Mold Contamination in Fiberglass Insulation

Mold Contamination in Fiberglass Insulation

Mold can grow on or get into

Fiberglass and/or Mineral wool building insulation

- POST a QUESTION or COMMENT about mold contamination in fiberglass building insulation

Mold contamination occurrences in fiberglass insulation:

This article explains the cause, detection, and hazards of mold growth in fiberglass insulation in residential and light-commercial buildings.

We illustrate how to find or test for moldy insulation in buildings, the probable cause of mold contamination in building insulation, and how to recognize conditions that make that problem likely in a particular case.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Cause & Detection of Mold Contamination in Fiberglass Insulation in Buildings

Mold and mold odors in building wall and ceiling and even floor cavities can be traced to leaks into the cavity or in humid climates, such as areas in the U.K. and North America, if homes in those climates are not properly constructed to keep both leaks and humid air out of the wall, ceiling or floor cavity.

Article Contents

- MOLD ON INSULATION FIBERS

- MOLD CONTAMINATION in CLEAN-LOOKING INSULATION

- MOLD GROWTH IN INSULATION

- MOLD GROWTH in FIBERGLASS DUCTWORK

- MOLD CONTAMINATED INSULATION FROM OTHER SOURCES

- MOLD CONTAMINATED INSULATION: WHERE TO LOOK

- WHEN TO TEST INSULATION FOR MOLD CONTAMINATION

The literature indicates that fiberglass can serve as a support matrix for the collection of debris which, when moist, have the capability of supporting the growth of mold.

Further, binding and paper-based moisture barriers from fiberglass resins are also capable of supporting the growth of mold when moist. (Van Loo 2004)

Our own study has shown that significant mold contamination can be found in some building insulation materials even when to the naked eye the insulation looks "clean".

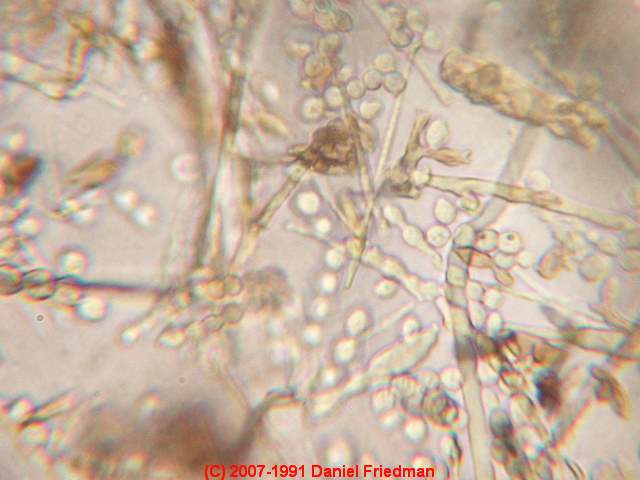

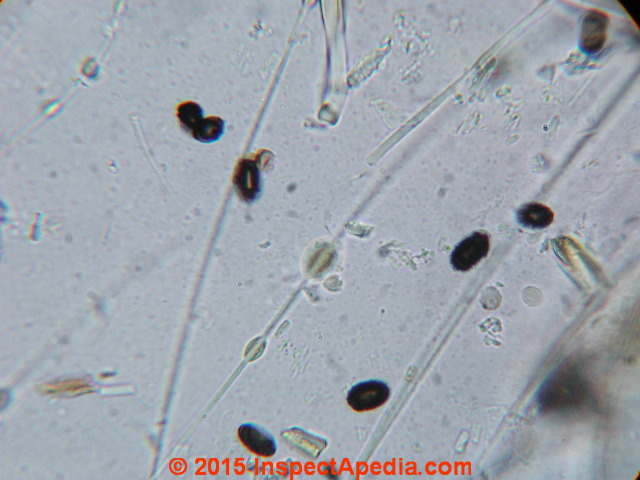

Our own photo just above shows a string of fungal spores growing along an single strand of fiberglass building insulation. The presence of spores in an attached chain confirms that it had been or was an active fungal growth, not simply an isolated fungal spore that fell into the insulation.

Originally that finding was a surprise, but one that was confirmed by repeated field and laboratory tests.

But research confirms that mold contamination and mold colonization has been reported in building insulation and in or on fiberglass air filters and HVAC duct liners as well. (Ahearn 1996, Buttner 1999, Chang 1996, Crane 2019, Ezeonuy 1994, 1995, Foarde 1996 and others cited in this article.)

Mold growth, specifically Fusarium sp., has also been reported in mineral wool or rock wool insulation. (Eparvier 1991)

Mold may be present in fiberglass insulation as airborne contaminant or as actual mold growth

This is an important finding because it means that in cleaning a mold-contaminated building or one whose insulation has been water-damaged, it could be a serious error to ignore the building insulation. Mold can show up in fiberglass insulation in several ways as we list here:

- Air-transported mold spores:

in sufficiently high concentration and where fiberglass (or possibly other insulating material) is thus contaminated. We find this fiberglass mold contamination particularly where there is or was a high concentration of smaller mold spores such as Penicillium / Aspergillus sp. as can occur when mold contaminates nearby surfaces or when mold is disturbed during a building mold remediation project.

Really? Not always. A few isolated airborne mold spores of just about any mold genera species that show up in building insulation are harmless; however if a vacuum test or other examination of fiberglass insulation finds fungal spores as a significant or dominant portion of the particles collected from the insulation, then it's mold-contaminated. - Actual fungal growth on and among fiberglass fibers:

such as shown in our photo here, taken from our own forensic lab.

NAIMA, the North American Insulation Manufacturers Association, a trade association supporting the insulation industry, asserts that "... fiberglass and rock and slag wool insulation does not support mold growth" - Personal correspondence, Angus E. Crane to D. Friedman, 2019/07/01.

Really? Well sort-of. I agree that a clean glass fibre (or other glass) does not readily support fungal growth. However in the real world of buildings, moisture, organic dust, and possibly even some organic binders used in fiberglass insulating products all can encourage mold growth in and on fiberglass insulation.

In the photo above I did not sneak in mold and stick it onto the fiberglass fiber shown in my micro-photograph (at 1200x). (My fingers are far too fat to do that.) - Ed.

In the same letter, Mr. Crane asserts that alternative insulation products such as cellulose and spray foam would not perform any differently. That's a serious mistake but one that we can forgive as the writer appears to be a lawyer not a forensic scientist.

Cellulose insulation is rather mold resistant, probably because the borate salts used as a fire-retardant also are mold retardants. (Otherwise many mold genera/species would love to move into wet or damp cellulose.) (Herrera 2005).

See details at MOLD RESISTANCE OF CELLULOSE BUILDING INSULATION

I have (on a few occasions) found mold growing on the surface of closed cell spray foam insulation, most likely as with fiberglass, because of organic dust or debris found thereon.

See details at MOLD in FOAM INSULATION - Mold growth on insulation kraft facing:

if building insulation has been wet from leaks or flooding or if it has been installed in a high-humidity area ,we may find fungal growth on the kraft facing in both its paper form and it's foil-faced paper form.

