Motor Start Capacitor Selection FAQs

Motor Start Capacitor Selection FAQs

How to specify motor start/run capacitors

- POST a QUESTION or COMMENT about installing a hard-start capacitor to get an air conditioner motor, fan motor, or other electric motor running.

Electric motor start-run capacitor selection guide Questions & Answers:

This article series explains how to choose & buy an electric motor start capacitor, hard start capacitor, or run capacitor that is properly rated for and matches the requirements of the electric motor such as an AC compressor motor or fan motor where the capacitor is to be installed.

This electric motor capacitor article series explains the selection, installation, testing, & use of electric motor starter start and run capacitors used on various electric motors found in or at buildings such as air conditioner compressors, fan motors, some well pumps and some heating equipment.

These electric motors use a capacitor to start and run the motor efficiently. We explain the choice & wiring procedures for a hard start capacitor designed to get a hard-starting air conditioner compressor motor, fan motor, refrigerator, or freezer compressor or other electric motor (such as a well pump) going.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

FAQs About How to Find, Choose, a Motor Starting Capacitor

Recently-asked questions & answers about how to select the proper start or run motor capacitor posted originally

Recently-asked questions & answers about how to select the proper start or run motor capacitor posted originally

at CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS - be sure to review that article.

Article Contents

- BUYING a CAPACITOR FAQs - supply sources

- CAPACITOR FAILURE INDICATIONS FAQs - signs of a bad capacitor: burns, bulges etc

- CAPACITOR LABELING FAQs - how to read the information on the capacitor

- CAPACITOR SIZE (MFD) RATING FAQs

- CAPACITOR VOLTAGE RATING FAQs

- CAPACITOR WIRING FAQs

- DOES MY MOTOR USE A START / RUN CAPACITOR? FAQs

- DUAL (START & RUN) CAPACITOR FAQs

- HVAC CAPACITOR DIAGNOSTIC FAQs - separate page

- RUN CAPACITOR SIZE FAQs

- SINGLE PHASE vs 3-PHASE MOTOR CAPACITOR FAQs

- STARTING CAPACITOR SIZE FAQs

- OTHER MOTOR CAPACITOR FAQs

...

Capacitor Wiring FAQs

Why is there no + and - marking on a motor capacitor?

I've got a 250uF /125v start capacitor on an ice machine that doesn't have a +/- % on it, does it have to test as 250uF? Motor is over amping and the cap tests at 266uF - On 2023-03-15 by Jason -

by InspectApedia Publisher - there is no plus or minus terminal and no polarity on a capacitor

@Jason,

See

MOTOR CAPACITOR WIRING GUIDE

You will see that there is no plus or minus terminal and no polarity

Can I Hook up Multiple Capacitors to Get my Motor Running?

I want to leave an old capacitor in place but add another one to help my motor start. Is this possible?

Explanation of how to calculate the value of capacitors wired in series or parallel - example

When two capacitors are connected in series to achieve a desired total capacitance you can calculate the total capacitance by adding the reciprocals of the rated capacitance of each and then inverting or taking the reciprocal of the result.

1/µF total = (1/µF-capacitor #1) + (1/µF-capacitor# 2)

You'll need to use simple algebra to complete this calculation by finding a common denominator for the two fractions on the right of the equation.

Let's wire a 7µF and a 10µF capacitor in parallel (or in series):

1/µF total = (1/7) + (1/10)

To find a common denominator multiply the numerator and denominator of each fraction by the other fraction's denominator:

1/7 can be re-written as 10/70 (multiply both numerator and denominator by 10)

1/10 can be re-written as 7/70 (multiply both numerator and denominator by 7)

Remember that if you multiply both the numerator and the denominator of any fraction by the same number, the overall value of the fraction is un-changed. 1/7 = 10/70 in value since we can simply 10/70 by dividing back by 10 to get 1/7.

1/µF total = 10/70 + 7/70

1/1/µF total total = 17/70

Now invert that fraction

70 / 17 = 4.11 µF total

How do I figure out which are the START and which the RUN termianls or wires on a capacitor?

I am fixing up a air compressor that has a 5 hp 60 cycle 220 volt single stage motor.

The capacitors were removed some years back but the owner did not keep them or replace them. Tried a set of 220 capacitors and the motor started but blew out the capacitor. Question.

How do I determine run capacitor wires from start capacitor wires. (I have 4 black wires with female spade terminals coming out of the motor)

How do I figure out what size start and run capacitors I need.?

Motor capacitor box has spaces for 4 capacitors. so I assume there was a jumper between each two.

I cant find the run capacitor information on the motor plate. I think it is a Baldor. On 2017-12-13 by Bruce Cunha

by (mod) -

A dual capacitor will have three terminals

- COMMON - marked by a C or unmarked entirely

- START - marked by an S

- RUN - marked by an R

Then when you are ready to buy a new capacitor, take a look at the voltage and current that the motor uses. Then take a look at

CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS

...

Capacitor Voltage Rating FAQs

Capacitor Voltage Rating Selection Limits

The voltage rating of a capacitor indicates the highest nominal voltage at which it is designed to operate.

Use of a capacitor at voltages below its rating will do no harm.

Run capacitors must not be subject to voltages exceeding 10 percent of the nominal rating, and start capacitors must not be subjected to voltages exceeding 30 percent of the nominal rating.

The voltage to which a capacitor is subjected is not line voltage, but is a much higher potential (often called back electromotive force or back EMF) which is generated in the start winding.

On a typical 230 volt motor, the generated voltage may be as high as 400 volts and is determined by the start winding characteristics, the compressor speed, and the applied voltage.

PARALLEL AND SERIES CAPACITORS Capacitors, either start or run, can be connected in series or parallel to provide the desired characteristics if the voltage and MFD are properly selected.

When two capacitors having the same MFD rating are connected in series, the resulting total capacitance will be one half the rated capacitance of a single capacitor. - Copeland Electrical Handbook

How do I match the voltage rating of motors to capacitor size during selection?

I need to replace a start cap on a pressure cleaner

It currently has a 165 volt 324/389 mfd capacitor

Or supply is 230 volt

Can I replace it with a 330 volt cap

Another cap is 330 volt 124/149mfd . Can I replace that with a 280 volt cap On 2017-06-12 by dayalan

Reply by (mod) voltage rating of electric motor starting capacitors should be rated at about 1.5 x the line voltage supplied to the motor.

Dayalan

The voltage rating of electric motor starting capacitors should be rated at about 1.5 x the line voltage supplied to the motor.

To me that suggests that your 330V cap is the right voltage.

Electric motor starting capacitors are typically 125, 165, 250 or 330 VAC and are in the 25 µF to 1,400 µF range in microfarads.

Watch out: I've read (not experienced personally) that a too-large capacitor can cause excessive start-up torque that can actually damage equipment.

The opposite problem: if a starting capacitor is too small then it won't be able to get the motor spinning: the motor may hum but not start. (Risking overheating and damage).

Electric motor "run" capacitors are typically in the 2 µF 80 µF range of capacitance and their voltage is usually 370 Vac or 440 Vac.

Keep in mind that many modern motors, especially smaller ones, use a combined Start/Run capacitor in one physical device with multiple connecting wires.

The voltage and MFD range of the run capacitor should be as close to factory spec as you can find. Typical capacitor tolerance is +/ 6% of the factory spec.

Now review the mfd specifications. The mfg of the capacitor should be close to the original - it is ok if it is off just a bit, say 5%.

What happens if we install a mis-matched capacitor:

1. them motor may not start and may be damaged

2. the motor may start with excessive torque and be damaged

3. the motor may run too slowly

4. the motor may overheat and be damaged

5. the motor may be noisy or may damage the equipment it operates

6. If the capacitor voltage rating is too small it will have a short life

Smart would be to check the data tag right on the motor as that should give the proper capacitor specifications.

The voltage rating of the capacitor should ALWAYS be equal to or greater than the motor's voltage.

Or find the manufacturer's tech support number and check with them.

Here's a nice capacitor explanation article that's geared to the non-engineer:

- Anthony Colone, Understanding and Using Capacitors", Industrial Equipment News, 19 May 2015 - we can provide a cc if you don't find it easily.

How do I know what Capacitor Voltage Rating I need?

Voltage Rating vs MFD Rating on Capacitors

The motor for my Delta 34-450 Unisaw is a model 83-611. It is 115/230v, 1.5HP. I am switching it from the current wiring of 115v to 230v. I noticed that a large capacitor on the side of the motor is a "SAFE-T-MIKE" Motor Starting Capacity, model 4488-500. It shows that it is 110/115 VAC.

Do I need to also switch this to a 230v capacitor in order to run this motor at 230v, or is this irrelevant for 230v operation? It's also worth noting the capacitor is 460-552 MFD. On 2023-01-14 by Jordan

Reply by InspectApedia Publisher - Most capacitors include the allowed voltage range in the device labeling

@Jordan,

Most capacitors also include the allowed voltage range in the device labeling. If yours doesn't, I'd swap it for one that is rated for 230V or higher.

