Shrinkage Cracks & Spalling Concrete

- Daniel Friedman 2018

On 2018-07-22 by Dale Hart - fine cracks in a new slab poured 4 days ago during a heat wave in South Texa s

Poured a new slab 4 days ago during a heat wave in South Texas.

We used #3 rebar on 12 inch centers with #5 rebar with stirrups every 30 inches in perimeter beam. Ground was well compacted.

What appears to be shrinkage cracks have begun to appear. We also used a product called Pene-krete that helps hold moisture

I have kept the slab wet continuously.

I'm worried although contractor has said these are shrinkage cracks because the heat has caused the slab to cure too soon but he said these cracks or cosmetic only.

The cracks are less than a 1/32 seconds of an inch. what are your thoughts?

[Click to enlarge any image]

This Q&A were posted originally

On 2018-07-23 by (mod) - Shrinkage Cracks? Possible Effects on Concrete Curing at High Temperatures in South Texas

Dale-

Those look like shrinkage cracks to me, too. If there is no settlement and no height difference across the cracks, at the outset these are only a cosmetic concern, perhaps aggravated by the heat.

Thermal cracking will occur when contraction due to cooling at the surface causes tensile stresses that exceed the tensile strength of the concrete. - Gajda 2002

Pouring concrete in either very hot or very cold conditions can result in damage. Air temperature, relative humidity, and wind during the concrete placement and curing procedure are important.

And of course there are other important factors that affect concrete durability and quality such as setting time, slump at the time of pour, or proper water content, and mix properties. But here we focus specifically on the relationship between temperature and concrete damage.

Effects of Temperature & Temperature-Related Shrinkage Cracks on Concrete

Usually in residential and small building concrete floor or slab construction building or home inspectors and engineers consider fine shrinkage cracks on the surface of concrete to be principally a cosmetic concern.

However the temperatures at which concrete is placed and cured are important. If concrete is exposed to very high temperatures or very cold temperatures during placement and curing, the allowable internal temperature range limits may be violated.

It's useful to understand that the temperature of concern in concrete placement and curing are not simply the outdoor air temperatures to which the concrete is exposed. Rather the critical limits are the range of internal temperatures across the slab's thickness during curing\Concrete generates internal heat during curing - heat is generated by the chemical process of the hydration of cement.

Temperatures rise during curing, then fall as the concrete cools down. In theory, if the heating and cooling occurred uniformly throughout the concrete pour, there would be no thermal stresses and the concrete would not crack nor be damaged.

However this is virtually never the case. Some restraint of the concrete across its dimensions of thickness, width, and length occur in just about every pour. (Neville 1997). The greater the temperature range between the concrete surfaces and its interior during curing the greater will be the restraint and thus the risks of cracking.

In very hot weather and perhaps more-so where there is also direct sun on the concrete, the temperature rise in the concrete caused by hydration will be increased, leading to thermal cracking.

In very cold weather there may also be such significant temperature differences between the concrete core (hot because of the process of hydration) and its exposed surfaces to also lead to thermal cracking.

Lucy Acquaye in her dissertation (2006) gives the external thermal concrete cracking graph I show here. She cites FitzGibbon (1976) in giving 20°C or 35°F as the critical temperature difference through the concrete during curing.

If the temperature difference between the concrete surface and the internal concrete core temperature range exceeds 20°C or 35°F damage can be expected.

Having inspected mostly residential buildings in the U.S., Mexico, Canada, and the E.U. over the last 40 years, in my personal experience, shrinkage cracks are rarely more than a cosmetic concern.

However concrete experts warn that there can on occasion be more serious or even more-delayed damage that appears later.

