Corrugated Asbestos Cement Roof Materials

Corrugated Asbestos Cement Roof Materials

Inspection, hazards, repairs or replacement?

- POST a QUESTION or COMMENT about identifying & maintaining or removing asbestos cement corrugated roofing

Guide to asbestos cement corrugated roofing:

This article provides a photo guide and text that can identify the condition of cement asbestos roofing products like asbestos-cement roof shingles.

We discuss how to identify corrugated cement asbestos roofing and how to treat this material when found on a building.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Corrugated Cement-Asbestos Roofing Guide

Asbestos cement roof shingles were in popular use in the U.S. from the 1920's (est) through the 1960's (est) and were sold in the U.S. into the 1970's and according to some sources even in the 1980's.

The mixture of asbestos fibers and portland cement to form a hard material that was was durable and fire resistant is credited to Ludwig Hatschek who, in 1900, came up with the name Eternit associated with a U.S. producer of these products.

[Click to enlarge any image]

Article Contents

- CORRUGATED CEMENT ASBESTOS ROOFING & SIDING MANUFACTURE

- CORRUGATED CEMENT ASBESTOS ROOFING LIFE

- CORRUGATED CEMENT ASBESTOS ROOF WEAR TYPES & ACTION GUIDE

- CORRUGATED CEMENT ASBESTOS ROOF STAINS

- CORRUGATED CEMENT ASBESTOS ROOF MAINTENANCE or REMOVAL?

- CORRUGATED CEMENT ASBESTOS ROOF DEMOLITION

- CORRUGATED CEMENT ASBESTOS ROOFING REPLACEMENTS

Large Asbestos-Cement Sheet Goods Production

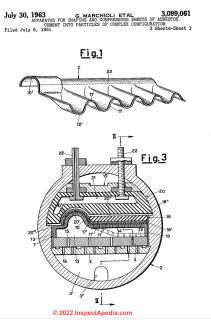

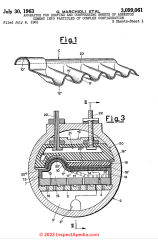

Illustration: Marchioili's 1963 US Patent-US3099061 described machinery to compress and form asbestos cement into a desired shape such as into corrugated panels that could be used for roofing and siding: one of the most-successful and widely-used forms of asbestos cement that is still in service in many buildings around the world. (Marchioli 1963)

Illustration: Marchioili's 1963 US Patent-US3099061 described machinery to compress and form asbestos cement into a desired shape such as into corrugated panels that could be used for roofing and siding: one of the most-successful and widely-used forms of asbestos cement that is still in service in many buildings around the world. (Marchioli 1963)

Excerpt: In

accordance with the invention, the sheet of asbestos ce

ment is placed while in the plastic state, on a rigid, con

toured part of a mould, a piece of elastically yielding material forming a lower part of the mould and having a

lower surface matching that of the upper face of the

moulded sheet and a flat upper surface is placed over

said sheet, and the whole is introduced into a press by sliding it in a direction parallel to the flat upper surface

of the piece of elastically yielding material.

The apparatus according to the invention permits com

plicated members such as tiles for roof ridges to be pro duced rapidly and almost continuously; it is hence with

reference to asbestos cement roof ridge tiles that the

invention will now be more fully described, ...

Amy Lamb Woods, in "Keeping a Lid On It" Asbestos-Cement Building Materials" (Woods 2000) provides a superb and concise description of the history and properties of asbestos cement building products, while beginning

in Rosato's ASBESTOS ORIGIN & NATURE

we provide the compete text of Rosato's 1959 seminal work on this topic. The following excerpts are from Woods (2000):

Large flat asbestos - cement sheets were available in sizes of twelve - feet long by four - feet wide and thicknesses ranging from approximately an eighth of an inch to one inch.

Asbestos-cement flat sheets were, at one time, manufactured only in the typical gray color of cement and usually only accepted for industrial purposes.

Eventually sheets were made with smooth surfaces, waxed or lacquered, with a variety of colors for use as office partition walls, kitchen walls, tabletops, acoustical panels, and building corridors.

They were often used where ease of cleaning was important. One popular material for interior lining was an embossed sheet with a figured pattern that could be painted or distempered, thus providing the effect of plaster at a relatively low cost.

Another popular variation consisted of a smooth surface and wood - grain appearance available in a range of colors.

Some sheets were glazed, thus presenting a smoother, more resilient finish. Flat sheets were often incorporated into composite products. ‘Transitop’ was a typical composition board consisting of an integrally impregnated insulating board core, faced on both sides with asbestos-cement board.

Waterproof adhesives were used to laminate the insulating core as well as to bond the noncombustible asbestos - cement faces to the core. ...

The Hatschek machine made possible the production of large asbestos-cement sheet goods.

See CEMENT ASBESTOS PRODUCT MANUFACTURE for details of the Hatschek machine and its operation.

With the advent of asbestos-cement corrugated sheets, the enclosure of factory buildings, warehouses, and train sheds was simple, economical, and effective for either permanent or portable structures.

Corrugated asbestos - cement sheets were applied in the same way that corrugated iron was applied, either nailed to wooden strips, bolted to the purlins, or clipped directly to the purlins by clips of hoop - iron or wire.

They were available in standard sheets, twenty - seven and a half inches wide and in lengths of four, five, six, seven, eight, and ten feet.

Two primary shapes were Trafford (with peaks), and Fibrotile (with waves).

A series of special hardware devices was designed for use with corrugated sheets so that buildings could be completely encased in the material. Corrugated asbestos - cement sheeting was also used for decorative purposes in uniquely styled buildings of all descriptions.

During the 1940s construction boom, a wider variety of colors became available, including a spackled look, where the colors were impregnated throughout the sheet so they would not powder or peel off.

When color change became desirable after installation, owners we re encouraged to paint the asbestos-cement products.

It was the “attractive home safeguarded with modern asbestos siding, fireproof, rot proof, termite proof” idea that intrigued many Americans during this era. By 1950, approximately one billion square feet of asbestos-cement products had been produced for use in the building industry. - Woods (2000)

Typical Life of Cement Asbestos Roofing

The typical life expectancy of an cement asbestos shingle roof was given as 30 years, But we have seen these roofs that were now 50 years old in good condition. Typical roof wear or failure patterns are either failure of the shingle fasteners or broken and falling shingles.

