History of Asbestos Use in Building Products

History of Asbestos Use in Building Products

Early and modern history of asbestos use

- POST a QUESTION or COMMENT about the history of asbestos use in building products

Early and modern history of asbestos use in building products.

This article provides a chronological look at the history, both early and modern, of asbestos use in building products.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

History and Patents for Asbestos Cement Shingles & Siding Products

Research and a patent search on asbestos cement shingles and siding give insights into the early and modern history and development of asbestos use in building products.

An excellent history of the use of asbestos was provided by Rosato whose complete text we provide a link to below on this page.

Article Contents

- EARLY HISTORY of ASBESTOS CEMENT SIDING & ROOF SHINGLES - PRODUCTION

- CHRONOLOGY & USE of ASBESTOS in BUILDING PRODUCTS

...

Early History & Age of Asbestos-Cement Siding & Roof Shingles: Production & Use

The Rosato text cited below and our research article and patent search on asbestos cement shingles and siding give insight into the history of and development of cement-asbestos shingles, siding, and cement board used on and in buildings.

Cementious siding and roofing such as fiber-cement siding, lap siding, and fiber cement roof shingles containing asbestos may then have appeared on homes constructed between 1906 and 1980 in North America and continuing later in some other countries.

At CEMENT ASBESTOS PRODUCT MANUFACTURE we provide a more detailed history of the development and use of asbestos in building and other products.

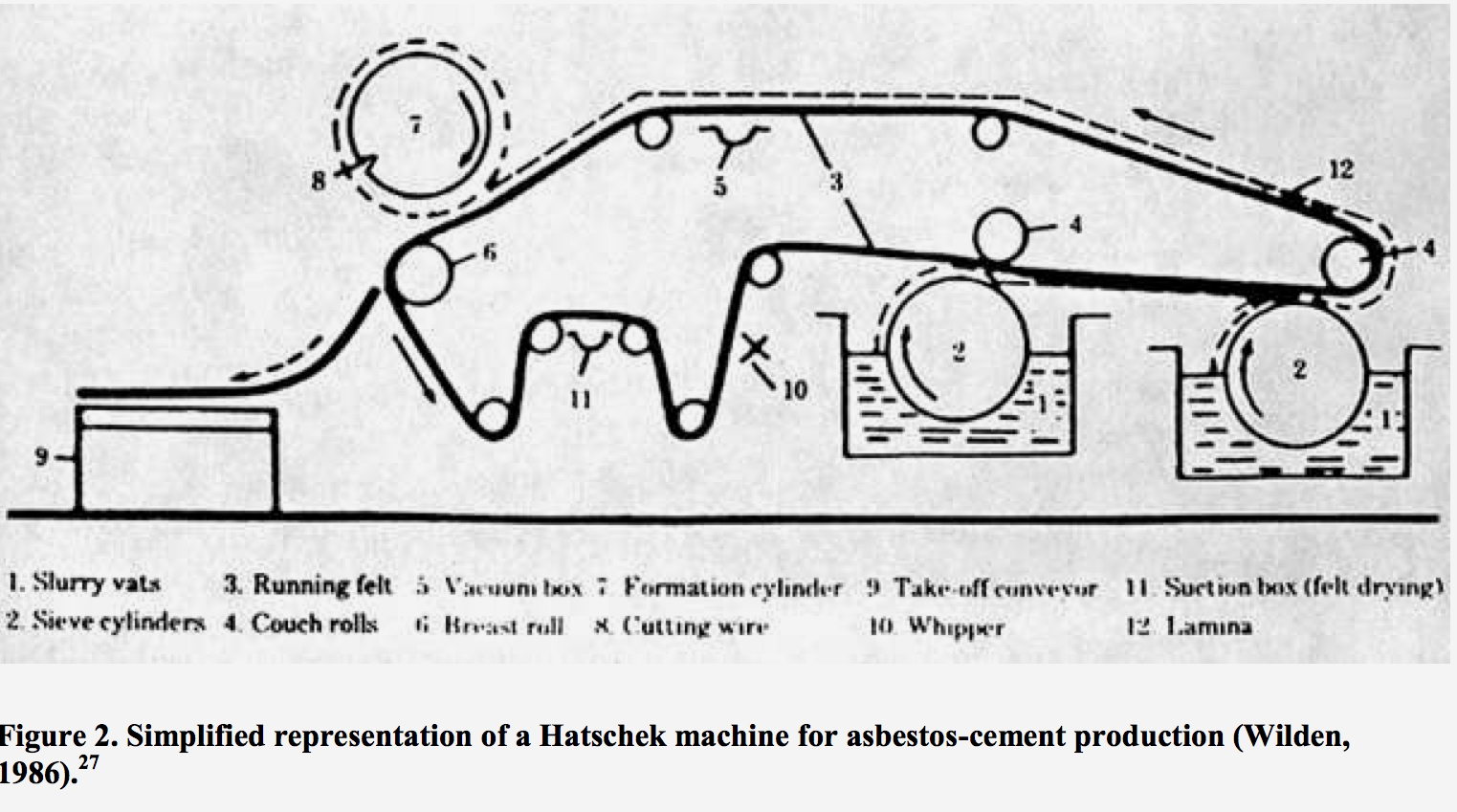

There we describe the Hatschek Machine for Production of Asbestos Sheet Goods.

Excerpt:

It was not until 1907 that the invention by an Austrian engineer, Ludwid Hatschek, made possible the manufacture of pre -formed asbestos-cement products.

The Hatschek machine, a wet transfer roller, was used to produce the initial asbestos-cement sheets, while two other manufacturing processes included the Mazza process for pipes, and the Magnani semi-dry process for corrugated sheets. - Woods (2000)

We learn further from patent citations that asbestos-cement products were in use in the U.S. before 1910, as inventions often cite improvements to existing designs and that an explosion of patents and products making use of asbestos-cement ensued between 1907 and 1940.

The improved fire-resistance of cement asbestos roofing led to its recommendation in the U.S. by the National Board of Fire Underwriters in 1920. (National Board of Fire Underwriters 1920).

A similar looking product, composite siding made of asphalt-impregnated fiberboard was also used for lap siding and wall shingles but is not an asbestos-cement product.

See SIDING TYPES, INSTALLATION, DEFECTS for a guide to siding products of various types.

...

History of Uses of Asbestos in Modern Products

When was asbestos used in modern products?

When was asbestos used in modern products?

Chronology of Inventions in the Use of Asbestos & Asbestos Cement in Building Materials

The following citations giving a history of the use of asbestos-cement in building products are arranged chronologically, rather than alphabetically - Ed.

- An excellent history of the use of Asbestos was provided by Rosato whose complete text we provide online beginning

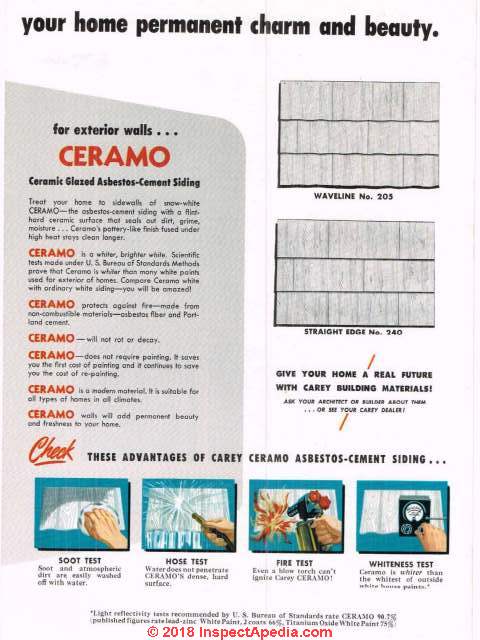

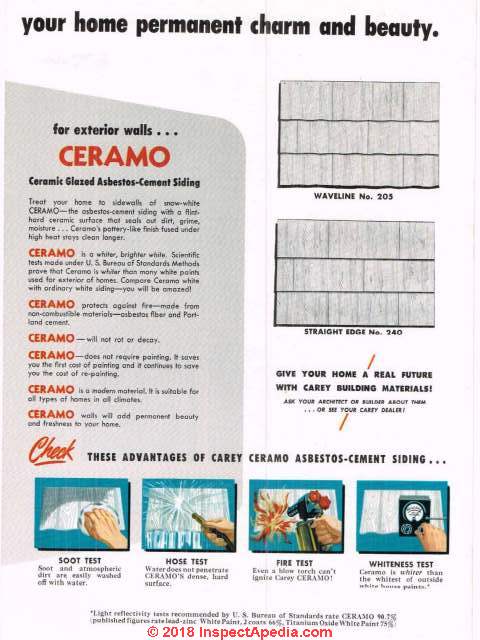

at ASBESTOS ORIGIN & NATURE - CERAMO CERAMIC-GLAZED ASBESTOS-CEMENT SIDING [PDF] - illustrated just above.

