Mineral Wool Building Insulation Under the Microscope

Mineral Wool Building Insulation Under the Microscope

Mineral wool: Rock or Stone Wool or Slag Wool

Compared With Fiberglass Insulation

- POST a QUESTION or COMMENT about Rock Wool mineral fiber insulation & microscopic examination or identification of mineral wool fibers

Rock wool or mineral wool insulation examined under the light microscope.

Microscopic examination & identification of mineral wool, slag wool also commonly referred to as rock wool used for building insulation. Photographs of mineral wool under the microscope.

This article describes and illustrates the microscopic properties of mineral wool or slag wool or "rock wool" insulation. Microscopic Images of mineral, stone or vitreous fibers are provided.

This mineral wool or "rock wool" insulation article series illustrates and describes mineral wool or "rock wool" and slag wool insulation materials. Rock wool or "rockwool" insulation is also called mineral wool and slag wool though there can be differences among the components of these insulations. We describe old-house or "antique" mineral wool insulation as well as modern mineral wool insulating products still used in buildings.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Mineral Wool Insulation Under the Microscope

Our first photo shows fibrous insulation sent to us by a reader who asked that it be identified.

Our first photo shows fibrous insulation sent to us by a reader who asked that it be identified.

While we describe variations in the appearance of mineral wool in a companion article - MINERAL WOOL IDENTIFICATION, APPEARANCE VARIATIONS - the usual colors of this insulating material range from white to a dirty gray.

We added this reader's photo to that article as well as other photos of his insulation sample to show that his insulation appeared in three color mixes.

In this article we provide forensic laboratory photographs and details that identify this insulation as mineral wool or slag wool.

Particularly where the insulation is many years old we may also find dust contaminants in the insulation that include insect fragments, road dust and debris, and occasionally mold spores and fungal hyphae.

[Click to enlarge any image]

If a building has been re-roofed we might find debris from roofing material such as mineral granules and fragments of asphalt from the roof-work.

The mixed rock-wool fragment below was from the same building as the all-brown-gray sample above.

This is what the reader provided for lab analysis. We found mineral wool and asphalt fragments.

Color variations appeared to be principally due to a mix of mineral wool of different compositions, perhaps different batches of slag or minerals from which the insulation was heated and spun into fibers.

Lab photos of the slag wool insulation above are given in this article beginning

Beginning below are more examples of slag wool or rock wool insulation of various colors and textures as seen under a high powered light microscope..

Gold Bond Rock Wool Insulation Lab Photographs

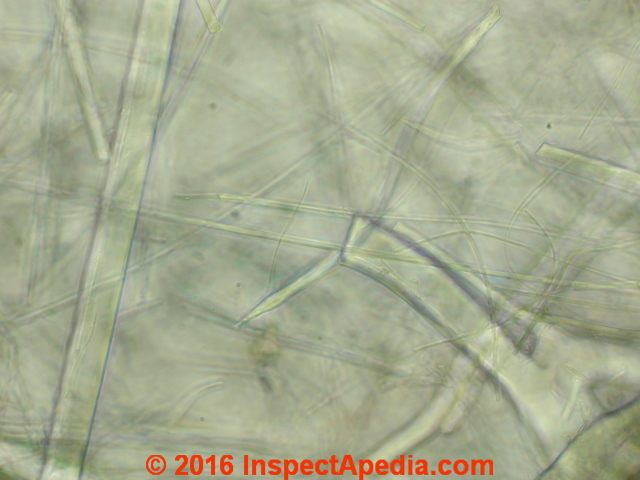

Above, low power (300x) then higher power (720x) light microscope images of Gold Bond™ Rock Wool insulation.

The smooth surface of these fibers of this insulation are microscopically similar to fiberglass, and like fiberglass, under a forensic microscope these fibers will "disappear" under polarized light.

However other fibers such as flax or cellulose, if present in the insulation sample, will show up under polarized lighting.

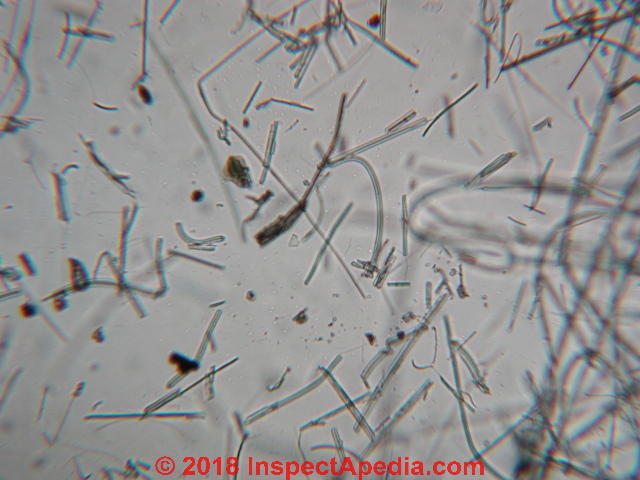

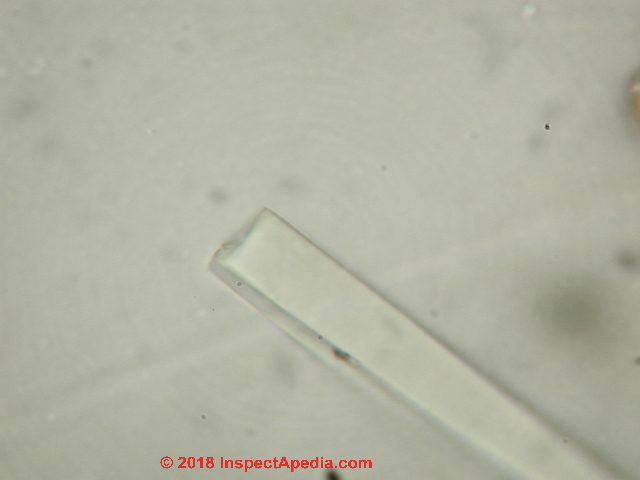

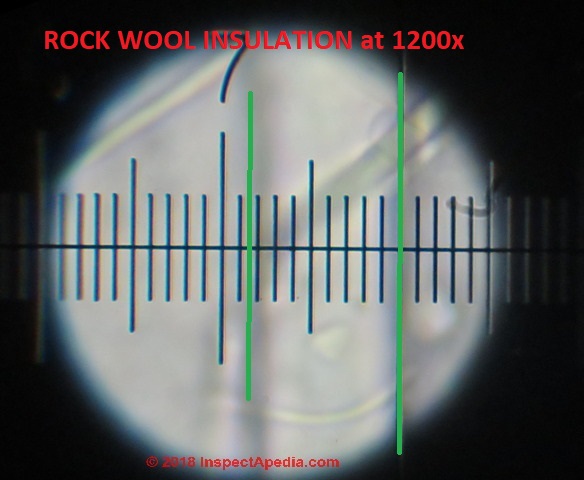

Above and below are two photographs of the same mineral wool sample at 1200x magnification.

