Guide to Corrugated Roof Covering Materials

Guide to Corrugated Roof Covering Materials

Asbestos cement, fiber cement, Duralita, fiberglass & metal corrugated roofing product guides

- POST a QUESTION or COMMENT about corrugated roofing types, installation, inspection, troubleshooting, repair

Types of corrugated roof coverings:

Here is a photo guide and text that can assist in identification and evaluation of the condition of corrugated roofing products. We describe fiber cement corrugated roofing panels, cement-asbestos corrugated roof panels, Duralita cardboard-cement roof panels, corrugated fiberglass roof panels, and corrugated metal roofing.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

A Guide to Types of Corrugated Roofing Panels

As you'll see in the contents index below, we illustrate and describe the various types of corrugated materials used for building roofing, and we include a general definition of "corrugated" that can help describe various corrugated building materials that may have used asbestos cement, fiber cement, metal, fiberglass, plastic, paper, or other materials.

As you'll see in the contents index below, we illustrate and describe the various types of corrugated materials used for building roofing, and we include a general definition of "corrugated" that can help describe various corrugated building materials that may have used asbestos cement, fiber cement, metal, fiberglass, plastic, paper, or other materials.

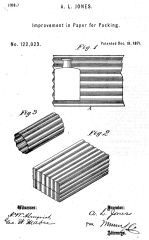

Illustration: from Jones corrugated paper patent issued in 1871 and discussed in detail

at CARDBOARD CORRUGATED FIBERBOARD - separate article.

[Click to enlarge any image]

Article Contents

- CORRUGATED MATERIALS - definition of corrugated fiberboard, paper

- ASBESTOS CEMENT CORRUGATED ROOFING - shown above on this page

- FIBER CEMENT CORRUGATED ROOFING

- DURALITA cardboard-cement reinforced roofing

- FIBERGLASS CORRUGATED ROOFS

- METAL CORRUGATED ROOFS

Corrugated Fiberboard & Paper Products - Not Roofing

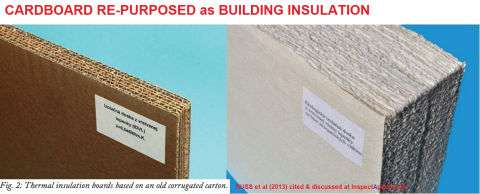

Illustration: corrugated paper building insulation, cited & discussed in the cardboard corrugated fiberboard article linked-to below.

Corrugated roofing and siding and other building products described on this page refers to a wavy-surfaced material made of metal, fiberglass, plastic or other material.

For clarity regarding our use of the term "corrugated" we include this

Definition of Corrugated Fiberboard

Corrugated fiberboard is a material consisting of a fluted corrugated sheet and one or two flat linerboards.[1] It is made on "flute lamination machines" or "corrugators" and is used for making cardboard boxes.

The corrugated medium sheet and the linerboard(s) are made of kraft container board, a paperboard material usually over 0.01 inches (0.25 mm) thick. Corrugated fiberboard is sometimes called 'corrugated cardboard', although cardboard might be any heavy paper-pulp based board. - Wikipedia, retrieved 2022/07/28, original source: https://en.wikipedia.org/wiki/Corrugated_fiberboard

See details about other corrugated building products

at CARDBOARD CORRUGATED FIBERBOARD

Corrugated Cement-Asbestos Roofing

Asbestos cement roof shingles and corrugated asbestos cement roofing like that shown here were in popular use in the U.S. from the 1920's (est) through the 1960's (est) and were sold in the U.S. into the 1970's and according to some sources even in the 1980's.

Asbestos cement roof shingles and corrugated asbestos cement roofing like that shown here were in popular use in the U.S. from the 1920's (est) through the 1960's (est) and were sold in the U.S. into the 1970's and according to some sources even in the 1980's.

The corrugated sheet asbestos cement roof panels shown here are installed on farm buildings at Brinstone Farm, St. Weonards, in Herefordshire, England, U.K. and are more than seventy years old.

[Click to enlarge any image]

The mixture of asbestos fibers and portland cement to form a hard material that was was durable and fire resistant is credited to Ludwig Hatschek who, in 1900, came up with the name Eternit associated with a U.S. producer of these products.

The typical life expectancy of an cement asbestos cement roof was given as 30 years, But we have seen these roofs that were now 50 years old in good condition. Typical roof wear or failure patterns are either failure of the shingle fasteners or broken and falling sections of corrugated sheets.

See details

at CORRUGATED CEMENT ASBESTOS ROOFING

Virtually all of the inspection points, installation limitations, and environmental concerns which we discussed

at GUIDE to CEMENT-ASBESTOS ROOF SHINGLES also apply to corrugated asbestos-cement roofing products.