Grainger sells a "Universal Motor Start Capacitor" (manufactured by Global) rated at 23-302 Mfd and 330VAC - you can use a cap like that on a lower-voltage motor as well. I have to say the price is a bit stunning - I'd suggest you stop by your local electrical supplier.

by Jordan:

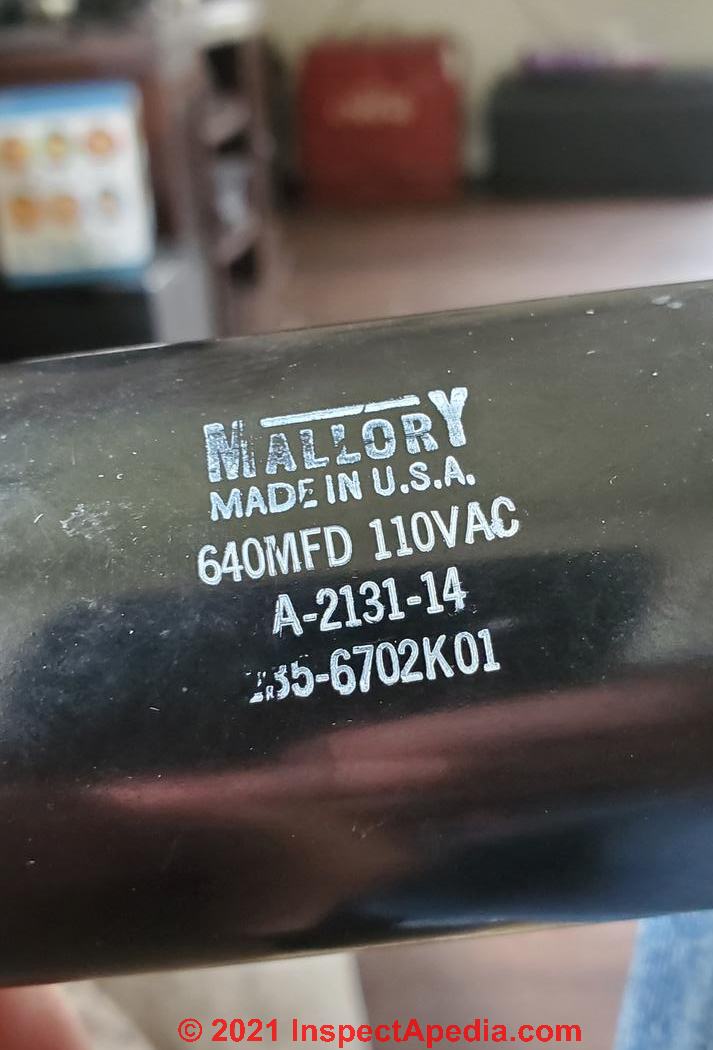

@InspectApedia Publisher, Hey there - thanks for the fast help! I've attached a picture of the capacitor I have on the motor, for others to see as well.

When looking for a motor start capacitor that would work, I would obviously want the same size (1 & 13/16 dia x 3 & 3/8" length), but how exactly do I know what MFD rating I need?If it's 460-552 MFD for 110/115V, what is the equivalent in 230v? On 2023-01-14 by Jordan

by InspectApedia Publisher

@ Jordan,

I think the MFD requirement may not change. That's the "amount of energy stored to get the motor moving".Most capacitors will be rated for the higher voltage and will work perfectly well at lower voltage levels. So you can use a 230 VAC capacitor with the right MFD reading as your old 110/115V capacitor.

But to be sure why not give one of the capacitor suppliers a call with this question - I don't want to steer you into a ditch by being embarrassed to say I don't know for certain for your application.

by InspectApedia Publisher - what a typical SAFE-T-MIKE (or MOTOR MIKE) capacitor looks like

@Jordan,

For other readers, here is what a typical SAFE-T-MIKE (or MOTOR MIKE) capacitor looks like - notice that this one, #H-124 is rated at 124-149 MFD and just 124VAC

Here's a closer look at the capacitor data for this device.

Can you use a 250 VAC 189-227uf in place of a 189-227uf 110 VAC

Can you use a 250 vac 189-227uf in place of a 189-227uf 110 vac for a irrigation pump On 2021-12-30 by Charles

by Inspectapedia Com Moderator - yes you can use a 250 vac 189-227uf in place of a 189-227uf 110 vac

@Charles,

Yes, the voltage rating on a capacitor is its maximum not its minimum rating

What size DUAL Capacitor can I use?

My condenser fan motor label read 7.5 370v. What size DUAL Capacitor can I use?

I’m installing a new motor on HVAC and needing different sized capacitor. Old was 35 5 370/440. Can I use a 40 7.5 440 v capacitor? Thank you. On 2022-07-05 by Jerry

by InspectApedia-911 (mod) - how to select the right capacitor

@Jerry,

At

CHOOSE a START / RUN CAPACITOR, HOW TO

https://inspectapedia.com/electric/Motor_Capacitor_Selection.php

You will see that you don't have to match the old capacitor exactly but the article will give you the percentage by which you can exceed the original capacitors value. Please take a look.

Clarify the voltage rating on my motor capacitor

I have a lathe with a dayton motor (5k482-B) everything is set up on 220v the capacitor however is rated at 110v is that normal?

If so I would like to buy a "hard start capacitor" any guidance or recommendations appreciated! Steve On 2020-06-27

by Steve

by (mod) - capacitor voltage can be higher but never lower than the rating on your motor

Steve

Capacitor voltage rating can be higher than your motor but it should not be lower. Otherwise it's likely the capacitor will burn up or fail quickly.

In order to protect the trust of our readers we don't sell any product or service,

But if you need d a hard start kit are plenty online.

...

Starting Capacitor Size / Rating FAQs

How does a start capacitor work?

How difer start capacitor off state after motor in rated speed? On 2021-07-07

by H

by (mod) - How does the start capacitor get turned off when the motor has reached its rated speed?

@How start capacitor working,

Thanks for your helpful question that I'd re-phrase as

How does the start capacitor get turned off when the motor has reached its rated speed?

Answer:

On many motors a centrifugal switch built into the motor and held closed by springs keeps the start capacitor in the motor power circuit until the motor has reached its rated speed.At that point the rotating speed of the motor is sufficient to open the centrifugal switch against its spring pressure, thus taking the starting capacitor out of the circuit, leaving the run capacitor in use.

To give you an idea what the centrifugal switch looks-like, below we show a Speedaire (brand) Centrifugal Switch Set Mfr #: PN22N031G as listed for sale at Zoro.com, Zoro #: G8641053

More about centrifugal switches is at

ELECTRIC MOTOR CENTRIFUGAL SWITCH or PTC PRD

I can't find the right start capacitor for my compressor motor

My 5hp compressor has 2 start and 1 run capacitors, I need to replace the start capacitors but can't find them. They say 216-259, 370-440 On 2022-03-16 by Harold Swanson

by Inspectapedia Com Moderator - choosing a replacement capacitor as well as 'ballpark' sizes based on motor type or motor horsepower

@Harold Swanson,

Take a look at this page where you'll find 4 methods for choosing a replacement capacitor as well as 'ballpark' sizes based on motor type or motor horsepower.

MOTOR CAPACITOR SELECTION - the home page for this topic

Please let us know if you have additional questions.

Alternate size start capacitor for roof top AC fan motor?

Alternate size start capacitor for roof top AC fan motor?

Hi, I currently have a 43-52 microfarad 250 VAC start capacitor that I need to replace (AC starts and gets cold but fan does not turn on).

This type of capacitor is sold out everywhere (or long lead times). What other size capacitor can I look for to start a 1/5 HP, 1650 RPM, 3 speed, 115 Volt, 2.5 Amp fan motor(Century ORV4540)?

Thanks! Margot On 2021-07-12 by Margot D -

by (mod) - capacitor substitution rule of thumb: upper limit 20% µF over-size

@Margot D,

From the article CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS we have this note:

As a general rule of thumb, electric motor start capacitors can be replaced with a micro-farad or µF or mfd rating equal to or up to 20% higher µF than the original capacitor serving the motor. On the replacement capacitor the voltage rating must be equal to or greater than the original.

That's about a 10 uf difference from the high-end of your stock motor cap, so you could try a capacitor that puts out up to 62 uf 250VAC

For example this capacitor (shown below) sold by grainger.com is described as

DAYTON 2MEL2 Round Motor Start Capacitor,53-64 Microfarad Rating, 330VAC Voltage

Also check out the explanation of capacitor voltage also discussed in the article I just cited above. You should agree that the 330V is simply an upper limit.

Can I Install a Larger START Capacitor to get my motor running?

I have a Century Gould 1hp motor rpm 3450 -8150240-2 -13-6/6.8 -Thermally protected - 115/230 --Mallory Capacitor 139852-45 - 400-480-mfd-110vac -m235-7629k-04 - psu 110-125 vac -start capacitor 72-88 ,this is all numbers I can find.

The motor hums, use a rubber stick like to turn the compressor just a little or small nudge, very lightly. it starts up, shut it down, and it will start, next time I have to give it a nudge again, .

I went to WW Grainger, they gave me a new Capacitor (their part #2MDT9), it did the same, I ask if I could get a more electrical power, he said no, it seems it just needs a little more start power not much, what size can I get to work for me.

The motor runs great when I get it started, no heat or any problems. Could you email me back with a Capacitor information ( numbers) so I can get one that will work. On 2017-03-28 by Bill P

by (mod) Don't install a much larger START capacitor on your motor

Bill,

IWatch out: would be reluctant to install a capacitor with a rating more than about 10% above the original, MFD rating as larger than that you are likely to damage the motor's start winding and ruin the motor.Watch out: considering that a motor may be hard-starting because it's own bearings are failing.

Be sure to read

and also

What start capacitor do I need for my Jacuzzi hot tub pump?

I have a 1.5 hp jacuzzi hot tub pump. The motor hums but wont start. I check the shaft and that spins freely. I'm guessing capacitor. It only has one and its located on top of the meter. Is that a start capacitor or run.

On 2021-05-26 by Tim

by (mod) - 30 uf is common size starting capacitor for small motors

@Tim,

Your photo was a bit blurry so I can't see whether it has two terminals or three.

I mention this because if there were three terminals than the capacitor would be a dual function start and run cap.

I can tell you that depending on the size of your motor, the 30 microfarad rating that shows in your photo might be used in a starting cap - for example on an air conditioner motor or on a pump.Run capacitors for such motors generally would use a smaller number as you'll see in the capacitor selection tables at CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS

New capacitor tested beow the range printed on its label

Is it common for a newly purchased capacitor to test below the listed rating right out of the box? Bought a 55 mfd recently and tested at 52.92 out of the box. On 2019-05-30 by Craig

by (mod) - Typical motor capacitor MFD variance is +- 5 to 10%

While the tolerance varies, it wouldn't surprise me for a capacitor to test a bit off from the label rating.

