Draft Adjustment on Pellet Stoves & Heaters

Draft Adjustment on Pellet Stoves & Heaters

Several adjustment controls & methods

- POST a QUESTION or COMMENT about pellet stove operating controls: dampers, fire/smoke dampers, duct dampers, or controls

Pellet stoves usually operate using a forced draft that supplies combustion air and effects the exhaust of combustion products, but to readers unfamiliar with these devices it can come as a surprise that a typical pellet stove heater has at least two and some more than two adjustments to the stove's draft and to its heat output.

Here we describe various methods used to control the draft and airflow through wood-pellet burning stoves or heaters.

This article series catalogs and describes all types of air and draft regulation devices used in buildings where control of heating appliances is needed.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Pellet Stove Draft Measurement, Settings, Controls

Pellet stoves usually make use of a draft fan for proper burning, though in event of a power failure some models permit limited operation using natural draft.

Pellet stoves usually make use of a draft fan for proper burning, though in event of a power failure some models permit limited operation using natural draft.

A separate blower fan helps extract heat from the pellet stove and transfer it to room air.

Using Castle Pellet Stove's Serenity Pellet Stove as an example, here we illustrate examples of controls on pellet stove heaters, all of which ultimately affect the stove's exhaust draft.

- Exhaust draft fan voltage adjusts fan speed

- Pellet stove airflow gate adjustment

Illlustration: The AGP Pellet Stove from Lopi, Travis Industries, excerpted from the company's instruction manual cited below. Travis Industries recommends a minimum vertical vent of 5’ to ensure adequate draft

during a power outage.

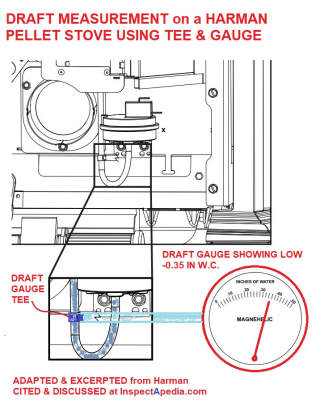

Other pellet stove installation manuals, for example the Harman Pellet Stove cited below, specifically describe using a manometer to check the appliance draft and may provide a mechanical adjustment of the combustion motor speed.

Harman specifies a normal pellet stove "high" draft (for their model) of -0.50 to -0.60 inches of W.C. (Water Column) and normal pellet stove "low draft) of -0.35 to -0.45 in. W.C.

Pellet Stove Exhaust Voltage Adjustment

From our same example pellet stove, the Serenity model, the manufacturer explains another control over pellet exhaust draft, the exhaust fan voltage.

Excerpt: Increasing the exhaust voltage, and thereby increasing the amount of air in the burn pot, will also assist in burning lowerquality fuels that may otherwise cause unwanted buildup.

The user can set the exhaust voltage, called "Stall voltage" at an of five settings between about 85V and 110V that in turn regulate the stove's blower.

Setting a higher voltage causes the fan to run faster, extracting more heat from the pellet stove.

Pellet Stove Exhaust Fan - Draft Fan

For example here is an excerpt from the Serenity Pellet stove produced by Castle:

For example here is an excerpt from the Serenity Pellet stove produced by Castle:

Your stove is equipped with an automatic ignition system that should ignite the fuel within 3-5 minutes of pressing the On/Off button.

As pellets fill the burnpot and ignite, outside air is drawn across the fuel and heated during the combustion process which is then pulled across the heat exchanger by the exhaust motor or the draft fan.

As the stove reaches operating temperature, room air is then circulated around the heat exchanger by a room air blower, distributing warm air into the room.

...

Because a forced draft pressure is required for the combustion process inside your stove, it is extremely important that the exhaust system be properly installed and maintained.

Also, the doors must remain closed while in operations and the seals on the doors must be properly maintained.

Watch out: implicit in the instructions just above is a mistake about which we warn with other heating appliances: woodstoves and coal stoves: leaving the combustion chamber ajar beyond during initial stove lighting procedures is very dangerous and can lead to severe stove overheating, damage, or even a house fire.

Pellet stove Airflow Gate Adjustment

This same Serenity pellet stove model from Castle includes an additional airflow or "draft" adjustment, the stove's airflow gate - shown below.

The airflow gate for this pellet stove is explained by the manufacturer:

IMPORTANT NOTE:

ADJUST THE AIRFLOW GATE BEFORE INCREASING THE EXHAUST VOLTAGE.

If you are having issues with getting enough air to your fire, FIRST try to adjust the air flow gate. SEE FIGURE 27. This will also adjust the air flow to the stove.

The exhaust voltage (controlling the combustion motor) allows you to adjust the stove for the fuel you are burning or compensate for inadequate ventilation situations.

In less than optimum venting situations, you can increase the exhaust speed for additional air circulation through the stove should ventilation be an issue.