- "The Industrial Uses of Asbestos," Scientific American (22 April 1876), 258-259.

Back issues of Scientific American magazine are available from http://www.scientificamerican.com/store/archive/?magazineFilterID=Scientific%20American%20Magazine - H. W. Johns, Patent Trademark Materials: Asbestos (New York: H. W. Johns Manufacturing Co., 1878) filed by H W JOHNS Manufacturing Co. [Predecessor to Johns Manville corp. ? - Ed.]

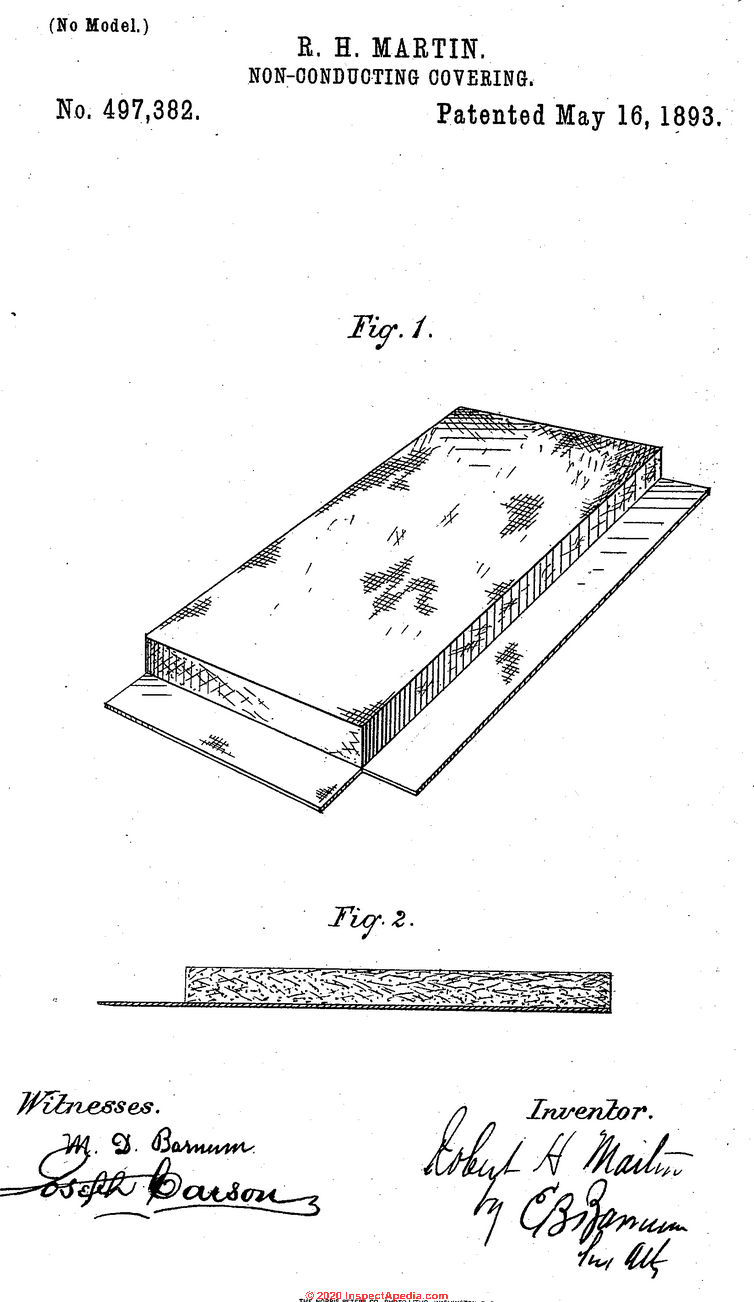

- Martin, R.H., Non-Conducting Covering [PDF] US Patent No. 497,382. Patented May 16, 1893.

Excerpt:

My improved non-conducting material is made in the form of a sheet of asbestos fiber in loose or flocky state ...shall be peculiarly soft, flexible, elastic and porous, being in the nature of a soft bat or wad, and the fibers are held together by an adhesive material which extends here and there, throughout the entire thickness of the bat,

so that it is held together by the adhesion of the fibers to each other at innumerable points through much adhesive material as to interfere with the softness, flexibility, elasticity and porosity of the sheet or bat and owing to the method employed by me for introducing the adhesive or cementitious material,

I am enabled to get a lighter product, possessing the qualities before referred to, than any heretofore known to me.

I also avoid an objectionable feature in other similar products, that is to say, they are liable to split, because my sheet or bat is made in one thickness and the fibers extend without scams or layers, from one side to the other side of the bat.

To make my improved product I feed the fiberized and cleansed asbestos fiber to a picker by which it is thoroughly disintegrated and thrown onto a traveling apron in such quantities as may be desired to make the sheet or bat of the requisite thickness.

The fiber is deposited upon the apron in an even manner.