- Concrete color variations: ... colour differences on the surface may result from different rates of hydration and cooling effects. - Hot Weather Concreting CCA 2018

- Concrete Surface Flaking: The compacted surface layer (from finishing) may cause the rising bleed water to be trapped below the surface, resulting in debonding of the surface layer and subsequent flaking. - Hot Weather Concreting CCA 2018

- Concrete Surface Spalling: There is some risk of future spalling of the concrete surface if the temperature effects on the pour and placement were severe. (Phan 2001)

- Concrete Shrinkage Cracks: Cracking due to thermal behavior may cause loss of structural integrity and monolithic action or may cause extreme seepage and shorten the service life of the concrete structure. - Acquaye 2006

- Concrete Durability: Studies have shown that the long-term durability of certain concretes can be compromised if the maximum temperature after placement exceeds the range of 155 to 165 F (68 to 74 C).

- Delayed Concrete Damage: The primary damage mechanism is delayed ettringite formation (DEF). DEF can cause internal expansion and cracking of concrete, which may not be evident for several years after placement. - Gajda 2002

Risks of High Temperatures During Concrete Placement

While weather is beyond the control of individuals like you and me, (as opposed to government policy that worsens global warming), it would be helpful to know the temperature ranges that occurred during initial set and curing.

Since the PeneKrete additive both enhances the concrete and extends its workability, I speculate that that extension may have prolonged the period during which the concrete was vulnerable to high temperatures.

It would be helpful to ask the company the number of days or length of time over which the new concrete set should not be exposed to temperatures over 100F.

You are indeed working in one of the hottest areas of the U.S. and one that's only going to get hotter still as the climate continues to warm.

Using McAllen TX , one of the hottest of the larger cities in South Texas, as an example (tell us your city and I'll get the exact temperature data for you if you don't already have it) high temperatures in 2018 in the last four days were as follows:

July 18 High 102°F

July 19 High 102°F

July 20 High 100°F

July 21 High 102°F

July 22 High 102°F

Temperature Limits for Using Concrete Additive

These are just barely above the maximum recommended by PeneKrete so assuming the mix was correct, temperature may not have exceeded PeneKete's requirements by much of a factor. in San Antonio temperatures were a bit lower and reached 102°F only on July 22.

Here is what Super-Krete® says about using their Pene-Krete™ additive:

Super-Krete products are to be applied only when surface temperatures are above 55° F and rising and not to exceed 100° F.

Super-Krete products are not to be applied when precipitation is expected within 24 hours following completion of application.

Do not allow materials to freeze.

Each Super-Krete product acts as an inherent part of a proven system. Super-Krete products are professional, contractor grade products. Training in the use of these products is available.

Consult Super-Krete for information and assistance locating approved contractors in your area or for training class dates. - S-1400 PENE-KRETE® ADDITIVE™ for Portland Cement [PDF] (Technical Data Sheet), Super-Krete® International, Inc., 2705 Via Orange Way Suite B, Spring Valley CA 91978 USA, Tel: 800-995-1716, Website: www.super-krete-com, original source: http://questbuilding.com/docs/S-1400_Pene-Krete_Additive_TDS.pdf retrieved 2018/07/23

If your slab is on a site where there is no likely future issue with water coming up through slab cracks then that's about all I'd offer.

More from Super-Krete® - this will be helpful to other readers:

Super-Krete® S-1400 Pene-Krete® Additive™ (for Portland Cement) is a non-hazardous liquid additive formulated to create a chemical reaction within Portland cement based products.The addition of Pene-Krete Additive enhances the concrete’s natural hydration process by prolonging the hydration of the cementing materials and increasing workability

.The addition of Pene-Krete Additive mixed with any Portland cement-based products such as but not limited to concrete, plaster, pre-cast concrete, gunite and block will densify the substrate, increase its structural strength, and encapsulate and expel excess alkali, lime and other contaminants from with substrate to allow for concrete coating on the eighth day after application.

When concrete is treated, its capillary pores are reduced in both size and number and the concrete becomes dramatically less porous. After its reaction, Pene-Krete Additive fills all remaining pores and capillaries with long, needle-like crystals throughout the concrete mass.

The resulting concrete is less permeable to the migration of water or waterborne chemicals. Pene-Krete Additive can increase compressive strength up to 23% depending on the amount and quality of the Portland cement contained in the mix design.The addition of Pene-Krete Additive reduces the acceleration of Portland cement-based materials and reduces curing cracks substantially.