Above: notice the characteristic square-ended mineral wool or rock wool fiber in this image. That helps distinguish rock wool insulation from fiberglass insulation.

So does our next photograph:

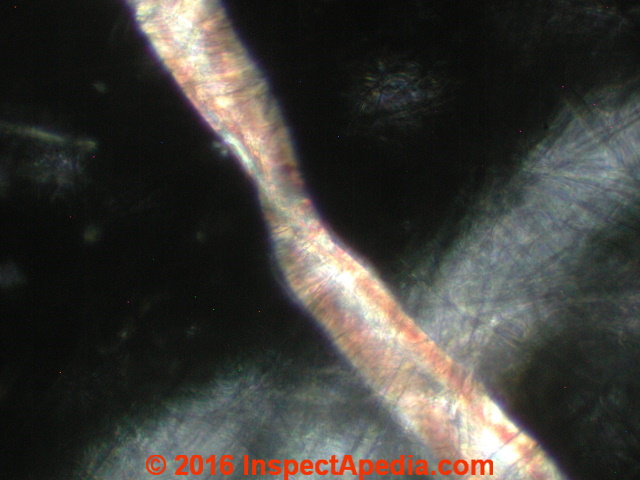

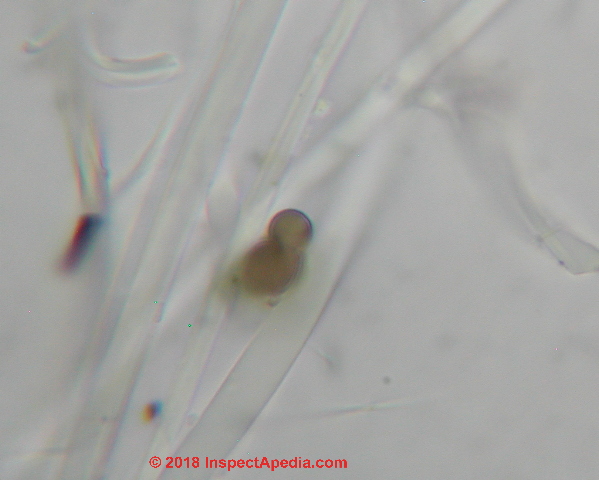

Above: our second photograph uses polarized light to show included fibers in the same sample that are not in fact mineral wool.

Fibres such as flax, linen, or other organic substances were added to mineral wool or slag wool by some processes in order to improve the insulation's coherence or adherence and to reduce sagging when the insulation was installed in walls.

A closer look at this fiber suggests this may be flax, similar to linen.

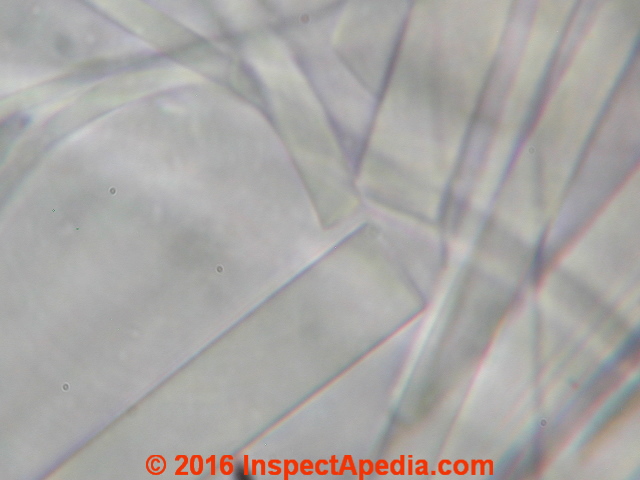

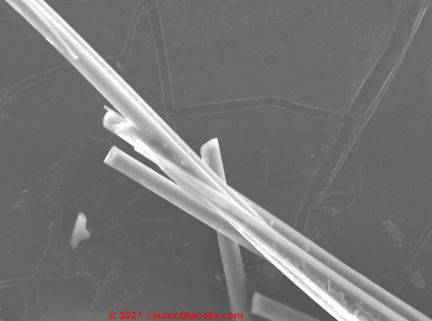

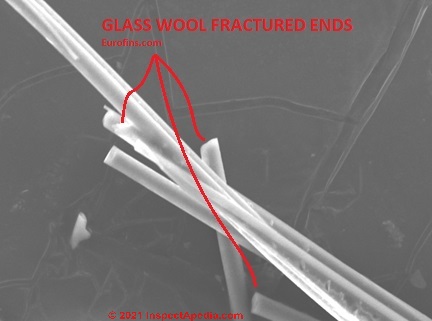

Below: additional microscope images of mineral wool insulation showing the broken end of an individual fiber.

In the first photograph just below you can see a fragment protruding from the broken mineral wool insulation fiber end. This is unusual and is similar to the ends of fiberglass fibers that break with a concoidal fracture.

Below, our second, more gray photo shows rather more typical square-ends of fibers in a sample of mineral wool insulation.

Unlike fiberglass, most of the mineral wool fiber ends we examined in this sample had square-cut ends without a concoidal fracture or fragments.