OPINION: The lichens growing on cement-asbestos roofing (photo at left), especially this thick corrugated material, is probably less of a wear concern than when that material appears on asphalt shingles or roll roofing.

Do not try to walk on this material without taking the same precautions as if accessing a slate roof: the material is easily damaged by foot traffic.

See CORRUGATED CEMENT-ASBESTOS ROOFING for details about this material, and about demolition or repair of corrugated cement asbestos roofs as well as for sources of non-asbestos replacement fiber-cement corrugated roofing products.

Corrugated Fiber Cement Roofing

Contemporary roofing product manufacturers make reinforced fiber-cement roofing shingles and other roofing products which look like, perform similarly to, and need to be installed similarly to the original corrugated asbestos-cement sheet roofing - but these new products are free of asbestos. (Photo at left: author points to new fiber cement roofing product.)

As we explained in our discussion of cement asbestos shingles, the replacements for corrugated asbestos cement roofing products are reinforced with a variety of fibers including fiberglass.

Other replacements for asbestos-cement roofing use both different fibers and a different aggregate (perlite) to replace the asbestos. Some of the substitute products have been in use for more than 30 years (2008).

For maintenance or replacement of asbestos-cement roofing products contact Supradur Manufacturing Corporation, PO Box 908, Rye NY 10580 800-223-1948, or from within New York State, call 914-967-8230. Ask about their Supradur(R) mineral fiber shingles.

For handling and disposal guidance concerning old roofing material contact the US EPA, your state Department of Environmental Protection/Conservation, or your local building and health departments.

Corrugated Duralita Cardboard-reinforced Cement Roofing Roofing Products

Duralita, an alternative to both clay roofing tiles as well as other fiber reinforced cement roofing products is produced in El Salvador and used widely throughout central america and north America. Duralita is a series of brightly-colored cardboard-reinforced cement corrugated roofing products produced by the Duralita, manufacturer of the same name. From the ground Duralita resembles clay roofing tiles.

Panels of Duralita are secured using fiber or rubber washers and threaded rods or bolts. Duralita tejalitas are sheets of reinforced concrete that are intended to resemble roof tiles.

Corrugated cardboard cement products of the same composition, Lámina [photo] are sold in sheets of various sizes and similar colors. You can see an installation of Duralita at the Posada del Bosque Encantado, (http://hotelposadaencantado.com/) a hotel operated by our acquaintance Terry Rubin who was kind enough to inform us about this product.

Other examples of corrugated roofing products (that do not look like clay roof tiles) can be seen

at CORRUGATED CEMENT-ASBESTOS ROOFING.

See DURALITA & METAL TILE ROOFS for details.

Corrugated Fiberglass Roof Panels

Corrugated fiberglass roof panels are installed where light is a premium, as shown in this photo of porch constructed by the author in 1983. Judith Weeks hired us to build a deck that grew into a covered porch.

As we drove out of HG Page lumber with our corrugated fiberglass roof panels poorly-secured atop my 1970 Chevy pickup, one panel blew off, landing in the buildign supplier's parking lot.

I leaped out of the truck out to try and rescue our panel, but before I could get there, the new fiberglass roof panel was immediately driven over by a heavy HG Page Lumber delivery truck.

We were stunned to see that the panel had survived the accident with no visible damage. It looked perfect, so we installed it on the roof shown in our photo above.

The next day when bright sun shone on the roof, Judith called.

"The porch is beautiful, " she said, "and I love the sunlight coming through the translucent fiberglass panels.

But something's really odd: there is a perfect imprint of a truck tire track across one of the roof panels!"

Below we illustrate a new translucent fiberglass roof panel during installation (not work performed by the author) after an older installation on the same roof leaked due to poor flashing.

Corrugated panels, like clay tiles, sport an irregular surface that requires use of flashing products that fit the panel surface in order to avoid leaks.

Corrugated Metal Roofing Panels

Photo, corrugated steel roofing on a building in Torrin, on the southwestern coast of Skye, Scotland, photo by Chloe Church, 2022. Ms. Church notes that Torrin has fishing, lots of sheep, and a quarry. Wikipedia suggests the quarries have been around since the early 1700s. This stone building looks quite old, but in fact we don't know its age.

[Click to enlarge any image]

Really? We're not sure. Below, the color variation in other photos of this barn found by our contributor suggest we might have a combination of painted corrugated steel or fibre cement, older-still asbestos cement that, from afar, can look like metal.