Concrete is overall improved when using Pene-Krete Additive and it can also be used as a water reducing agent in concrete mixes. - Op Cit

On 2018-05-15 by LL - we discovered a pretty sizeable (old) crack In the living room concrete slab

Hello. We recently bought a house built in the late 80’s with a half basement foundation. While tearing up some cold carpet to prep for hardwood install, we discovered a pretty sizeable crack In the living room concrete slab (no basement underneath).

Hello. We recently bought a house built in the late 80’s with a half basement foundation. While tearing up some cold carpet to prep for hardwood install, we discovered a pretty sizeable crack In the living room concrete slab (no basement underneath).

No moisture or water is apparent.. contractor suggests that we get an structural engineer to evaluate - which we plan to do.

The two sides of the crack appear to be relatively level with no significant difference in height either. Wanted to get your take on the matter. Picture attached.

On 2018-05-15 by (mod)

OPINION: I'm not a masonry nor any other sort of engineer but I do have some experience with the detection, diagnosis and repair of concrete cracks. I agree that your photograph shows a significant crack in the floor slab, but I can't yet say you need structural engineer.

An important question when evaluating a concrete floor or slab crack is whether or not the crack has affected the building structure.

A second question is even if the slab is not monolithic and does not affect of the building structure, are there other worrisome effects such as water or radon leaks or settlement and trip hazards.

The crack in your picture is wider than a typical concrete shrinkage crack, but, then we can't see much of the slab and I can see not a bit of the structure.

IF you see a gap (shrinkage crack or gap) around the perimeter of the floor slab THEN I suspect that the slab was poured inside of a physically separate footing or foundation wall (you don't say if this is a basement slab or a slab on grade home).

In that case a crack in the slab is a crack in the floor, NOT a crack in the structure - it's "structure" that holds up the home.

IF there were evidence that the crack continues into the building foundation or walls (such as cracks visible in a footing (unlikely that you can see the footings without excavation) THEN yes there'd be a more significant concern.

The fact that the floor is level across the crack argues against any significant settlement.

If there are no wall cracks, sticking doors, or other signs of movement, I suspect that your structural or civil engineer is going to say

Yep this is a structural failure because we engineers consider ANY crack in concrete to be a "failure".

If in this 20-30 year old home there is no sign of movement in the structure I suspect a decent engineer to say that there is no justification for doing more than seal, patch with mesh tape if you're putting down tile, and re-cover the floor.

A newbie or one who has spent time in court as a defendant will be more cautious. If there is no view of the foundation or footing she might say"well you have to dig up the footings outside this area to let me take a look"

Please read one or more of the articles on this problem starting at

CONCRETE SLAB CRACK EVALUATION

Take a look at OTHER PEOPLE'S MONEY to understand the problem of balancing risk with cost of investigation.

Cracks in Concrete Slab Poured in Very Cold Weather

On 2018-02-07 by Al Nardslico - shrinkage cracks in a concrete slab poured in very cold weather

On 2018-02-07 by Al Nardslico - shrinkage cracks in a concrete slab poured in very cold weather

I attach a photo of a new slab my contractor recently poured during very cold weather. It has a number of cracks. Should I be concerned?

Al@livingbeach.com

On 2018-02-07 by (mod)

Looks like shrinkage cracks as if the control joints were perhaps any effective.

I can't tell what's going on with that slab is that dark color due to water, or ice, or something else?

If the entire slab is above grade there might not be a future problem with water coming up through those cracks

At CONTROL JOINT CRACKS in CONCRETE we note the following:

Because concrete shrinks as it cures (about 1/16 inch for each 10 liner feet or by other sources, about .66 inches per 100 feet), and because there may also be some expansion and contraction of poured concrete in response to temperature (about 0.25 inches per 100 feet per 25 degF temperature change, with a maximum of about 0.5" per 100 feet) and moisture changes in its environment, a large solid slab of poured concrete for a floor or slab is likely to crack.