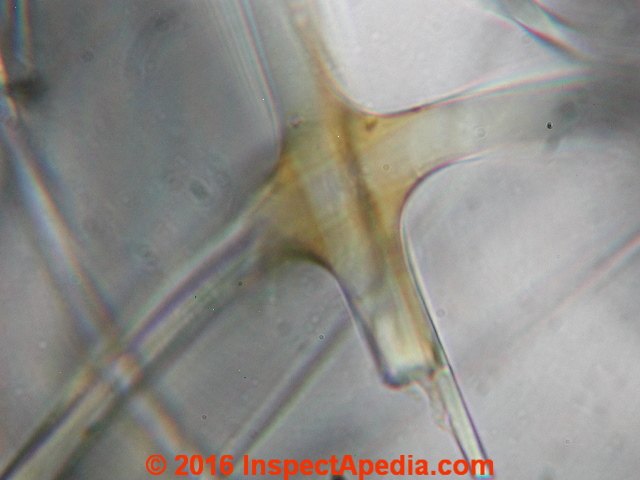

Below: a high power light microscope image of Gold Bond Rock Wool insulation showing the resin binder on crossing fibers.

These enlarged slag wool / stone wool photographs were taken at roughly 1200x using Gold Bond Rock Wool insulation mounted in triacetin.

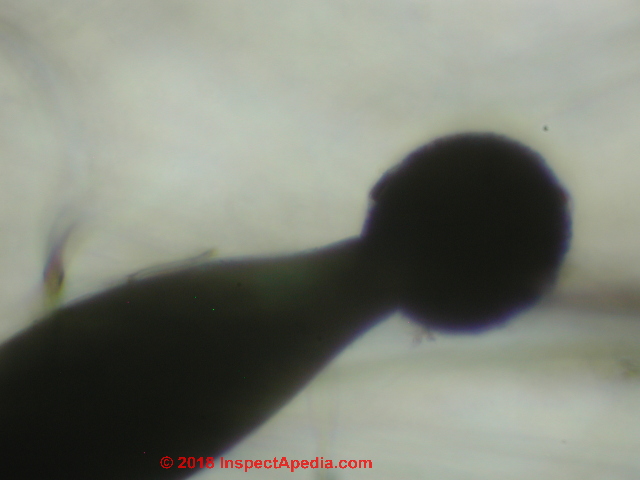

Below my macro-photograph of slag wool insulation shows characteristic globules of blast furnace debris.

Below: glassy globules visible under low power magnification of a mineral wool fiber sample, changing our lighting method from the photo above. [Click to enlarge any image]

Lab Analysis of Reader's White & Dark-Brown to Black Mineral Wool Sample

Above: a reader mailed this sample of insulation for identification. [Please do NOT attempt to mail us samples for laboratory analysis unless we have previously agreed by email to perform that service.]

[Click to enlarge any image]

We photographed the insulation sample above at various magnifications under the stereo-microscope (below) and under a POLAM high-powered light microscope at magnifications up to 1200x.

This series of photographs confirms that the material is mineral wool, shows mineral wool fibres of several colors including hyaline (colorless that appears "white" to the naked eye), and dark brown that appears gray or almost black to the naked eye.

Our slag wool photo below, taken from this sample under the stereo microscope and digitally-enlarged, illustrates the presence of spherical particles (red arrows) that are probably an artifact of the slag wool production process that involves the melting and spinning of mineral or slag raw materials.

Our greatly-enlarged view of one of these black particles, shown at 1200x, gives more detail.

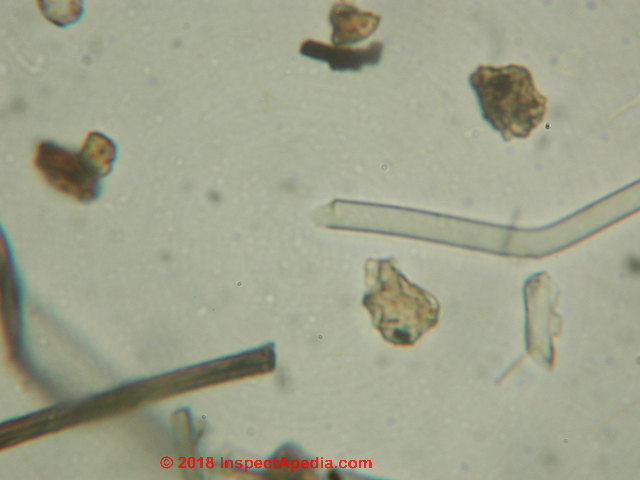

We found other black particles in this insulation, possibly asphalt, used as a binder, and still other particulate contaminants that are common in older insulation such as mold hyphae and spores and non-fungal granular debris typical of road dust or soil particles.

We examined this slag wool insulation sample at increasing levels of magnification to study its various components and properties.

Above: at 120x we see a range of rock wool fibre diameters, lengths, shapes, and colors as well as particulates in the insulation sample.

Below is a portion of this mineral wool sample magnified to 720x, prepared in lacto-phenol as a mounting medium.

In the photo above we see two very different fibers. The fractured end of the colorless fiber is not typical: most mineral wool fibers break off in a relatively straight or square-cut end.

But don't let the presence of an occasional fractured end fool you into thinking this is fiberglass (whose ends terminate in a concoidal fracture). This is not fiberglass.

Most likely the darker square-end fiber is either from a different batch of mineral wool or slag wool produced by the same fabricator but at a different time, later mixed together.

The mineral wool picture above also shows us that there is plenty of non-fungal granular debris in the sample: "dirt" or soil particles possibly from road dust or airborne soil dust.

Above and just below our photographs illustrate the presence of hyphal fragments and mold spores in this insulation - no surprise in an older building.

Below at 1200x in the next two photographs of Rock Wool under the microscope

we see the characteristic square-cut end of these mineral wool fiber fragments.

Below we illustrate that mineral wool fibers also vary in shape - not all are simple straight fibers.

Because in this sample the hyaline fibers were generally straight to slightly curved and the darker fibers were often curved or even branched as in our photo, we inferred that this insulation sample contained mineral wool spun from more than one batch of raw material minerals and slag.

Rock Wool insulation fibers will appear in a sample in a wide range of diameters, from about 1.6 u (micros) to about 80 u in this case.

Our photo below shows a measurement of one of the larger insulation fibers using an eyepiece micrometer with our POLAM microscope at 720x.

At 720x with this microscope each division on the micrometer is about 1.35u.

Counting the divisions on the scale in the photo gives us about 8.5 x 1.35 or about 11 microns as a common size, but we found some fibers much larger in diameter, up to about 80 microns, and other fibers as small as under 2 microns.