(55 - 52.92) / 55 = 0.037 or less than 4% variance from the capacitance in MFD printed on its label.

Typically a starting capacitor label will say that its MFD rating can vary by 5 to 10% above or below its labeled MFD number.

Look for a plus / minus specification on your capacitor to tell us what the manufacturer's expected variation was.

Perhaps you can attach photos of the labeling on the capacitor. One per comment.

...

Dual (Start/Run) Motor Capacitor FAQs

How do I find the right capacitor for my A/C compressor motor?

Hi experts!

Hi experts!

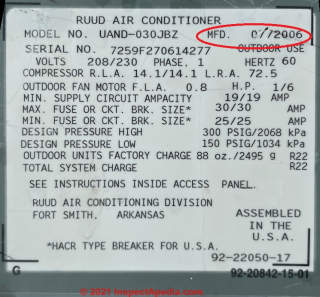

I'm looking for a dual capacitor replacement for an old RUUD AC compressor model UAND-030-JBZ, the serial number start with 7259.

The capacitor's housing is in plastic and the specs (etched) disappeared over time, so I have no idea which capacitor I should order.

:(

I'm attaching an image of the compressor's specs if it helps.

Thanks for your help! On 2021-06-30 by Thomas

by inspectapedia.com.moderator (mod) - Start/Run Capacitor for a RUUD Condenser unit

@Thomas,

To select a start/run capacitor for an old AC unit when the values of the original capacitor are not legible,

A service tech might use the capacitor selection rough guidelines like those at CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS , or

consult the service manual for the compressor/condenser unit that may give the exact OEM specification, or

she might give Ruud service a call - for which one needs just what you have on that service tag: the Ruud A/C model no. UND-030JBZ

and they may want its serial numberOn 2021-06-30 by Anonymous

@inspectapedia.com.moderator, Thanks for the quick reply. I'll try my luck with RUUD Service first. ;)

...

Run Capacitor Sizing FAQs

If the starting 300uf what would be the size of the run capacitor

If the starting 300uf what would be the size of the run capacitor On 2017-06-30 by israel

Reply by (mod): how to choose a RUN capacitor if you know the START capacitor µF

Israel

There is no direct translation between an arbitrarily-specified 300 µF motor start capacitor and the required run capacitor for the same motor - of unspecified voltage in your question.

Electric motor "run" capacitors are typically in the 2 µF 70 or 80 µF range of capacitance and their voltage rating will be 370 Vac or 440 Vac. But that's a general remark not an exact specification.

If the run capacitor is too big or too small in µF rating, the result can be motor vibration, exceeding the motor's rated run temperature, motor vibration and noise, motor wear and thus reduced motor life, and more expensive motor operation.

Typical run capacitor sizes that will be in the “ballpark are

1/8hp motor: 4 to 5 µF

1/2 hp motor: 10 µF

1-2 hp motor: 10-15µF

3 hp motor: 20µF

5 hp motor: 40µF or more likley 30 µF

(Similarly, you will find tables matching motor size in kW and capacitor value in µF for starting capacitors. But read on before slapping a capacitor you found in a toolbox or in a table of data.

When choosing the run capacitor for your specific motor, the µF you choose should match the run Capacitor rating on the motor's data tag. It's almost certainly going to be below 70 µF . But to repeat a key point: you need the manufacturer’s run capacitor rating to get the right capacitor.

There are rule-of-thumb equations for guessing at the run cap µF if you don't have the manufacturer's data tag, but those rely on measuring the motor when running under load - and can be in error depending on the existing motor and capacitor when the measurements are made.

So I cannot recommend that approach for choosing a new or replacement capacitor, even if the motor is running. An accurate measurement to choose the run cap size would require use of an oscilloscope and examination of the motor power phase to compare start vs run windings - not something a field technician is likely to do.

Another approach suggested by Lemau is to install a run capacitor of 30-50 uF/kW, measure the motor’s performance, and choose a subsequent capacitor rating accordingly. Lemau offers a formula to calculate the capacitor size that is a function of current, Hz frequency, applied voltage, a power factor, and a dissipated power in watts.

Best bet: read the data tag, or if it's illegible, let's find the motor's manufacturer and model and then look up the specifications.When you have the motor's run-capacitor specification, typically the run capacitor you install can be +/- 6% (or by some writes +/- 5-10%) of that rating (according to what I've found by researching this question).

That's for capacitance. The voltage rating needs to be equal to or greater than the motor's voltage rating. Unlike the µF rating, a higher voltage rating won't cause the same troubles. A lower capacitor voltage means a shorter capacitor life. Industry standards for motor capacitor life and testing, including the Highly Life-Testing methods include the

- EIA-456-A Standard, Electronics Industries Alliance (USA Standard for motor run caps and other special capacitors)

- IEC-60252-1 Standard for run capacitors, International Electrotechnical Commission (Europe and Asia Pacific Region)

- Techumseh H-115 Standard for Run Capacitors

See also

- Colone, Anthony, ”Understanding and Using Capacitors", Industrial Equipment News, 19 May 2015

- Lemau, “Single Phase Capacitor Sizing”, (2011), published by electricneutron.com

We can dig out our file copies of these articles but they’re readily found online by a simple search as well.

Fan will start but won't keep running. Bad Run Capacitor?

The fan on my Conquest 80 will not stay on (interior fan). It starts and then stops after a few seconds. It was installed in 2005. Help. (June 1, 2014) Anonymous

Reply: Suggests a bad RUN capacitor - or other issue

Anon,

The start capacitor is for getting a motor started, not keeping it running.

Often motors have two windings, a start winding and a run winding. Your motor's run winding may be damaged.

Or your fan motor may require a dual capacitor (start and run) or a separate run capacitor to keep it spinning.

Or your system may have a faulty control.

What happens when you install a bigger RUN capacitor?

If I want to increase starting torque of motor do I need to increase or decrease the size of the start capacitor or is it fixed by the manufacturer On 2016-10-28 by Steve

by (mod) re:

A bigger START capacitor gives more starting oomph for the motor.

And a bigger RUN capacitor will increase motor torque by increasing the phase shift (the rotating electrical field) powering the motor.

Watch out: don't exceed the original motor capactior MFD by more than 20% (10% would be safer) or you'll probably burn up the motor..

Watch out: However too big, combined with a motor that's failing may simply result in an electrical burn-up.

...

Capacitors for 3-Phase vs Single-Phase Motors FAQs

Capacitor to convert a three phase (380V) compressor motor into single phase (240V).

I want to convert a three phase (380V) compressor motor into single phase (240V).

What is the right capacitor size to use?

On 2021-04-23 by nkatu30

by (mod) - convert a three phase (380V) compressor motor into single phase (240V).

@nkatu30, I don't have an authoritative answer

but it seems to me that as the motor's basic mass and windings haven't changed you'd need the same sized cap; typically in motor capacitor specifications the voltage range given is a safe upper limit and it's ok to use, for example, an XXufd starter cap or run cap rated for 380V on a 240V application.

Shown is a Round Motor Run Capacitor,30 Microfarad Rating, 370-440VAC Voltage from Titan

3 phase compressor that I want to run on single phase current

Good day. I have 3 phase compressor that I would like to run on single phase current. What size capacitor would I need and will it need a run cap as well? On 2019-10-08 by Mogamat

Good day. I have 3 phase compressor that I would like to run on single phase current. What size capacitor would I need and will it need a run cap as well? On 2019-10-08 by Mogamat

by (mod) -

Mogamat

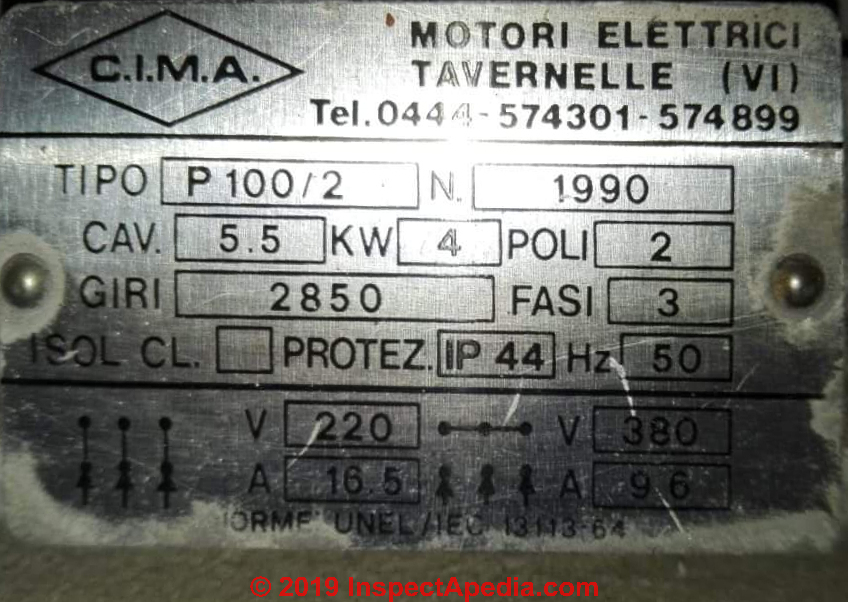

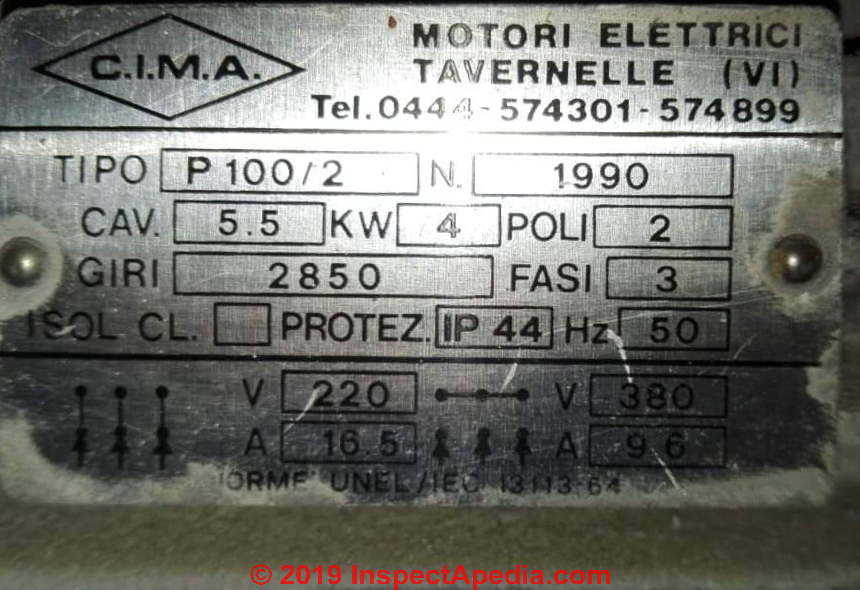

It looks as if your motor runs at 220 or 380 Volts 3 phase and at 220V runs at 16.5A while at 380V it runs at 9.6A.