As long as concretre is placed and cured in ambient temperatures between 50°F and 90°F, it can cure properly but will require different lengths of curing time to reach its rated strength.

When concrete is poured in freezing weather the pour itself must be protected from freezing during its set time and perhaps longer. If we assume that the proper water-cement-aggregate mix was used if the water freezes the concrete will not cure properly and may be significantly-weakened, losing 50% or more of its normal 28-day strength rating.

Just how long that protection is required depends on the exposure temperatures of the new pour. At 30°F that could be two days or longer.

Concrete Admixtures & Other Measures to Off-set Temperature Effects

Our photo shows a well-designed insulated radiant-heated concrete slab with an insulated foundation perimeter being installed in Two Harbors, Minnesota in 2007.

Our photo shows a well-designed insulated radiant-heated concrete slab with an insulated foundation perimeter being installed in Two Harbors, Minnesota in 2007.

The temperature of concrete at the job site depends on at least the following factors:

- The temperature of the ingredients used in the concrete mix: the cement, the aggregate, and the water.

Concrete should be delivered within the right temperature range specified by AS 1379 (this is for Australia, use the equivalent in your country) concrete temperatures at the point of delivery should be within the range 5°C (41°F) to 35°C (95°F). - The temperature of the ground, concrete forms where the concrete is placed (and the ground's water content)

- The ambient temperature during concrete placement and during concrete curing.

Concrete contractors can block the effects of wind by covering curing concrete.

Contractors often block the effects of too much humidity (or rain), or use wetting to deal with too little humidity (evaporation exceeds the rate of water bleed-through to the concrete surface) during concrete curing.

To address the effects of high or low curing temperatures special concrete additives (admixtures) as well as concrete blankets that can provide concrete cooling or warming are used to protect concrete from damage during curing in cold and freezing weather.

Cold Weather Concrete Admixtures

In cold weather concrete cures more-slowly because the hydration process, a chemical reaction that generates heat, is itself slowed by the lower temperature. Concrete will need about 1/3 more curing time for each 10F drop in ambient temperatures as long as the temperature remains above freezing, or down to about 40°F.

Admixtures that act as a concrete curing accelerant might be used to speed this process, thus reducing the risk of freezing or cold-weather damage to the new concrete pour. Calcium chloride is a long-established and widely-used concrete set accelerator for cold weather, but CaCl, a salt, is prohibited in some jurisdictions.

Other non-chloride concrete cure accelerants are available both to speed cure and to prevent freezing damage to the new concrete. (Nmai 1998).

Hot Weather Concrete Admixtures

Various types of chemical admixtures can be beneficial in hot weather conditions. Water reducers (plasticisers) can be used to reduce the water content or to aid the workability. This enables rapid placement and consolidation of the concrete with beneficial effects on the ultimate strength and durability.

Set-retarders can provide additional time to place and finish flatwork. With rapid drying of the surface, caution is required with the use of set retarders, as the surface may appear ready for finishing, but the concrete below may still be plastic from the retarder, leading to a ‘spongy’ feel under foot. This could affect the uniformity of the surface finish. - Source: HOT WEATHER CONCRETING CCA Australia cited in detail below

There are other measures for dealing with placing concrete in hot weather.

Concrete contractors may order special types of cement such as slower-hydrating mixes for use in hot weather (Type LH concrete mix).

Contractors may also adjust the actual cement content in the concrete, taking care to avoid using a mix with more portland cement than is required for the specified concrete finished productr strength and durability. Adding more cement than needed raises the hydration temperature of the concrete.