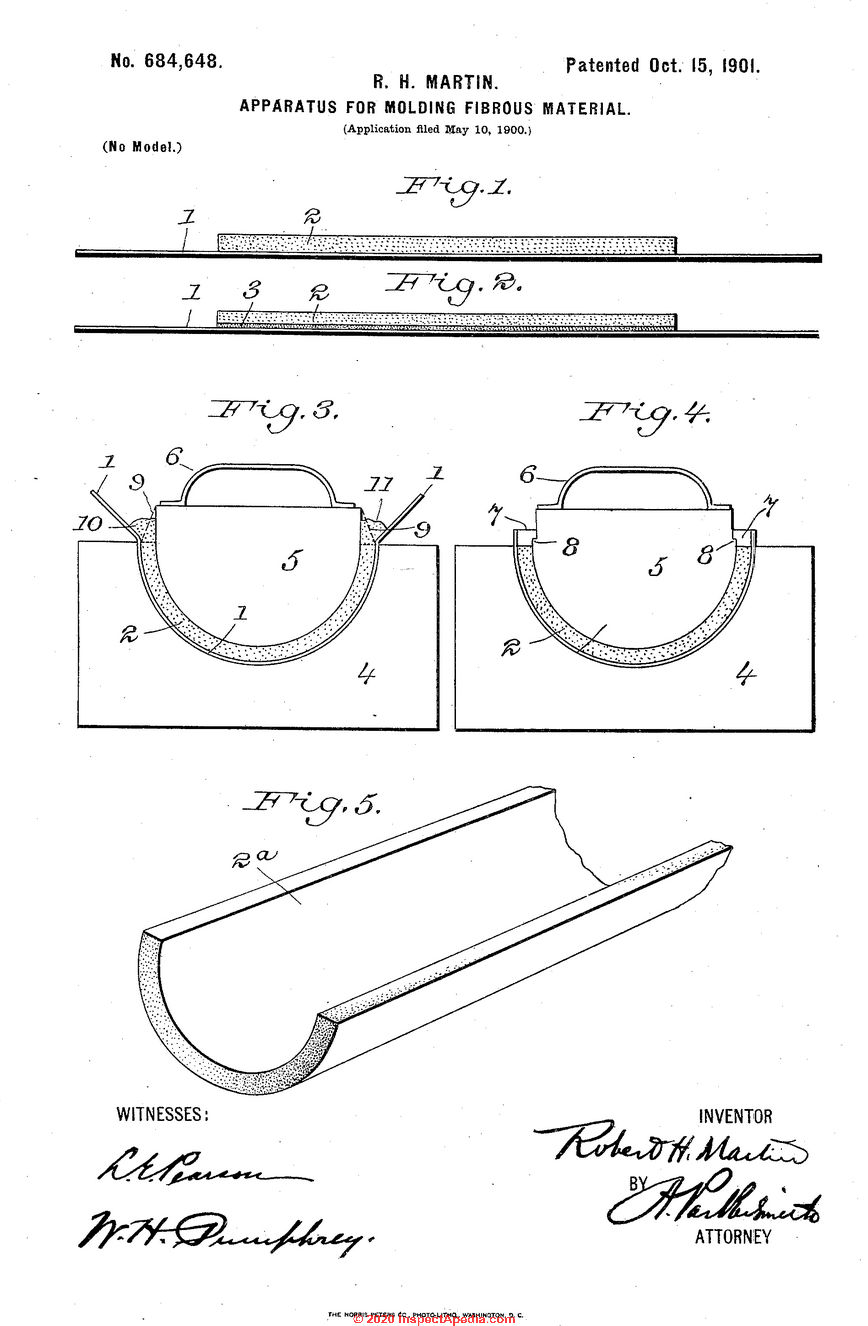

Shown below: Martin's 1901 patent, assigned to H.W. Johns Manufacturing Co.

- Martin, Robert H. Apparatus for molding fibrous material [PDF] U.S. Patent 684,648, issued October 15, 1901 Assignee

H.W. Johns Manufacturing Co.

Excerpt:

My invention in general relates to an apparatus for forming layers of fibrous material into various curved shapes. More specific ally, it consists of an improved apparatus for forming curved sections designed to serve as a non-heat-conducting covering for steampipes, 850.

In the manufacture of such pipecovering I preferably employ a material known in the trade as fire-felt, which consists, ordinarily, of a layer or hat of asbestos fibers having intermingled therewith a sufficient quantity of some agglutinating compound, such as silicate of soda, for the purpose of causing the said fibers to adhere one to the other and form a self-sustaining mass.

This product may be substantially that described and set out in Letters Patent of the United States No. 497,382, issued to me on the 16th day of May, 1893. - Jacobs, Frank Davis. "Roofing and siding material." U.S. Patent RE12,475, issued April 24, 1906.

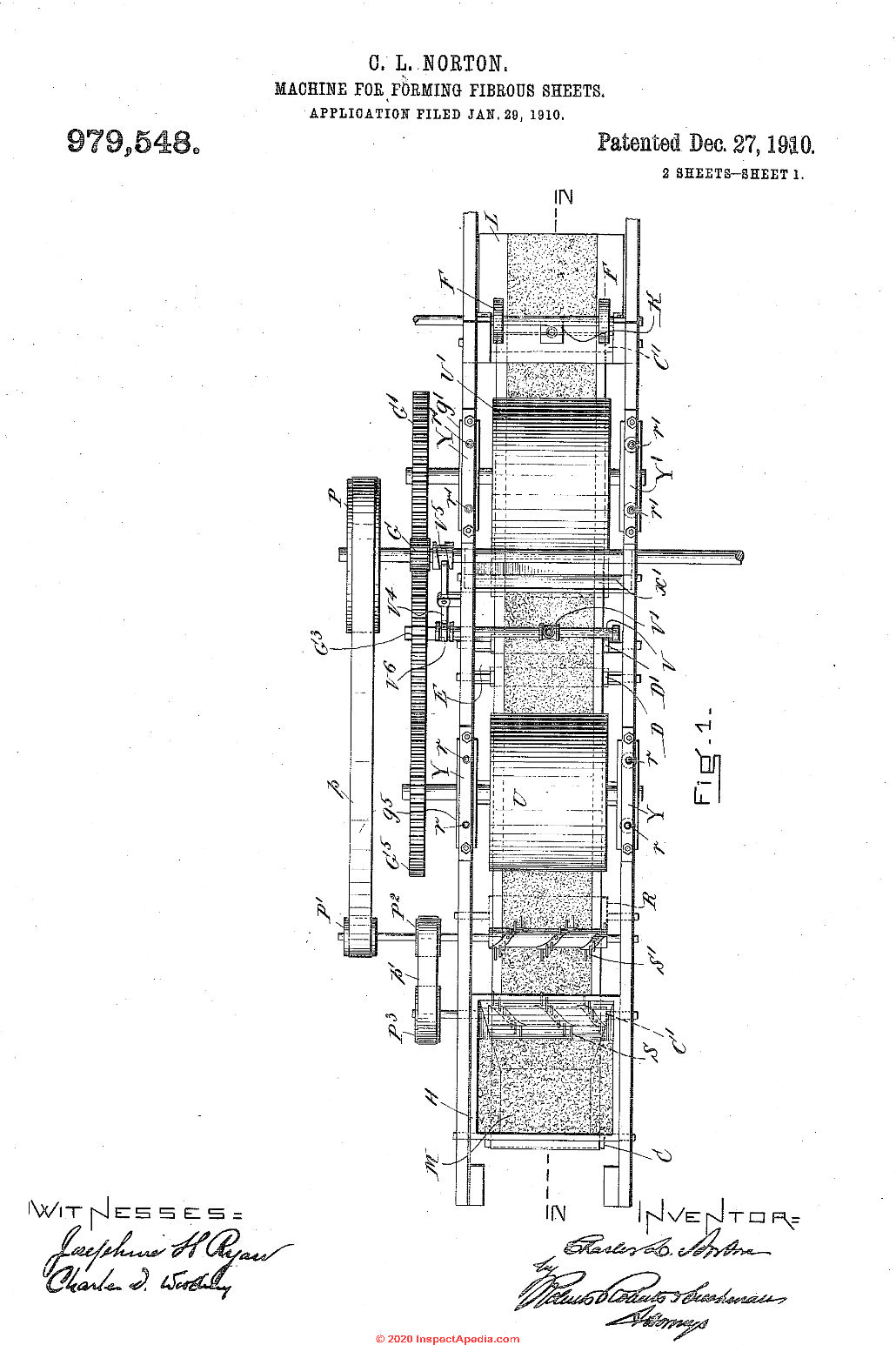

Shown here: Norton's patent for forming continuous fiber-cement or asbestos cement sheets.

- Norton, Charles Ladd. Process for forming fibrous sheets [PDF] U.S. Patent 979,547, issued December 27, 1910.

Excerpt:

Be it known that 1, CHARLES LADD NORTON, a citizen of the United States, and resident of Hudson, in the county of Hillsboro and State of New Hampshire, have invented 'newand useful Improvements ,in Processes for Forming Fibrous Sheets, of which the following is a specification.

This invention relates to the manufacture of sheets, slabs,and similar articles, of cement and fiber, or fiber-concrete, and consists in a new process of manufacture whereby such articles may bemade rapidly, continuously and economically.

Slabs or sheets of fiber and cement have been made singly in fiber presses, and with success, using heavy pressure upon wet mush or pulp composed of fiber. and cementitious material, but though the improvements in compounding and handling such material by the press-process have reduced the cost and increased the output, the advantages of a continuous process have not, so far as I am informed, been attained.

My invention relates particularly to the manufacture of fire-proof sheets or slabs for structural and analogous purposes, in which asbestos fibers, or the similar fibers obtained by grinding serpentine rock and a hydraulic cement, constitute the ingredients of the fiber-concrete, and the following specifications will be addressed to the manufacture of asbestos fiber and hydraulic cement sheets or slabs.