It's possible, even likely, that this corrugated roof covering replaced an earlier roof covering such as slate, concrete tiles, or perhaps thatch or turf bricks as we cite just below.

It's possible, even likely, that this corrugated roof covering replaced an earlier roof covering such as slate, concrete tiles, or perhaps thatch or turf bricks as we cite just below.

Slate, a bit expensive for a barn or outbuilding, could have been used, and is still used on some roofs on Skye where slate roofers continue in business today, for example in Edinbane Portree and in Denny on the Isle of Skye.

Our guess of durable roofing that might have been used on older outbuildings in Scotland would be incomplete without mentioning the muckle roof, large square sections of Caithness sandstone "slates" illustrated by Emergon (p. 49) at Murkle near Thurso.

- Emerton, Gerald, , The Pattern of Scottish Roofing, Research report, Technical Conservation Research and Education Division, Historic Scotland, (2000) ISBN 1903570 09 3 Web: https://issuu.com/hspubs/docs/res_report_-_the_pattern_of_scottis offers

A detailed visual overview of the range of roofing materials and techniques that are to be found in Scotland. - MacCulloch, John Arnott. The Misty Isle of Skye: Its Scenery, Its People, Its Story. O. Anderson & Ferrier, 1905.

- Suddaby, Ian, Melanie Johnson, Torben Bjarke Ballin, Adam Jackson, Dawn McLaren, Nicholas Holmes, Sue Anderson et al. "Excavation of post-built roundhouses and a circular ditched enclosure at Kiltaraglen, Portree, Isle of Skye 2006–07." Scottish Archaeological Internet Reports 54 (2013): 1-74.

- Wilkinson, Brian. "A study of turf: historic rural settlements in Scotland and Iceland." Architectural Heritage 20, no. 1 (2009): 15-31.

Corrugated metal roofing panels, dating from Henry Robinson Palmer's invention in 1829, have a long history of use on roofs and also as building siding. Palmer, a British engineer and architect was employed at the London Dock company and is credited with the invention of what was first called "corrugated wrought iron" or CGI.

By the 1900s corrugated iron panels used for both roofing and siding had been widely adopted by Australia, India, New Zealand, and the United States, for use on commercial buildings, with producers in all of those countries.

Within the next decades these corrugated metal panels found still-wider use on farm buildings and utility structures.

The corrugated metal barn roof shown above is on a building in Poughkeepsie, New York is described further

These corrugated metal panels may be made of pressed aluminum sheets or of pressed iron or steel sheets formed into the corrugated surface patterns shown in these photos

The patched corrugated metal roofing shown below covers a pre-1900 home currently used as a parsonage in Dover Plains, NY.

Corrugating stiffened the sheets, and allowed greater span over a lighter framework, as well as reduced installation time and labor. In 1834 the American architect William Strickland proposed corrugated iron to cover his design for the market place in Philadelphia.

Galvanizing with zinc to protect the base metal from rust was developed in France in 1837. By the 1850s the material was used on post offices and customhouses, as well as on train sheds and factories. In 1857 one of the first metal roofs in the South was installed on the U.S. Mint in New Orleans. The Mint was thereby "fireproofed" with a 20-gauge galvanized, corrugated iron roof on iron trusses. (Sweetser - U.S. NPS)

The modern corrugated roofing shown below tops a gambrel-roofed barn in New England.

More on roof shapes and architecture is

at ARCHITECTURE & BUILDING COMPONENT ID.

Corrugated metal roofing on very old buildings such as this pre-1900 home in Pawling, NY, may be patched with newer corrugated sections where a chimney has been abandoned.

Find details at ABANDONED CHIMNEYS: Outdoors.

Corrugated metal roof panels are sold in both aluminum and steel.

Watch out for wind damage to any metal roof covering, especially where a simple nail-over panel has been installed such as shown here.

Corrugated metal roofing on very old buildings such as this warehouse in Hudson, NY, may be stunningly rusted and yet not leaky.

Corrugated metal roof panels are sold in both aluminum and steel.

The damage at the lower left roof corner was from a truck at the loading dock.

Also see the metal roofing articles listed in the ARTICLE INDEX

We discuss asbestos-cement and fiber cement corrugated panels separately

at CORRUGATED CEMENT ASBESTOS ROOFING

Find the history of corrugated metals, aluminum, iron, steel,

at STEEL & IRON BUILDING SIDING

- Sweetser, Sarah M., ROOFING for HISTORIC BUILDINGS - Preservation Brief [PDF] (1Preservation Brief 4, Technical Preservation Services, National Park Service, U.S. Department of the Interior, web search 9./29.10, original source: http://www.nps.gov/history/hps/tps/briefs/brief04.htm

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-03-09 - by (mod) - following up on questionable roof installation

@Anonymous,

Even without being a roofing expert yourself you should be able to identify the manufacturer and specific product of corrugated roofing that has been installed.