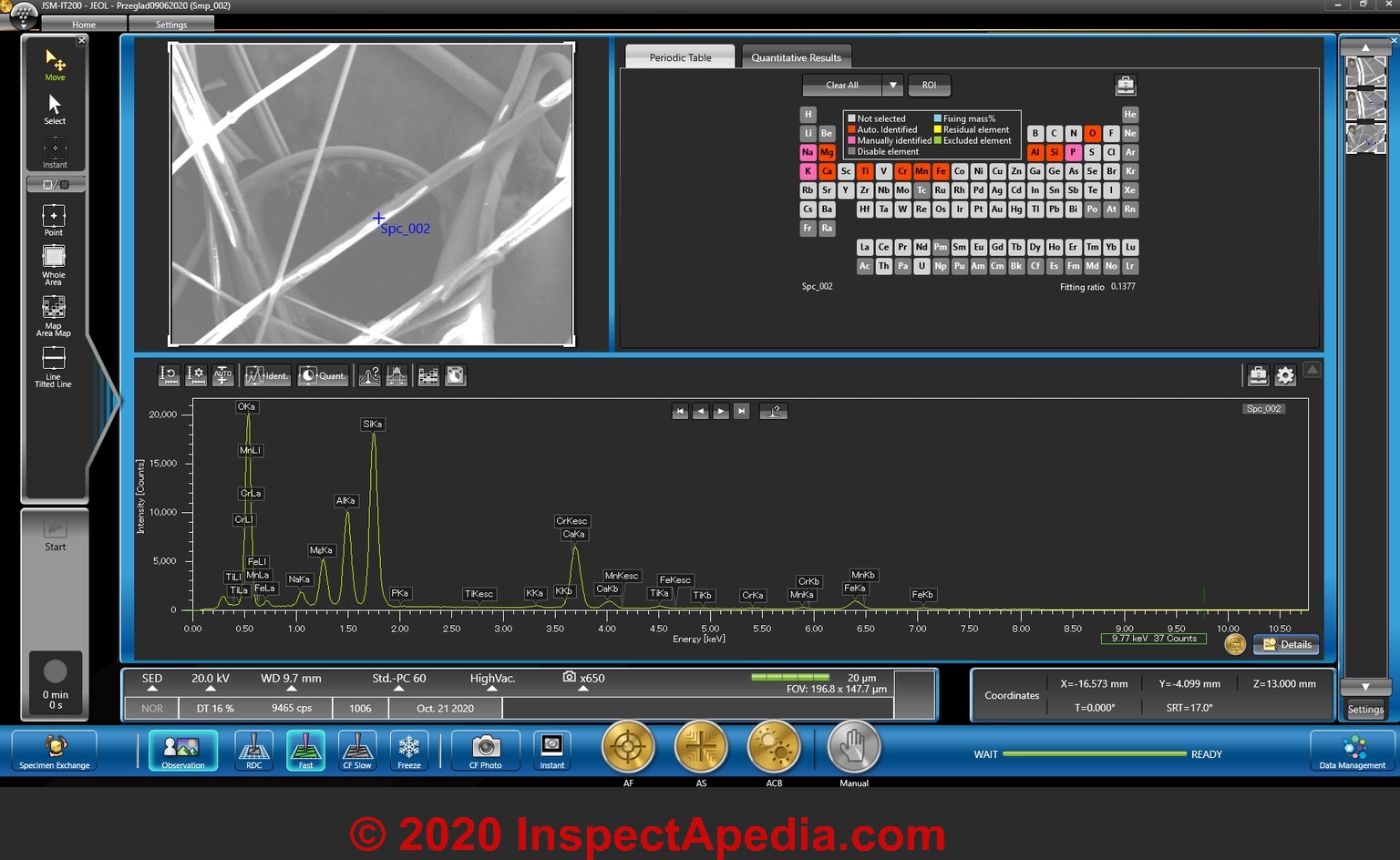

SEM Photographs & Identification of Fiberglass vs Rock Wool vs Slag Wool

Continuing our discussion of the differences between rock wool and slag wool found

at MINERAL WOOL - ROCK WOOL INSULATION - topic home,

these Scanning Electron Microscope (SEM) photographs have been contributed by Aleksandra Pawelek, an SEM microscopist and project leader in Environmental Laboratory in Poland which provides asbestos and mineral wool analysis of building and road materials. (October 2020) - Email: AleksandraPawelek@eurofins.com

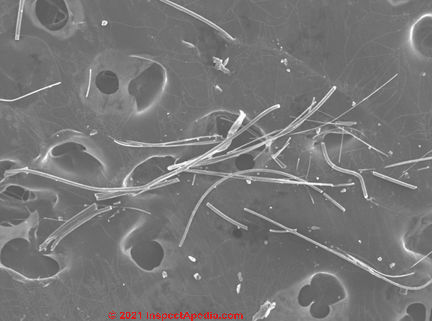

Rock Wool Fibre Identification by SEM

[Click to enlarge any image]