The CAV on the data plate of this Italian motor from Tavernelle indicates that it's a 5.5 hp motor.

Typically the run capacitor on a 5 hp. motor is around 30 µF - 40 µF 370VAC

Typically the start capacitor for a 5 hp motor is around 600uF

To take a stab at answering "how to convert a 3 phase motor to run on single phase power" I found a variety of answers ranging from "it's easy" to "it's a really bad idea, even dangerous".

Kemet (cited in the guidebooks given in the article CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS ) notes: By connecting a capacitor to the two phases it is possible to make a three-phase motor work as a single-phase motor.

Watch out: you cannot simply hook up a 3 phase motor arbitrarily to single phase current; you need to review the wiring recommendations from motor companies or engineers.

Options include:

A phase shift capacitor;

Motor re-winding

Using a VFD or variable frequency drive

Use a converter to convert your single phase power to DC (Direct Current) and then use an inverter to power the motor. From what I read this is your best bet. As one EE notes "You can run a three phase motor from single phase by converting the single phase AC-DC(rectification) and then DC-AC(3 phase inverter)."However pretty much everyone says this is an inefficient way to run a motor - i.e. your electric bill will be higher than necessary.

On Quora a Bombay writer recommended:

Use capacitor of say 36 / 72 / 108 mfd 440 V rating.Depending upon motor rating. Connect one end of this capacitor to open unconnected terminal of motor.

The other terminal of capacitors can be connected to one of the two live phases, and the motor will start running.

If you change over the capacitor terminal to other phase , its direction of rotation will get reversed.

This system is routinely used in India particularly in rural areas for running of pumps.This arrangement is certainly not the optimum for the motor, and the phase difference between the windings will differ from 120 degrees needed.

However, this does makes the motor start and save the day for farmers when 3 phase supply is not available. - www.quora.com/How-do-I-run-a-3-phase-motor-in-a-single-phase-line-using-a-capacitor

How to properly operate a three-phase motor using single-phase power

See: www.gohz.com/3-phase-motor-running-on-single-phase-power-supply

See this article by Chuck Yung:Note that operating the motor on single phase may be expensive.

How to convert a 3 phase motor to run on single phase power - Tavernelle Notori Elettrici

I have 3phase compressor that I would like to run on single phase current... What size capacitor would I need and will it need a run cap as well? On 2019-10-08 by Mogamat

I have 3phase compressor that I would like to run on single phase current... What size capacitor would I need and will it need a run cap as well? On 2019-10-08 by Mogamat

by (mod) -

Mogamat

It looks as if your motor runs at 220 or 380 Volts 3 phase and at 220V runs at 16.5A while at 380V it runs at 9.6A.The CAV (short for cavalli or horsepower) on the data plate of this Italian motor from Tavernelle indicates that it's a 5.5 hp motor.

Typically the run capacitor on a 5 hp. motor is around 30 µF - 40 µF 370VAC

Typically the start capacitor for a 5 hp motor is around 600uF

To take a stab at answering "how to convert a 3 phase motor to run on single phase power" I found a variety of answers ranging from "it's easy" to "it's a really bad idea, even dangerous".

Kemet (cited in the guidebooks given in the article above) notes: By connecting a capacitor to the two phases it is possible to make a three-phase motor work as a single-phase motor.

Watch out: you cannot simply hook up a 3 phase motor arbitrarily to single phase current; you need to review the wiring recommendations from motor companies or engineers.

Options include:

A phase shift capacitor;

Motor re-winding

Using a VFD or variable frequency drive

Use a converter to convert your single phase power to DC (Direct Current) and then use an inverter to power the motor. From what I read this is your best bet. As one EE notes "You can run a three phase motor from single phase by converting the single phase AC-DC(rectification) and then DC-AC(3 phase inverter)."However pretty much everyone says this is an inefficient way to run a motor - i.e. your electric bill will be higher than necessary.

On Quora a Bombay writer recommended:

Use capacitor of say 36 / 72 / 108 mfd 440 V rating. depending upon motor rating. Connect one end of this capacitor to open unconnected terminal of motor.The other terminal of capacitors can be connected to one of the two live phases, and the motor will start running. If you change over the capacitor terminal to other phase , its direction of rotation will get reversed.

This system is routinely used in India particularly in rural areas for running of pumps.This arrangement is certainly not the optimum for the motor, and the phase difference between the windings will differ from 120 degrees needed. However, this does makes the motor start and save the day for farmers when 3 phase supply is not available. - www.quora.com/How-do-I-run-a-3-phase-motor-in-a-single-phase-line-using-a-capacitor

See www.gohz.com/3-phase-motor-running-on-single-phase-power-supply

See this article by Chuck Yung www.plantengineering.com/articles/how-to-properly-operate-a-three-phase-motor-using-single-phase-power/ on running a 3-phase motor on single phase power.Note that operating the motor on single phase may be expensive.

...

Capacitor Purchase Source & Substitution FAQs

Will any brand capacitor with the same MFD and VAC work?

I need to replace an old 270-324 mfd 110-125 vac from an Baldor single phase 1/2 hp motor.

Will any brand with the same mfd and vac work? Some brands seem to be about a half inch or so shorter, but same diameter.

Got to get my log splitter goin again.

Could you roughly tell what caps I will need On 2017-12-07 by mark p

by (mod) - yes but ...

Mark,

Some motors do not use capacitors for start/run - it depends on the motor type and application.

Typically a motor uses a start and run capacitor combined in one physical device or sometimes as two separate devices.

The specific capacitor size or rating you need depends on the motor: see the examples and datain CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS .

Do let me know if I can clarify further.

Can you sell me a new capacitor 210-260 MFD?

I have a Belsaw 1/2hp 3450 rpm that is old and need a capacitor 210-260 mfd - 2021-04-15 by Tom

by (mod) -

@Tom,

Sorry but we can't sell you the capacitor you need. At InspectApedia we do not sell anything. No products, no services.

And no motor start capacitors.

But you can find your capacitor very easily at your local electrical supplier, at some building suppliers and at a stunning number of online vendors, starting perhaps with grainger.com or amazon. An example is below.

InspectAPedia.com provides building and environmental diagnostic and repair information.

In order to absolutely assure our readers that we write and report without bias we do not sell any products nor do we have any business or financial relationships that could create such conflicts of interest.