If not insist that the builder give you that information. With that information it should be entirely possible for you to download the installation specifications from the manufacturer and you can yourself do some spot checks to see if it looks as if you need to bring in a more expert roofer to give you an opinion.

On 2021-03-09 by Anonymous

Thanks for your reply I think the roofing contractor must have had an apprentice do my whole roof by himself, just the lack of knowing what was right and what was wrong was completely missing on my roof.

On 2021-03-09 by (mod) - limitations of roof inspections during construction.

@Tim Nels, Thank you for the comment about the limitations of roof inspections during construction.

In my OPINION, no building code inspector can possibly inspect 10)% of the work being done at a property - they would have to be on-site 100% of the time instead of visiting multiple sites per day.

As a result the code official typically spot checks, performs key checks at specific defined intervals, and ultimately relies on knowing and trusting the contractor.

But of course the quality of job supervision, even among good contractors, also varies enormously.

On 2021-03-09 by Tim Nels - The roof is corrugated aluminum.

Just a comment/cautionary tail:

I purchased a home a few years ago in Hilo, HI which was built in 1989. The roof is corrugated aluminum. My comment is; where are the building inspectors when a roof is built, possibly the most important part of a home, especially when you got leaks.

Everything the contractor did at the roof was absolutely wrong most of which the building inspector should have caught if he was doing his job.

Roof Issues:

1) per plans roof purlins should be spaced every 24" my roof they are spaced every 36".

2) Corrugated roof panels per spec are to be overlapped a minimum of 2" this would give a 1-1/2 "hump" overlap, my roof was only overlapped by less than 1" giving a 1/2 hump overlap (the corrugated panel has 1 long end up on one side and 1 long end down these ends overlap and that's it, panel should have been moved to the next hump over.

Hilo rains very heavy and this heavy rain fills up the corrugated valley and overfills it, leaking into the house, especially when windy.

3) Roof valley metal should have a overlap of 12" per spec. my valleys were overlapped just 1".

|

4) Roof panels intersecting roof valleys - not sure what the spec is but I'm assuming the the roof panels should be back an inch or 2 from the valley peak or point (I'm referring to the tip of the "W" in the valley), my roof panels actually touch the valley peak this has caused several leaks due to expansion and contraction of the metal.

5) Per plans the metal roof should overhang the fascia by 3".

My roof panels are at best even with the fascia and at worst the fascia sticks past the roofing by 1/2". It did not help that the gutters only have a 1" tab that goes under the roofing on the gutter to act as flashing.

6) Per plans all roof ends (where gutters are) at fascia should have a 2X4 purlin right behind the fascia board.

Not one roof end has this purlin instead the builder or roofer used the fascia as a nailer for the roof. Also with the problems of my roof I've had to get on the roof all the time, when you climb on a roof with tools and buckets where do you need the most support - the roof ends, so these metal roof ends have been damaged due to the abuse.

7) Absolutely no roof to fascia flashing except for the gutter.

On 2020-04-14 - by (mod) - can't distinguish asbestos-cement corrugated roofing from non-asbestos fiber-cement corrugated roofing by visual inspection

John

You cannot tell the difference between asbestos cement board, panels, or corrugated roofing and fiber cement roofing by visual inspection alone - both are fiber-cement products but the older one used asbestos fibres and also asbestos shorts as filler.

So to know if your roofing contains asbestos or not you need to either know the age (or source) of the roofing panels or you'd need to have a sample tested by an ASBESTOS TEST LAB (see ARTICLE INDEX)

On 2020-04-14 by John

Hi

My roof has either asbestos panels or fiber cement panels. How do you know the difference? I have walked all over this roof and it is extremely strong. I have a couple of busted ones above. My garage o need to replace but can't figure out to get them? The rest of the roof is in great shape. Just needs cleaned and sealed. Thank you for your time

On 2019-06-29 - by (mod) -

Corrugated roof panels made out of cellulose or wood products is not something that I have come across nor seen any reference to nor have I been able to find such a reference. You could try a patent search.

On 2019-06-28 by Phil Mayfield

I recently saw a reference to "corrugated wood-fiber roofing," which I believe was a mistaken identification. I've heard of cellulose fibers being used and cardboard, but I would like to know if there is such a thing as wood-fiber roofing panels.