Virtually all of the asbestos cement roof shingle inspection points, installation limitations, and environmental concerns which we discussed

at CEMENT-ASBESTOS ROOF SHINGLE GUIDE also apply to corrugated asbestos-cement roofing products.

OPINION: The lichens growing on cement-asbestos roofing (photo at left), especially this thick corrugated material, is probably less of a wear concern than when that material appears on asphalt shingles or roll roofing.

Do not try to walk on this material without taking the same precautions as if accessing a slate roof: the material is easily damaged by foot traffic.

Cleaning stains, mold algae, lichens from cement-asbestos roofs

Watch out: As we discuss at POWER WASHING ROOFS we do not recommend power-washing asbestos-cement nor any other roofing.

However there are techniques for preventing or killing off algae growth that stains roof surfaces.

See BLACK or GREEN ALGAE STAIN REMOVE / PREVENT for advice on diagnosing, cleaning, and preventing stains on roofing.

Forms of Cement Asbestos Roof Wear & Deterioration

My opinion (I am not an engineer but have field experience and have done some research on the topic) is that if the corrugated asbestos-cement roof decks you describe have been protected from the weather (including leaks through the roof membrane) and thus from water and freeze-thaw cycle effects then the materials may be in better condition than the roofs I've inspected that have been directly exposed to the weather. Asbestos cement roof deterioration elements we expect to find in the field include:

- Algal or cyanobacterial growth on asbestos cement roofing: Biological Growth

These organisims develop on corrugated cement roofing through penetration of filamentous components into the roof material soften and weaken it.

Murphy (2002) on fiber cement roofing shakes cites the effects of algae or cyanobacteria that take several forms that reduce the roof service life: structural and mechanical stresses, effects of nitric acid interacting with lime components in the roofing material, mechanical deterioration, loss of original polymer coatings, moisture migration, water absorption and other forces.

At BLACK or GREEN ALGAE STAIN REMOVE / PREVENT we explain that addition of copper strips near a roof top can kill and prevent future growth of algae, lichens, moss on roofs.

Watch out: As we discuss at POWER WASHING ROOFS we do not recommend power-washing asbestos-cement nor any other roofing. In addition to damaging the roof surface, power-washing an asbestos-cement roof can create an environmental hazard. - Effloresence on asbestos cement roofing

Woods (2000) and others point out that

Efflorescence appears on many portland cement products that are exposed to weathering. This form of crystalline growth indicates that water is passing through the material, which can promote deterioration of the asbestos-cement, in addition to making it unsightly.

Generally this is seen at the beginning of the material’s life, where rain and weathering tend to remove it over time.

While it is possible to remove effloresence by gentle brushing or even treating with a vinegar solution, that treatment on roofs may be unnecessary and is not a functional requirement. But do inspect to be sure that the effloresence is not an indicator of a local roof leak that needs to be repaired.

- Embrittlement of asbestos cement roofing

Amasco (1987) cites asbestos cement sheeting embrittlement with age and cracking as a result of wind or . vibration. - Cracking in asbestos cement roofing

Cracking of the asbestos cement materials, usually from mechanical stress from walking on, impact, or around fasteners or due to thermal movement of the materials (See Larsen (1990) and Hansen (2009)).

Some experts add effects of wind and vibration such as from nearby street traffic or in locations such as New Zealand, earthquake-induced roof movement.

Larsen concludes:

... that natural and glass fibres are losing strength and ductility in a cementitious matrix. This results in a drastically reduced fracture energy of the composite material over the years.

In the worst cases practically no fibre effect is left after some ten years of normal out-door exposure. - Larsen (1990)

Woods (2000) recommends use of portland cement for repair of larger cracks - a repair that might have a modest chance of success (in our OPINION) if first the roof surface is sufficiently cleaned of debris or biological growth sufficiently that the portland cement will bond to the old roof surface.

Cracks will need to be repaired both to stop leaks and to avoid an increase in the rate of roof deterioration in cold climates where the roof is exposed to freezing. (Patch with fabric & mastic or epoxy). - Discoloration of asbestos cement roofing

of asbestos cement roofing or siding is usually only a cosmetic concern; evaluate the material to confirm that it is not flaking or soft.

Discoloration of asbestos-cement products stems from a build-up of surface contamination (such as soiling), stains produced by leaching of other material byproducts (such as corrosion run-off), or a direct change in color due to the environment (such as ultra-violet sun bleaching).

These discoloration occurrences typically result from normal weathering, but indicate a chemical reaction that may decrease the strength or durability of the material when neglected over time. (Woods 2000)

Woods recommnds removing discoloration. We're not sure we agree - at least not for non-historic buildings.

See the warnings given

at ASBESTOS ROOFING / SIDING POWER WASHING - Eroding, spalling, flaking of asbestos cement roofing

Watch out: this is a more-serious deterioration of the mateiral that can mean that friable asbestos is being shed where it may become a hazard.

While there are preservation methods available (Woods 2000) they may not be cost-effective for non-historic buildings.

See details at ASBESTOS CEMENT ROOF ERODING SPALLING FLAKING (below on this page) - Fastener deterioration / failure in asbestos cement roofs

Watch out: while it is possible to add even remove and replace deteriorated fasteners used to hold corrugated asbestos cement panels in place, particularly on roofs special care will be needed to avoid walking directly on the roof surface lest your weight cause still more damage by breaking the surface.

Special fasteners using lead (originally) or nylon (modern) washers reduce the risk that the fastener itself or stresses against it cause additional cracks or breaks in the roofing or siding panels.

If the fasteners for the asbestos-cement product have become deteriorated or have broken from corrosion, they should be replaced with a more durable metal.

Various metals can be considered for the replacement, but should be compatible with the sheathing. Stainless steel is generally recommended because of its superior corrosion resistance.