I can't find the same brand capacitor for my greenhouse fan motor

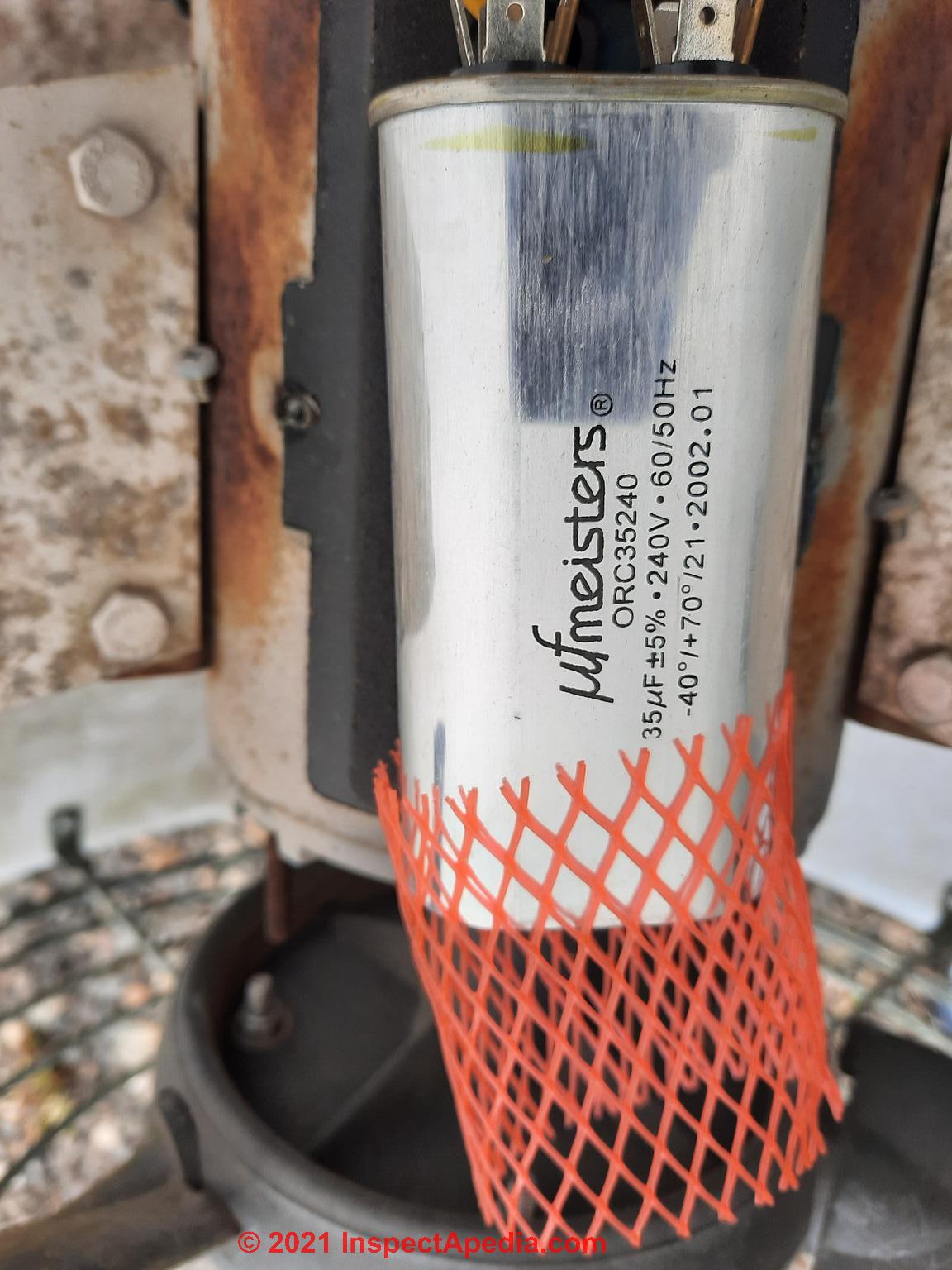

I have been looking all over for a replacement to this capacitor 35/5 240V, but to no avail. It is for a Leeson 1/2 hp greenhouse exhaust fan motor. Do know where I can find one? Thanks. On 2021-04-13 by Devan

by (mod) - you don't have to replace a capacitor with the same brand, just match the rating; the shape? Depends on where it fits.

@Devan,

Sure, glad to help.

You may have made the very common mistake of thinking that to replace a motor capacitor you have to buy the exact brand and shape as the original. You don't.

Key is the capacitor rating - yours is 35uf or 35 microfarads - probably this is a motor run capacitor.

All of the data for your motor capacitor is written out as: 35uf +-5% (tolerance), 240V, 50/60 Hz. You'll read in the article CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS that a suitable match that's 35uf will be ok even if it's voltage rating is higher (as that's simply a safe upper limit);

The shape of the capacitor isn't critical, though it'd be nice if it would fit where the original did; if it won't it can be mounted and wired from outside the space used by the original capacitor.

The cap you want is available from any electrical supplier, motor repair shop, or HVAC supplier, and also from many online vendors, even big Amazon.

Below is an example, a QH QX6535 35uf Capacitor Motor Run Round 35 uF MFD 370V HVAC as shown at Amazon.

Please also take a look at the electric motor capacitor selection advice CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS on this page.

What do I do if I can't find the same brand and exact specs as the original motor capacitor?

I have a pool/spa pump and motor assembly that came with a CSC capacitor (10,000AFC, 25+10UF +-6%, 370 VAC/B, 50/60 Hz), It is round and is located on top of the horizontally mounted pump/motor assembly.

It was installed in Sept. 2013. I cannot find a replacement capacitor anywhere in the "pool equipment supply world" and I can't find CSC, I can find a few CSC capacitors available around the Internet (used or surplus) but not the capacitor this assembly was provided with. Would you have any advice? Thanks! On 2016-06-09 by Rick

by (mod)

I'd call the manufacturer, or look on the old cap to see its manufacturer - that makes finding a replacement easier.

Any replacement capacitor of the proper voltage and MFD range will be OK.

Where can I buy a starting capacitor in Hindi Language?

Haihow many starting capacitor in makes for induction motor in Hindi language

example------. by filter capacitor -100/120 & 120/150 &. 150/200 mfd simple language

practical or diagram On 2016-08-15 by Virendra

by mod

Virendra, there will be hundreds of starting and start/run capacitor combinations; regardless of language all will be specified in microfarads, as you suggest.

A source you might check for buying start/run capacitors in India is http://dir.indiamart.com/impcat/motor-run-capacitors.html

As for wiring diagrams, there is little language on them, right? I searched and reviewed 25 motor wiring diagrams and capacitor instructions using the keyword Hindi in the search term: all of the results I found were in English. Sorry.

...

Capacitor Size - MFD Rating & Value Range FAQs

Why do some capacitors specify their value in uF as a range?

Why do some capacitors specify their value in uF as a range? For example: 270-324uF. Surely the capacitor can only have one value. On 2020-05-13 by Dan

by (mod) -

Thanks for asking Dan, that's a helpful question.

The range in uF listed on a capacitor is the range over which the capacitor can be used successfully.

For example, a 270-324uF capacitor can be used in any application **within that range**

Put another way, if a cap had a minimum capacity of 100uF and maximum capacitance of 200 uF you could **not** use it for a motor that required a 300 uF Cap, but you **could** use it safely on a motor that required a 150 uF cap

What's an acceptable replacement capacitor MFD range when matching an old capacitor?

I am looking at replacing a starting capacitor on my AC outdoor unit fan. The one in the unit is 330V 176-216MFD. Does the new one have to be exact match or will one +-5% or +-10% work just as well? On 2017-04-13 by Anonymous

by (mod) re: +-5% or +-10% of capacitor rating is an acceptable range

I'm not an EE but it seems to me you are perfectly within range. Some standards specify +/- 6 to -7%

Can I use 10 MFD capacitor as start capacitor?

Can i use 10 MFD capacitor as start capacitor On 2021-04-02 by Anonymous

by (mod) - that's probably too small - typical motor start capacitor ratings in uF and voltage for motors of various horsepower or size.

@Anonymous,

Not likely, anon; take a look through the motor start capacitor selection advice in the article CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS and you'll see typical motor start capacitor ratings in uF and voltage for motors of various horsepower or size.

