Electric Motor Capacitor Test Procedures

Electric Motor Capacitor Test Procedures

Testing Guide to A/C Compressor & Other Electric Motor Start-Boost & Run Capacitors

- POST a QUESTION or COMMENT about installing a hard-start capacitor to get an air conditioner motor, fan motor, or other electric motor running.

How to test an electric motor capacitor:

This article gives a description of electric motor capacitor test procedures to determine if a capacitor is damaged or working normally & test procedures to measure the capacitor's capacitance or microfarads, MFD, or uF to determine if it is working within its rated capacitance range.

This article series gives electric motor start-run capacitor and hard-start capacitor installation instructions to get a hard-starting air conditioner compressor motor, fan motor, refrigerator, or freezer compressor or other electric motor (such as a well pump) going.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Start or Run Capacitor Diagnostic Checks: How to Use a VOM or Multimeter to Test a Motor Starting Capacitor

Discussed here: description of electric motor capacitor test procedures to determine if a capacitor is damaged or working normally & test procedures to measure the capacitor's capacitance or microfarads, MFD, or uF to determine if it is working within its rated capacitance range.

Discussed here: description of electric motor capacitor test procedures to determine if a capacitor is damaged or working normally & test procedures to measure the capacitor's capacitance or microfarads, MFD, or uF to determine if it is working within its rated capacitance range.

If an electric motor that uses a starting or run capacitor won't run try replacing the capacitor.

If the electric motor runs, check the current draw (AMPS) on both of the capacitor leads. You should see current draw on both leads. If not the capacitor is probably failed. Here are details:

There are two quick indicators of a bad electric motor start capacitor:

- The motor will draw higher than normal current when it is trying to start, having trouble starting, refusing to start at all, perhaps humming and overheating, and perhaps tripping an internal thermal overload switch or tripping the circuit breaker or blowing a fuse.

[Click to enlarge any image or table]

These symptoms may come and go depending on the operating state of the A/C or heat pump system: when the system is operating under load (high refrigerant pressures are present) the compressor motor will have a harder time starting than when the system has been turned off for some period and refrigerant pressures are equalized.

See REFRIGERANT PRESSURE READINGS & CHARTS

Intermittent compressor hard-starting: A bad starter capacitor can cause the compressor to fail to start sometimes while other times it seems to start and run OK.

Compressor hard starting, fan runs OK: If the compressor is having trouble starting or won't start at all but the condenser fan runs just fine, we figure it's a bad start capacitor or possibly a bad run capacitor.

Compressor and condenser fan both won't start: we suspect a bad capacitor that is designated as a combination start/run capacitor unit wired to both devices.

A service technician can test for a failing motor by measuring the current draw in amps during start and run, and by comparing the result to information on the motor's data tag. - A quick test of the starter capacitor itself can indicate that it is faulty as we detail here.

How to Use a VOM to Check a Motor Capacitor - step by step

- Turn Off Electrical Power

Watch out: First, turn off electrical power to the motor.

Watch out: you may also need to discharge the capacitor to ground by touching both terminals together using a metal screwdriver that you hold only by its insulated handle.

Don't touch the metal screwdriver shaft or if you live, you'll never forget the experience! There are dangers of electrical shock or worse. - Label the wires & terminals

Watch out: after taking note of the various wire colors or identifies and labeling them if necessary to relate the wire to the terminals on the capacitor, then disconnect all external wires from the capacitor before testing it;

For a combination start/run capacitor the terminals on the cap will be marked

S = start wire connector

R = Run wire connector

C = common connector - Remove the capacitor: f possible, remove the capacitor from the electric motor. While you have the capacitor in hand and after it has been discharged, take note a of all of the markings on the capacitor including

Number of terminals and any terminal identification markings

Capacitor ratings in uF - Prepare to test the capacitor: set your VOM or DMM to Ohms reading and set the ohms to its highest setting. Use the DC setting and terminals.

Watch out: See DMMs VOMs SAFE USE OF or if you need,

TEST EQUIPMENT, ELECTRICAL - Test the Motor Capacitor: attach the ohmmeter's leads to the capacitor's terminals, one pair at a time and check the reading on the ohmmeter.

- Ohm reading drops to zero then slowly rises: the capacitor is probably serviceable

- Infinite resistance: If the ohms reading stays at a very high value or at infinity then the capacitor has an open circuit internally and is probably shot. Replace the capacitor.

- Low or zero resistance: If there is zero resistance (zero ohms) the capacitor is shorted internally. You are seeing low or no resistance, or very low ohms reading. This capacitor is no good. Replace this capacitor.