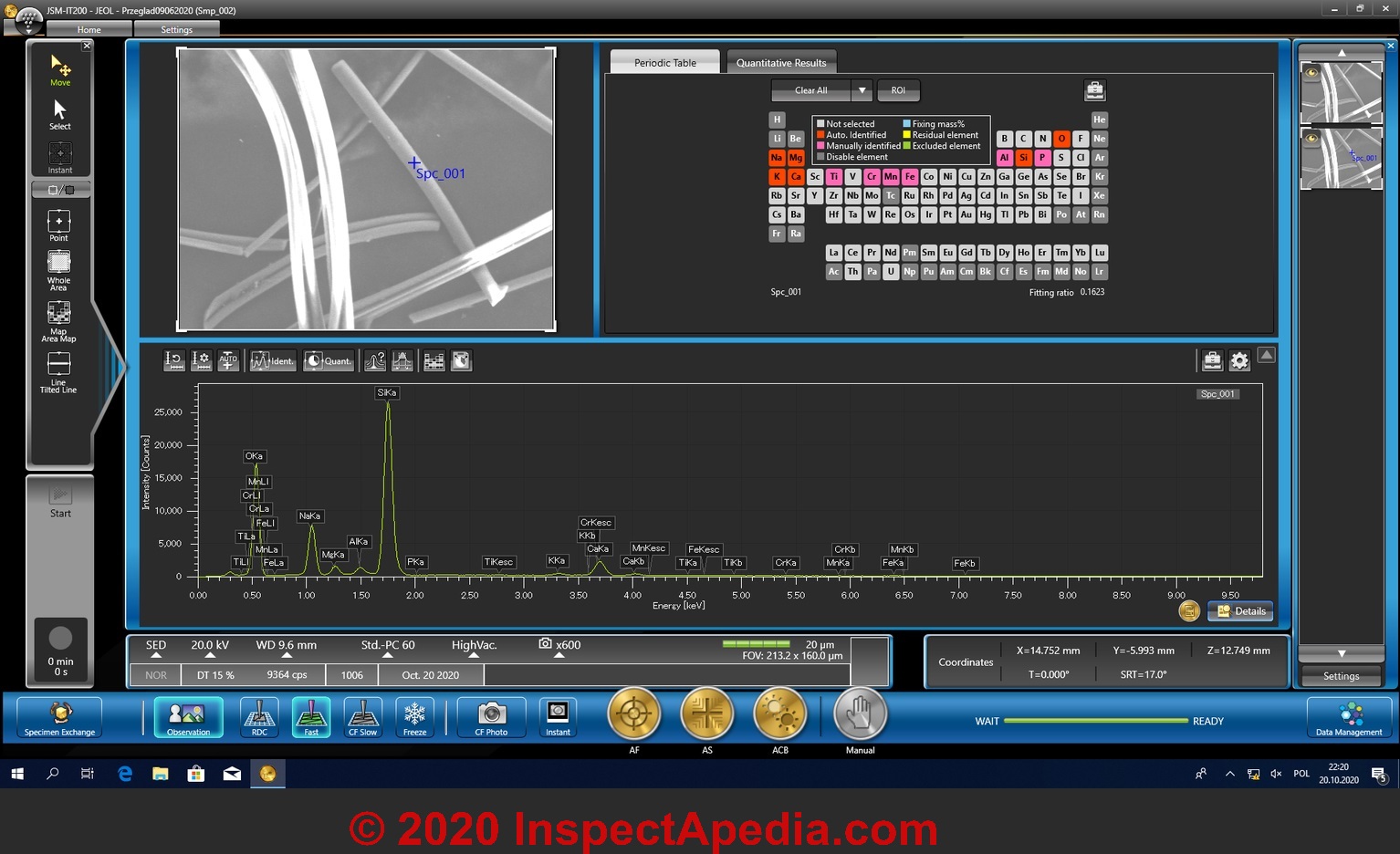

You will notice that in these Scanning Electron Microscope analyses of Stone Wool (Rock Wool) insulation the system automatically detected these elements:

Mg, Ca, Ti, Cr, Mn, Fe, Al, Si, and O and manually identified P, Na, K. For those readers not familiar with the atomic symbols found in the periodic table we can also write these as

Sodium, Magnesium, Potassium, Calcium, Titanium, Chromium, Manganese, Iron, Aluminum, Silicone, Oxygen , Phosphorous.