How to calculate Capacitor Size from Motor Watt Rating

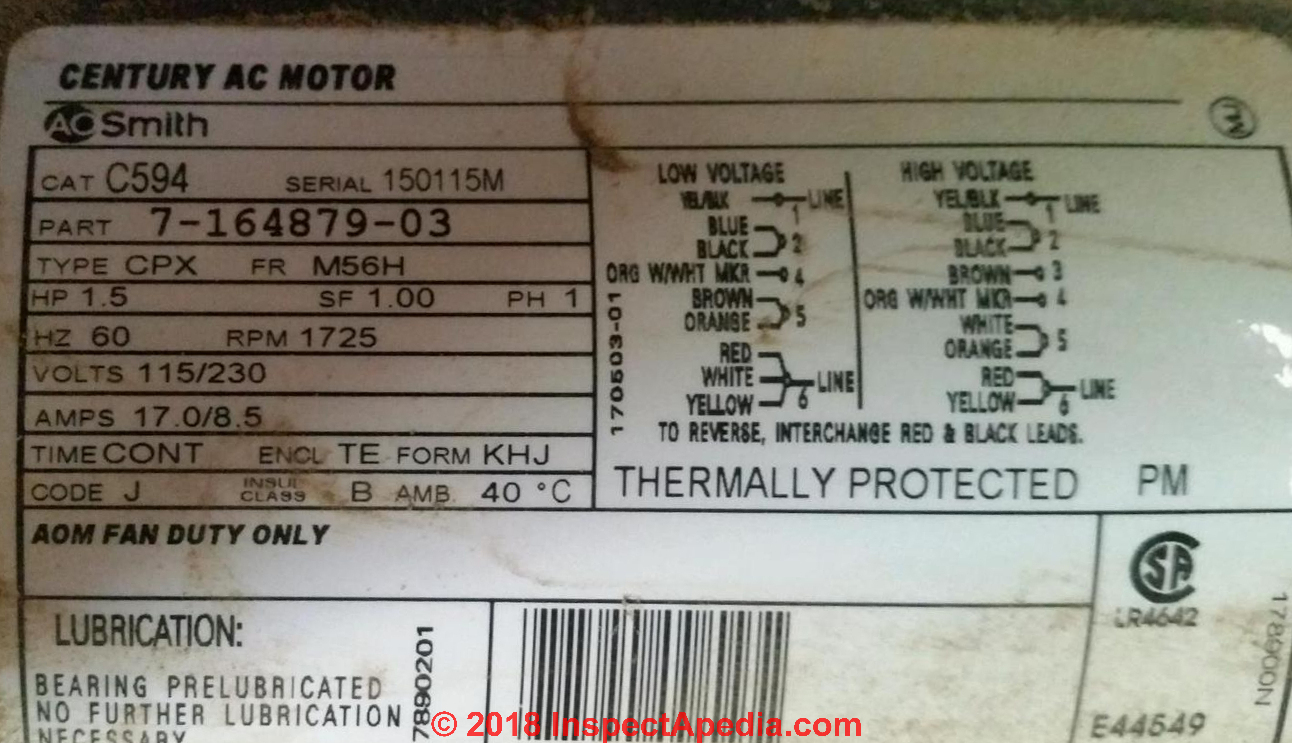

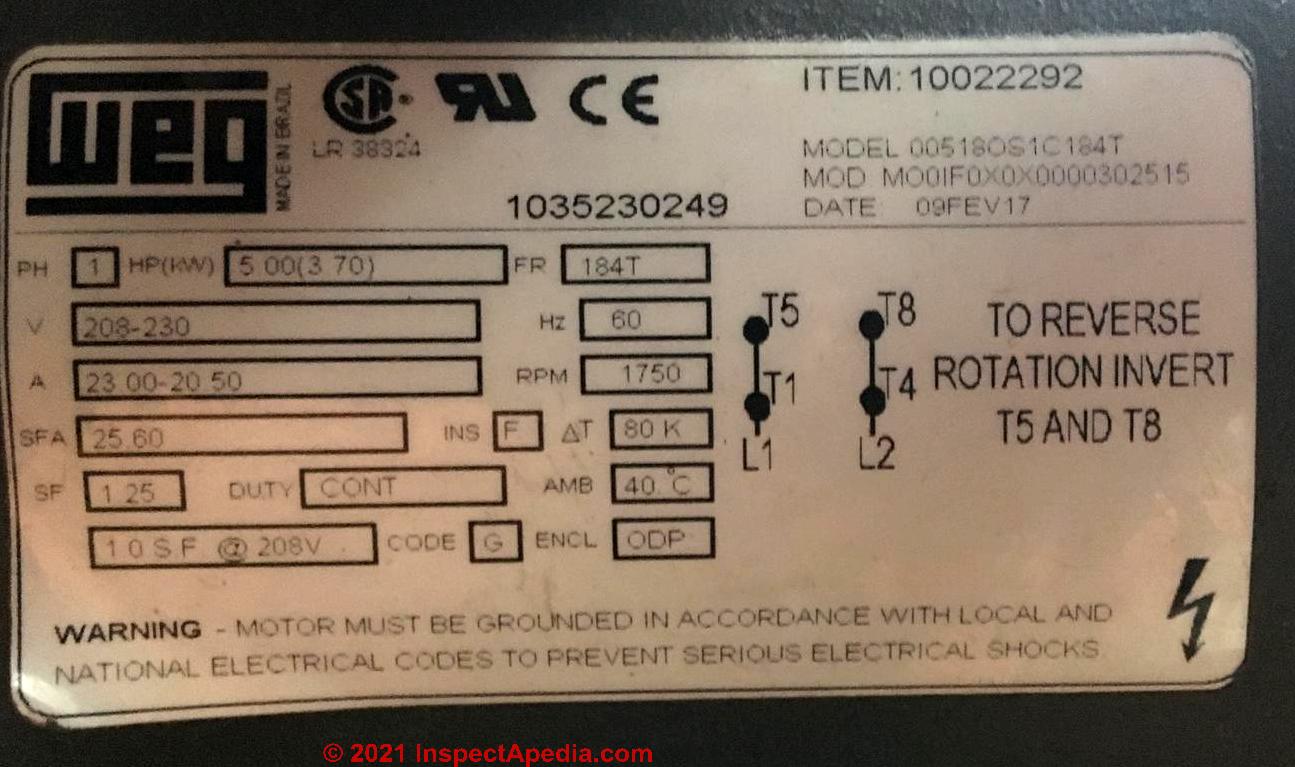

Can anyone tell me what capacitor I would need for this air compressor motor? Previous owner took the old one off so I dont have it to get a replacement. On 2019-05-16 by Rick

Can anyone tell me what capacitor I would need for this air compressor motor? Previous owner took the old one off so I dont have it to get a replacement. On 2019-05-16 by Rick

Reply by (mod) -

Rick

In the article CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS there are tables of motor size with suggested capacitor values as well as a table of typical capacitor values for some common motor types.

Or

Looking at the data tag on your Century brand AC Compressor motor we see that it's a 230VAC motor that is rated for a maximum of 15Amps.

Watts = Amps x Volts

Watts (of your motor) = 15 x 230 = 3450 Watts

Any online converter of Watts to mechanical horsepower will give us 3450 = 4.6 hp.

OR we can just read the motor data tag where it says the motor is a 3. HP unit. (Which is more conservative in a sense).

AND stop by your electrical supplier for that data to ask the service tech to recommend a different value than what we have below:

THEN we can use either the watts or the HP to choose a "typical" capacitor value from tables given at CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS

That would suggest a starting value for a run capacitor of 20-25 µF 370VAC

And a starting value (to try) for a start capacitor of 500-580 µF or a bit larger

IF Century were still in business (apparently now Century / Regal Beloit ) you could simply have contacted Century Electric Inc., in St. Louis, give them the part No. of your AC Motor: 8-158630-02 Type CS HP 3.0 SPL, 60 Hz, RPM 3450 Volts 340, Amps 15.0 and ASK them what start / run capacitor(s) they use with that motor.

Century Regal Beloit Website: www.regalbeloit.com/Brands/Century - evidently the company does NOT want to be called (not so consumer friendly, right?) but their website includes a contact page that might work for you.by (mod) Is it permissible to replace the 12uF cap with a 15uF, 440V?

You can safely go about 10% over the motor's original rating so

check the brand and model of your motor - the information on the motor data tag.

Take a look at its specifications, duty cycle, and perhaps even check with the manufacturer.

To get the right capacitor for your motor you can almost always find a suitable product from an electrical supplier, matched to the motor specifications - as we describe

How to find the capacitor needed from the motor label

What Capacitor would I need for this motor? On 2018-06-18 by Sharon Lehman -

Reply by (mod) - Where to Find specifications for replacement capacitor for a 1.5 hp AO Smith electric motor

Sharon

We asked for help from CSH Electric Motor Supply Corp at http://www.cshincorporated.com/

Whose online chat tech contacted a company rep who specified:

Start cap part # 15769655 ratings 189-227 mfd @ 125 Vac

Run Cap part # 17586315 ratings 15 mfd @ 370vac

You can substitute equivalent parts, for example a 15DVR, 15MFD-370V Motor Run Capacitor available from www.cshincorporated.com/15dvr-15mfd-370v-motor-run-capacitor-round/

Product description:15DVR, 15MFD-370V Motor Run Capacitor (Round) as of 6-28-06, Now being replaced with dual voltage 370V-440V, dimension Dia. 1.65 in x 3.15 in. height.

Cross Reference: 6100-6022

Translate motor label information to start & run capacitor size - example

how to know the size of run and start capacitors of this kind of motors

60hz

1740 rpm

5 hp

220v

26amp

single phase

- On 2018-04-15 by ruel quiambao

by (mod) - typical run capacitor sizes for various sized electric motors

Ruel

In the article CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS you'll find a couple of tables giving typical motor start/run capacitor sizes matched to motor current draw in Amps.

Typical run capacitor sizes that will be in the “ballpark are

1/8hp motor: 4 to 5 µF

1/2 hp motor: 10 µF

1-2 hp motor: 10-15µF

3 hp motor: 20µF

5 hp motor: 40µF or more likley 30 µF

Can I use a replacement capacitor for a GE washing machine even though the original is no longer produced?

Can I use a replacement capacitor for a GE washing machine even though the original is no longer produced?

I will post pics of the original (w/specs) along with a possible replacement.

GE says the capacitor is model specific, but the replacement is from GE and is exactly the same specs and is used in later units with the same motor. Thanks!- On 2021-02-15 by Paul

by (mod) - Yes

Paul:

Normally it is absolutely reasonable to replace a motor start or run capacitor with another one of the same specifications in voltage and capacitance - as we describeat CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS

Sometimes there is a physical "fit" problem that an original cap fit into a special and odd space where its replacement, that may be different in size or shape, is not so comfy.

But nonsense: capacitors are connected by wires. If a cap doesn't fit in its old cubby, as long as it can be safely secured and protected from damage and thence connected to the motor it serves, it ought to be fine.

It may be that whomever spoke with you doesn't want to crawl out on the limb of common sense, having perhaps Liticaphobia.

Watch out: Keep in mind that if a motor capacitor burnt up because of an underlying problem with a motor that's dead or dying or unsafe wiring, replacing the capacitor won't address the motor and fire-safety concerns.

You might ask that person

1. What's the technical or safety objection to replacing the GE OEM washing machine capacitor with a replacement unit of equivalent value in volts and farads

and depending on that answer,

2. Ask that person to review the costs of spending other people's money for the person's peace of mind.

Or give out a copy of

inspectapedia.com/home_inspection/Other_Peoples_Money.php OTHER PEOPLE's MONEYby Paul

Thanks for the quick response, Dan! The symptom that leads me to the capacitor is a failure for the washer to spin/drain in the last part of the cycle...turning off the power and shutting off the breaker, then waiting 30-45 minutes to allows it to cool off enough to re-engage and drain and spin effectively.

I recently replaced the drain motor (broken impeller) and drive motor, but problem still exists.

Strong electrical odor of something overheating coming from the area of the capacitor.The location of the washer prohibits quick access to the motor/mechanical interior of machine to check/feel what is overheating.

I'll replace the capacitor and report back in the near future as to whether or not this works. Thanks again!

by (mod) - Strong electrical odor of something overheating coming from the area of the capacitor. /p>

Be sure we've not missed a bearing somewhere else such as in the tub assembly.

Also you may be able to check the motor remotely by checking its current draw.by Paul

Thanks, I will as soon as I can get full access to the 'innards'... ;)

by Paul

Hi, Dan. Sorry for the delay in responding. Got slammed with work; I finally was able to get the washer up and be able to get at the motor, transmission, capacitor, etc. Checked the transmission, turns smoothly and effortlessly. Motor is fine.

Replaced the capacitor as we talked about earlier-was able to zip tie the new, cylindrical one to the original mounting bracket of the old box shaped one and started washing a full load.

I watched it through the first cycle, and when the spin cycle started, it kinda of stumbled before the motor kicked. It continued to drain and spin afterwards until the 'unbalanced' notification stopped it.

I had to re-level the clothes twice, then reset the controls to spin only; this time, the motor kicked in almost immediately and finished the cycle without a hitch.I also monitored the control panel/circuit board temp. as it would very noticeably get quite warm a few minutes after starting the washer (with the original capacitor).

With the new one installed, there was a only the slightest sensation/feeling of warmth, but nothing compared to the original.