Fasteners such as nails should be long enough to hold the materials securely (self-clinching nails can help with this). (Woods 2000)

- Leafing or delaminating of asbestos cement roofing

of the asbestos cement material from water and freeze-thaw cycles.

Watch out: as we cite for spalling and flaking (above) and softening (below),this is a more-serious deterioration of the mateiral that can mean that friable asbestos is being shed where it may become a hazard.

- Leaks in asbestos cement roofing

in the roof deck contribute to softening, cracking (+ frost action), acidification, and mechanical damage through temperature or freeze-thaw cycles.

Leaks limited to areas of cracking may be repairable by on-roof surface repair methods that combine a geotextile or fiberglass patch fabric with an appropriate epoxy or mastic coating. - Softening of asbestos cement roofing

Over its long life softening of the asbestos cement materials can appear and be seen as an increase in flaking or shedding of material.

Watch out: as was the case for leafing or delaminating, this is a serious deterioration of the mateiral that can mean that friable asbestos is being shed where it may become a hazard.

OPINION: While for historic preservation purposes there are spray-on liquids that can colsolidate and extend the life of asbestos cement roofing or siding, in our experience [DF] a softened asbestos cement roof or siding product is not economically repairable and will need replacement.

Importance of Visual Assessment of Asbestos-Cement Roof Condition

However without lab testing combined with an intelligent assessment of the extent of roof area over which a particular form of deterioration is observed, in my opinion, a quantitative statement of roof life remaining would be unreliable. See Giller (1993) on visual assessment of roof decking.

A more detailed inspection of the asbestos-cement corrugated material-roofed building(s) you are evaluating is needed to determine the leak history as well as to find other instances of mechanical or other damage to the roofs.

Certainly one of your photos shows one of the worst, most heaved, out of flat membrane roof surfaces I have seen. One might choose the most-suspect roof area for further, more invasive inspection or materials testing.

In my opinion, an astute roofer would be reluctant to accept a roof-over job on such a roof because of lack of confidence in the durability of that approach, or s/he would make clear in writing that there was little or now warranty on the roof job unless the new roof could be installed over an appropriately secure and smooth roof deck.

Also you may want to take a look at ASTM E2394 and at Oberta's proposed Standard for repair and maintenance of Asbestos-Cement materials.

Response to an Asbestos Cement Roof that is Eroding, Spalling, or Flaking

The following is excerpted from the US National Park Service advice by Amy Woods (2000) cited in detail below, and noting that the objectives of historic preservation of buildings are more constrained than the preservation of other buildings that will take a more utilitarian and lower-cost approach:

Erosion removes cement particles and can result in the release of asbestos fibers, leaving the

material with less reinforcement.

Due to the high density, low permeability, and low porosity of the

material, this tendency is virtually unnoticeable.

However, erosion can become a more serious

problem under regular and extremely harsh weather conditions. If intense erosion occurs, the

durability of the material can be compromised.

Although rare, spalling or flaking occurs when elements permeate beneath the surface of the

asbestos-cement material and then expand, causing a portion of the material to be released due to

the resulting stress.

As the moisture content increases, more severe deterioration can occur. This

deterioration is more likely to occur in products that were cured at lower temperatures and therefore

are more vulnerable to water penetration.

To control eroding, spalling, or flaking, chemical consolidants and/or breathable sealers (most

commonly silane) can be applied to strengthen the material while adding water protection.

Testing

is critical since consolidants and sealers can promote spalling if water is getting in through the

backside of the material.

A grout or latex-patch may also be considered, but must be compatible with, and typically softer

than, the asbestos-cement material to form a good bond and not promote increased spalling.

This

repair procedure can be tricky and may lead to constant patching, and may be unsightly if not done

with extreme care.F

or these types of deterioration tendencies, the material may be better off left alone or partially replaced.

When Corrugated Asbestos Cement Roofing or Siding Needs to Be Replaced

Again excerpting from Woods (2000)

Since asbestos-cement products were manufactured

in standard sizes, shapes, colors, and textures,

partial replacement is well suited for

implementation.

This process is acceptable when

part of, or pieces of, the existing asbestos-cement

building material have deteriorated to such a degree

that it is much more feasible to replace than repair

(Figure 6). Since the United States no longer

produces asbestos-cement products, an alternative

material should be selected to match the original.

Some materials that have been manufactured to

replicate asbestos-cement building components are

non-asbestos reinforced cement, fiberboard with

asphalt, fiberglass, metal, and vinyl.

For the

purposes of preservation, one of the non-asbestos

reinforced cement products is most appropriate.

See ASBESTOS CEMENT ROOF / SIDING REPLACEMENT SOURCES

Maintain or Remove Corrugated Asbestos or Fiber Cement Roofing?

Reader Question: What should I do about corrugated fiber cement roofing on my home - is it asbestos? Is it dangerous?

I just bought my house. It was inspected a friend who saw my roof, photos [above and below] and who says it is asbestos. Can you tell by looking at a photograph if this is an asbestos-cement roof ?

- How do I determine if this corrugated roofing is asbestos cement?

- Do I need to remove it?

- Is corrugated asbestos cement roofing a problem as it is? - S.S.

Reply: It depends ...

A competent onsite inspection by an expert usually finds additional clues that help accurately diagnose a problem or that can more accurately estimate the age and thus the chances that your corrugated roof is an asbestos-containing product.

That said, here are some things to consider:

- If you know that the material is quite old, say from the 1970's or older, it may be a cement-asbestos product

- Because there are fiber cement roofing products that replaced asbestos-fiber-cement roofing products that were subsequently made when asbestos use stopped, and because those newer roofing products look so much like the older asbestos-containing product, without a marking stamped into the roofing material that gives an age, product number or date, or without a lab test on a material sample, and without an idea of the age of the material, one cannot can't reliably guess at whether the material contains asbestos or not.

- Were is the building located?

- How old is the building?

- Are there any receipts for roofing installation that show the date, age, materials, or roofing supplier?

Those questions can also help answer your question about asbestos roofing.

What to do with this corrugated fiber cement or asbestos cement roof

- Remember that asbestos is not harmful by its presence alone - it's not radioactive.