The photo at the top of this page illustrates heavy mold growth on the surface of fiberglass insulation. - Mold growth on the surface of fiberglass duct lining:

is a common occurrence when the duct insulation is both coated with dust. Skin cells and some fabric fibers, the dominant particles in house dust, contain organic debris that, when combined with water or high moisture, invite growth by a number of fungal genera/species. We illustrate this condition below.

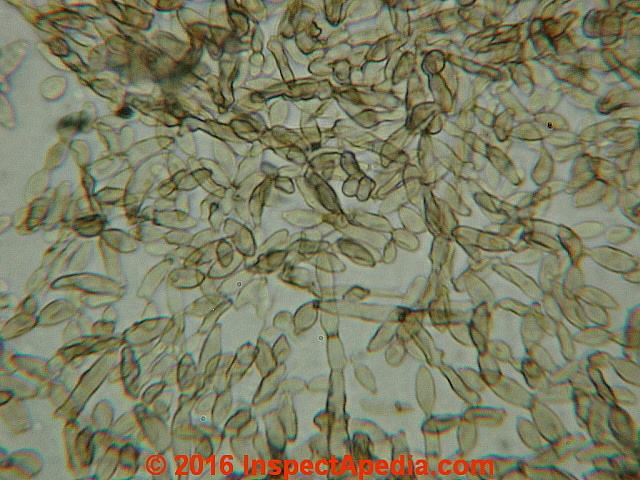

The colonization, determined by the microscopic observation of conidiophores with conidia, was primarily of acrylic-latex-facing material, but eventually the fungi permeated the fiberglass matrix.

Isolates of Aspergillus versicolor were most often obtained from non-challenged insulation, whereas Acremonium obclavatum appeared to be the primary colonizing fungus in high-humidity (>90%) challenge chambers.

At a lower humidity (about 70%) Aspergillus flavus was one of the more prominent fungi. Not all duct liner samples were equally susceptible to colonization and duct board appeared relatively resistant to colonization. (Price 1994)

Note: Given a few boosts of temperature, humidity, or food it likes, mold of one genera/species or another can grow on just about anything.

Here we focus on mold growth in and on fiberglass insulation; paper and other organics such as flax insulation, more affected by moisture, may be even better hosts for mold growth. (Klamer 2004).

The 720x photographs above and just below show active fungal growth (red arrows) along the surface of a fiberglass insulation fiber collected from the suspended ceiling of a building suffering wet conditions and moldy in-slab HVAC ducts.

Fiberglass in building insulation is a topic I have been testing and studying for nearly forty years, after having first traced a building mold contamination reservoir to a hidden source in this material. I frequently find high levels of mold-contaminated fiberglass insulation in buildings which contain other large mold reservoirs.

I [DF] have also detected high levels of problematic mold in fiberglass building insulation where other mold reservoirs were either not present or had been previously removed.

Our moldy building insulation photo at page top (contributed by a reader) shows an obvious case: very wet fiberglass insulation under a roof and extensive black mold growth on at least the insulation surface, probably inside the insulation as well.

But in a more subtle, and not easily visible form, problematic building contamination by mold is often found in otherwise clean-looking basement fiberglass insulation, crawl space fiberglass insulation, fiberglass wall insulation, heating or cooling duct fiberglass insulation, and attic or roof insulation in buildings which have either been wet or have been exposed to high levels of mold from other sources.

That "hidden" insulation mold is the focus of our discussion in this article.

Clean-looking Fiberglass Insulation may be Mold Contaminated if Exposed to Wet Conditions or A Secondary Airborne Mold Source

Except for some superficial "dust staining" that is often simply thermal tracking by house dust, the pink fiberglass insulation shown below (left) looked clean.

Unlike our black insulation mold photo above, there was no visible mold on the pink fiberglass insulation shown below.

The gray debris on the surface of this insjulation is not mold but simply building dust commonly found where air has been moving across the insulation's surface or through it in an air bypass leak.

But vacuuming the center (most clean-looking area) of that same insulation - the most-pink, clean-looking fiberglass produced a dust sample that we then checked in the lab.

Not visible to the naked eye but clear under the microscope, the vacuum dust sample showed the long Penicillium/Aspergillus spore chains (below) consistent with local problematic mold growth.

High levels of mold may be present in fiberglass insulation:

We have measured very high levels of airborne problematic mold spores which were traced to a building reservoir of moldy fiberglass insulation.

Notice that here we see Pen/Asp fungal spores in long spore chains often of six or more spores together. (I've marked a few of them with red lines.)

As such these spore chains are very fragile and break apart quickly into individual spores when airborne, we are confident that this photograph shows that there was actual mold growth in or adjacent to this insulation or both.

Recapping, the pair of photographs (above) shows fairly clean-looking fiberglass insulation over a crawl space which in fact had been subjected to flooding.

While the insulation itself did not appear to have been flooded, and while there was no mold visible on or in this fiberglass insulation, a simple vacuum test demonstrated that the insulation was severely contaminated with Aspergillus sp. mold.

- BASEMENT MOLD - includes examples of moldy fiberglass insulation found in basement

- CRAWLSPACE MOLD - includes additional examples of moldy fiberglass insulation found in crawl spaces

- CRAWL SPACE DRYOUT - home - discusses how to dry out crawl spaces to prevent mold growth

Fiberglass insulation can host active mold growth

The presence of both mold spore chains and conidiophores of Aspergillus sp. in the insulation test samples whose photos are shown above confirmed that not only was the crawl space ceiling fiberglass insulation moldy, but it was supporting active fungal growth.

Our screening samples confirmed that this mold was present in other building areas, most likely emanating from this mold reservoir of mold-contaminated fiberglass insulation.

In some cases, non-visible mold contamination in fiberglass insulation has been enough to cause IAQ, health, or other mold-related complaints by building occupants.

In the partially opened basement wall shown here, the water track stains on the cavity side of the exposed drywall (shown after a test cut was made) indicate that water passed in this wall from above.

In this circumstance, even when the fiberglass insulation looks clean, I often find high levels of Penicillium sp. or Aspergillus sp. in this material.

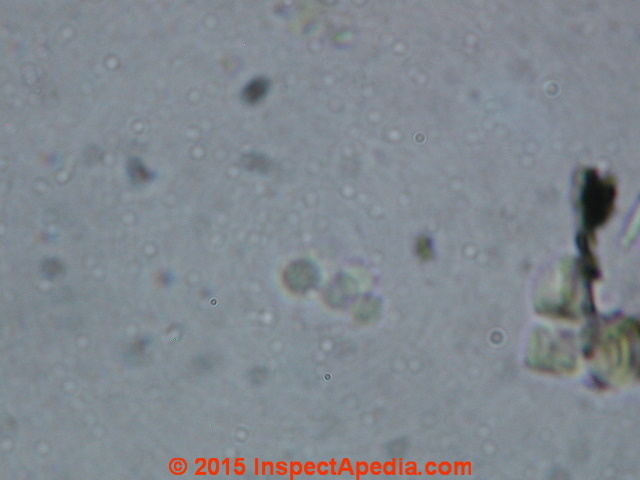

The photo above shows a very dense presence of small hyaline (colorless) mold spores and spore chains as well as a portion of a conidiophore (lower left) in this insulation test sample.

I've circled a few of the spore clusters and chains in red to make them easire to spot. The presence of the conidiophore, probably a species of Aspergillus (yellow arrow) - the spore-producing organism, and long spore chains growing off of it (orange arrows) confirm that there is actual mold growth in this fiberglass sample.