Research on the effects of temperature on concrete curing

Photo: concrete placement during construction of a new science building at Vassar College, Poughkeepsie, NY in December 2013

- Acquaye, Lucy, EFFECT OF HIGH CURING TEMPERATURES ON THE STRENGTH, DURABILITY AND POTENTIAL OF DELAYED ETTRINGITE FORMATION IN

MASS CONCRETE STRUCTURE [PDF] Dissertation, University of Florida, (2006) retrieved 2018.07/23, original source: http://etd.fcla.edu/UF/UFE0013837/acquaye_l.pdf

This paper discusses externaland internal thermal cracking in concrete as an effect of high temperature curing, as well as other concrete curing effects of temperature. - Aitcin, Pierre-Claude, Adam Neville, and Paul Acker. "Integrated view of shrinkage deformation." Concrete International 19, no. 9 (1997): 35-41.

Abstract:

In common usage, the term shrinkage is a shorthand expression for drying shrinkage of hardened concrete exposed to air with a relative humidity of less than just under 100 percent. This paper describes the concomitant effects of hydration: development of strength, development of heat, and reduction in the volume of hydrating cement paste system (autogenous shrinkage).

Plastic shrinkage, drying shrinkage, autogenous shrinkage, and thermal shrinkage are discussed with particular reference to their effects in various types of structural elements made with high-performance concrete. - Alexander, Stuart. "Why does our concrete still crack and leak?." In Application of Codes, Design and Regulations: Proceedings of the International Conference held at the University of Dundee, Scotland, UK on 5–7 July 2005, pp. 155-164. Thomas Telford Publishing, 2005.

- AS 1379-1997, Specification and supply of concrete, Australia

- AS 3600 Concrete structures., Australia

- Burg, Ronald G. THE INFLUENCE OF CASTING AND CURING TEMPERATURE ON THE PROPERTIES OF FRESH AND HARDENED CONCRETE [PDF] No. R&D Bulletin RD113T,. Portland Cement Association, 1996.

Abstract:

Concretes, made with two different cements, were cast in the laboratory at temperatures of 10,23 and 32°C (50, 73, and 90”F). The concrete mix design was held constant for each cement used in the study.

Fresh properties, including slump, air content, and time of initial and final set, were measured. These concretes were moist cured at their casting temperature.

In the case of the concrete cast at 23°C (73°F), an additional set of specimens was cured at a temperature of 10”C (50°F). Compressive strength was determined at ages between three and 56 days,

Test results show workability, as measured by slump, is greatly affected by casting temperature. Slump at 10”C (50”F) was as much as 214~0 of the slump at 23°C (73”F), while slump at 32°C (90”F) was as little as 80% of the slump at 23°C (73”F). Time of set was similarly affected.

Low temperature setting time was as much as 195% of setting time at 23°C (73°F).

High temperature setting time was as short as 68% of setting time at 23°C (73°F). As expected, early age compressive strength of concrete cast and cured at high temperature was greater than concrete cast and cured at 23°C (73”F).

However, after seven days, compressive strength of concrete cast and cured at high temperature was lower than concrete cast and cured at 23°C (73°F).

Concrete cast and cured at low temperature had initial strength lower than concrete cast and cured at 23°C (73°F). However, later age strength either equaled or exceeded that of concrete cast at 23°C (73”F). - CCA HOT WEATHER CONCRETING, [PDF] CCA, Cement Concrete & Aggregates, Australia, retrieved 2018/07/23, original source: https://www.ccaa.com.au//imis_prod/documents/ Library%20Documents/ CCAA%20Datasheets/ CCAA-HOT-WEATHER-CONCRETING.pdf

Excerpt:

While hot weather conditions are commonly encountered in summer, combinations of high temperatures, winds and low humidity could result in conditions leading to problems with concrete placement and finishing at any time.