The potential hazard would be from disturbance and fiber release at high enough levels to form a health risk. In any case the roofing material, even if it contains asbestos, is not an "asbestos roof" - it is a cement roof that may or may not include asbestos in its mix. The "cement" means it's not easily friable - it should not easily crumble in to dust if mashed between your thumb and forefinger. - If the roof is not leaking nor damaged, and provided that the roofing has not become soft or broken-up, you do not need to remove it

- Asbestos cement roofing is more likely to be a possible problem source of asbestos material if the roof is power-washed or mechanically damaged (such as by running a power saw through it) during demolition or replacement.

- Watch out: don't let an inspector or contractor walk on the roof - fiber cement roofing material (asbestos or not) is often fragile enough that it could be broken leading to costly damage.

Planning demolition of corrugated cement asbestos roofing materials?

The risk of high levels of airborne asbestos from cementious roofing products is probably very low unless the workers are using power equipment like sanders and saws on these substances.

[Click to enlarge any image]

According to NRCA, the National Roofing Contractors' Association, their studies up to February 1992 had not found a single roofing job at which these limits were exceeded, and NRCA reported that in some cases no fiber release was detected.

But it appears that the association may have been referring only to asphalt-based roofing materials, not jobs involving the demolition of other ACRM such as cement-asbestos roof shingles (or "asbestos roof tiles" as some consumers refer to them) which might produce different statistics.

See ASBESTOS MATERIAL REGULATIONS

and ASBESTOS REGULATION Update that address the handling of asbestos containing building materials, including ACM (asbestos containing materials), PACM (presumed asbestos containing materials), SACM (suspect asbestos containing materials), and ACRM (asbestos containing roofing materials).

Reader Question: what are the engineering properties of transite roof decking (cement asbestos roofing)?

I need to find the engineering properties of a specific profile of transite roof deck. Please see the attached sketch and picture. I will gladly purchase the correct catalog if you can help me identify which catalog that is. - Anon, 11/18/2014

Reply:

For engineering properties of a contemporary material you'd find easiest results contacting the manufacturer. And Woods (2000) cites Hannant (1978) as a source for the engineering properties of various fiber cement roofing materials.

The original properties of corrugated cement roofing using asbestos, which you referred to as transite roofing, can also be found in some early patent applications, though I have not seen complete engineering analysis of the materials strengths and other properties in those documents.

For the engineering properties of an older asbestos-cement roofing product (which is what I think I see in your first photo above and again at left) that is of course no longer in production one might find an old specification document but in my OPINION that would be dangerously misleading as weathered, worn building materials change in properties such as density and impact resistance.

My experience with direct inspection as well as owner reports of older fiber cement and asbestos cement and corrugated asbestos cement is that the material becomes quite fragile - at that age its properties would be quite different from the original product specifications.

For that situation, if it were actually justified, one would have to send representative samples of the material to a materials testing laboratory - which of course raises its own issues about roof damage and material disturbance.

Reader Follow-Up

I notice in one of the links you provided that the life expectancy of cement asbestos shingles was given as 30 years with some 50 years old roofs in good condition.

- Can you reference any documents that extensively discuss life expectancy, types of failures, etc. for cement asbestos roof deck that has not been exposed to direct sunlight?

- Do you think it will be possible to determine the original manufacturer?

- Can you offer opinions on the structural stability of the existing roofs?

Reply:

The most detailed analysis of the engineering properties of Asbestos-Cement roof decking materials is the by el Hakim cited below. His conclusion begin on p. 280 of the thesis and are illuminating.

But again I emphasize that as with other building materials, after years of service the mechanical properties of asbestos cement are likely to be different than when first produced, more-so if exposed to the weather or to leaks and/or freeze-thaw cycles or to the effects of algae or cyanobacteria and of course if exposed to mechanical damage or stresses.

- El Hakim, Noor El-Din Mohamed, DIAPHRAGHM ACTION of ASBESTOS CEMENT DECKS [PDF] , Thesis in the Faculty of Engineering, Concordia University, Montreal, Quebec, Canada, 1980. Retrieved 11/19/2014, original source: http://spectrum.library.concordia.ca/3009/1/NK49609.pdf

My own direct inspection as well as field anecdotal data show that the when exposed to the weather, more water and temperature variations than sunlight, asbestos cement products used on roofs tend to become soft and quite fragile.

Effects of biological agents, particularly lichens, moss and to a degree, fungi also play a role in this deterioration.

Fiber cement roof life expectancy & evaluation: research & maintenance standards

- Akers, S. A. S. "Cracking in fibre cement products." Construction and Building Materials 24, no. 2 (2010): 202-207.

- Amasco Ltd, Briggs. "The Maintenance and Refurbishment of Commercial Roofing." Property Management 5, no. 3 (1987): 222-228. This same reference is often cited to "Board, Contractors Advisory, and Employers Federation."

- ASTM E2394-11, "Standard Practice for Maintenance, Renovation and Repair of Installed Asbestos Cement Products", available from ASTM, http://www.astm.org/Standards/E2394.htm

- Babic, Branko R. "The use of cement fibre composites in prolonged wet environments." In 10th international inorganic-bonded fiber composites conference, pp. 260-73. 2006.

- Belardi, G., and L. Piga. "Influence of calcium carbonate on the decomposition of asbestos contained in end-of-life products." Thermochimica Acta 573 (2013): 220-228.

- Campopiano, Antonella, Deborah Ramires, Aneta Maria Zakrzewska, Rosa Ferri, Antonio D'annibale, and Giancarlo Pizzutelli. "Risk assessment of the decay of asbestos cement roofs." Annals of occupational hygiene 53, no. 6 (2009): 627-638.

- Chiappino, G., and I. Venerandi. "[The erosion of asbestos cement roofs: an important source of environmental pollution]." La Medicina del lavoro 82, no. 2 (1990): 99-121.

- Dias, C. M. R., M. A. Cincotto, H. Savastano Jr, and V. M. John. "Long-term aging of fiber-cement corrugated sheets–The effect of carbonation, leaching and acid rain." Cement and Concrete Composites 30, no. 4 (2008): 255-265.