Mold was actively growing in this insulation, not simply accumulated there from some other building mold reservoir.

Comparison tests of fiberglass which is new at a building supply store or in homes where the insulation has not been wet nor infested with rodents or other pests, mold is rarely a problem. That signifies that mold is not arriving in new clean building insulation, but it can get there after installation.

Mold Growth Found on Fiberglass-Lined HVAC Duct Interiors

Mold on the Interior Surface of Fiberglass-lined HVAC Ducts

[Click to enlarge any image]

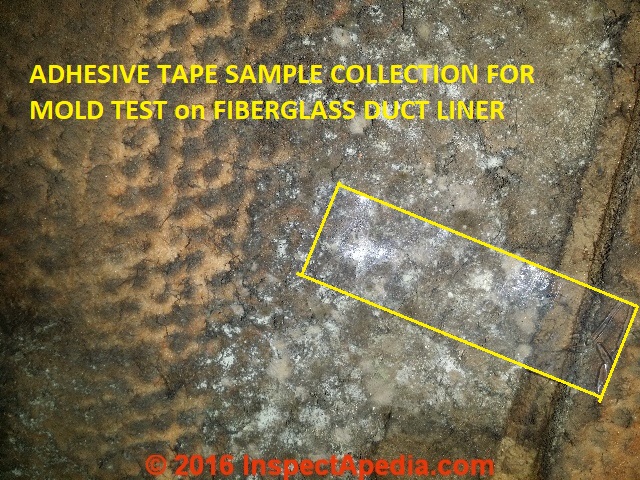

Above: white "growth" found on the interior surface of fiberglass-lined HVAC ducts in a home in Atlanta, GA in 2016.

Look closely to see the presence of clear adhesive tape being used to collect a sample from this surface to permit laboratory analysis.

Samples from this fiberglass duct were examined in our InspectApedia.com forensic laboratory. Below: an example of lab test results included these:

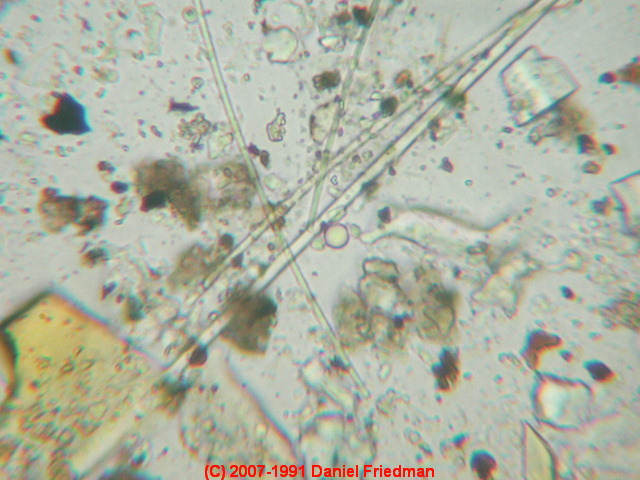

Above first photo, sample 2, Aspergillus sp. conidiophore and hyphae at upper left, Penicillium conidiophore at lower right.

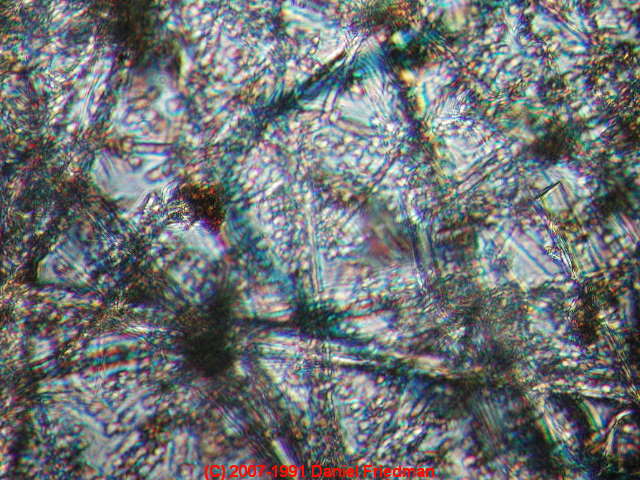

Below, second photo sample 2, Cladosporium sp. in dense fungal growth on the surface.

Details of this air duct mold contamination study are found

at FIBERGLASS AIR DUCT MOLD TEST

Fiberglass Insulation May Have Been Contaminated by Airborne Mold Spores or Other Pathogens from Other Sources

Just below is an individual Curvularia-like mold spore to the left of what is probably a fragment of gypsum or drywall material.

More subtle in this photo are individual Penicillium/Aspergillus mold spores.

Small and colorless these are harder to see unless the microscopist takes care and time. In this photo we were focusing on the dark spore and the hyaline (colorless) and smaller mold spores in the background are not in good focus.

The combination of these particles in a vacuum sample of fiberglass insulation suggests that this insulation became contaminated by airborne debris, perhaps during demolition of moldy drywall.

Below is a large hyphal fragment in fiberglass insulation; from this observation we can be confident that wet conditions and growing mold have been present in the building where this sample was collected.

The image does not mean that this fungus was necessarily growing in or on the fiberglass itself. As we said in our introduction, a few isolated spores in insulation are insignificant. All mold is everywhere, all the time - at low levels.

But when we find large hyphal fragments in any indoor environmental sample we know that most likely there is or was significant nearby mold growth in or on the building.

Below are multiple Stachybotrys chartarum mold spores (black arrows) in a fiberglass insulation sample and in the background I see some colorless Pen/Asp spores (red arrows) as well.

This sample strongly suggests that there has been demolition of moldy materials, probably drywall, in the area where this fiberglass was exposed.

There is no evidence that these fungi are growing on or in this particular insulation sample.

Any thick fibrous material can collect airborne particles and can be difficult or impossible to clean completely. This mold-contaminated fiberglass insulation should be discarded.

Below, my photo illustrates a short three-spore chain of Penicillium or Aspergillus mold spores (circled in red).

These fungal contaminants are a particular concern because their small size (often in the 1u range) means they can be inhaled deeply into the lungs.

High exposure levels, or repeated exposure to high levels of this type of airborne mold can cause serious illness such as Aspergillosis.

See ASPERGILLOSIS for details.

Watch out: Because these spore chains are very fragile and break into individual spores quickly when airborne, when we find a spore chain of Penicillium or Aspergillus mold in an environmental sample, I am confident that there has been or is currently nearby active growth of one or both of these mold genera/species.

I have on occasion found actual Penicillium or Aspergillus mold conidiophores growing in fiberglass insulation (as well as on or in a very large number of other building materials).

These mold contamination problems occur in buildings that have been wet, flooded, or occasionally subject to very high humidity.

Where to Look for & How to Prevent Mold in Building Insulation

For buildings which do not have other known mold reservoirs, special attention needs to be given to inspecting and testing for problematic mold in

- Fiberglass insulation in any building cavity, basement, crawl area, attic area that has been wet.

- Fiberglass insulation in attics or roof cavities where there has been leakage.

- Fiberglass insulation in building walls subject to leaks from plumbing failures, previous wetting due to building fire extinguishment, or in freezing climates, walls subject to leaks from ice damming.