This data sheet provides guidance on the effects of hot weather conditions on the properties of concrete, and the precautions that should be taken, particularly with flatwork, to minimize any potential adverse effects when placing concrete under these conditions. - CCA, SPECIFYING CONCRETE [PDF], CCA, Op. Cit., retrieved 2018/07/23, original source: http://210.10.254.97/publications/pdf/Specifying.pdf

Excerpt:

This Data Sheet provides guidance on the preparation of specifications for the supply of premixed concrete. It is general in nature and does not provide specification wording. Issues specific to a particular project should be discussed with the concrete supplier. - Fitzgibbon, Michael E. "Large pours for reinforced concrete structures", Cement and Concrete Association, 53 Grosvenor Gardens, London SW1W 0AQ, England,Current Practice Sheet 2P/15/1, No. 28." The Concrete Society, Concrete 10, no. 3 (1976). Accession Number: 00137482

Abstract:

Reinforced sections of high-strength concrete, rich in cement, can be cast in one continuous pour whether 30 M3 or 3000 M3 in volume. The technique was developed to solve an increasing problem facing the construction industry when casting large amounts of structural-quality concrete for reinforced sections.

Although it is current practice, some explanation of the technique is included where necessary to emphasize its striking contrast with the traditional method developed for mass concrete dam construction. This current practice sheet describes the principles and planning leading up to the decision to cast in one or monolithically. - Gajda, John, and Martha Vangeem. CONTROLLING TEMPERATURES in MASS CONCRETE [PDF] Concrete International 24, no. 1 (2002): 58-62. Retrieved 2018/07/23, original souirce: https://gab.wallawalla.edu/~larry.aamodt/engr325/concrete_heating.pdf

Excerpts:

Specifications generally limit temperatures in mass concrete to prevent cracking and durability problems.

Temperature limits are specified to seemingly arbitrary values of 135 F (57 C) for the maximum allowable concrete temperature and 35 F (19 C) for the maximum allowable temperature difference between the center and surface of the mass concrete section.

Typically, the contractor must meet all of the specification requirements, but without a good understanding of mass concrete, keeping concrete temperatures within limits can be a difficult task. Often, well-established temperature control measures are sufficient to meet project specifications.

However, if these are overlooked or poorly understood, they could result in concrete temperatures and temperature differences that greatly exceed specified limits, causing delays to the construction schedule or damage to the concrete.

...

Studies have shown that the long-term durability of certain concretes can be compromised if the maximum temperature after placement exceeds the range of 155 to 165 F (68 to 74 C).

The primary damage mechanism is delayed ettringite formation (DEF). DEF can cause internal expansion and cracking of concrete, which may not be evident for several years after placement.

Other reasons to limit the maximum concrete temperature include reducing cooling times and associated delays, and minimizing the potential for cracking due to thermal expansion and contraction. Temperatures over 190 F (88 C) can also reduce expected compressive strengths. - Ghani, Usman, Faisal Shabbir, and Kamran Muzaffar Khan, EFFECT OF TEMPERATURE ON DIFFERENT PROPERTIES OF CONCRETE [PDF] In Proceedings of the 31st Conference on Our World in Concrete and Structures, Singapore. 2006.

Abstract:

In this research work, the effect of low and high temperature on various properties of concrete was investigated. The properties investigated were modulus of rupture of concrete beams, compressive strength and tensile strength of concrete. Three different temperatures were used for this purpose. These were low, room and high temperatures. The low temperature was 5°C, room temperature was 28°C and high temperature was taken as 55°C.

For compressive strength calculations, cubes of sizes (6˝x6˝x6˝) were cast. Cylinders of sizes (6˝x12˝) were made for tensile strength measurement, and for modulus of rupture beams of sizes (4˝x4˝x18˝) were cast. Locally available material was used in casting these samples. After casting these samples, curing was carried out at low and high temperature along with room temperature. These samples were then tested after three, seven and twenty eight days of curing and a comparative study was carried out. - Hanson, USING CONCRETE in COLD WEATHER [PDF] Hanson Heidelberg Cement Group, U.K., Website: hanson.com, [the HeidelbergCement company, with offices world wide, does not provide their address via their website] Email: concrete@hanson.com retrieved 2018/07/23, original source: http://www.concreteconstruction.net/_view-object?id=00000153-8b76-dbf3-a177-9f7fa9810000

Abstract:

Additional care must be taken when placing concrete in cold weather. If young concrete is allowed to cool below freezing point it may be damaged to such an extent that it will be unfit for use.