- Giller, Richard A., Ronald M. McCoy, Gary R. Wagenblast, and Westinghouse Hanford Site. "Structural assessment of roof decking using visual inspection methods." In Mitigation Conference, p. 571. 1993.

- Hannant, D. J., and S. Magnani. "Designer's Corner: A comparison of severe hailstorm damage on two types of fibre-reinforced cement roofing sheets." Composites 25, no. 3 (1994): 243-245.

- Hansen, Klavs Feilberg, and Birgitte Dela Stang. "Safety against formation of through cracks of profiled fibre-reinforced cement sheets for roofing." Construction and Building Materials 23, no. 1 (2009): 334-339.

- Larsen, Erik Stoklund, and Herbert Krenchel. "Durability of FRC-materials." In MRS Proceedings, vol. 211, p. 119. Cambridge University Press, 1990.

- Murphy, Colin Murphy, and FRCI RRC, BLUE GREEN ALGAE AND ITS EFFECT ON FIBER-CEMENT-CEMENT ROOFING WITHIN A MICROCLIMATE - an investigation of biodeterioration of fiber-cement roofing by cyanobacteria and its implications for the roofing industry in Hawaii [PDF] Interface (2002). - retrieved 11/19/2014, original source https://www.rci-online.org/interface/2002-01-murphy.pdf - retrieved 2022/09/22 new source: https://iibec.org/wp-content/uploads/2016/04/2002-01-murphy.pdf

Murphy found that algal growth (or more precisely cyanobacteria) did not significantly impact the water-shedding properties of the roofs he examined in Oahu bu that

"... the service life of the roofing system has been compromised significantly" [by Scytonema cyanobacterial filaments growing on and into the roof material and the effects of bacteria-fixed organic acid (nitric acid) on the fiber cement]

Note: Also see ALGAE STAINS on ROOFS - Neumann, S. M., K. N. Popov, and A. G. Mezhov. "Investigation of the chrysotile cement roofing sheets properties of various operation term Хризотилцементтен жасалған əр түрлі мерзім қолданылған жамылғы табақтардың қасиеттерін зерттеу." ХАБАРШЫСЫ ВЕСТНИК (2012): 66.

- Oberta, Andrew F. A NEW STANDARD FOR REPAIR AND MAINTENANCE OF INSTALLED ASBESTOS-CEMENT MATERIALS [PDF] - retrieved 11/19/2014, original source: http://www.worldasbestosreport.org/conferences/gac/gac2004/pl_6_06_e.pdf

Andrew F. Oberta, MPH, CIH The Environmental Consultancy www.asbestosguru-oberta.com (512) 266-1368 andyobe@aol.com

Abstract excerpts:

The ASTM Standard Practice for Maintenance, Renovation and Repair of Installed Asbestos Cement Products has been developed by ASTM International1 and assigned the designation E2394. The standard provides the underlying rationale and detailed procedures for working with asbestoscement products – roofing, siding, ducts, pipes and other construction materials – that have already been installed in and between buildings.

It covers operations that can produce dust and airborne asbestos fibers – drilling, cutting, breaking, filing, etc. – during routine maintenance, repairs and small-scale renovation. Control of dust and fiber release using wet methods – soapy water, shaving cream and similar substances – is stressed. Four appendices cover underground pipes, buried ducts, drilling holes and removing panels, and additional appendices will be prepared to cover other operations and materials.

Installation of new asbestos-cement products is not encouraged by the standard.

Large-scale abatement is not the intended purpose, although some of the procedures may apply to such operations.

The procedures are intended for use in developing as well as industrialized countries; therefore, the use of hand tools and easily-obtained equipment and supplies is emphasized. The use of power tools is discouraged to minimize the possibility of creating airborne fiber levels that would require wearing respiratory protection.

E2394 is intended for use by supervisors and managers responsible for construction and maintenance as well as by government agencies and NGOs responsible for worker and community health programs.

The standard offers useful guidance for countries in the process of developing their asbestos laws and regulations. - Spurny, K. R. "Asbestos fibre release by corroded and weathered asbestos-cement products." IARC scientific publications 90 (1988): 367-371.

References: Properties of Corrugated Cement Roofing & Siding Products

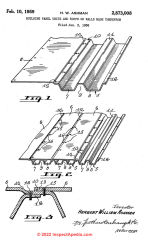

Illustration: Ashman's 1959 patent for producing asbestos-cement roofing and siding panels, cited below.

[Click to enlarge any image]

- See additional corrugated asbestos cement roofing citations atReferences or Citations

- Amasco Ltd, Briggs. "THE MAINTENANCE AND REFURBISHMENT OF COMMERCIAL ROOFING." Property Management 5, no. 3 (1987): 222-228.

- Ashman, Herbert William. BUILDING PANEL UNITS AND ROOFS OR WALLS [PDF] U.S. Patent 2,873,008, issued February 10, 1959.

Excerpt:

This invention relates to improvements in trough or cavity type structures made from corrugated panel units or sheets of asbestos-cement, metal or suitable material, from which a roof, decking or wall can be constructed. - Babic, Branko R. "The use of cement fibre composites in prolonged wet environments." In 10th international inorganic-bonded fiber composites conference, pp. 260-73. 2006.

- Baker, Jenifer M., H. Davies, A. J. Majumdar, and P. J. Nixon, eds. Durability of Building Materials and Components: Proceedings of the Fifth International Conference. Routledge, 2006.

- Berry, James A., and Morton Sherman. STRUCTURE FOR RETROFITTING CORRUGATED BUILDING EXTERIORS [PDF] U.S. Patent 4,494,343, issued January 22, 1985.

Excerpt:

Presently, there are literally thousands of buildings whose roofs are in need of repair. The existing roofs, having seen years of service and weathering, are deteriorating and rusting out, are under-insulated, and are subject to leaks, etc.

These buildings with roll formed metal or corrugated cement asbestos roofs enclose millions of square feet of uninsulated space.