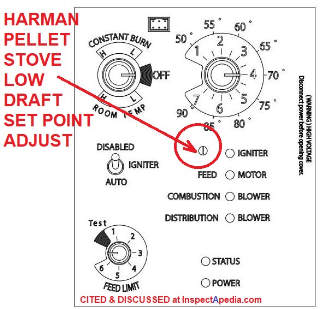

Below: Illustrations from Harman's Pellet Stove IO manual showing how a manometer or draft gauge is connected to a service tee on the pellet stove to measure the stove's draft level, and a second illustration of the manual setting of the stove's low-draft set-point.

Pellet Stove Draft Adjustment Sources

- CASTLE SERENITY PELLET STOVE INSTALLATION INSTRUCTIONS [PDF] (2014) Ardisam, Inc., Castle Stoves™, Division d’Ardisam, Inc.1160 8th Avenue, PO Box 666Cumberland, WI 54829 USA Tel: 800-345-6007 | Télécopie 715-822-2223Courriel : info@castlestoves.comwebsite: www.castlestoves.com

- Harman PELLET STOVE MANUAL [PDF] (2017) Harman, 352 Mountain House Road, Halifax, PA 17032 USA Website:

www.harmanstoves.com retrieved 2018/10/13, original source: https://downloads.hearthnhome.com/installManuals/XXV_I.pdf

Excerpts:

The factory low draft setting may not be correct for the unit’s permanent installation conditions. The control board on the XXV is equipped with a low draft adjustment port located on the control face just to the right of the igniter light. - Lopi AGP PELLET STOVE IO MANUAL [PDF] (2013) Travis Industries, Inc. 4800 Harbour Pointe Blvd. SW Mukilteo, WA 98275 USA , Website: www.travisproducts.com, retrieved 2018/10/13, original source: https://www.lopistoves.com/TravisDocs/100-01330.pdf

- Our index to PDF copies of pellet stove manuals, certifications and fire clearances is

at PELLET STOVE CLEARANCE DISTANCES

...

Continue reading at PELLET STOVE CLEARANCE DISTANCES & MANUALS, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- DAMPERS & DRAFT REGULATOR TYPES

- DRAFT INDUCER FANS

- DRAFT MEASUREMENT, CHIMNEYS & FLUES

- DRAFT REGULATOR, DAMPER, BOOSTER

- FIRE CLEARANCES INDOORS

- FIRE CLEARANCES, WOOD COAL & PELLET STOVES

- FIREPLACE DAMPERS

- GAS FIREPLACES & GAS LOGS

- KEROSENE HEATER DRAFT CONTROL

- PELLET STOVE CLEARANCE DISTANCES & MANUALS

- PYROLYSIS EXPLAINED

- WOOD STOVE, CATALYTIC PUFF-BACKS

- WOODSTOVE DRAFT CONTROL

- WOOD STOVE DRAFT TEST

Suggested citation for this web page

PELLET STOVE DRAFT CONTROL at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING FIRE SAFETY

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Airflow Breeze air movement register booster fans are produced by AirFlow Technology, Airflow Technology 1427 West 86th Street, Suite 328 Indianapolis, IN 46260 1-800-458-5540 website: http://www.aftproducts.com/Airflow_Breeze_3ff0ef340c6e0e13b.dept

- Fuel Oil & Oil Heating Magazine, 3621 Hill Rd., Parsippany, NJ 07054, 973-331-9545 rk 3rd Ed 1969.

- National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- [1] "Instructions for Installing FIELD Type AF Barometric Draft Controls," Form No. 31 DC 30666, Field Corporation, Mendota, IL 61342, web search 04/02/2011, original source: http://www.fieldcontrols.com/pdfs/04592700.pdf, Field Controls, Kingston, North Carolina 28501, Tel: 919-522-3031

- [2] Tjernlund Draft Controls, A Series (single action for oil, solid fuel, and fan-assisted gas burners) and B Series (double action for gas heating appliances), web search 04/02/1011, original source: http://www.tjernlund.com/Tjernlund_8500490.pdf , Tjernlund Products, Inc., 1601 Ninth Street, White Bear Lake MN 55110-6794, Tel: 651-426-2993 or 800-255-4208 website: www.tjernlund.com Email: fanmail@tjfans.com

- Carbon Monoxide Gas Toxicity, exposure limits, poisoning symptoms, and inspecting buildings for CO hazards

- DUST, HVAC CONTAMINATION STUDY An Investigation of Indoor Dust Debris Blamed on a Heating/Cooling System Reveals Carpet Dust

- Fuel Oil & Oil Heating Magazine, 3621 Hill Rd., Parsippany, NJ 07054, 973-331-9545

- Goodman Furnace High Temperature Plastic Vent HTPV safety recall US CPSC notice

- Home Heating System Should Be Checked[for proper venting and for CO Carbon Monoxide Hazards - DJF]

- Inspection Procedures for Oil-Fired Heating Systems Detailed step by step approaches for inspecting complex systems]

- Lennox Pulse Furnace Safety Inspection/Warranty Program: Carbon Monoxide Warning

- Plastic Heating Vent Pipe & Other Heating Safety Recall Notices

- Weil McLain Model GV Gas Boiler/gas valve CPSC recall/repair

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Warm Air Heating Systems". Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.