It should be noted that even if temperatures do not drop below zero the concrete will develop strength significantly slower than during the warmer ambient temperatures. - Neville, Adam. "The confused world of sulfate attack on concrete." Cement and Concrete research 34, no. 8 (2004): 1275-1296.

- Neville, Adam, and Pierre-Claude Aitcin. "High performance concrete—an overview." Materials and structures 31, no. 2 (1998): 111-117.

- Neville, Adam. "Aggregate bond and modulus of elasticity of concrete." Materials Journal 94, no. 1 (1997): 71-74.

- Neville, Adam. "Maintenance and durability of structures." Concrete International 19, no. 11 (1997): 52-56.

- Nmai, Charles K. "Cold weather concreting admixtures." Cement and Concrete Composites 20, no. 2-3 (1998): 121-128.

Abstract:

Significant strides fave been made in the manufacture, placement, curing and protection of concrete under cold weather conditions. As a result, construction companies no longer discontinue concrete placements during cold winter months. In this paper, design considerations that need to be taken into account for the production of high-performance concrete mixtures for cold weather concreting are briefly discussed, with particular emphasis on accelerating admixtures.

Performance data for high-performance cold weather concrete mixtures treated with a nonchloride accelerator that contains sodium thiocyanate and provides protection against freezing in the plastic state at ambient temperatures as low as −7 °C (20 °F), are presented for four projects.

The data show the effectiveness of this cold weather admixture (CWA) over a range of abovefreezing and subfreezing temperatures, and provide further support for the use of accelerating admixtures as a viable and economical option for cold weather concreting. - Phan, Long T., James R. Lawson, and Frank L. Davis. "Effects of elevated temperature exposure on heating characteristics, spalling, and residual properties of high performance concrete." Materials and structures 34, no. 2 (2001): 83-91.

These authors note the possibilty of spalling concrete surfaces resulting from high temperature exposure during pour and set of concrete structures. - Soudki, K. A., E. F. El-Salakawy, and N. B. Elkum. "Full factorial optimization of concrete mix design for hot climates." Journal of materials in civil engineering 13, no. 6 (2001): 427-433.

Abstract:

This paper presents the results of a statistical analysis aimed to optimize a concrete mix design for hot climates. A full factorial experiment with 3 × 4 × 4 × 3 treatment combinations (432) samples) of 48 mixes at three levels of temperature was used.

The influences of the water/cement ratio (0.4, 0.5, and 0.6), coarse aggregate/total aggregate ratio (0.55, 0.6, 0.65, and 0.7), total aggregate/cement ratio (3, 4, 5, and 6), and temperature (24, 38, and 52°C) on compressive strength were characterized and analyzed using polynomial regression. Mathematical polynomials were developed for concrete strength as a function of temperature and mix proportion.

Based on the statistical analysis, recommendations are provided on the optimum concrete mix for different temperatures as well as the mix that is least sensitive to temperature variations. - SuperKrete S-1400 PENE-KRETE® ADDITIVE™ for Portland Cement [PDF] (Technical Data Sheet), Super-Krete® International, Inc., 2705 Via Orange Way Suite B, Spring Valley CA 91978 USA, Tel: 800-995-1716, Website: www.super-krete-com, original source: http://questbuilding.com/docs/S-1400_Pene-Krete_Additive_TDS.pdf retrieved 2018/07/23

...

...

Continue reading at CONCRETE SLAB CRACK EVALUATION - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CONCRETE COLD POUR JOINTS