It would be highly desirable if a strong, lightweight, incombustible, simple, easily installed and economical to utilize fixing structure could be found for the application of an insulation layer and cover sheet assembly to these difficult-to-insulate corrugated structures. - Buttiker, Gero, Otto W. Gordon, and Peter E. Meier. METHOD FOR THE PRODUCTION OF A FIBER-REINFORCED HYDRAULICALLY SETTING MATERIAL [PDF] - Not Asbestos - U.S. Patent 4,306,911, issued December 22, 1981.

Abstract

Asbestos-free fiber reinforced hydraulically setting materials, which comprise a slurry of one or more hydraulic binding agents, fibers, water and perhaps additional additives, are obtained when, as fiber, 2 to 20% by volume of filter fibers and 0,5 to 20, preferably 1 to 10% by volume reinforcing fibers are used, both of which are subjected to preliminary treatment which improves their dispersability.

By means of the preliminary treatment the fibers can be uniformly distributed in the slurry.

The material can be worked on apparatus common for the production of asbestos cement and used for the same purposes as asbestos cement. - Harper, Stephen, and David G. Hiscock. "Boards and panels." U.S. Patent 4,637,860, issued January 20, 1987.

- Hannant, D.J.,

Fibre Cements and Fibre Concretes

(New York: John Wiley & Sons, 1978), 146

-

155. This reference give qu

antitative engineering properties for asbestos- cement and other fiber-cements. - Heinemann, Horst D., and Alfred Jost. "Roof construction." U.S. Patent 4,691,482, issued September 8, 1987.

- Johnson, Robert M., and Elmer M. Melling. "Reinforced cement sheet product containing no asbestos for fabricating on hatschek machine." U.S. Patent 4,428,775, issued January 31, 1984.

- Johnson, Robert M., and Elmer M. Melling. "Reinforced cement sheet product containing wollastonite for reduced shrinkage." U.S. Patent 4,377,415, issued March 22, 1983.

- Johnson, Robert M., and Elmer M. Melling. "Reinforced cement sheet product containing fibers other than asbestos, clay and thickener." U.S. Patent 4,363,666, issued December 14, 1982.

Illustration: Marchioli's 1963 patent of a machine for shaping and compressing sheets of asbestos cement into particles of complex configuration: corrugated asbestos cement roofing & siding panels - cited below.

Illustration: Marchioli's 1963 patent of a machine for shaping and compressing sheets of asbestos cement into particles of complex configuration: corrugated asbestos cement roofing & siding panels - cited below.

- Marchioii, Giorgio. APPARATUS FOR SHAPING AND COMPRESSING SHEETS OF ASBESTOS [PDF] U.S. Patent 3,099,061, issued July 30, 1963.

Excerpt:

As is known, some roofing tiles or covering members with somewhat complicated shapes, such as, for example, tiles for roof ridges, are made by hand starting with plastic material consisting of a mixture of cement and asbestos in leaf or sheet form

(which is obtained by caus ing a fluid mixture of asbestos cement and water contained in a tank, to be deposited on and adhere to a rotating drum which dips into said tank), which is made to dry between shaped moulds.

After more or less drying out between the moulds, the sheet assumes the shape of the moulds.

However, pieces obtained by this process, besides being costly on account of the great length of time required for their manufacture, are not satisfactory because of their uneven thickness, consistency and moisture content, some of the tiles being too hard and others too fragile.

By using the apparatus according to the present inven ion, these and other drawbacks may be overcome. - National Trust for Historic Preservation, "Coping with Contamination: A Primer for Preservationists," Information Bulletin No. 70 (1993) - can be found online as an eBook that can be "borrowed" - Ed.

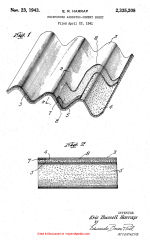

- Russell, Harrap Eric. REINFORCED ASBESTOS CEMENT SHEET [PDF] U.S. Patent 2,335,208, issued November 23, 1943.

Excerpt: Eric Russell Hal-rap, Ohorlton-cum-Hardy, England, assignor to Turners Asbestos Cement Company, Limited, Rochdaie, England, a. company of Great Britain Application April 22, 1941, Serial No. 389,747 In Great Britain May 7, 1940 3 Claims. (Cl. 154-45-9)

This invention is concerned with corrugated sheets made from fibrous materials and binding agents that set rigid from a plastic state, such as asbestos and cement. Asbestos-cement corrugated sheets are largely used as roofing materials.

Asbestos-cement possesses excellent qualities for this purpose, as it is resistant to weather and corrosion and light in weight.

However, it is relatively brittle and has not as much resistance to impact as is desirable.

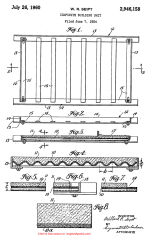

For this reason various proposals have been made to reinforce the sheets with metal inlays or to increase the depth of the corrugations, but none has led to wholly satisfjactory results. - Seipt, Willard R. COMPOSITE BUILDING UNIT [PDF] U.S. Patent 2,946,158, issued July 26, 1960.

Excerpts:

l't s a primary object of the invention to provide a building element, useful for roofing, siding and the like, which has the structural strength necessary for such purposes, and also provides effective thermal insulation.

My novel composite building unit comprises two ele ments, each of which is similar to a known type of single building unit. Thus, the strength member may take the form of a sheet of asbestos fiber bonded with Portland cement, which, in the preferred embodiment of the in vention, may be corrugated. Sheets of this general kind are known and have been used for many years as roofing, siding and the like.

The insulating member of my building unit comprises cast hydrous calcium silicate, preferably reinforced with asbestos fibers. This material, as it known, is an ex tremely effective insulator and can be produced in masses of very low density having excellent insulating properties.

[Shown below]

- Simon, Hans. "THE ROOF OF A BUILDING." U.S. Patent 3,660,955, issued 1972.

