Temperature Properties

of Asbestos Cloth or Fabric

Temperature Properties

of Asbestos Cloth or Fabric

The temperature characteristics of asbestos cloth by grade of asbestos

- POST a QUESTION or COMMENT about asbestos definition, chemical, mechanical, composition, iron content, thermal & other properties

The temperature properties of asbestos: this article describes the heat resistance of asbestos in various forms and notes the effects of high temperature on asbestos fibers, cloth, or other products.

This article series describes the physical properties of asbestos including its mechanical, chemical, electrical and related properties both in pure asbestos form and when asbestos is mixed with other materials like cement or rubber. As the author points out, while this is a lenghty article, there is far more detailed information about asbestos properties, chemistry, etc.

Page top photograph: aluminized asbestos fabric used as the vibration dampener on a warm air furnace ©Daniel Friedman. In the textile field ASTM Grade AAAA asbestos fabric has been reported to have a service temperature as high as 900°F.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Temperature Properties of Asbestos Fabric or Cloth by Grade

As Rosato notes at ASBESTOS PROPERTIES, some forms of asbestos actually become stronger when subjected to high temperatures.

As Rosato notes at ASBESTOS PROPERTIES, some forms of asbestos actually become stronger when subjected to high temperatures.

[Click to enlarge any image]

Asbestos fiber or paper treated with a 20 per cent, by weight, of aqueous solution of magnesium chloride, dried, dipped in a 20 per cent aqueous solution of concentrated ammonium hydroxide, and dried at 175° F, causes an increase in strength ten times greater than its original strength. It also produces a 165 per cent increase in dielectric strength.

When asbestos fibers are subjected to a temperature of 1,200°F, their tensile strength values are extremely high. In comparison, tensile strength values of organic and inorganic fibers are completely destroyed or melt between 200 and 900°F.

Ultimate tensile strength of chrysotile asbestos fibers is approximately 42,000 psi after two minutes at 1,2Q0°F ; 32 per cent strength retention occurs.

After one hour at 1,200°F, tensile strength drops to 2,000 psi. When the fibers are com- bined with silicone resin to produce structural plastics, the reinforced plastic can retain 50 per cent of its room temperature tensile strength or produce a minimum 10,000 psi after 5 to 10 hr. at 1,200°F.

With phenolic resins, asbestos products are produced which will provide insulation and retain strength when subjected to 5,000°F for periods of minutes (1 to 30 minutes) . See Figure 2.1 in which a rocket motor part is subjected to a temperature of 5,000°F. Figure 2.1. Rocket motor aft (asbestos-phenolic insulator) before and after firing at 5,000°F.

The temperature approximately 1/8 in. from the surface exposed to 5,000°F will be approximately 200°F after 1/2 to 1 min. of exposure.

When combined with magnesium carbonate and other similar products, heat insulators can be produced which will be useful for many years in such applications as boilers operating at temperatures from 500° to 1,200°F or 1,800°F.

Although asbestos fiber mechanically breaks down at approximately 1,500°F, it does not completely disintegrate until 2,770°F. At this temperature, it can be related to such a ceramic material as magnesium oxide. When combined with other materials, it provides for interesting products in different temperature and time environments.

In an effort to investigate the elevated temperature properties of some of the asbestos textile products and to make comparisons between various grades and constructions, a test set-up was adopted that had previously been developed and used to determine the high temperature serviceability of treated leather and some glass textiles.

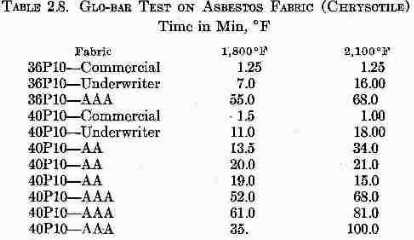

The unit consists of a Glo-bar heating element sop ositioned that a sample of material to be tested can be placed in contact with it. The material can be drawn or dragged over the heated Glo-bar while suspending a load of 2 lb. In this work, the samples contacted the heating element four times per min for a duration of 7 1/2 sec over a 4-in. length.