- Fiberglass heating or cooling duct material, especially if it has been wet from building leaks or A/C condensate mishandling.

See WET CORRODED DUCT WORK - Fiberglass insulation in any building area that has been exposed to high levels of airborne mold - such as during a mold remediation job.

See FIBERGLASS DETECTION in BUILDING AIR & DUST - Any building area that has been flooded or subject to leaks from any source: roof, plumbing, sewage backups.

See SEWAGE BACKUP, WHAT TO DO - Wet basements and crawl spaces.

see WET BASEMENT PREVENTION

Moldy building or duct insulation may look clean on visual inspection

What can be tricky in investigations of mold contamination in building insulation is that severely mold-contaminated fiberglass insulation may look pretty clean to the naked eye.

The first photo, above, shows clean fiberglass insulation fragments (taken from a sample of new fiberglass building insulation).

The fiberglass fibers in our photo above look clean under the microscope too, but the microscopist has to focus with care, up and down on the sample, because small particles may disappear in a blurred background if the focus is too high or too low.

In contrast, the second photo of a dust sample collected from fiberglass insulation in an older building exposed to moisture and leaks shows a high level of particulate debris, almost certainly including organic debris such as skin cells, animal hair, and insect fragments which can form a base for mold growth.

Special vacuum and agitation methods are needed to sample and test this material and special care is needed in choosing the sample or test location when looking for mold in fiberglass or other building insulation.

See details at FIBER & HAIR IDENTIFICATION

Not All Stained Insulation is Harmful and Other Building Materials are also at Risk

Watch out: not all stained or dirty-looking fiberglass is moldy or even contaminated.

A very common source of black, gray or tan "stains" on building fiberglass is air bypass leaks that deposit ordinary house dust or building dust on or in the insulation as air passes over or through the material.

This is not mold contamination and this fiberglass insulation - shown in our photo below - does not need to be removed. Rather it makes sense to find and fix those air bypass leaks.

See for details INSULATION STAINS - AIR BYPASS LEAKS

Keep in mind that the air bypass stains as well as mold, insect fragments or other contaminants described in this article can also be found on or in many building materials and in porous materials may be difficult or impossible to clean economically.

Also see MOLD APPEARANCE - STUFF THAT IS NOT MOLD

When to Test Building Insulation for Mold

Details of this topic are now

at WHEN to TEST INSULATION for MOLD

We do not recommend routine mold testing of building fiberglass for mold

in non-suspect cases. "Spot checks" by "mold testing" in buildings, if conducted without an expert diagnostic visual inspection and history gathering, are simply not reliable and thus not cost-justified.

We also do not recommend mold testing of fiberglass or other building insulation that is visibly moldy

(such as mold growth on kraft paper facings) nor of building insulation that has been wet. Such testing is not necessary and would not change the advice given by experts: Such insulation areas should be treated as follows:

- Remove the wet, moldy, dirty, or suspect insulation

- Clean the building cavity

- Correct the leak or other cause of contamination

- Install new insulation

See ATTIC MOISTURE or MOLD SOURCES for a discussion of common sources of moisture in attics that can cause moldy insulation, and similarly,

See BASEMENT LEAKS, INSPECT FOR for the same problem in basements.

Readers ducting cool air through a crawl space or who have damp or wet crawl spaces under their building should

So when might mold testing of building insulation be merited?

- If a physician treating someone suspected of building-related illness wants to know what mold genera/species to which the occupants may have been exposed.

- If a building-related illness is known or suspected to be caused, aggravated, or contributed-to by possible contamination of building wall and ceiling cavities that have been wet or that have been exposed to airborne contaminants but the insulation and cavities appear clean, it may be useful to try vacuum-testing some representative samples of the insulation for mold.

Vacuum-test the most suspect area(s). - See INSULATION MOLD CONTAMINATION TEST if testing is appropriate for your situation.

Research on Mold Contamination of Fiberglass Insulation

- Eparvier, Agnès, Philippe Lemanceau, and Claude Alabouvette. "Population dynamics of non-pathogenic Fusarium and fluorescent Pseudomonas strains in rockwool, a substratum for soilless culture." FEMS Microbiology Letters 86, no. 2 (1991): 177-184.

Abstract

In soilless cropping systems, soil-borne plant pathogens, especially Fusarium oxysporum, are responsible for severe damage in vegetable and flower cultures. Non-pathogenic Fusarium and fluorescent Pseudomonas are able to control fusarium diseases, thereby increasing the yield.

The association of the non-pathogenic Fusarium strain Fo47 and of the fluorescent Pseudomonas strain C7R12 gave a better control of fusarium diseases compared to single inoculations of each antagonistic microorganism. So far, no data have been available on the survival of these two microorganisms in soilless growing substrate.

The results of this study indicate that both microorganisms survive well in rockwool when inoculated alone or together as well as in the absence or the presence of plants. Under the present experimental conditions, a single application of the antagonists appears to be enough to get a significant control of fusarium wilts. - Ezeonu IM, DL Price, SA Crow and DG Ahearn. 1995. Effects of extracts of fiberglass insulations on the growth of Asperigillus fumigatus and A. versicolor. Mycopathologia 132: 65–69.

Abstract:

Water extracts of thermal and acoustic fiberglass insulations used in the duct work of heating, ventilation and air conditioning (HVAC) systems supported germination of conidia and growth of Aspergillus versicolor (Vuillemin) Tiraboschi 1908–9 andAspergillus fumigatus Fresenius 1863.

Urea, formaldehyde and unidentified organics were detected in the extracts.

Formaldehyde in concentrations similar to those found in the extracts restricted the growth of both species in enriched media .A. versicolor, the more common species associated with fiberglass insulations, was more resistant to formaldehyde than A. fumigatus. - Ezeonu IM, JA Noble, RB Simmons, DL Price, SA Crow and DG Ahearn. 1994. Effect of relative humidity on fungal colonization of fiberglass insulations. Appl. Environ Microbiol 60: 2149–2151.

- Ezeonu IM, DL Price, RB Simmons, SA Crow and DG Ahearn. 1994. Fungal production of volatiles during growth on fiberglass. Appl Environ Microbiol 60: 4172–4173.

- Morey PR. 1993. Microbiological contamination in buildings: precautions during remediation activities. In: Indoor Environment 93 Conference Proceedings, pp 128–134, IAQ Publications, Bethesda, MD.

- Summerbell RC, F Staib, DG Ahearn, M Ando, L Ajello, SA Crow, D Fung, T Gregor, J Noble, DL Price, RB Simmons, S Marlo and W Woychuk. 1995. Household hyphomycetes and other indoor fungi. J Med Vet Mycology 32 (suppl I): 277–286.

- Van Loo, Jason M., Coreen A. Robbins, Lonie Swenson, and Bruce J. Kelman. "Growth of mold on fiberglass insulation building materials—a review of the literature." Journal of Occupational and Environmental Hygiene 1, no. 6 (2004): 349-354.

Abstract:

An exhaustive search of the literature on the growth of mold on fiberglass insulation materials was conducted.

Because of the paucity of published material, both peer-reviewed and non-peer-reviewed articles were included.

The literature indicates that fiberglass can serve as a support matrix for the collection of debris which, when moist, have the capability of supporting the growth of mold.