On 2017-11-08 by Rajamallu

In a hot country like India How can we protect hot from sun while two or three rooms made up with roofing sheets like iron or asbestos etc

On 2017-04-28 - by (mod) -

SR

Corrugated galvanized steel roofing is typically sold in three thickness or gauges:

24 gauge - BWG .022 BWG mm / .559 in BWG inches or in the U.S. .0250 in / .635 mm in US Gauges

26 gauge - BWG .018 .457 or US .0188 .478 (inches then mm)

29 gauge - BWG .013 in .330 mm or US .0141 in .358 mm

On 2017-04-27 by sreenivas

what is the thickness of Corrugated AC Sheet for House Roofing

...

Continue reading at CORRUGATED CEMENT ASBESTOS ROOFING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ASBESTOS ROOFING / SIDING DUST

- BARN ROOFING, METAL

- CARDBOARD CORRUGATED FIBERBOARD

- CORRUGATED CEMENT ASBESTOS ROOFING

- CORRUGATED ROOFING

- DURALITA & METAL TILE ROOFS

- GALVANIZED STEEL ROOFS

- ENAMELED STEEL ROOFS

- HEMP / JUTE INSULATION in a corrugated metal sided/roofed building in Scotland

- METAL ROOFING

- STEEL & IRON BUILDING SIDING

Suggested citation for this web page

CORRUGATED ROOFING at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Duralita: produces cement & cardboard corrugated and clay tile-like roofing products: Duralita is a combination of cement and cardboard - see www.duralita.com/ Si tiene alguna pregunta, por favor escribanos a: sales@duralita.com -

El Salvador: +503 22.25.57.44 ext.31 USA +1 305.677.3597

- Terry Rubin, proprietor of the Posada del Bosque Encantado (web http://hotelposadaencantado.com/ ) can be contacted at gringamaya@yahoo.com or call (502) 5208-5334 or (502) 4146-1050 use 011 (502) from the US.

- Corrugated Iron, Building on the Frontier, Simon Holloway

- [1] Follansbee Roofing, Follansbee WV 26037, Tel: 800-624-6906, website: www.follansbeeroofing.com and http://www.follansbeeroofing.com/products/TerneII.aspx Quoting Follansbee on TerneII properties:

Follansbee Steel is the only manufacturer of a pre-painted or natural Terne roof and is a leading supplier of metal roofs for new and retrofit commercial, institutional, residential and historic preservation projects. - Metal Roofing Alliance, E. 4142 Hwy 302, Belfair, WA 98528, Telephone:(360) 275-6164, Customer Support 410-534-6900, Email: support@metalroofing.com,

Website: www.metalroofing.com. Quoting:

The Metal Roofing Alliance was formed in 1998 by a small group of forward-thinking metal roofing manufacturers with the main goal of educating consumers about the many benefits of metal roofing.

Since our inception, we've shown millions of people just how beautiful, durable and money-saving metal roofing can be for them. Over the years, our membership has grown to include paint companies, material suppliers, industry publications and more. Be sure to take advantage of all of the great resources our members offer. - The Metal Initiative, 4700 W. Lake Ave., Glenview, IL 60025, P:847.375.4785 Website: www.themetalinitiative.com/, Email: Louise Ristau lristau@connect2amc.com Quoting:

The Metal Initiative is a coalition of manufacturers, individuals and associations that have come together to provide information on the features and benefits of metal in construction. Carrying its message of metal primarily to the professional building owner community, The Metal Initiative seeks to gather and disseminate useful information for decision-makers. - Metal Roofing, an Illustrated Guide, R.A. Knowlton , [metal shingle roofs],

- Building Pathology, Deterioration, Diagnostics, and Intervention, Samuel Y. Harris, P.E., AIA, Esq., ISBN 0-471-33172-4, John Wiley & Sons, 2001 [General building science-DF] ISBN-10: 0471331724 ISBN-13: 978-0471331728

- Building Pathology: Principles and Practice, David Watt, Wiley-Blackwell; 2 edition (March 7, 2008) ISBN-10: 1405161035 ISBN-13: 978-1405161039

- Concrete Folded Plate Roofs, C. Wilby PhD BSc CEng FICE FIStructE (Author), Butterworth-Heinemann, 1998, ISBN-10: 0340662662, ISBN-13: 978-0340662663

- Concrete Roofing Tile, History of the, Batsford, 1959, AISN B000HLLOUC (availble used)

- Metal Roofing, an Illustrated Guide, R.A. Knowlton , [metal shingle roofs],

- Roofing The Right Way, Steven Bolt, McGraw-Hill Professional; 3rd Ed (1996), ISBN-10: 0070066507, ISBN-13: 978-0070066502

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.