Such cement-asbestos concrete nec essarily requires the presence of water to set the cement, and also requires considerable pressure to compact the mass before the hydration, or setting, of the cement is completed.

Attempts to produce compressedsheets by feeding a wet mass of concretepulp through rollers or other progressive pressure devices have been embarrassed by the persistence with which the wet pulp sticks to the pressure devices and to other objects which come in contact with wet uncompressed pulp.

My improved process which obviates the difllculties encountered in handling wet uncompressed pulp, is characterized by a preliminary continuous or progressive dry pressing of a properly compounded mixture of fiber and cement: the dry pressing comi pacts the mixture and gives it consistency and integrity which, when setting liquid is afterward added, is effective to prevent the concrete mass from sticking to objects with which it makes contact, so that a final wet continuous or progressive pressing is easily applied to give the finished product the necessary density and strength for mechanical and structural uses, and a progressive or continuous manufacture of'concreted sheets is made practical and possible. - Newsome, Edgar Thomas. "Protected metal sheet." U.S. Patent 1,002,301, issued September 5, 1911.

- Stewart, Perez M. "Composite building structure." U.S. Patent 1,068,541, issued July 29, 1913.

- Asbestos Shingle, Slate and Sheathing Company, Asbestos Corrugated Sheathing, Ambler, Pennsylvania: The Keasbey & Mattison Company, 1913

- Heppes, George P. "Shingle." U.S. Patent 1,159,766, issued November 9, 1915.

Excerpt:

In both views the same reference characters are employed to indicate similar parts. While my invention may be used in connection with shingles and tiling generally it is especially adapted for composition shingles, such as those made of asbestos and the like and a more or less flexible asphalt shingle of which felt forms the base. - Wardell, Henry R. "Cement shingle." U.S. Patent 1,244,148, issued October 23, 1917.

Excerpt:

Be it known that I, HENRY R. WARDELL, a citizen of the United States of America, residing at New York city, borough of Man- 5 hattan, county and State of New York, have invented certain new and useful Improvements in Cement Shingles, of which the following is a specification.

My invention relates to the production of 10 cement shingles, or to shingles formed of hydraulic cement and asbestos known as asbestos shingles, and is particularly designed to produce a shingle, or similar slab, which shall have a surface variegated in color, or of a dominant color different from that of the cement or other materials of which the body of the slab is formed, and which color shall be permanent and not removable by the action of Water

. In certain aspects my invention constitutes an improvement on the fibrous sheets set out in U. S. Letters Patent to Charles L. Norton, numbered 979,547 and 97 9,548, granted'December 27, 1910.

The asbestos shingles or other articles made by the Norton process, or by any other process known to me, are extremely difficult to color-permanently. Furthermore the color produced by known methods is usually a flat even shade, devoid of relief or variegation.

If architects or owners object to the natural light s gray color of such shingles it has been customary to treat them after manufacture with various coloring solutions, but when in use the rain gradually washes out the coloring matter entirely or so as to produce an unsightly streaked appearance.

Many ex periments have been made in the attempt to produce a coloringmaterial which will per 40 manently resist the effects of weather and the action of sunlight when applied to or incorporatechin these asbestos shingles, but so far without-entirely satisfactory results as far as'I know. - MacMillan, A. "Asbestos-Cement Roofing." Industrial & Engineering Chemistry 9, no. 10 (1917): 983-983.

Excerpt: ... After being finely ground and freed from extraneous matter the asbestos, which acts as a reinforcing agent, is mixed with Portland cement in the ...

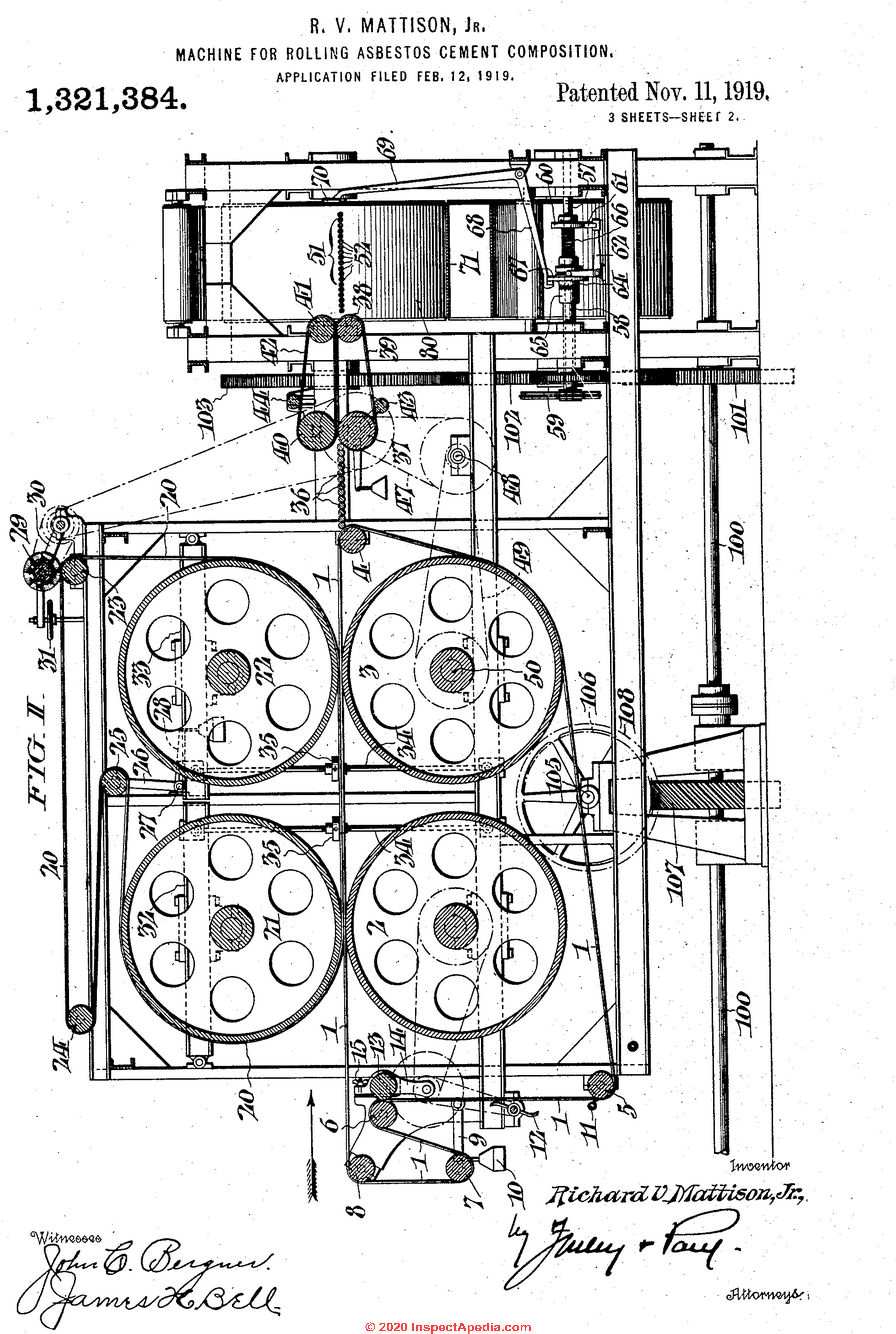

- Mattison, Richard V., Machine for Rolling Asbestos Cement Composition [PDF] US Patent 1321384 issued November 11, 1919

Excerpt: I, Richard V. Mattison, Jr., a citizen of the United States, residing in Upper Dublin township, in the county of Montgomery and State of Pennsylvania, have invented a certain new and useful Machine for Rolling Asbestos-Cement Composition, of which the following is a specification, reference being had to the accompanying drawings.