Further, binding and paper-based moisture barriers from fiberglass resins are also capable of supporting the growth of mold when moist. - Also see the fiberglass mold studies & field research at RECOMMENDED ARTICLES at the bottom of this page.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: dark gray spots on cathedral ceiling insulated with fiberglass

We are searching for an answer to gray spots that have appeared on the inside surface of our cathedral ceiling. It has fiberglass insulation between the sheetrock and the shingled roof.

The house and ceiling is 40 years old These spots started appearing two years ago and are slowly increasing in size.

They only appear on the western side leaving the eastern side completely clear. There is an outside ridge vent on the roof and vents in the eves.

The summer they were first noticed was a drought year here in Nebraska so not much moisture was present for quite some time. Any guidance on what this could be, who to contact, or advise is greatly appreciated. Thank you. - (July 28, 2014) Bill B said:

Reply:

Bill I suspect you're describing thermal tracking where ceiling drywall nails or screws are placed, not mold contamination.

Take a look at

inspectapedia.com/interiors/Thermal_Tracking.php

Question: mold problem in attic - blown in yellow fiberglass insulation - or is it dirt? or rodents?

I recently discovered a mold problem in my attic (blown in yellow fiberglass insulation) due to an old roof leak from before I bought the house and remediated a small area (just a few square feet).

While I was in the attic, I noticed other areas with no evidence of leakage, but where the yellow fiberglass was a gray-brown color and in some places, closer to the bottom of the pile, it was very dark, almost black.

I'm not sure if this is mold or simply accumulation of dirt over time (house is 36 years old). There was also evidence of rodents (mice) in at least a couple places, but no evidence that they are currently present. Two questions-

-1) Are the darker areas in the fiberglass likely mold, and if so, do I need to remove all the insulation in the attic?

2) Would a past rodent infestation be a possible cause of mold? - (Jan 2, 2015) danebendixen said:

Reply:

Dan

Often we see gray-to-black deposits on fiberglass insulation where there are air bypass leaks that deposit house dust - that's not mold. But any insulation that was wet should be replaced.

See this article on air bypass leak stains on insulation

inspectapedia.com/interiors/Stains_on_Insulation.php

Rodents in mold leave urine and fecal contamination - another reason to replace any such infested insulating materials.

Other insulation that has not been wet, is not mouse infested, can be left in place. Where insulation is marked by air-bypass leakage alone (no water nor rodents) it can be left in place but I'd give some attention to finding and fixing the air leaks.

Research on Fiberglass Fragments as an Indoor Air Quality & Health Concern and a summary of indoor fiberglass hazards are

We got sick after insulating the attic

We just had the attic insulated after they left we started having serious problems with stuff falling from the vents and health issues we are still having. The entire home has been infected by these black specks.The bathroom where we shower has been affected with it all over the walls.

While I was getting a cup from the kitchen cabinet the vent over head blew in the black dots. I then put a cup that had not completely dry away on top of it not knowing .

Within just a week I began to notice that the wood was decaying. I didn't know at the time what it was so I began to clean it off. My head was inside the area where i was exposed to the airborne particles.

I became very sick during this time trying to clean up whatever was happening at this time. I didn't know until almost 3 months when I happen to see it coming from the vents in all the rooms. It is impossible for us to clean the house from this exposure. Our Insurance company refuses to cover damages. The company who installed it has refused to fix it. I have test results on the insulation and the entire home.

We also have photos plus test results from the infections we have had over the past year since it was installed. I am at a total loss on what to do about this. I have called the EPA, Center for Disease , Board of Health, Environmental toxins, From local state and federal government all have given me the run around. I am in bed most of the time now it is very difficult to make these phone calls.

Unless someone is being paid for their service they don't want to be involved. We have had quotes up to $20-30 thousand dollars. We don't have that kind of money . We have been told to move it's not that easy we only have each other and no other place to go.

We just purchased this home in 2014 the infection happened in 2016. Could this insulation have come from the factory contaminated? Or could this be insulation from some other place where they thought it was safe. I am not sure of much these days. I know for a fact it was not happening before they installed the insulation. - On 2017-03-23 by Linda Benson -

Reply by (mod) - Making sense of "we got sick after the attic was insulated"

Linda,

I can understand that a qualified professional would be reluctant to take on a complex contentious mess pro-bono.

But there should have been some simple steps that could sort out some of the concerns you describe.

1. You say "tests were performed' - simple particle collection (search InspectApedia.com for DUST SAMPLE METHOD ) can provide representative samples that any forensic lab could use to identify the dominant particles in the building's settled dust and probably the "black specks" you describe. Knowing what particles are can usually point to their source.

2. A visual inspection of the insulation job work area as well as a review of just what was done would also be instructive.

I would not assume a thing about what came contaminated before knowing what the material is. For example someone could have inadvertently damaged an HVAC duct, or roof debris from a re-roof job could have gotten into an HVAC air return, or insulation could have been blown-in improperly - I can't sort that out from your note.

You need an onsite expert who will sort through the visual data, historical data, complaint data, and perhaps help you collect a very few samples for diagnostic testing.

"Air tests" if that's what was done, are unreliable as we discuss in an article series here at Inspectapedia.

The wise lady from Philadelphia says let's find out what's in the home that's suspected of bothering you, and let's get your doctor to comment on the possible relationship between your illness complaints and anything that could be in the environments where you spend a lot of time.

Can new insulation be contaminated!

Can new insulation be contaminated! We put in our new house we are building and some of it has started to turn black and melt. Is this normal- On 2017-02-04 by Gail -

Reply by (mod)

Yes if it has been wet or if it was left unwrapped and stored in a moldy area; otherwise: unlikely

Replace Johns Manville green insulation with some black mold?

I have Johns Manville green insulation with some black mold at bottom in bathroom walls for at least 60 years. Is replacing the black insulation and spraying sufficient to resolve this? - On 2016-07-23 by Pat-

Reply by (mod)

Pat

Remove insulation that has been wet as well as visibly-moldy materials;

Physically clean the exposed building cavity;

Then if you want to add a fungicidal spray (search InspectApedia for FUNGICIDAL SPRAY for details) that's fine.

I don't recommend using spraying as a substitute for cleaning as you risk leaving toxic or harmful particles in place even if the spray rendered them non-viable.

My family has health complaints that someone told us is from mold and fiberglass insulation. Is that right?

My family has gone to the doctors for the past 3 months.we are coughing, stuffy, joint pain. The man came and said mold and fiberglass insulation is causing this? - On 2015-11-18 by dawn

Reply by (mod) - man came and said mold and fiberglass insulation is causing this

What man? What is his expertise? Where and what did he see? Causing what illness? What does your doctor say?

If your building has a large mold reservoir professional action is required.

Does lack of basement insulation in an Oregon home cause mold?

Is my mold caused by lack of insulation in my basement?

I live in NW Oregon, and its cold and wet most of the time.

My problem is, the last person that lived in my house removed the insulation in the basement ceiling (house floor) which are hardwood. Im getting allot of mold and puddles of water along the walls and floor. It's so bad that in one week we have to clean at least 3 times - On 2013-02-09 by Dan .L -

Reply by Mod: maybe

Dan L:

Missing insulation means higher energy cost, colder floors, less comfort, and possibly condensation that aggravates mold problems. However putting fiberglass insulation under a floor over a wet crawl space or basement is not a good idea - it risks forming a new mold reservoir.The solution is to dry out the areas below the floor first, inspect and clean moldy surfaces there, install moisture-resistant insulation such as solid foam, and if it's a crawl space, convert it to a dry, conditioned space.