Let's hope this turns out to be a successful fix for the problem. Thanks for your insight and help with this! I'll keep you notified if anything else happens.

by (mod) -

@Paul,

thanks for the helpful feedback-follow-up;

Sometimes all we need is a new start/run capacitor;

but be warned that sometimes the failed cap is a telltale that the real issue is a failing motor - such as due to a bad bearing. Keep me posted.

...

Capacitor Label Information FAQs

Confused about values printed on an old capacitor

I have a 2 capacitor 1.8 hp 120 volt motor on an old ridgid air compressor . I'm confused about the values on a black plastic round cap that has 5904708 mfd 125 vac 60 hz and has 2 terminals .

I did not see any thing like this on your web site .What do I have to do to replace this. I ohmed it and it comes up ( 0 ) I think that say's it's open circuit . The problem I have is the the motor runs 5 seconds and cuts off and pops a breaker . Can you help me.

Regards

Sal licata

sallicata66@yahoo.comO n 2021-03-17

by Sal Licata

Reply by (mod) -

@Sal Licata, I suspect that the "5904708 MFD" is either a misprint or a mixup of part number and MFD value. A 1.8 HP motor would typically use a starting capacitor somewhat smaller than 105-126 µF / 220VAC (Don't fret the voltage; these capacitor values and their sources are found in tables

at CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS)

The breaker trip could be due to a non-starting motor due to a bad cap as you've diagnosed, but be alert for a motor with failing bearings or a shorted winding too.The fact that your motor starts to rotate and then trips the breaker argues for a motor failure, perhaps a winding that shorts when the motor gets to speed or simply a bad bearing, giving the motor-rotation resistance that soon causes an over-current.

Can't read the values on the old capacitor: how do I choose a new one?

need start and run caps for this pic motor it runs an air compressor the one is readable the other blew out and is not readable

the one has the number but can not find

need to order both if replacable is possible

Thanks

On 2021-03-11 by Mr Casey -

How to read the specifications on a Facon motor capacitor

i have had a capacitor blow on my home made compressor which my Dad made many years ago so has great sentimental value i use it but have had this capacitor blow and would like to repalce it.

it has an italian motor on it and the make of cap is FACON but i am having problems tracking down a repacement

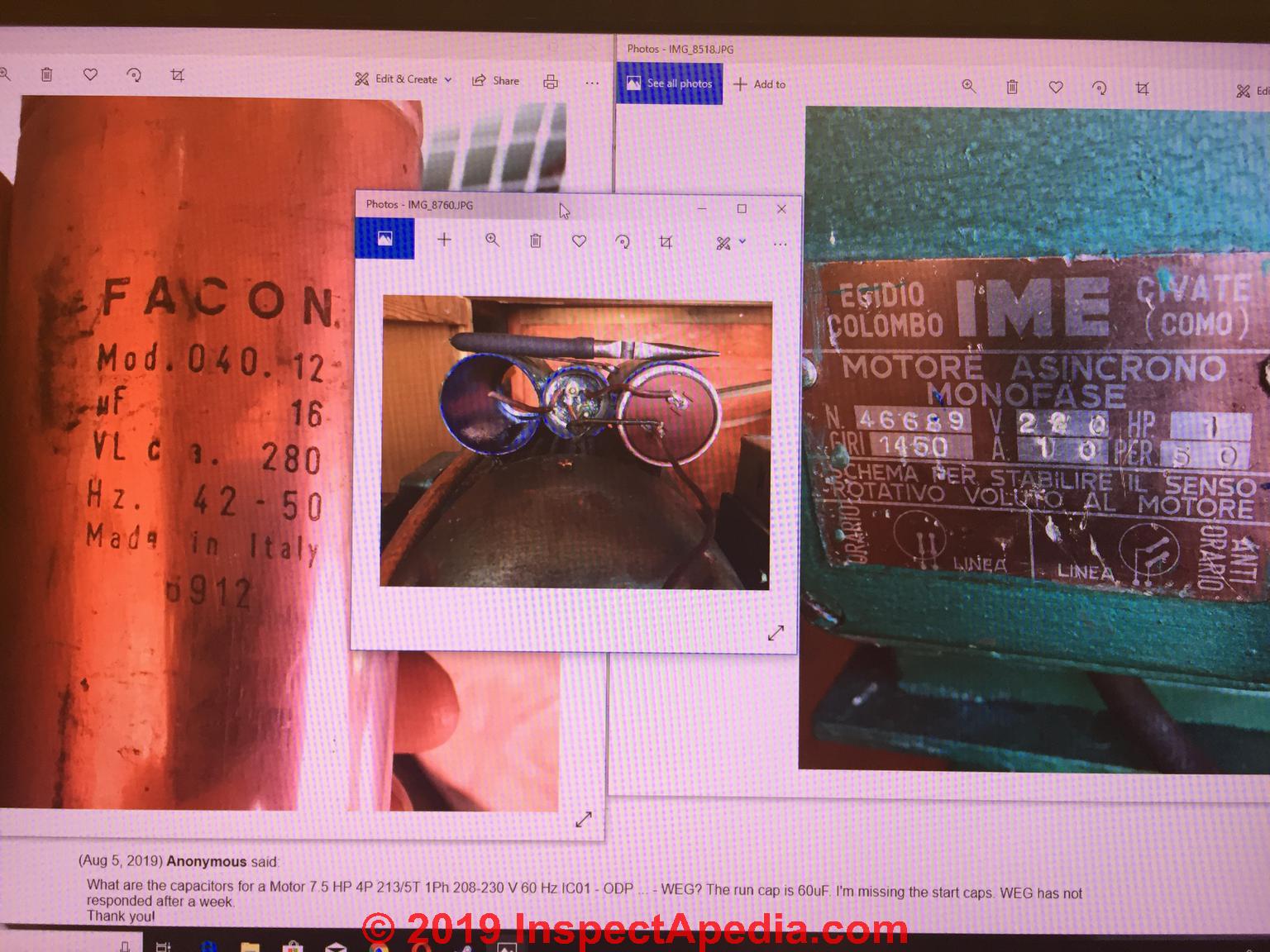

can i just replace the one thats blown or would it be wide to repalce both sorry to show my ignorance but i have no clue to whatthe middle one is i am assuming it could a starter cap? thank you in advance mick cOn 2019-08-25 by mick

by (mod) -

Your photo (shown above) of your old capacitor is a 16 uF 42-50Hz 280V capacitor made in Italy - you'll see that data imprinted on the capacitor cover.

If you can't find an exact match to that capacitor at your local electrical supplier, details on how to get a sufficiently-close match to the original capacitor are found

Cap label says ABC - What's an ABC capacitor?

I need to replace a capacitor that says "ABC" on it. I've found a lot for sale that say "ABS." Is there a difference? On 2021-03-04

by Guisepi

by (mod) - Don't confuse capacitor brand with rating information

@Guisepi,

Most likely "ABC" is the brand; you can use any brand, if you properly-match the capacitor specifications for voltage and capacitance.Look again at that label - it reads ABC MOTOR STARTING (capacitor) and above that we read that this is a motor starting capacitor rated at 400 MFD (MicroFarads) and wioth a voltage rating of 125VAC, produced by Y.C. Electric Company Limited. That "ABC" isn't useful information.

See details at

CHOOSE a START / RUN CAPACITOR, HOW TO - topic home

...

Capacitor Failure Indications FAQs

How can I Identify these Failing Capacitors? - Note the White Powder & Leakage Signs

I’m needing help identifying these.

I’m needing help with this capacitors. On 2018-12-17 by Jon Compton

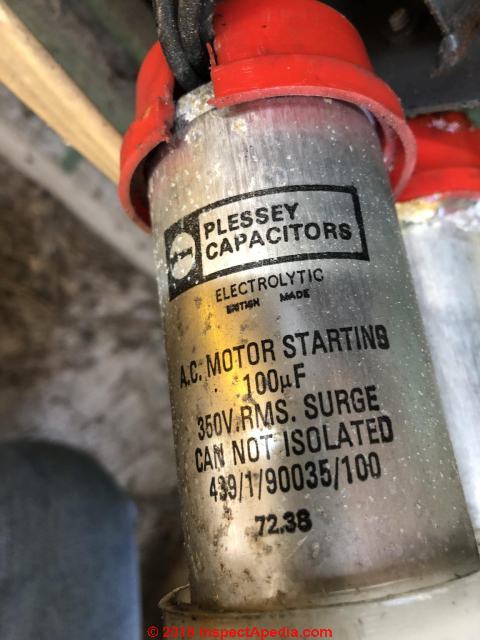

by (mod) - Plessy brand 100 uf stdarting capacitor substitutes ok

The Plessy brand capacitor whose imprint I can read is a 100 microfarad starting capacitor.

You don't need to replace it with the same brand but just with the equivalent rating.

Notice also the voltage rating and other specifications on your AC Motor Starting Capacitor. 350V RMS Surge, 439/1/90035/100 where the last 100 = 100 uf

Burnt connections on the start capacitor

I find burnt connections on the start capacitor. Looks as though the start terminal was over heated. I cant figure out why. On 2021-02-04 by SFCJerry

by (mod) -

A reasonable guess is that the motor that is trying to start is failing, perhaps with a bad bearing or burnt winding and it is drawing High current

You'll need to replace the capacitor and then check the motor's current draw as it tries to start.

Compare that with the motor's FLA Rating (Full Load Amps) or other ratings on the motor data tag.

Bulged capcitor means it's shot?

Hello, I have a Bryant AC unit model # 698BNX036000ABAA and I saw the compressor capacitor is bulging and I want to replace it.

The current capacitor is 45 uF, 370VAC, 50/60 Hz but I cannot find out online if this is the correct specs for the capacitor or if someone installed the wrong capacitor for this unit and that is why it has gone bad. On 2019-04-25 by nicole wallace

by (mod) -

Nicole

CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS explains how to choose the right replacement capacitor - please take a look and let me know if that information is unclear.