The sample moved over the heating element at a rate of 80 ft per hr. Abrasion occurs during the test.

* Shaw , M. C., Report No. 42, Sept., 1957, Report No. 44, March, 1958. Asbestos Textile Institute, Phila., Penna.

Fabrics composed wholly of glass have also been tested on this machine; it has been found that such materials fail immediately at 1,100°F. Upon making contact with the heat- ing element at 1,100°F, the glass materials melt and the sample tears apart.

Asbestos fabrics in grades from Underwriters through AAA were studied. However, several other styles of chryso- tile asbestos textiles were included, as well as samples of a blue asbestos cloth in a style comparable to the standard 36P10 construction.

Tests performed on samples of blue asbestos revealed that under the conditions of the test, this material proved to be quite durable up to 1,500°F however, at 1,600°F failure was induced after 5 1/2 mm at 1,700°F failure was promoted after one min; at 1,800°F failure occurred upon the second contact or in approximately 10 sec.

Failure in the latter case was caused primarily by melting; the abrasive action served only in a minor degree to hasten destruction. Chrysotile data are given in Table 2.8 fpimd below.

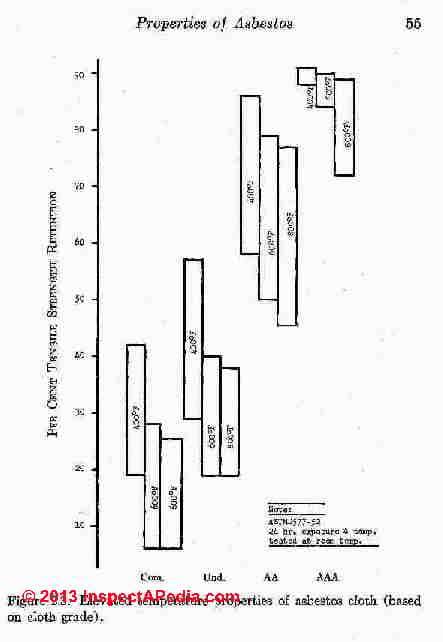

An asbestos textile may be composed entirely of asbestos fibers with varying amounts of an organic fiber, usually cotton and rayon. The resistance to degradation by heat is principally a function of the asbestos content and the higher the asbestos content the higher will be its elevated temperature serviceability characteristics.

However, features of construction, weight and weave may also influence the ele vated temperature properties and there should be an ap- preciation of the potential influence of these factors if the most efficacious adoption of an asbestos textile to a given application is to be effected.

TABLE 2.8. GLO-BAR TEST ON ASBESTOS FABRIC (CHRYSOTILE) Time in Mm, oF

* Review chapter on Textile for identification of grades.

! Shaw, M. S., Report No. 45, June 6, 1958. Asbestos Textile Insti-

tute, Philadelphia, Penna.

The generally accepted system of grading or classification for asbestos textiles includes six grades ranging from 75 to 100 per cent asbestos content (see chapter on Textiles).

Manufacturing operations are such that as the asbestos content is lowered and the cotton or other organic fiber content is increased, it is possible to utilize asbestos fibers of a shorter length than when there is a complete absence of or only very small amounts of organic fiber present. The organic fibers normally serve as a carrier fiber in the manufacturing operation and contribute quite markedly to the original strength of the textiles so formulated.

However, as the asbestos content of the cloth is increased and the organic fiber content decreases, it becomes necessary to utilize asbestos fibers of greater length. This action serves to improve both the high temperature degradation resistance characteristics and the strength properties over the entire range of serviceability.