My pink bat insulation is bright in some areas: is that due to water?

I have pink bat insulation in basement In some places the insulation has become a bright pink is this due to water damage? - On 2013-03-21 by Anonymous -

Reply by mod:

Wet insulation might look darker in color, but there are natural variations in the color as well as the amount of binder in pink (Owens Corning) fiberglass batt insulation.

Give that dark pink insulation a closer look and a little squeeze. If it's wet, replace it.

On 2012-11-13 by TA

Black stuff on insulation in attic where we had major snow & water damage, it was raining through the light & alarm fixtures. They said they clean it out but they only shoveled out the snow nothing else.

also dust covering the inside of condo, almost pulled out rock quarry in dust & rust. looking inside there appears to be cement corrosive rust & large white looking weird mold looking organisms.

Raw sewage leaks & not proper clean u 2 times in common hallway.

In a nut shell all occupants of our building seem to be very sick including out cat. What can we do to find out if there is mold & toxic dust. Also what is supposed to be proper clean-up efforts for raw sewage leaks involving carpeting? PLEASE or child is very sick as are the rest of us experiencing major issues. THANKS SO MUCH!

Big hailstones damaged our roof and our attic insulation got wet: the insurance company won't replace it

We had a huge hail storm over three months ago, large hail stones bigger than golf balls damaged many roof tiles so our roof was flooded and insulation was saturated. After agreeing that the insulation has to be replaced our insurance company now says its dry and they wont replace it.

We have been told that it will eventually get mouldy and dangerous. We are very worried and upset that the insurance company is reneging on what they said they would do. - On 2012-03-29 by mary sant -

Reply by (mod) - your insurance company is taking a costly risk

As we've shown, mold contamination of fiberglass insulation is common and can be expected if the insulation got wet. Currently most insurance companies know that wet insulation should be discarded, the area cleaned and dried, and then new insulation installed.

OPIONO based on field experience: If instead your company leaves the old insulation in place they risk doubling the cost of the repair by having to return later to do the replacement.

I cut holes and checked my drywall - didn't see any mold

I have cut out holes in my drywall with no visible evidence of mold growth. The insulation is also dry. Am I safe to assume that there is no mold growth? -On 2012-01-14 by PD -

Is ductwork made of foil covered insulation a health concern?

Is ductwork made from insulation (foil on outside) a hazard to your health, with the exception of a mold condition? - On 2011-12-19 by joseph dorsett -

Reply by (mod) - No, foil-faced fiberglass ductwork is not an innate health hazard

Joseph,

In my OPINION, no, foil-faced fiberglass ductwork is not an innate health hazard as long as it is in good condition. The material typically is more dense than fiberglass insulation batts, and is covered on outside with reinforced aluminum foil and on the inside the material is typically coated with a binder to avoid significant fiberglass fiber release.

However if the ducts are mechanically damaged by aggressive cleaning attempts, the interior binder can become damaged and the result is not only an increased particle and debris release into building air circulating through the ducts, but also possibly an increased rate of accumulation of other airborne debris that cannot be effectively removed or cleaned.

And any HVAC ductwork system, if flooded or wet, can become a problem mold or pathogen reservoir.

Can a dirty air filter cause a crack in the evaporator pan? Serious mold contamination.

Glad to! Well, I just submitted a question/comment for a response in the section re: Dirty Air Conditioner Filters section and this comment is related.

Here is my comment from the other section:

"Renting a year-old 'manufactured' home (1 of 8) that was left standing w/the roofs exposed for approximately 2 years to 'the elements', including horrendous rainstorms;

I changed the air filter once within 11 months -- HVAC unit, condenser, evaporator, etc. -- housed indoors within a closet. What developed was a huge problem of mold infestation in and outside the closet area where the HVAC unit is housed, accompanied with lots of water on the floor of the closet housing the unit.

The 'landlord' came out, looked at the damage, in and around the closet housing the unit, removed the filter without me seeing him do so, returned inside the house and told me the damage was caused because I hadn't changed the filter -- which he refused to show me.

Anyway, that same day I called out an HVAC guy who's been in the business for 30 years, who did a thorough inspection and found, among other things, a crack in the evaporator pan as well as insulation debris and some kind of cork debris inside the evaporator!!! He opined that the (substantial) leak was either caused by the crack in the pan or a drain blockage . . .

after all of that, my question is can a dirty filter -- in this case, 6 months old -- cause a crack in the evaporator pan as well as cause the debris found there."

And my comment here, regarding "Mold in Fiberglass" is that the fiberglass insulation that was on the floor of the closet housing the HVAC unit was totally covered with 'black' mold. I called in a mold inspector,

We had a mold report done and there were 810,000 Pen/Asp spores per cubic meter, 820,000 Alternaria and 1.3 million Monodictys spores indoors, in the area that houses the HVAC unit . . . Are those high spore amounts? Thanx, Cynthia C. - On 2011-10-11 by Cynthia C.-

Reply by (mod) - about the evaporator pan crack and debris

Cynthia:

re: "can a dirty filter -- in this case, 6 months old -- cause a crack in the evaporator pan as well as cause the debris found there."

No, not at all likely.

A dirty filter might slow air across the cooling coil, lead to an icing problem, loss of cooling, and even leaks when the ice melted off later. But it would not cause a crack in the condensate tray.Reply by (mod) - about moldy insulation in the air handler

And about moldy insulation in the air handler, or elsewhere, since it's virtually impossible to clean that material, proper procedure is to remove it, clean the exposed surfaces, and install new proper type of insulation. This is the case whether we're discussing the air handler internals or a wet moldy wall cavity.

...

Continue reading at WHEN to TEST INSULATION for MOLD, advice about when where how and why to test building insulation for mold contamination., or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BLOWER LEAKS, RUST & MOLD for Readers concerned with mold contamination in heating and air conditioning air handlers and ductwork

- FIBERGLASS AIR DUCT MOLD TEST - using tape to test & identify debris on HVAC duct interior surfaces

- FIBERGLASS INSULATION MOLD - home

- INSPECTION of INSULATION for MOLD before testing - noting that contaminated building insulation may look clean to the naked eye.

- INSULATION MOLD CONTAMINATION TEST

- INSULATION STAINS - AIR BYPASS LEAKS

- TEST CHOICES for MOLD in FIBERGLASS

- TEST PROCEDURE for MOLD in FIBERGLASS

- VACUUM TEST INSULATION CONTAMINANTS

- WHEN to TEST INSULATION for MOLD

- WHY DOES MOLD GROW in INSULATION? that includes photos and test results examining suspected mold on the surface of fiberglass-lined HVAC ductwork.

Suggested citation for this web page

FIBERGLASS INSULATION MOLD at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to MOLD CONTAMINATION & REMEDIATION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Ahearn, D. G., S. A. Crow, R. B. Simmons, D. L. Price, J. A. Noble, S. K. Mishra, and D. L. Pierson. "Fungal colonization of fiberglass insulation in the air distribution system of a multi-story office building: VOC production and possible relationship to a sick building syndrome." Journal of Industrial Microbiology 16, no. 5 (1996): 280-285.