You'll also see that there is a bit of latitude, so you don't have to get exactly 45uF.

You'll read there that

as a general rule of thumb, electric motor start capacitors can be replaced with a micro-farad or µF or mfd rating equal to or up to 20% higher µF than the original capacitor serving the motor. On the replacement capacitor the voltage rating must be equal to or greater than the original.

So don't buy a cap that is rated LOWER than 45uF but you can go up to (1.20 x 45 = 54 uF)

Or contact Bryant directly to ask for an OEM replacement and to confirm the cap they recommend.

Bryant A/C customer support: 1-800-428-4326 for assistance in locating a dealer in your area.

Or submit a non-emergency question to Bryant at https://www.bryant.com/bryant/en/us/contact-us/

Motor that has trouble starting may indicate a bad start capacitor

I have a 1hp water well jet pump (115vac, 11 amp) with a startup capacitor that is beginning to fail. Its 10 months old with a one year warranty,

I'm sure it the capacitor because the motor struggles to startup after cut-out and will struggle to restart.

So far it will eventually restart and runs well when it does restart but the condition is getting worse.

I was told by the supplier I can return and exchange the whole unit, a major undertaking.

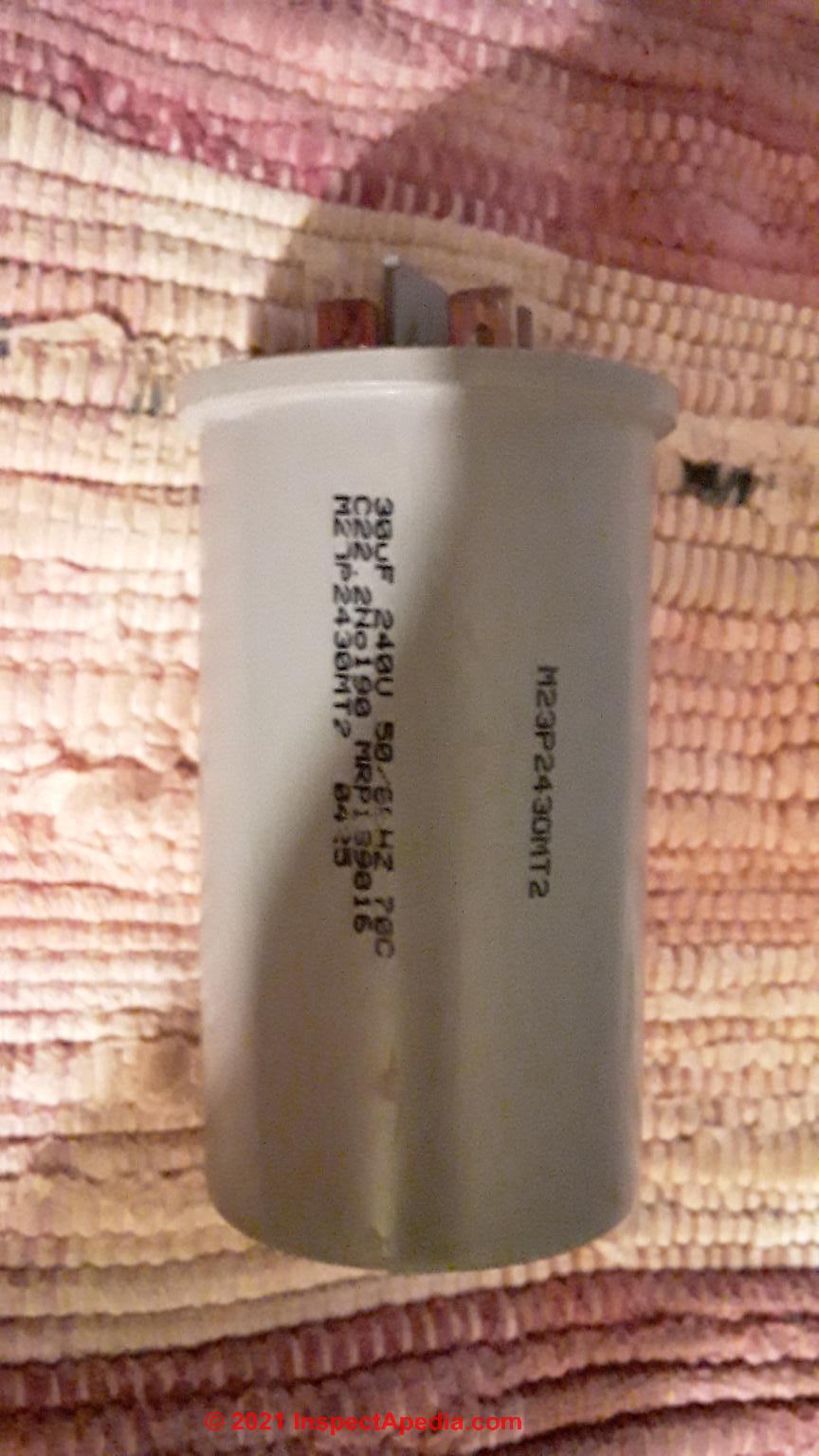

I was thinking that I could replace the capacitor and that would resolve the problem. I've included an image of the capacitor markings and would like your input on finding a replacement.

The unit was made in China for Tractor Supply Company. Anything else you could tell me would be appreciated. Thanks. On 2019-01-18 by organizome49

Reply by (mod) -

Org

The cost to try a new capacitor is trivial so sure go ahead and try it.However if the underlying problem is a failing pump motor, a new starting capacitor will give but short term relief. So be sure you can exchange the pump within warranty period if needed.

Before replacing the cap, you might want to test it to see if the problem lies there.

See TEST a MOTOR START or RUN CAPACITOR

Watch out: if you are not trained in safe electrical wiring and work you could be shocked or killed.

Will a hard start capacitor reduce current draw and stop tripping a breaker?

I have a commercial hood & exhaust fan (120v) running in a food truck that is used for catering.

We occasionally need to run off a generator (3000w) and we've found that the fan cause the generator overload to trip.

The fan has been tested and observed to draw 8 amps running at full speed. Given this, would it be possible to add a hard start kit, such as SUPCO SPP4E? Will need to confirm the motor size, just wondering if this would help.

The total draw of all items is less than 20 amps and the generator is capable of supplying 25 amps constant.

Thanks for the advice. (June 7, 2014) Joel said:

Reply: probably not in this case

Joel

Watch out: I think the problem lies elsewhere and needs some further diagnostics. I suspect that your total current draw is exceeding the ability of the generator - you may be running more than the fan, such as lighting, a cooler, toasters, other electrical appliances. If it were just the fan, drawing 8A, it has no business tripping the breaker.

Put another way if the problem is the fan and there are NO other appliances running, then there is a failing fan motor drawing high current, or an electrical short circuit or other unsafe condition to find and fix.

A start capacitor or a run capacitor won't change the current drawn by the motor.

...

Does my Motor even Need a Capacitor? FAQs

Can my grinder run without a capacitor? What does Capacitor Size Range mean?

Can you run a bench grinder without its capacitor?

What do you mean by size range? On 2020-04-05 by Sonny -

by (mod) - Can you run a bench grinder without its capacitor?

Sonny

There are some electric motors that don't use a start-run capacitor, but if yours does use capacitors then you cannot run it without them.Even if you gave the motor a spin to get it running without a working "starting" capacitor, if it's "run" capacitor isn't present the motor will not work properly, may not run at all, and is going to be damaged.

by (mod) - Explanation of capacitor size range

Sonny

Capacitor "size range" means the voltages at which the capacitor can be used and the capacitor's power usually in uf or microfarads.

For example if you Look for and record all of the markings on the capacitor.

Typically on the capacitor's markings or label you'll see a rating in microfarads like the 25uF and you'll also see a voltage range rating such as the 370VAC (maximum voltage) rating also in the red circle of our photo.

Details are at CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS

There are some electric motors that don't use a start-run capacitor, but if yours does use capacitors then you cannot run it without them. Even if you gave the motor a spin to get it running without a working "starting" capacitor, if it's "run" capacitor isn't present the motor will not work properly, may not run at all, and is going to be damaged.

...

Thank you to our readers for their generous comments

Excellent webpage! Keep up the good work. - On 2018-07-04 by Peter E

On 2018-01-22 by CWHONKAHI - Thanks for the great site.

On 2017-12-08 by Tibcon Motor Capacitor Company

Tibcon said: Interesting blog ...very useful information provided to users ... ...thanks for sharing us...keep it posting

Note, Tibcon is a supplier of motor capacitors

...

...

Continue reading at CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see CHOOSE a START RUN CAPACITOR FAQs-2 - more-recent questions and answers about how to select a replacement motor capacitor.

Or see these

Recommended Articles

- BASIC ELECTRICAL TESTS for BURNED OUT COMPRESSOR MOTORS

- CAPACITOR TYPES, for MOTORS

- CAPACITORS for HARD STARTING MOTORS

- CAUSES of HARD STARTING ELECTRIC MOTORS

- CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS

- COPELAND ELECTRICAL HANDBOOK [PDF]

- HARD STARTING COMPRESSOR MOTORS

- HOW a STARTING CAPACITOR WORKS

- HOW to TEST the MOTOR to ID TERMINALS

- LOCATE the STARTING CAPACITOR

- MOTOR CAPACITOR WIRING GUIDE

- STARTING CAPACITOR SAFETY

- TEST a MOTOR START or RUN CAPACITOR

- ELECTRIC MOTOR CENTRIFUGAL SWITCH or PTC PRD

- ELECTRIC MOTOR DIAGNOSTIC GUIDE

- HARD STARTING ELECTRIC MOTOR CAUSES

Suggested citation for this web page

CHOOSE a START or RUN CAPACITOR FAQs at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.