FIGURE 2.3 above describes the temperature properties of asbestos cloth or fabric of different grades. [Click to see an enlarged, detailed version of this or any image or table at InspectApedia.com]

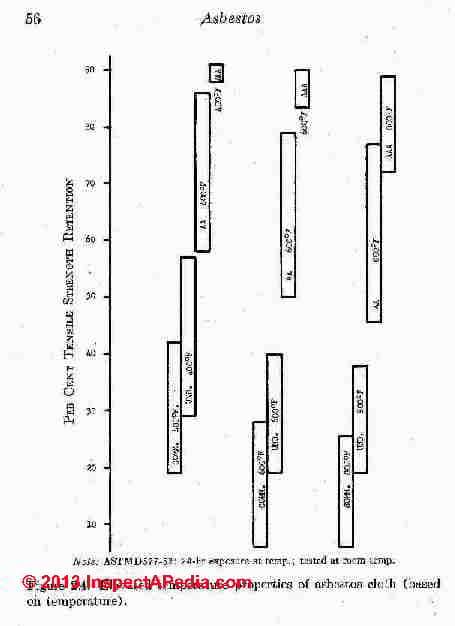

Asbestos textiles are manufactured in a great many styles and weaves, each being designed and manufactured to meet specific application. Present day fabrics normally range weights from 1.00 to 3.70 lb per sq yd in single cloth constructions.

FIGURE 2.4 above describes the hight temperature properties of asbestos cloth or fabricbased on temperature. [Click to see an enlarged, detailed version of this or any image or table at InspectApedia.com]

Asbestos yarns range from 8 to 35 cut; these are utilized to provide several varieties of designs and weaves. The varying . conditions of design and construction definitely influence the physical properties and elevated temperature characteristics of each type of cloth ; the extent of this influence must be understood if there is to be a proper application of these materials.

The elevated temperature serviceability characteristics of wide variety of asbestos textiles have been determined as function of the tensile strength retention properties ; this information is set forth graphically in Figures 2.3 and 2.4.

Thermal Insulation Properties of Asbestos

There are some organic and inorganic materials which can be classified as better insulating agents against heat and electricity) than asbestos. However, in many instances, these materials lack physical and chemical properties. Asbestos possesses a combination of different properties which make ft particularly suitable for insulation.

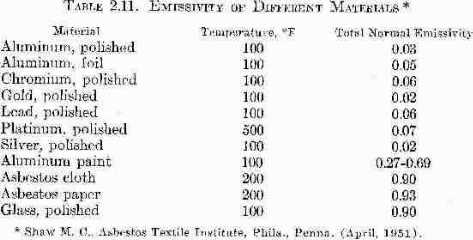

TABLE 2.11. EMISSIVITY OF DIFFERENT MATERIALS

[Click to enlarge]

Material Temperature, F Total Normal Emissivity

Shaw M C Asbestos Textile Institute Phila.,Penna.. (April 1951)

Organic fibers in cork may be strong and resistant enough for heat insulation, but they are subject to oxidization and to thermal decomposition. Magnesia, less sensitive against oxygen and decomposition than cotton, has no inherent strength. Asbestos combines these properties as well as others. In heat insulation, it is important that numerous air cells or air pockets exist. Asbestos provides for this type of structure.

Thermal reflectivity of materials is an important characteristic. The ratio of heat radiated by a body to that of a black body or the emissivity of asbestos is desirable for insulation. In Table 2.11 [shown above] emissivity of various materials is listed.

...

Continue reading at ASBESTOS TYPES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Suggested citation for this web page

ASBESTOS TEMPERATURE PROPERTIES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] ASBESTOS HISTORY & PROPERTIES [Book online] D.V. Roasato, engineering consultant, Newton MA, Reinhold Publishing Co., NY, 1959, Library of Congress Catalog No. 59-12535. We are in process of re-publishing this interesting text. Excerpts & adaptations are found in InspectApedia.com articles on asbestos history, production & visual identification in and on buildings.

- [2] "Asbestos in Plastic Compositions", A.B. Cummins, Modern Plastics [un-dated, pre 1952]

- [3] "Asbestos in Your Home," Spokane County Air Pollution Control Authority, Spokane WA 509-477-4727 www.scapa.org provides a one-page image, a .pdf file drawing of a house warning of some possible sources of asbestos in the home. The sources are not ranked according to actual risk of releasing hazardous levels of airborne asbestos fibers and the list is useful but incomplete.