Abstract:

Complaints characteristic of those for sick building syndrome prompted mycological investigations of a modern multi-story office building on the Gulf coast in the Southeastern United States (Houston-Galveston area).

The air handling units and fiberglass duct liner of the heating, ventilating and air conditioning system of the building, without a history of catastrophic or chronic water damage, demonstrated extensive colonization withPenicillium spp and Cladosporium herbarum.

Although dense fungal growth was observed on surfaces within the heating-cooling system, most air samples yielded fewer than 200 CFU m−3. Several volatile compounds found in the building air were released also from colonized fiberglass.

Removal of colonized insulation from the floor receiving the majority of complaints of mouldy air and continuous operation of the units supplying this floor resulted in a reduction in the number of complaints. - Ahearn, D. G., S. A. Crow, R. B. Simmons, D. L. Price, J. A. Noble, S. K. Mishra, and D. L. Pierson. "Fungal colonization of fiberglass insulation in the air distribution system of a multi-story office building: VOC production and possible relationship to a sick building syndrome." Journal of Industrial Microbiology 16, no. 5 (1996): 280-285.

Abstract:

Secondary air filters in the air-handling units on four floors of a multi-story office building with a history of fungal colonization of insulation within the air distribution system were examined for the presence of growing fungi and production of volatile organic compounds.

Fungal mycelium and conidia of Cladosporium and Penicillium spp. were observed on insulation from all floors and both sides of the air filters from one floor. Lower concentrations of volatile organics were released from air filter medium colonized with fungi as compared with noncolonized filter medium.

However, the volatiles from the colonized filter medium included fungal metabolites such as acetone and a carbonyl sulfide-like compound that were not released from noncolonized filter medium. The growth of fungi in air distribution systems may affect the content of volatile organics in indoor air. - Buttner, Mark P., Patricia Cruz-Perez, Paula J. Garrett, and Linda D. Stetzenbach. "Dispersal of fungal spores from three types of air handling system duct material." Aerobiologia 15, no. 1 (1999): 1-8.

- Chang, John CS, Karin K. Foarde, and Douglas W. VanOsdell. "Assessment of fungal (Penicillium chrysogenum) growth on three HVAC duct materials." Environment International 22, no. 4 (1996): 425-431.

- Crane, Angus E. (NAIMA Executive Vice President, General Counsel) to Daniel Friedman, Editor, InspectApedia.com, "Inspectapedia's False and Misleading Statements Concerning Fiberglass and Mineral Wool Health and Safety", 1 July 2019, personal correspondence.

- Ezeonu, I. M., J. A. Noble, R. B. Simmons, D. L. Price, S. A. Crow, and D. G. Ahearn. "Effect of relative humidity on fungal colonization of fiberglass insulation." Appl. Environ. Microbiol. 60, no. 6 (1994): 2149-2151.

Abstract:

Fiberglass duct liners and fiberglass duct boards from eight buildings whose occupants complained of unacceptable or moldy odors in the air were found to be heavily colonized by fungi, particularly by Aspergillus versicolor. Unused fiberglass was found to be susceptible to fungal colonization in environmental chambers dependent upon relative humidity. No colonization was observed at relative humidities below 50%. - Ezeonu, Ifeoma M., Daniel L. Price, Sidney A. Crow, and Donald G. Ahearn. "Effects of extracts of fiberglass insulations on the growth of Aspergillus fumigatus andA. versicolor." Mycopathologia 132, no. 2 (1995): 65-69.

Abstract:

Water extracts of thermal and acoustic fiberglass insulations used in the duct work of heating, ventilation and air conditioning (HVAC) systems supported germination of conidia and growth ofAspergillus versicolor (Vuillemin) Tiraboschi 1908–9 andAspergillus fumigatus Fresenius 1863.

Urea, formaldehyde and unidentified organics were detected in the extracts. Formaldehyde in concentrations similar to those found in the extracts restricted the growth of both species in enriched media. A. versicolor, the more common species associated with fiberglass insulations, was more resistant to formaldehyde than A. fumigatus. - Ezeonu, I. M., D. L. Price, R. B. Simmons, S. A. Crow, and D. G. Ahearn. "Fungal production of volatiles during growth on fiberglass." Appl. Environ. Microbiol. 60, no. 11 (1994): 4172-4173.

Abstract:

Acoustic and thermal fiberglass insulation materials used in heating, ventilation, and air-conditioning systems were colonized with fungi in laboratory chambers.

The mixed fungal population, principally Aspergillus versicolor, Acremonium obclavatum, and Cladosporium herbarum, produced odoriferous volatiles, including 2-ethyl hexanol, cyclohexane, and benzene.

These volatiles may be related to poor indoor air quality and the sick building syndrome. - Foarde, K. K., D. W. VanOsdell, and J. C. S. Chang. "Evaluation of fungal growth on fiberglass duct materials for various moisture, soil, use, and temperature conditions." Indoor Air 6, no. 2 (1996): 83-92.

- Gu, Ji-Dong, T. Ford, K. Thorp, and R. Mitchell. "Microbial growth on fiber reinforced composite materials." International Biodeterioration & Biodegradation 37, no. 3-4 (1996): 197-204.

- Herrera, José. "Assessment of fungal growth on sodium polyborate-treated cellulose insulation." Journal of occupational and environmental hygiene 2, no. 12 (2005): 626-632.

Abstract:

Cellulose insulation has rapidly gained a large market share among general contractors and homeowners. Recent interest regarding health effects of high concentrations of fungi within indoor environments (building-related illnesses or sick building syndrome) has promoted concern about susceptibility of building materials, including wood products (in general) and cellulose insulation (specifically), to fungal attack.

This study reports an assessment of fungal growth on cellulose insulation made from recycled paper and treated with varying concentrations of sodium polyborate within half-scale wall units exposed to variable and high ambient temperatures and relative humidities throughout the summer.

Boron-treated and untreated (control) cellulose insulation within the wall units were challenged with a suspension containing high concentrations of spores of five fungal species commonly found in indoor environments.

Our results suggest that cellulose insulation treated with sodium polyborate

(a) precludes the growth of the five common fungal species;

(b) harbors fewer fungal species before and after being challenged with the fungal spore suspension; and

(c) is likely having a cytotoxic or sporocidal effect on many, if not all, fungal species.

These results suggest that cellulose insulation treated with sodium polyborate, when properly applied and installed, precludes fungal growth for at least 124 days at high temperatures and relative humidities. - Jankowska, Elzbieta, Tiina Reponen, Klaus Willeke, Sergey A. Grinshpun, and Kyung-Ju Choi. "Collection of fungal spores on air filters and spore reentrainment from filters into air." Journal of Aerosol Science 31, no. 8 (2000): 969-978.

- Klamer, Morten, Elisabeth Morsing, and Thor Husemoen. "Fungal growth on different insulation materials exposed to different moisture regimes." International biodeterioration & biodegradation 54, no. 4 (2004): 277-282.

Abstract:

Commercially available paper, flax, glass wool and rock wool insulation materials were tested for sensitivity to moisture and the ability of fungi to grow on them under different moisture regimes.