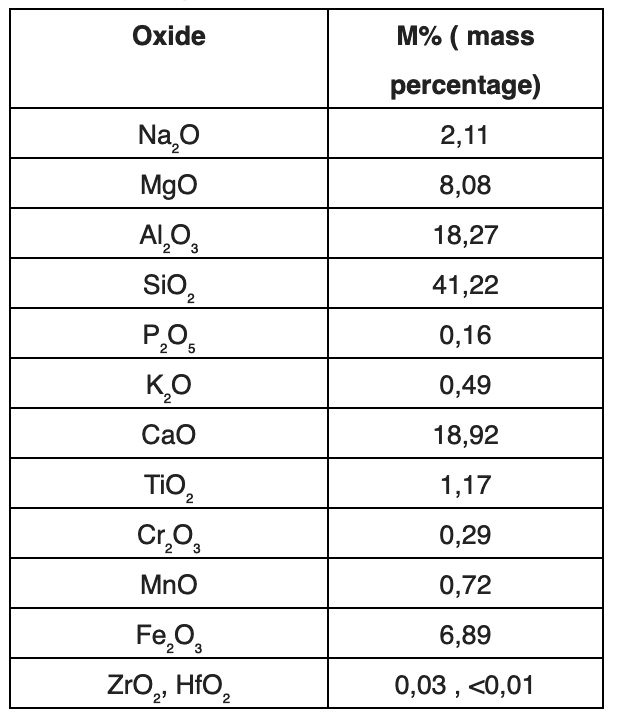

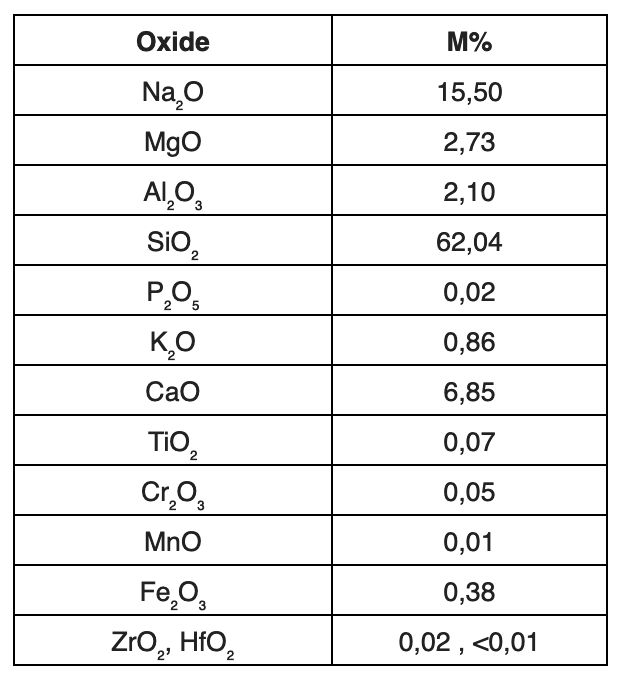

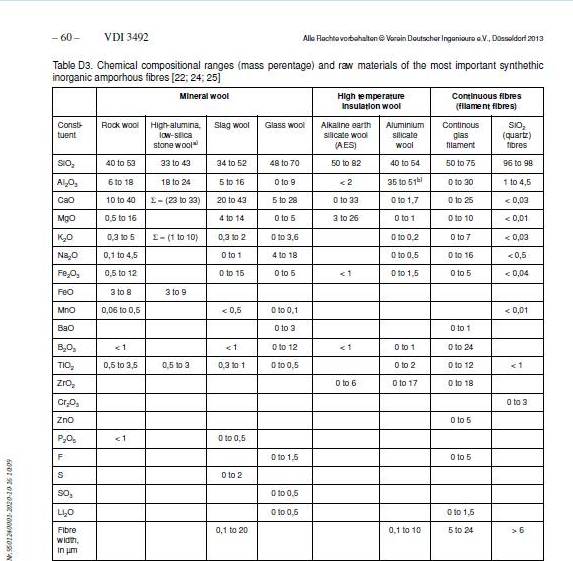

Here is the chemical composition of reference rock wool fibre in reference to German standard VDI 3492, considers for following oxides:

[Click to enlarge any image]

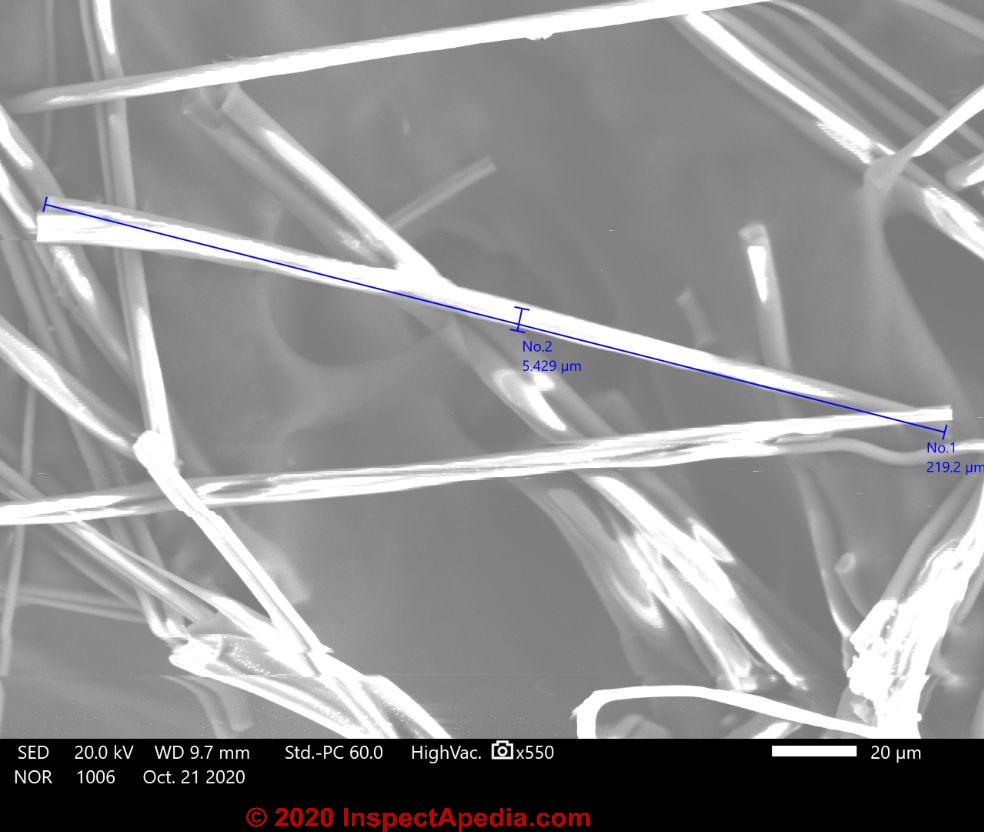

Below: Rock wool insulation SEM photograph by our contributor with marked typical dimension.

Glass Wool Fibre Identification by SEM

You will notice that in these Scanning Electron Microscope analyses of Glass wool insulation the system automatically detected these elements:

Na, Mg, K, Si, and O and manually identified Ti, Cr, Mn, Fe, Al, P. For those readers not familiar with the atomic symbols found in the periodic table we can also write these as

Sodium, Magnesium, Potassium, Calcium, Titanium, Chromium, Manganese, Iron, Aluminum, Silicone, and Oxygen , Phosphorous.

Below is the chemical composition of reference glass wool fibre in reference to German standard VDI 3492, considers for following oxides:

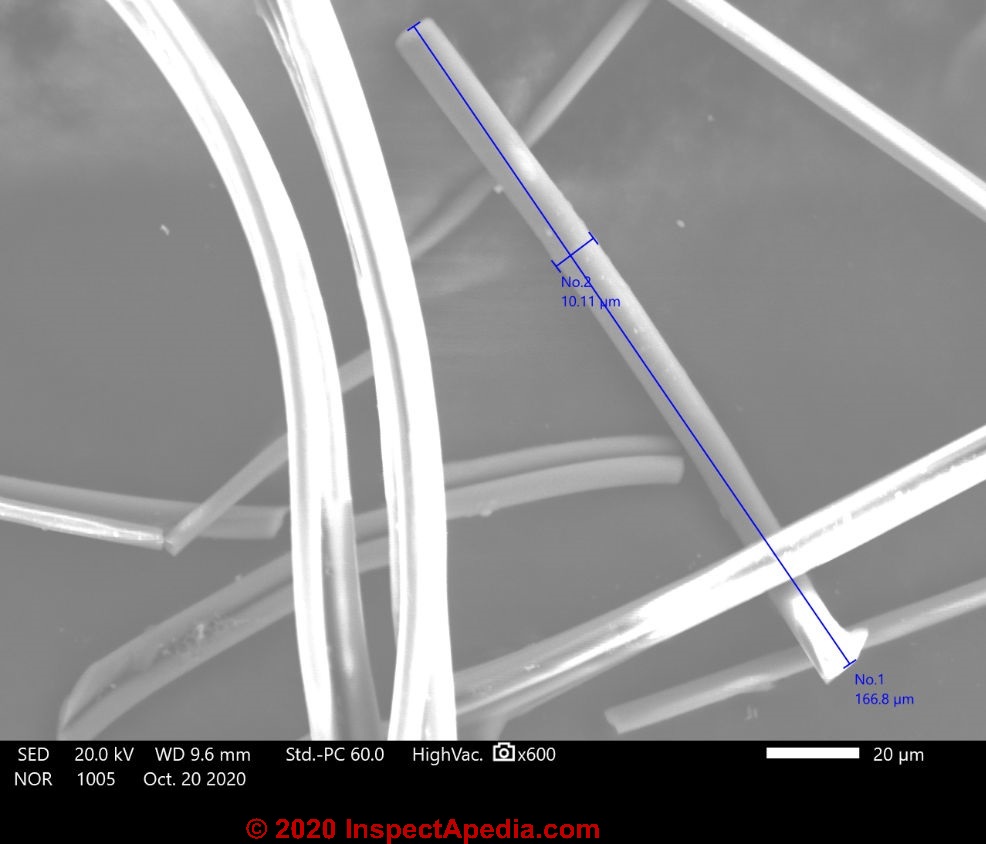

Below: Glass wool insulation SEM photograph by our contributor with marked typical dimension.

Slag Wool SEM Identification Photographs & Composition Data - samples wanted

Slag Wool SEM Identification Photographs & Composition Data

Additional analysis of slag wool insulation will be posted here when available.

Any reader who can provide a sample which could be classified as slag wool

Please contact : AleksandraPawelek@eurofins.com

and/or contact InspectApedia.com using the page top or bottom CONTACT link.

Mineral Wool or Rock Wool Research & References

- APC Standards VDI 349 2 INDOOR AIR MEASUREMENTAMBIENT AIR MEASUREMENT MEASUREMENT OF INORGANIC FIBROUS PARTICLES SCANNING ELECTRON MICROSCOPY METHOD Step by Step [PDF] (2014) retrieved 2020/10/29 original source: http://www.sviva.gov.il/subjectsEnv/Asbestos/Professionals/Documents/Labs-Seminar/VDI%203492_Step_by_Step_1_4.pdf

- Cummings, J. M. "Possibilities for the Manufacture of Mineral Wool in British Columbia" [PDF], British Columbia Department of Mines, (1937)

- includes tables comparing properties of various insulation and other materials to mineral wool and balsam wool, retrieved 12/6/2014, original source: 142.32.76.167/Mining/Geoscience/ PublicationsCatalogue/MiscellaneousPublications/ Documents/PossibilitiesManufactureMineralWool1937.pdf - Eparvier, Agnès, Philippe Lemanceau, and Claude Alabouvette. "Population dynamics of non-pathogenic Fusarium and fluorescent Pseudomonas strains in rockwool, a substratum for soilless culture." FEMS Microbiology Letters 86, no. 2 (1991): 177-184.

Abstract

In soilless cropping systems, soil-borne plant pathogens, especially Fusarium oxysporum, are responsible for severe damage in vegetable and flower cultures. Non-pathogenic Fusarium and fluorescent Pseudomonas are able to control fusarium diseases, thereby increasing the yield.

The association of the non-pathogenic Fusarium strain Fo47 and of the fluorescent Pseudomonas strain C7R12 gave a better control of fusarium diseases compared to single inoculations of each antagonistic microorganism.

So far, no data have been available on the survival of these two microorganisms in soilless growing substrate. The results of this study indicate that both microorganisms survive well in rockwool when inoculated alone or together as well as in the absence or the presence of plants.

Under the present experimental conditions, a single application of the antagonists appears to be enough to get a significant control of fusarium wilts. - Fonteno, William C., and Paul V. Nelson. "Physical properties of and plant responses to rockwool-amended media." Journal of the American Society for Horticultural Science 115, no. 3 (1990): 375-381.

Abstract:

Loose rockwool had a total porosity similar to peatmoss (92%, by volume) but with water retention capabilities similar to sand. Root media formulations containing loose rockwool were tested with seven plant species for plant response and nutrient uptake.

The volume percent formulation, 20 rockwool : 10 peatmoss : 20 vermiculite : 45 pine bark : 5 perlite, was superior to formulations containing 10% or 30% rockwool. Plant response in this rockwool medium in bedding plant flats was superior to that in two high-performing commercial media for impatiens (Impatiens sultanii Hook), marigold (Tagetes patula L.), and petunia (Petunia hybrida Vilm) and equal to one commercial medium for tomato (Lycopersicon esculentum Mill.).

However, response of chrysanthemum (Chrysanthemum × morifolium Ramat.), geranium (Pelargonium × hortorum Bailey), and poinsettia (Euphorbia pulcherrima Willd. ex Kl.) in 1.58-liter pots was inferior to both commercial media in one-half of the trials.

Differential plant responses in the root media treatments did not relate directly to differences found to occur in plant nutrient composition. The high initial pH level of rockwool necessitated reduced application of limestone and increased application of calcium sulfate to offset Ca deficiency. - Hazardous Materials 152, no. 2 (2008): 624-631.

Abstract:

The need to find economically and environmentally more viable methods for the management of industrial wastes has opened the way to the research and development of processes which were still in the laboratory only a few years ago.

The examples given concern two very common and acutely-felt problems: the inertization and recycling of hydrometallurgical red muds (RM) and of mine tailings. In the case of red mud, one potential process involves the extraction of metals (mainly Zn, but also Cd, Sn, Ph, Fe), and another involves mixing the RM with granite chippings and cullet to produce glass-ceramics materials via melting and crystallization.

The paper also discusses a new flowsheet in which mine tailings are utilized to produce either glass-wool or very strong glass-ceramic products, with good resistance to chemical attack. - Kim, K-A., W. K. Lee, J. K. Kim, M-S. Seo, Y. Lim, K-H. Lee, G. Chae, S-H. Lee, and Y. Chung. "Mechanism of refractory ceramic fiber-and rock wool-induced cytotoxicity in alveolar macrophages." International archives of occupational and environmental health 74, no. 1 (2000): 9-15.

- Leeman, M., J. A. Van Pelt, F. M. Den Ouden, M. Heinsbroek, P. A. H. M. Bakker, and B. Schippers. "Induction of systemic resistance byPseudomonas fluorescens in radish cultivars differing in susceptibility to fusarium wilt, using a novel bioassay." European Journal of Plant Pathology 101, no. 6 (1995): 655-664.