- [4] The US EPA provides a sample list of asbestos containing products epa.gov/earth1r6/6pd/asbestos/asbmatl.htm

- [5] "Characterization of asbestos exposure among automotive mechanics servicing and handling asbestos-containing materials", Gary Scott Dotson, University of South Florida, 1 June 2006, web search 3/9/2012 original source: scholarcommons.usf.edu/cgi/viewcontent.cgi?article=3505&context=etd [copy on file as /hazmat/Automotive_Asbestos_Exposure.pdf ].

- [6] Asbestos Identification and Testing References

- Asbestos Identification, Walter C.McCrone, McCrone Research Institute, Chicago, IL.1987 ISBN 0-904962-11-3. Dr. McCrone literally "wrote the book" on asbestos identification procedures which formed the basis for current work by asbestos identification laboratories.

- Stanton, .F., et al., National Bureau of Standards Special Publication 506: 143-151

- Pott, F., Staub-Reinhalf Luft 38, 486-490 (1978) cited by McCrone

- [6] ASBESTOS IN YOUR HOME U.S. EPA, Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- [7] Asbestos products and their history and use in various building materials such as asphalt and vinyl flooring includes discussion which draws on ASBESTOS, ITS INDUSTRIAL APPLICATIONS, ROSATO 1959, D.V. Rosato, engineering consultant, Newton, MA, Reinhold Publishing, 1959 Library of Congress Catalog Card No.: 59-12535 (out of print, text and images available at InspectAPedia.com).

- [8] "Handling Asbestos-Containing roofing material - an update", Carl Good, NRCA Associate Executive Director, Professional Roofing, February 1992, p. 38-43

- [9] EPA Guidance for Controlling Asbestos-Containing Materials in buildings, NIAST, National Institute on Abatement Sciences & Technology, [republishing EPA public documents] 1985 ed., Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- EPA ASBESTOS MATERIALS BAN: CLARIFICATION 1999

- Basic Information about Asbestos, US EPA, web search 08/17/2010, original source: http://www.epa.gov/asbestos/pubs/help.html

- "Handling Asbestos-Containing roofing material - an update", Carl Good, NRCA Associate Executive Director, Professional Roofing, February 1992, p. 38-43

- EPA Guidance for Controlling Asbestos-Containing Materials in buildings, NIAST, National Institute on Abatement Sciences & Technology, [republishing EPA public documents] 1985 ed., Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- EPA, ASBESTOS IN YOUR HOME [PDF] - U.S. EPA, Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- Vermiculite:

Protect Your Family from Asbestos-Contaminated Vermiculite Insulation, U.S. EPA , web search 08/17/2010, original source: http://www.epa.gov/asbestos/pubs/verm.html

Web search 01/20/2011, original source: http://epa.gov/asbestos/pubs/verm_questions.html - Proteja su familia del aislante de vermiculita contaminado con asbesto, U.S. EPA HOJA INFORMATIVA - Proteja a su familia del aislante de vermiculita contaminado con asbestos, web search 08/17/2010, original source http://www.epa.gov/asbestos/pubs/verm-ques-sp.pdf

- [copy on file as /hazmat/Vermiculite_US_EPA.pdf/ Current Best Practices for Vermiculite Attic Insulation - May 2003, U.S. EPA

- [copy on file as] /hazmat/Vermiculite_Health_Canada.pdf] Vermiculite Insulation Containing Amphibole Asbestos - September 2009, Health Canada

- Managing Asbestos in Place, How to Develop and Maintain a Building Asbestos Operations and Maintenance (O&M) Program, U.S. EPA, web search 01/20/2011, original source: http://www.epa.gov/asbestos/pubs/management_in_place.html

- Asbestos Strategies, Lessons Learned about Management and Use of Asbestos: Report of Findings and Recommendations on the Use and Management of Asbestos, 16 May 2003, US EPA, web search 01/20/2011, original source: http://www.epa.gov/asbestos/pubs/asbstrategiesrptgetf.pdf

prepared by the: Global Environment & Technology Foundation, 7010 Little River Turnpike, Suite. 460, Annandale VA 20003 - Other US EPA Publications on asbestos: web search 01/20/2011, see http://www.epa.gov/asbestos/pubs/pubs.html

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.