- Woods, Amy Lamb, KEEPING A LID ON IT: ASBESTOS CEMENT BUILDING MATERIALS [PDF], U.S. National Parks Service, (2000), www.cr.nps.gov/hps/tps/recentpast/asbestosarticle.htm

Excerpt: With the advent of asbestos-cement corrugated sheets, the enclosure of factory buildings, warehouses, and train sheds was simple, economical, and effective for either permanent or portable structures.17

Corrugated asbestos-cement sheets were applied in the same way that corrugated iron was applied, either nailed to wooden strips, bolted to the purlins, or clipped directly to the purlins by clips of hoop-iron or wire. They were available in standard sheets, twenty-seven and a half inches wide and in lengths of four, five, six, seven, eight, and ten feet.

Two primary shapes were Trafford (with peaks), and Fibrotile (with waves).

A series of special hardware devices was designed for use with corrugated sheets so that buildings could be completely encased in the material. - "Roof and roofing sheets for use therein." U.S. Patent 2,417,899, issued March 25, 1947.

Other Research Citations on Asbestos Cement Roofing

- Dias, W. "Useful life of Buildings." University of Moratuwa, Moratuwa, June. http://www. slaasmb. org/ USEFUL LIFE OF BUILDINGS. doc. Accessed 23, no. 03 (2003): 2012.

- Dong, Jin Mei, Hong Fa Yu, and Qian Qian Liu. "The Study on Accelerated Life Mechanism of Glass Fiber Reinforced Magnesium Oxychloride Cement." Advanced Materials Research 306 (2011): 1118-1121.

- Dyczek, Jerzy. "Surface of asbestos-cement (AC) roof sheets and assessment of the risk of asbestos release." In conference presentation Krakow, Poland, September 28e29. 2006.

- Education Administration. Roofing farm buildings. No. 2170-2175. Dept. of Agriculture, Science and Education Administration: for sale by the Supt. of Docs., US Govt. Print. Off., 1978.

- Gehrke, H. "[Precautionary measures for asbestos-cement corrugated roofs]." Zentralblatt fur Arbeitsmedizin und Arbeitsschutz 22, no. 8 (1972): 227-228.

- Gilbert, O. L. "Further studies on the effect of sulphur dioxide on lichens and bryophytes." New phytologist 69, no. 2 (1970): 605-627. - describing effects of Sulphur dioxide on lichens and bryophytes that in turn affect the life of asbestos roofing and siding.

- Hannant, D. J. "Fibre reinforcement in the cement and concrete industry." Materials science and technology 11, no. 9 (1995): 853-862.

- Milani, A. P., F. A. Souza, J. E. P. Turco, and E. A. Almeida. "Thermal behavior of materials used in coverage of roofs of husbandry buildings." In Structures and Environmental Technologies. International Conference of Agricultural Engineering-CIGR-AgEng 2012: agriculture and engineering for a healthier life, Valencia, Spain, 8-12 July 2012., pp. P-0420. CIGR-EurAgEng, 2012.

- Poole, Anthony L. "Roof slates and tiles–the cheaper alternative to the “real thing”." Structural Survey 10, no. 2 (1992): 123-126.

- Sebastien, P., J. Bignon, and M. Martin. "Indoor airborne asbestos pollution: from the ceiling and the floor." Science 216, no. 4553 (1982): 1410-1412.

- Spurny, K., H. Marfels, C. Boose, G. Weiss, H. Opiela, and F. J. Wulbeck. "[Fiber emissions from weathered asbestos cement products. 1. Fiber release in ambient air]." Zentralblatt fur Hygiene und Umweltmedizin= International journal of hygiene and environmental medicine 188, no. 1-2 (1989): 127-143.

Abstract:

Emissions of fibrous aerosols were measured on buildings with weathered and corroded asbestos-cement-plates (roofing and facade shingles) by means of an already published equipment and procedure.

The measured emission factors for asbestos fibers longer than 5 microns were in the range of 10(6) to 10(8) fibers/m2.h. They depended on the type of the AC-plates as well as on their age and corrosion intensity. - Subramanian, V., and N. Madhavan. "Asbestos problem in India." Lung cancer 49 (2005): S9-S12.

- Viani, Alberto, Alessandro F. Gualtieri, Michele Secco, Luca Peruzzo, Gilberto Artioli, and Giuseppe Cruciani. "Crystal chemistry of cement-asbestos." American Mineralogist 98, no. 7 (2013): 1095-1105.

- Woods, Amy Lamb. "Keeping a lid on it: asbestos-cement building materials." Preserving the recent past 2 (2000).

Sources of Replacements for Corrugated Asbestos Cement Roofing

(Photo above: author points to new fiber cement roofing product.)

Contemporary roofing product manufacturers make reinforced fiber-cement roofing shingles and other roofing products which look like, perform similarly to, and need to be installed similarly to the original corrugated asbestos-cement sheet roofing - but these new products are free of asbestos.

As we explained in our discussion of cement asbestos shingles, the replacements for corrugated asbestos cement roofing products are reinforced with a variety of fibers including fiberglass.

Other replacements for asbestos-cement roofing use both different fibers and a different aggregate (perlite) to replace the asbestos. Some of the substitute products have been in use for more than 30 years (2008).

Sources of modern fiber cement corrugated roofing (non-asbestos):

- For maintenance or replacement of asbestos-cement roofing products contact Supradur Manufacturing Corporation, PO Box 908, Rye NY 10580 800-223-1948, or from within New York State, call 914-967-8230. Ask about their Supradur(R) mineral fiber shingles.

- See DURALITA ROOFING ALTERNATIVES for an example of cardboard-reinforced cement roofing products that include corrugated roofing panels.

- See CORRUGATED ROOFING where we list other corrugated roofing products that do not contain asbestos.

- See also our complete list

at FIBER CEMENT PRODUCT MANUFACTURERS

For handling and disposal guidance concerning old roofing material contact the US EPA, your state Department of Environmental Protection/Conservation, or your local building and health departments.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-11-10 by (mod) - asbestos cement & fibre-cement roofing identification stamps in the U.K.

Matt

Matt

I agree that you'd treat old fibre cement products like corrugated siding as presumed to contain asbestos.

That's an interesting marking in your photo - it might be a production date as it looks to me like a series of numbers including ?? 11 0 81

[Click to enlarge any image]

That "81", if it means "1981", is significant because in the U.K. (If that's where your building is located) manufacturers did not begin using non-asbestos fibre cement products before about 1984.