- Marabini, Anna Maria, Paolo Plescia, Dante Maccari, Francesco Burragato, and Mario Pelino. "New materials from industrial and mining wastes: glass-ceramics and glass-and rock-wool fibre." International journal of mineral processing 53, no. 1 (1998): 121-134.

- Marsh, G., R. Stone, A. Youk, T. Smith, M. Quinn, V. Henderson, L. Schall, L. Wayne, and K. Lee. "Mortality among United States rock wool and slag wool workers: 1989 update." JOURNAL OF OCCUPATIONAL HEALTH AND SAFETY AUSTRALIA AND NEW ZEALAND 12 (1996): 297-312.

- McCullagh, M., R. Utkhede, J. G. Menzies, Z. K. Punja, and T. C. Paulitz. "Evaluation of plant growth-promoting rhizobacteria for biological control of Pythium root rot of cucumbers grown in rockwool and effects on yield." European Journal of Plant Pathology 102, no. 8 (1996): 747-755.

- Mihuta-Grimm, L., W. A. Erb, and R. C. Rowe. "Fusarium crown and root rot of tomato in greenhouse rock wool systems: sources of inoculum and disease management with benomyl." Plant disease 74, no. 12 (1990): 996-1002.

- NAIMA (North American Insulation Manufacturers Association) 11 Canal Center Plaza, Suite 103 Alexandria, VA 22314 Phone: (703) 684-0084 Fax: (703) 684-0427 Website: https://insulationinstitute.org/

- Neuhaus, Thomas, O. Reinhard, and A. Clausen. FORMALDEHYDE EMISSIONS FROM MINERAL WOOL IN BUILDING CONSTRUCTIONS INTO INDOOR AIR [PDF] Indoor Air (2008). - Retrueved 2921/07/25 original source: https://www.eurofins.com/media/2266/formaldehyde_emissions_from_mineral_wool_in_building_constructions_1086.pdf

- Postma, Joeke, Margarit JEIM Willemsen-de Klein, and Jan Dirk van Elsas. "Effect of the indigenous microflora on the development of root and crown rot caused by Pythium aphanidermatum in cucumber grown on rockwool." Phytopathology 90, no. 2 (2000): 125-133.

- Olympios, C. M. "Soilless media under protected cultivation rockwool, peat, perlite and other substrates." In Symposium on Soil and Soilless Media under Protected Cultivation in Mild Winter Climates 323, pp. 215-234. 1992.

- Rockwool Int'l., ROCKWOOL SUSTAINABILITY [PDF], Rockwool International A/S · Hovedgaden 584 · 2640 Hedehusene · Telephone (+45) 46 56 03 00 · Telefax (+45) 46 56 33 11 , website: http://www.rockwool.com/, is a current manufacturer of mineral wool insulation products used for fire insulation, sound insulation, and building insulation.

- Savvas, D., and F. Lenz. "Effects of NaCl or nutrient-induced salinity on growth, yield, and composition of eggplants grown in rockwool." Scientia Horticulturae 84, no. 1 (2000): 37-47.

- Smith, Denis. Rockwool in horticulture. Grower Books, 1987.

- 3/07: thanks to Gary Randolph, Ounce of Prevention Home Inspection, LLC Buffalo, NY, for attentive reading and editing suggestions. Mr. Randolph can be reached in Buffalo, NY, at (716) 636-3865 or email: gary@ouncehome.com

- ThermaFiber, Thermafiber, Inc., 3711 Mill Street, Wabash, Indiana 46992, Toll Free: 888-834-2371 (U.S. & Canada) ; Phone: 260-563-2111, is a current manufacturer of mineral wool insulation products. http://www.thermafiber.com/ Web search 07/28/2010, quoting:

Thermafiber manufactures and customizes mineral wool insulation for commercial buildings, industrial applications and residential construction.

We specialize in high-rise construction - that's why we developed Thermafiber Insolutions™, a systematic approach to help you precisely plan and install insulation on time and on budget. - See additionalReferences or Citations at the end of this page

...

...

Continue reading at MINERAL WOOL - ROCK WOOL INSULATION - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ASBESTOS-FREE INSULATION MATERIALS

- ASBESTOS INSULATION

- BALSAM WOOL BATT INSULATION - a cellulose product, not a mineral fiber

- FIBER & HAIR IDENTIFICATION

- FIBERGLASS PARTICLE CONTAMINATION TEST

- FIBERGLASS UNDER the MICROSCOPE

- FIBERGLASS vs MINERAL WOOL vs SLAG WOOL SEM IDENTIFICATION

- FORENSIC & IAQ LAB MICROSCOPE TECHNIQUES

- INSULATION IDENTIFICATION GUIDE - home

- MINERAL WOOL - ROCK WOOL INSULATION

- CAREY ROCK WOOL CATALOG 1950 [PDF]

- MINERAL WOOL IDENTIFICATION, APPEARANCE

- MINERAL WOOL IDENTIFICATION by MICROSCOPE

- MINERAL / SLAG WOOL AIRBORNE PARTICLES

- MINERAL WOOL / STONE WOOL ASBESTOS CONTENT

- MINERAL WOOL / ROCK WOOL DEFINITIONS

- MINERAL WOOL / ROCKWOOL COMPOSITION

- MINERAL or SLAG WOOL HEALTH EFFECTS

- MINERAL / ROCK WOOL INSTALLATION, SETTLING

- MINERAL WOOL / STONE WOOL R-VALUES

- SPINTEX MINERAL WOOL PROPERTIES - MANSVILLE

Suggested citation for this web page

MINERAL WOOL by MICROSCOPE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INSULATION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Seattle Energy Code, Seattle Energy Code History, web search 12/6/2011, original source: http://www.seattle.gov/dpd/Codes/Energy_Code/Overview/history.asp

- Adams, P. "Effects of increasing the salinity of the nutrient solution with major nutrients or sodium chloride on the yield, quality and composition of tomatoes grown in rockwool." Journal of Horticultural Science 66, no. 2 (1991): 201-207.

- Awang, Y. B., J. G. Atherton, and A. J. Tay

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.