Three levels of moisture were used, ambient, simulated rain and water holding capacity. After wetting, the materials were inoculated with a mixture of fungi and incubated at 26°C in boxes with high moisture levels for 4 weeks. The greatest degree of fungal growth was observed on paper and flax insulation materials initially conditioned to ambient moisture levels.

Paper and flax insulation were strongly affected by moisture, with all treatments showing losses in dry mass of approx. 20%, except for paper subjected to simulated rain treatment in which the loss was 39%. Glass and rock wools were not sensitive to moisture and were resistant to fungal degradation, showing only traces of fungal growth and minimal loss in dry mass over 4 weeks. - Lutz, Brock D., Jiankang Jin, Michael G. Rinaldi, Brian L. Wickes, and Mark M. Huycke. "Outbreak of invasive Aspergillus infection in surgical patients, associated with a contaminated air-handling system." Clinical Infectious Diseases 37, no. 6 (2003): 786-793.

- Maus, R., A. Goppelsröder, and H. Umhauer. "Survival of bacterial and mold spores in air filter media." Atmospheric Environment 35, no. 1 (2001): 105-113.

- NAIMA, North American Insulation Manufacturers Association, 11 Canal Center Plaza Suite 103, Alexandria VA 22314 USA, Tel: 703-684-0084 Website: https://insulationinstitute.org

Website excerpts:

NAIMA (North American Insulation Manufacturers Association) is the recognized voice of the insulation industry, bringing together North American manufacturers of fiberglass and mineral wool insulation products. - Original source: https://insulationinstitute.org/about-naima/

NAIMA and its members are committed to protecting the health and safety of consumers, employees and workers who manufacture and install fiberglass, rock wool, and slag wool insulation products.

NAIMA cooperates with government organizations to provide documentation that demonstrates that the products are safe to manufacture, install and use. NAIMA and its members have invested tens of millions of dollars in independent health and safety research projects in the United States and abroad. - Noble, J. A., S. A. Crow, D. G. Ahearn, and F. A. Kuhn. "Allergic fungal sinusitis in the southeastern USA: involvement of a new agent Epicoccum nigrum Ehrenb. ex Schlecht. 1824." Journal of medical and veterinary mycology 35, no. 6 (1997): 405-409.

Excerpts:

Epicoccum nigrum is a common airborne fungus in the environment … II. Health Implications of Fungi in Indoor Environments … Fungal colonization of fiberglass insulation in the air distribution system of a multi-story office building: VOC production and possible relationship to a sick … - Price, D. L., R. B. Simmons, I. M. Ezeonu, S. A. Crow, and D. G. Ahearn. "Colonization of fiberglass insulation used in heating, ventilation and air conditioning systems." Journal of industrial microbiology 13, no. 3 (1994): 154-158.

Abstract:

The number of fungal species colonizing thermal and acoustic fiberglass insulations used in heating, ventilation, and air conditioning (HVAC) systems was fewer than that obtained from initial direct culture of these insulations.

The colonization, determined by the microscopic observation of conidiophores with conidia, was primarily of acrylic-latex-facing material, but eventually the fungi permeated the fiberglass matrix.

Isolates of Aspergillus versicolor were most often obtained from non-challenged insulation, whereas Acremonium obclavatum appeared to be the primary colonizing fungus in high-humidity (>90%) challenge chambers.

At a lower humidity (about 70%) Aspergillus flavus was one of the more prominent fungi. Not all duct liner samples were equally susceptible to colonization and duct board appeared relatively resistant to colonization. - Price, Daniel L., Robert B. Simmons, Sidney A. Crow Jr, and Donald G. Ahearn. "Mold colonization during use of preservative-treated and untreated air filters, including HEPA filters from hospitals and commercial locations over an 8-year period (1996–2003)." Journal of Industrial Microbiology and Biotechnology 32, no. 7 (2005): 319-321.

- Simmons, R. B., D. L. Price, J. A. Noble, S. A. Crow, and D. G. Ahearn. "Fungal colonization of air filters from hospitals." American Industrial Hygiene Association Journal 58, no. 12 (1997): 900-904.

Abstract

Air filters of various types, selected on the basis of discoloration, were collected from the primary and secondary filter banks of the heating, ventilating, and air-conditioning systems in seven hospitals in the eastern United States and examined with direct microscopy for fungal colonization. Microscopic observations and culture results showed that filters from five of the hospitals were colonized with fungi including species of Acremonium, Alternaria, Aspergillus, Cladosporium, Epicoccum, Penicillium, and Rhinocladiella, and a Beauveria-like fungus. Several of these commonly airborne species, e.g., Epicoccum purpurescens (syn. E. nigrum) and Rhino-cladiella sp., had not been previously reported to colonize (with conidiogenesis) air filters. - Simmons, R. B., J. A. Noble, L. Rose, D. L. Price, S. A. Crow, and D. G. Ahearn. "Fungal colonization of automobile air conditioning systems." Journal of Industrial Microbiology and Biotechnology 19, no. 2 (1997): 150-153.

- Simmons, R. B., and S. A. Crow. "Fungal colonization of air filters for use in heating, ventilating, and air conditioning (HVAC) systems." Journal of industrial microbiology 14, no. 1 (1995): 41-45.

- Summerbell, R. C., F. Staib, D. G. Ahearn, M. Ando, L. Ajello, S. A. Crow, D. Fung et al. "Household hyphomycetes and other indoor fungi." Journal of medical and veterinary mycology 32, no. sup1 (1994): 277-286.

Excerpt:

… Moreover, the fungus was only observed in summer months, not in winter months … Effect of relative humidity on fungal colonization of fiberglass insulation … 7. HOCKING, AD & PITT, JI 1980. Dichloran-glycerol medium for enumeration of xerophilic fungi from low moisture foods ... - Takuma, Takahiro, Kaoru Okada, Akihiro Yamagata, Nobuyuki Shimono, and Yoshihito Niki. "Mold colonization of fiberglass insulation of the air distribution system: effects on patients with hematological malignancies." Medical mycology 49, no. 2 (2011): 150-156.

- Toas, Murray, and Kenneth Knapp. "Insulation product having antimicrobial/antifungal facing, and facing for same." U.S. Patent Application 10/772,063, filed August 4, 2005.

- Van Loo, Jason M., Coreen A. Robbins, Lonie Swenson, and Bruce J. Kelman. "Growth of mold on fiberglass insulation building materials—a review of the literature." Journal of occupational and environmental hygiene 1, no. 6 (2004): 349-354.

Abstract:

An exhaustive search of the literature on the growth of mold on fiberglass insulation materials was conducted. Because of the paucity of published material, both peer-reviewed and non-peer-reviewed articles were included.

The literature indicates that fiberglass can serve as a support matrix for the collection of debris which, when moist, have the capability of supporting the growth of mold. Further, binding and paper-based moisture barriers from fiberglass resins are also capable of supporting the growth of mold when moist. - Yost, Nathan, and Joseph Lstiburek. "Basement insulation systems." Building Science Corporation online, www. buildingscience. com/resources/foundations/basement_insulati on_systems. pdf, dated July (2002).

- ENVIRONMENTAL HEALTH & INVESTIGATION BIBLIOGRAPHY - our technical library on indoor air quality inspection, testing, laboratory procedures, forensic microscopy, etc.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.