- CONCRETE SHRINKAGE CRACKS

- CONCRETE SLAB CRACK EVALUATION

- CONTROL JOINT CRACKS in CONCRETE

- FREEZING & WATER DAMAGED SLABS

- FROST HEAVE / EXPANSIVE SOIL CRACKS in SLABS

- SETTLEMENT CRACKS in SLABS

- SETTLEMENT vs. FROST HEAVE CRACKS

- SETTLEMENT vs. SHRINKAGE CRACKS

- SHRINKAGE CRACKS in SLABS

- SHRINKAGE CRACKS at FOUNDATION WALLS

- TEMPERATURE EFFECT on CONCRETE POUR

- CONCRETE SLAB CRACK REPAIR

Suggested citation for this web page

TEMPERATURE EFFECT on CONCRETE POUR at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Branz Corporation, "Concrete Slabs and Conrol Joints", Build, Aug/Sept 2005, Branz, Moonshine Road, Judgeford, Porirua City 5381, New Zealand Post: Private Bag 50 908, Porirua 5240, New Zealand Phone: +64 4 237 1170 Fax: +64 4 237 1171 Email: branz@branz.co.nz Publication sales: publicationsales@branz.co.nz , Tel: Professionals helpline - 0800 80 80 85 - is available free to those who work within the New Zealand building and construction industry. Tel: consumer helpline is 0900 5 90 90. Calls cost $1.99 per minute, plus GST. Quoting: BRANZ is an independent and impartial research, testing, consulting and information company providing resources for the building industry.

- "Concrete Slab Finishes and the Use of the F-number System", Matthew Stuart, P.E., S.E., F.ASCE, online course at www.pdhonline.org/courses/s130/s130.htm

- Thanks to Alan Carson, Carson Dunlop, Associates, Toronto, for technical critique and some of the foundation inspection photographs cited in these articles

- Dave Wickersheimer, P.E. R.A. - IL, professor, school of structures division, UIUC - University of Illinois at Urbana-Champaign School of Architecture. Professor Wickersheimer specializes in structural failure investigation and repair for wood and masonry construction. * Mr. Wickersheimer's engineering consulting service can be contacted at HDC Wickersheimer Engineering Services. (3/2010)

- *These reviewers have not returned comment 6/95

- Building Pathology: Principles and Practice, David Watt, Wiley-Blackwell; 2 edition (March 7, 2008) ISBN-10: 1405161035 ISBN-13: 978-1405161039

- Diagnosing & Repairing House Structure Problems, Edgar O. Seaquist, McGraw Hill, 1980 ISBN 0-07-056013-7 (obsolete, incomplete, missing most diagnosis steps, but very good reading; out of print but used copies are available at Amazon.com, and reprints are available from some inspection tool suppliers). Ed Seaquist was among the first speakers invited to a series of educational conferences organized by D Friedman for ASHI, the American Society of Home Inspectors, where the topic of inspecting the in-service condition of building structures was first addressed.

- Design of Wood Structures - ASD, Donald E. Breyer, Kenneth Fridley, Kelly Cobeen, David Pollock, McGraw Hill, 2003, ISBN-10: 0071379320, ISBN-13: 978-0071379328This book is an update of a long-established text dating from at least 1988 (DJF); Quoting:This book is gives a good grasp of seismic design for wood structures. Many of the examples especially near the end are good practice for the California PE Special Seismic Exam design questions. It gives a good grasp of how seismic forces move through a building and how to calculate those forces at various locations. THE CLASSIC TEXT ON WOOD DESIGN UPDATED TO INCLUDE THE LATEST CODES AND DATA. Reflects the most recent provisions of the 2003 International Building Code and 2001 National Design Specification for Wood Construction. Continuing the sterling standard set by earlier editions, this indispensable reference clearly explains the best wood design techniques for the safe handling of gravity and lateral loads. Carefully revised and updated to include the new 2003 International Building Code, ASCE 7-02 Minimum Design Loads for Buildings and Other Structures, the 2001 National Design Specification for Wood Construction, and the most recent Allowable Stress Design.

- Building Failures, Diagnosis & Avoidance, 2d Ed., W.H. Ransom, E.& F. Spon, New York, 1987 ISBN 0-419-14270-3

- Domestic Building Surveys, Andrew R. Williams, Kindle book, Amazon.com

- "Avoiding Foundation Failures," Robert Marshall, Journal of Light Construction, July, 1996 (Highly recommend this article-DF)

- "A Foundation for Unstable Soils," Harris Hyman, P.E., Journal of Light Construction, May 1995

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.