My invention relates to rolling mechanism to be employed for drying and com pressing fiat sections of cement composition such as asbestos cement, in the shape of tiles or shingles. Such asbestos cement composition is usually mixed wetjand in this condition may be-worked in a pug or auger mill by the employment of a proper nozzle and die.

The plastic mixture is extruded from the auger mill in the shape of a fiat endless ribbon from which suitably sized sections are successively cut off as bya wire cutter.

In order to obtain proper results, it is neces sary that these flat asbestos cement sections be rolled under sufiicient pressure to remove the surplus moisture which they contain and to properly compress the material before they are allowed to set, and to accomplish this compression properly, it is important. that the sections be rolled first in one direction and then izra direction at right angles thereto.

- The National Board of Fire Underwriters, Dwelling Houses (New York: The National Board of

Fire Underwriters, 1920), 2nd ed. pp 36-37.

Also see National Board of Fire Underwriters: Dwelling houses : a code of suggestions for construction and fire protection recommended by the National Board of Fire Underwriters, New York, to safeguard homes and lives against the ravages of fire.

([New York : National Board of Fire Underwriters], 1920) (page images at HathiTrust) This book can be viewed in PDF form from a copy obtained from the University of Minnesota

Excerpt from p. 36-37:

Whenever possible use a fire-resistive roof covering. The safety which it offers is well worth the additional expense. There is a variety of approved roofings on the market which will afford satisfactory protection and service; a number of them are but little more expensive than first class wooden shingles.

The first cost of a roofing material must be averaged with the years of service it will render in order to ascertain the real expense of maintaining the construction. The life of the best fire-resistive roofings is considerably longer than that of the wooden shingle, and this fact should be considered in selecting.

Among the recommended roofings are tile, tin, slate, asbestos shingles, and other composition shingles and prepared roofings which have been tested and approved for fire-resistance and durability. - Norton, Charles L. "Process for controlling the setting of cement products." U.S. Patent 1,379,204, issued May 24, 1921.

- Burkhardt, Curt R., Scharwath John A., "Asbestos shingle." U.S. Patent 1,404,483, issued January 24, 1922.

Excerpt:

The shingle or artificial slate of this invention comprises a slab of asbestos cement, tapered in thickness from one end to the ot er as indicated at1 5 and provided in the .back thereof, at the lower thicker end, with recesses 01'' depressions 6, said recesses being separated and defined by an intervening rib or ribs 7,

These recesses are shown as extending longitudinally throughout greater portion of the thickened section of the shingle and as tapering in depth from, the lower to the upper end thereof to accord with the reduced thickness of the shingle and so produce a substantially even thickness of wall and distribution of weight throughout theshingle.

The intervening rib or ribs 7 strengthen and support the reduced or thinned portion of the shingle, reinforcing and preventing breakage of the same.

In the first form disclosed, there are only two depressions 6, but in Figure 4 we have illustrated three such -de ressions, with two in tervening ribs 7 and it will be apparent that this number may be increased, if desired. - Overbury, Frederick C. "Roof and roof covering." U.S. Patent 1,447,567, issued March 6, 1923.

- Brossler, Franz. "Asbestos slate material and process for manufacturing it." U.S. Patent 1,541,106, issued June 9, 1925.

- Blake, Ernest G., Roof Coverings: Their Manufacture and Application, New York: D. Van Nostrand Company, 1925.

- Buczkowski, Edward J. "Apparatus for forming shingles." U.S. Patent 2,010,425, issued August 6, 1935. assigned to Keasbey & Mattison Company

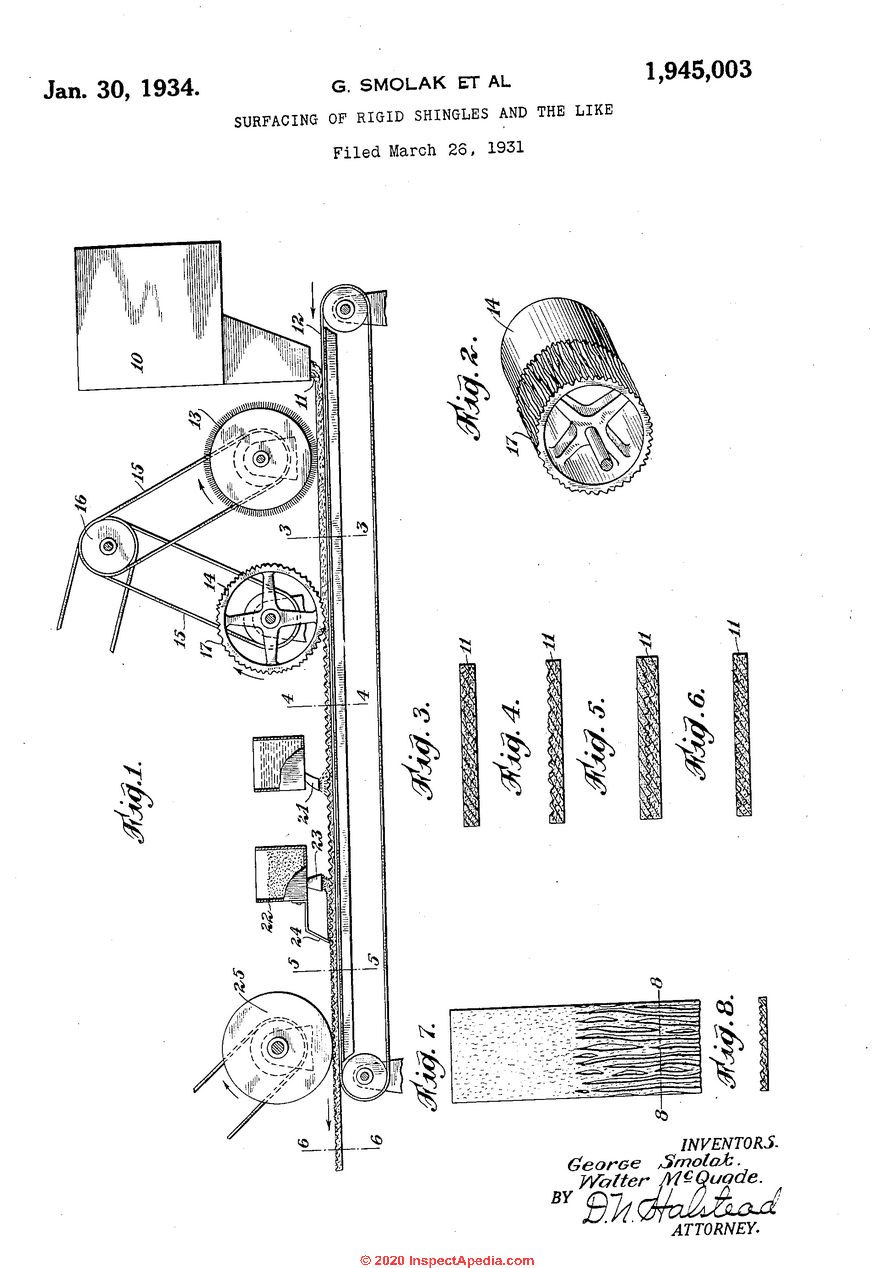

Shown here: Smolak's 1934 patent for surfacing asbestos cement shingles with an embossed pattern.

- George, Smolak, and Mcquade Walter. Surfacing of rigid shingles and the like [PDF] U.S. Patent 1,945,003, issued January 30, 1934. assigned to Johns Manville

Excerpt:

The present invention relates to a method of surfacing materials which are plastic or readily deformable in one stage of their manufacture.

The invention is primarily concerned with the provision of ornamental contours in the surface of such materials while in the readily deformable state by impressing suitable depressions and prominences in the surface portion, and preserving these contours against substantial deformation during subsequent operations such as hardening and densifying of the material by the application of pressure, by filling the depressions with a readily removable filler material.