In the U.K. some corrugated fibre cement manufacturers encoded their identity as well as production date in a product stamping like the one you show, but I think your photo does not show all of the markings or embossed lettering that should have been present if not already weathered away.

Later, by the early 1990s, rather than emobssing the fibre cement with raised or depressed letters and numbers, the under-side of some fibre-cement roofing in the UK was marked in ink with the manufacturer's identification code and lot number.

On 2020-11-10 by Matt Keniston

Hi, I've inherited a shed on an allotment, it's timer framed with a tin roof, sides are partially clad in corrugated cement fibre, I'm guessing 30 yrs old so likely to contain asbestos. Probably won't touch them as the shed s water tight, just wondered if the markings in the photos mean anything?

Thanks,

Matt

On 2018-11-25 by (mod) - CCMNTA X 160306I or F stamped on roofing?

Andy I see why you ask.

Searching for CCMNTA leaves us drowned in information about the Canadian Council of Motor Transport Administrators (CCMTA) .

I don't know the product in your photo and am doing some more research.

It would help to know what we're looking at.

Is this fiber cement corrugated roofing?

In what country and city?

What is the building age?

Do we know the roof age?

Meanwhile, knowing nothing else about your material I would err on the side of caution and treat it as PACM - presumed asbestos containing material (or have a sample tested).

The CMNT "A" could suggest that it's a cementious product with "A" - asbestos. But in truth we don't know.

Certainly many manufacturers of asbestos-cement and fiber cement roofing and siding stamped their products or embossed them with a date code, production lot number, and manufacturer's identification code or number.

On 2018-11-25 by Andy

Do you have any idea if this is asbestos or cement many thanks, as far as I can tell it says

CCMNTA X 160306I or F

IMAGE LOST by older version of Clark Van Oyen’s Comments Box code - now fixed. Please re-post the image if you can. Sorry. Mod.

...

Continue reading at ASBESTOS ROOFING / SIDING DUST or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see CORRUGATED CEMENT ASBESTOS ROOFING FAQs - questions & answers about corrugated sheet asbestos cement roofing & siding posted originally at this page.

Or see these

Asbestos-Cement Roofing Articles

- ASBESTOS & FIBER CEMENT ROOFING - home

- ASBESTOS CEMENT OSHA REGULATIONS

- ASBESTOS CEMENT ROOF & SIDING HISTORY

- ASBESTOS CEMENT ROOF REPAIR

- ASBESTOS CEMENT SHINGLE REMOVAL

- ASBESTOS DISPOSAL REGULATIONS

- ASBESTOS LEFT in PLACE in BUILDINGS - MANAGEMENT GUIDES

- ASBESTOS MATERIAL REGULATIONS

- ASBESTOS ROOFING, CORRUGATED

- ASBESTOS ROOFING / SIDING DUST

- ASBESTOS ROOFING / SIDING POWER WASHING

- ASBESTOS ROOFING WEAR SIGNS

- ASBESTOS TESTING LAB LIST

- CORRUGATED CEMENT ASBESTOS ROOFING

- OSHA REGULATIONS, ASBESTOS ROOFING, SIDING

Suggested citation for this web page

CORRUGATED CEMENT ASBESTOS ROOFING at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or See

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Arnon Bentur and Sidney Mindess, Fibre Reinforced Cementitious Composites (London: Elsevier Applied Science, 1990), 288 -304. Woods (2000) reports "This text reviewed long -term performances of asbestos -cement and concluded that “in natural weathering the composite is excellent.” More detailed quantitative material properties are also given in this text."

- D.J. Hannant, Fibre Cements and Fibre Concretes (New York: John Wiley & Sons, 1978), 146 - 155. This reference give qu antitative engineering properties for asbestos - cement and other fiber - cements.

- D.V. Rosato, Asbestos: Its Industrial Applications (New York: Reinhold Publishing Corp., 1959), 1, 62.

- "The Industrial Uses of Asbestos," Scientific American (22 April 1876), 258 - 259.

- John E. Wilden, A Guide to the Art of Asbestos Cement (Winchester, England: Taylor & Part ners Translations, 1986)

- L. Michaels and S.S. Chissick, eds., Asbestos, Properties, Applications, and Hazards (New York: Wiley, 1979), 1 - 2. Resource for various kinds of asbestos, their properties and chemical constituencies.

- United States Department of the Interior Bureau of Mines, Mater ials Survey: Asbestos , (Washington D.C.: US Government Printing Office 1952), I - 1 - I - 4

- Caleb Hornbostel, Construction Materials: Types, Uses and Applications (New York: John Wiley & Sons, 1978), 82.

- H. W. Johns, Patent Trademark Materials: Asbestos ( New York: H. W. Johns Manufacturing Co., 1878), 12.

- D.A. St John, A.B. Poole, and I. Sims, Concrete Petrography: A Handbook of Investigative Techniques (London: Arnold Publishers, 1998), 320 - 322.

- "Asbestos - Cement Products for War Buildings," Asbestos (April 1942), 2 - 4

- Ernest G. Blake, Roof Coverings: Their Manufacture and Application (New York: D. Van Nostrand Company, 1925), 144 - 171. Resource for detailed descriptions of many asbestos - cement roof shingle forms, styles, and hardware.

- James McCawley, Asphalt and Asbestos - Cement Shingle Residing (New York: United Roofing ContractorsAssociation, 194 0).

- E. Lechner, “Recent Innovations in the Manufacture of Asbestos - cement,” Cement and Cement Manufacture , 7:6 (June 1934), 180 - 181.

- Asbestos Shingle, Slate and Sheathing Company, Asbestos Corrugated Sheathing (Ambler, Pennsylvania: The Keasbey & Mattison Company, 1913), 1.

- “Johns - Manville” product advertisement, Sweet’s Catalogue of Building Construction (F. W. Dodge Corporation, 1906 - 1961)

- Asbestos Shingle, Slate and Sheathing Company, Asbestos Corrugated Sheathing (Ambler, Pennsylvania: The Keasbey & Mattison Company, 1913), 1.

- Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.