Rigid shingles prepared from a mixture of Portland cement and asbestos fibers in presses, or by machines of a type similar to that described in Norton U. S. Patent 979,548, dated 12/27/10 are illustrative of the products and materials to which our invention has been successfully applied, and the invention is specifically described hereafter with reference to such products. - Lechner, E. “Recent Innovations in the Manufacture of Asbestos-cement,” Cement and Cement Manufacture, (June 1934).

- Brown, George B. "Apparatus for making an asbestos product." U.S. Patent 2,230,880, issued February 4, 1941. assigned to Johns Manville

- James McCawley, Asphalt and Asbestos-Cement Shingle Residing, New York: United Roofing Contractors Association, (1940).

- Asbestos-Cement Products for War Buildings," Asbestos (April 1942)

- De, Vault Aylett F. "Method of making asbestos cement shingles." U.S. Patent 2,307,733, issued January 12, 1943.

- Wayne, Rembert Ernest. "Manufacture of fiber-cement sheets." U.S. Patent 2,401,663, issued June 4, 1946. Assigned to Johns Manville

- Otis, Harold J., and Hesse Jack. "Manufacture of cementitious sheets." U.S. Patent 2,446,782, issued August 10, 1948.

- Nelson, William L. "Apparatus for texturing asbestoscement sheets." U.S. Patent 2,529,175, issued November 7, 1950.

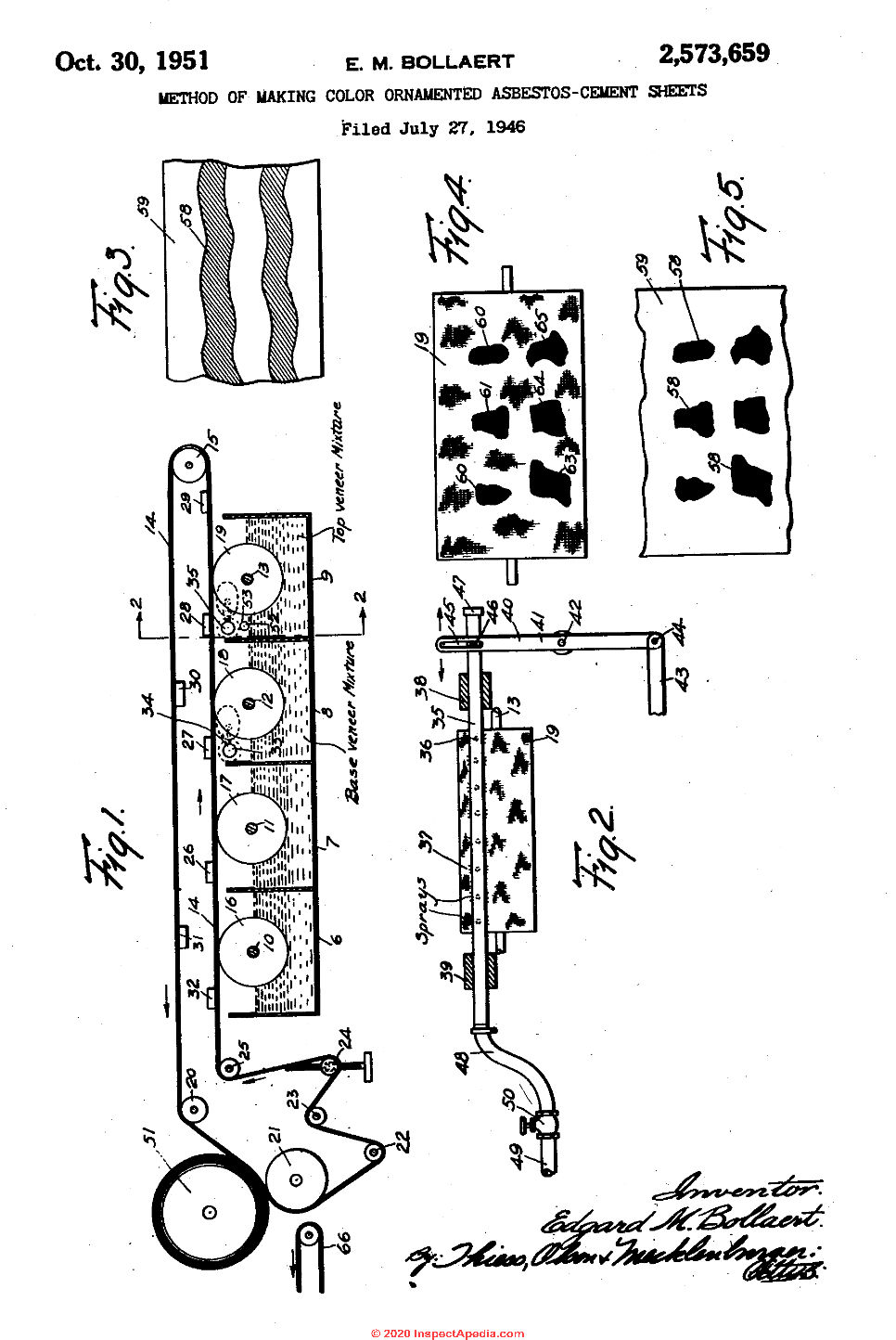

Above: Bollaert's 1951 patent illustrated a decorative pattern embossed into asbestos cement siding sheets, shingles, boards.

- Bollaert, Edgard M. Method of making color ornamented asbestos-cement sheets [PDF] U..S. Patent 2,573,659, issued October 30, 1951.

Excerpt: A demand has therefore sprung up for more or less ornamental asbestos-cement siding and shingles which present a more pleasing appearance, with a smooth surface to which dirt will not adhere; They also present a variegated appearance occasioned by a difference in the color of the various areas of the product. - Greider, Harold W., and Marion F. Smith. Asbestos sheet material and method of manufacture [PDF] U.S. Patent 2,567,558, issued September 11, 1951. Filed by Philip Carey Manufacturing Co.,

Excerpt:

This invention relates to asbestos products and relates especially to products which comprise fibrous material containing asbestiform mineral fibers disposed in intimately contacting relation as by felting or other operation adapted to form a sheet or sheet-like body.

The asbestos products which find most extensive commercial use are asbestos sheet materials that are usually produced by water laying and that are generally referred to as asbestos paper or asbestos millboard, which is referred to herein generally as paper.

The bulk of the asbestiform mineral fiber that is used in asbestos paper usually runs from about to A in length, although the fiber that is supplied for paper making generally contains a considerable quantity of shorter fibers of varying lengths and may contain a portion of longer fibers.

The most generally accepted system of classification of asbestos fibers is that of the Quebec Asbestos Producers Association.

The asbestos fibers which are most commonly used for the manufacture of asbestos paper are those which range from Group 5 or paper classification to the Group '7 or shorts classification'of the Quebec Asbestos Producers Association, or mixtures thereof. - United States Department of the Interior Bureau of Mines, Materials Survey: Asbestos, (Washington D.C.: US Government Printing Office 1952).

- Buczkowski, Edward J., Stanley J. Ostrowski, and Harvey R. Anderson. "Method and apparatus for making decorated asbestos-cement sheet material." U.S. Patent 2,738,713, issued March 20, 1956.

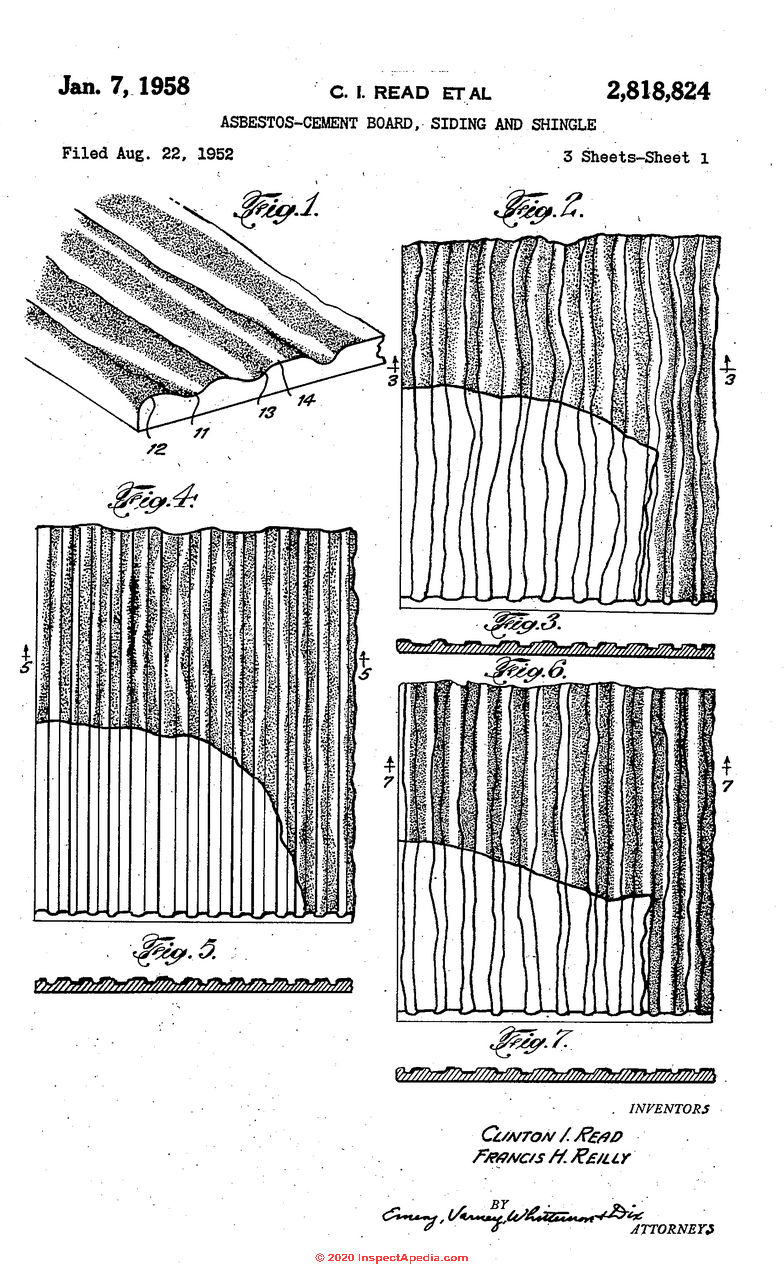

Above: Read's 1958 patent for asbestos cement siding that is prepared with a colored and embossed or patterned surface resembling wood shingles or wood board siding.

- Read, Clinton I., and Francis H. Reilly. Asbestos-cement board, siding and shingle. [PDF] U.S. Patent 2,818,824, issued January 7, 1958.

Note: This patent, describing rolled asbestos-cement board or shingle siding, illustrates the characteristic and popular "wood grain" like embossed finished surface on these products.

Excerpt: Clinton I. Read, Trumbull, and Francis H. Reilly, Stratford, Conn., assignors to Tilo Roofing Company, Inc., Stratford, Conn., a corporation of Delaware Application August 22, 1952, Serial N o. 305,754 7 Claims. (Cl. 10S-)... ing or siding or shingle that has the: great advantage of showing its contrasting colors irrespective of whether it is viewed from directly in front, i. e., 90 to its front surface, or at an angle to -that surface, say or other angle to the front surface.

This advantage alone is very important as.it is highly desirable to have a fireproof and waterproof cementitious type of siding or shingle represent a wooden type of siding or shingle no matter from what angle lthe siding or shingle is viewed.

For instance, when an observer approaches and moves past a building that is wooden shingle clad, he appreciates from any angle that the building is shingle clad, and that the appearance of the siding is pleasing.

Heretofore, when an observer approached and moved past a building that was clad with the `contrasting color type of cementitious covering or siding or shingle previously made, he could only appreciate the varied color effect when he was substantially directly in front of the building, i. e., when standing at approximately 90 to the full front surface of the building or shingle.

- Hamme, Richard B., and Robert M. Johnson. "Method for making integrally colored asbestos-cement products." U.S. Patent 3,491,174, issued January 20, 1970.

- Hannant, D.J., Fibre Cements and Fibre Concretes, New York: John Wiley & Sons, (1978).

- Gazzard, Warwick H., and Roger M. Kearin. "Embossed patterning of asbestos-cement and like sheets." U.S. Patent 4,072,460, issued February 7, 1978.

- Gazzard, Warwick H., and Roger M. Kearin. "Embossed patterning of asbestos-cement and like sheets." U.S. Patent 4,216,043, issued August 5, 1980.

- Wilden, John E., A Guide to the Art of Asbestos Cement , Winchester, England: Taylor & Partners Translations, (1986).

- Bentur, Arnon & Sidney Mindess, Fibre Reinforced Cementitious Composites, London: Elsevier Applied Science, 1990.

- Woods, Amy Lamb, "Keeping a Lid On It: Asbestos Cement Building Materials" [PDF], U.S. National Parks Service, (2000), www.cr.nps.gov/hps/tps/recentpast/asbestosarticle.htm

- Ward, Michael. Fire officer: Principles and practice. Jones & Bartlett Learning, 2005.

- Burdett, G., Investigation of the chrysotile fibres in an asbestos cement sample [PDF] (2006), U.K. HSE, HSL/2007/11 retrieved 2018/08/28,original source: http://www.hse.gov.uk/research/hsl_pdf/2007/hsl0711.pdf

- IAFC, "Live Fire Training: Principles and Practice", International Society of Fire Service Instructors, Barnes & Noble, Jones & Bartlett Learning, (2014) (2016 in e-book edition),

ISBN-13:9781284041231

Description:

All fire fighters need the safe and controlled “real life” training offered through live fire exercises in order to be fully prepared for the hazards of the fireground. Live Fire Training: Principles and Practice Revised First Edition provides a definitive guide on how to ensure safe and realistic live fire training for both students and instructors.

Updated to address all the requirements for NFPA 1403, Standard on Live Fire Training Evolutions, 2012 Edition... - Wilson, Richa, Kathleen Snodgrass, "Early 20th-Century Building Materials:

Siding and Roofing" [PDF], U.S. Department of Agriculture Forest Service, Technology & Development Program (February 2008) #0873-3208-MTDC, USDA Forest Service, Missoula Technology and

Development Center

5785 Hwy. 10 West

Missoula, MT 59808–9361

Phone: 406–329–3978

Fax: 406–329–3719

E-mail: wo_mtdc_pubs@fs.fed.us retrieved 2016/09/08, original source: http://www.fs.fed.us/t-d/pubs/pdfpubs/pdf08732308/pdf08732308dpi72.pdf

Excerpt:

In the early 1900s, manufacturers reinforced Portland cement with asbestos fibers to create a fire-resistant and durable building material. The product, first made in 1905, served as a coating for boilers, steam pipes, and equipment that generated heat.

Asbestos-cement coatings also were used to patch roofs and seal areas where pipes or other items penetrated the roof. The production of asbestos-cement sheets became possible in 1907 when Austrian Ludwig Hatschek brought his patented process to the United States.

Forming and curing processes were improved and it was not long before shingles and corrugated panels for roofs and walls were manufactured. A wide range of asbestos-cement products, such as pipes, faux ceramic tiles, and decorative moldings, became available.

Successful manufacturers included Eternit, Johns-Manville, and the Asbestos Shingle Slate and Sheathing Co. The National Board of Fire Underwriters, with its initiative to eliminate the fire hazards of wood shingles, was instrumental in the public’s acceptance of asbestos-cement roofing.

By the 1920s, large asbestos-cement roof shingles were available in a natural gray color, as well as red and blue-black colors that resembled tile and slate. Pigments, either added to the wet mixtures or rolled into surfaces, faded when they were exposed to the elements. - ASBESTOS (CHRYSOTILE, AMOSITE, CROCIDOLITE, TREMOLITE, ACTINOLITE AND ANTHOPHYLLITE) [PDF] , U.S. NCBI, National Center for Biotechnology Information, NIH, National Institutes of Health, U.S. Website: https://www.ncbi.nlm.nih.gov/,

Excerpt:

Asbestos is the generic commercial designation for a group of naturally occurring mineral silicate fibres of the serpentine and amphibole series.

These include the serpentine mineral chrysotile (also known as ‘white asbestos’), and the five amphibole minerals – actinolite, amosite (also known as ‘brown asbestos’), anthophyllite, crocidolite (also known as ‘blue asbestos’), and tremolite (IARC, 1973; USGS, 2001).

The conclusions reached in this Monograph about asbestos and its carcinogenic risks apply to these six types of fibres wherever they are found, and that includes talc containing asbestiform fibres.

Erionite (fibrous aluminosilicate) is evaluated in a separate Monograph in this volume. [see the book link below]

in Arsenic, Metals, Fibres and Dusts [PDF book] , retrieved 2018/08/28, original source: https://www.ncbi.nlm.nih.gov/books/NBK304374/

...

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: when was asbestos cement siding first used?

In what year did they start to use asbestos in cement siding ?

This question was posted originally

at ASBESTOS DISPOSAL REGULATIONS - 2016/09/08 Gary

Reply:

Gary, a reasonable guess for the start of widespread use of asbestos cement siding in the U.S. would be 1920, but patent disclosures and other research make clear that such products were in development and use one or two decades earlier.

The earliest use of asbestos in modern building products that I found was discussed in a Scientific American article published in 1876 and cited below. Asbestos researchers note that human interest in the properties and uses of asbestos is more than 2000 years old.

...

Continue reading at ASBESTOS CEMENT SIDING - home or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ASBESTOS CEMENT PRODUCTS

- ASBESTOS CEMENT SIDING - home

- ASBESTOS & FIBER CEMENT ROOFING - home

- SIDING ASPHALT SHINGLE or SHEET - some asphalt shingle products contain asbestos too

- SIDING, FIBER CEMENT - newer non-asbestos cement-based siding

Suggested citation for this web page

HISTORY of ASBESTOS USE in BUILDING PRODUCTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Asbestos products and their history and use in various building materials such as asphalt and vinyl flooring includes discussion which draws on Asbestos, Its Industrial Applications, D.V. Rosato, engineering consultant, Newton, MA, Reinhold Publishing, 1959 Library of Congress Catalog Card No.: 59-12535 (out of print).

- "Copy on file as - /exterior/Asbestos_Cement_Shingles_NPS.pdf - Keeping a Lid on it - Asbestos Cement Building Materials - ", Amy Lamb Woods, Technical Preservation Services, National Park Service, 2000. Web search 07/08/2010 original source: http://www.nps.gov/history/hps/tps/recent past/asbestosarticle.htm

Asbestos-cement products were developed in an era of ingenuity for creating easy to install and economic building materials. Although asbestos-cement has acquired a poor reputation by association of its title, it has not gained that reputation through a lack of durability or utility. In order to preserve this twentieth-century material, understanding what makes, or does not make, asbestos a hazard is truly important. In this case, no hazard is created when asbestos-cement building materials are sound and left in place, or when treatments incorporate non-abrasive means.- END NOTES to the above article provide excellent historical references for asbestos cement products:

1D.V. Rosato, Asbestos: Its Industrial Applications (New York: Reinhold Publishing Corp., 1959), 1, 62. This text is an excellent resource for information on the manufacture and production of asbestos products.

2 L. Michaels and S.S. Chissick, eds., Asbestos, Properties, Applications, and Hazards (New York: Wiley, 1979), 1-2. Resource for various kinds of asbestos, their properties and chemical constituencies.

3 Arnon Bentur and Sidney Mindess, Fibre Reinforced Cementitious Composites (London: Elsevier Applied Science, 1990), 288-304. This text reviewed long-term performances of asbestos-cement and concluded that “in natural weathering the composite is excellent.” More detailed quantitative material properties are also given in this text.

4 L. Michaels and S.S. Chissick, eds., 306-312

5 United States Department of the Interior Bureau of Mines, Materials Survey: Asbestos, (Washington D.C.: US Government Printing Office 1952), I-1 - I-4.

6 Caleb Hornbostel, Construction Materials: Types, Uses and Applications (New York: John Wiley & Sons, 1978), 82.

7 H. W. Johns, Patent Trademark Materials: Asbestos (New York: H. W. Johns Manufacturing Co., 1878), 12.

8Rosato,63.

9 D.A. St John, A.B. Poole, and I. Sims, Concrete Petrography: A Handbook of Investigative Techniques (London: Arnold Publishers, 1998), 320-322.

10"Asbestos-Cement Products for War buildings," Asbestos (April 1942), 2-4

11 Rosato, 75.

12 The National Board of Fire Underwriters, Dwelling Houses (New York: The National Board of Fire Underwriters, 1920), 36-37.

13 Ernest G. Blake, Roof Coverings: Their Manufacture and Application (New York: D. Van Nostrand Company, 1925), 144-171. Resource for detailed descriptions of many asbestos-cement roof shingle forms, styles, and hardware.

14 James McCawley, Asphalt and Asbestos-Cement Shingle Residing (New York: United Roofing Contractors Association, 1940).

15 E. Lechner, “Recent Innovations in the Manufacture of Asbestos-cement,” Cement and Cement Manufacture, 7:6 (June 1934), 180-181.

16 R.C. Smith, Materials of Construction, Third Edition (New York: McGraw-Hill Book Company, 1979), 358-359

17 Asbestos Shingle, Slate and Sheathing Company, Asbestos Corrugated Sheathing (Ambler, Pennsylvania: The Keasbey & Mattison Company, 1913), 1.

18 “Johns-Manville” product advertisement, Sweet’s Catalogue of Building Construction (F. W. Dodge Corporation, 1906-1961), 8b/4.

19 Rosato, 63.

20 National Trust for Historic Preservation, "Coping with Contamination: A Primer for Preservationists," Information Bulletin No. 70 (1993), 12.

21 Bentur and Mindness, 304.

22 Guidance given here only makes recommendations based on national agency laws and regulations; all applicable federal, state, and local laws and regulations must be followed for any asbestos-containing material project.

23 Roger C. Whitman, More First Aid for the Ailing House (New York: McGraw-Hill Book Company, 1977), 282.

24 Martin E. Weaver, Conserving buildings, Guide to Techniques and Materials (New York: John Wiley & Sons, Inc., 1993), 26.

25 D.J. Hannant, Fibre Cements and Fibre Concretes (New York: John Wiley & Sons, 1978), 146-155. This reference give quantitative engineering properties for asbestos-cement and other fiber-cements..

26 "The Industrial Uses of Asbestos," Scientific American (22 April 1876), 258-259.

27 John E. Wilden, A Guide to the Art of Asbestos Cement (Winchester, England: Taylor & Partners Translations, 1986), 108. This resource is primarily concerned with the experience or art of producing asbestos-cement and reflects the practical side of production.

- END NOTES to the above article provide excellent historical references for asbestos cement products:

- ASBESTOS IN YOUR HOME U.S. EPA, Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- Asbestos products and their history and use in various building materials such as asphalt and vinyl flooring includes discussion which draws on ASBESTOS, ITS INDUSTRIAL APPLICATIONS, ROSATO 1959, D.V. Rosato, engineering consultant, Newton, MA, Reinhold Publishing, 1959 Library of Congress Catalog Card No.: 59-12535 (out of print, text and images available at InspectAPedia.com).

- "Handling Asbestos-Containing roofing material - an update", Carl Good, NRCA Associate Executive Director, Professional Roofing, February 1992, p. 38-43

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.