If you reverse the + and - leads of the DC ohmmeter it will repeat. If you do not see any resistance in the capacitor then it has an internal short and it's shot - you need a new one.

- Re-Use or Replace the Capacitor: if the tests showed the capacitor is defective or doubtful replace it.

See CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS - Install the electric motor capacitor: if the capacitor tested as good, re-install it using the same wiring connections as you found originally. If you had to buy a new capacitor, install that one in its place.

At MOTOR CAPACITOR WIRING GUIDE we show how to hook up a typical capacitor.

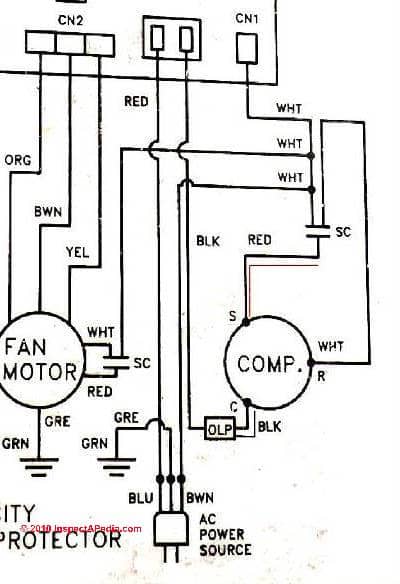

In the partial wiring diagram above, the compressor (COMP) is at lower right, and the component labeled SC shows the position of the starting capacitor in the air conditioning equipment's wiring schematic.

- Here is the

FULL WIRING DIAGRAM [image] for this portable air conditioner. - Here is a simple electrical

WIRING DIAGRAM for a WINDOW or ROOM AIR CONDITIONER [PDF from Sears Roebuck]

Watch out: while you might get lucky by finding that just replacing the starter capacitor fixes an air conditioner compressor, a fan motor, or another electrical motor, a hard-starting motor can be an indication that the more expensive A/C compressor or electrical motor is itself beginning to fail.

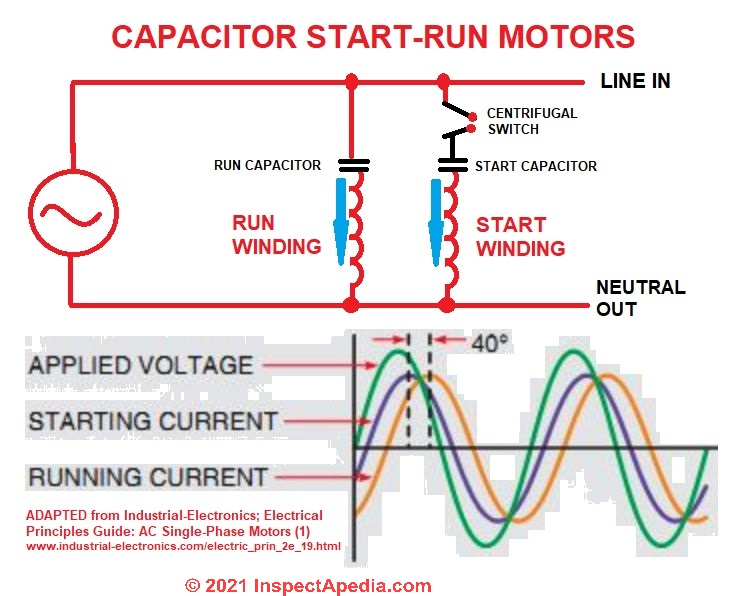

Difference Between a Starting Capacitor, a Run Capacitor, and a Dual Run Capacitor

A starting capacitor has the single job of giving a very large voltage boost to a motor to start it spinning. It does not keep at the job once the motor is operating. The rating on a starting capacitor will include a high MFD number and the operating voltage range. Temperature ranges and other data may also be provided on all caps.

A run capacitor has the job of keeping an electric motor spinning. The rating on a run cap will include the MFD rating and voltage range.

Dual run capacitors combine two different capacitor ratings and provide run support for two different motors. In a common air conditioning application these would be the compressor (marked Herm), and the compressor/condenser unit fan (marked F or Fan).

The rating on a dual run cap will include two MFD ratings and a voltage range, such as 45/5/440 which translates as

- 45 MFD (typically to run a compressor motor)

- 5 MFD (typically to run a fan motor)

- 440 (the maximum voltage range)

How to Measure the Capacitance of a Run Capacitor or a Dual Run Capacitor

A standard digital VOM or multimeter that includes a MFD (microfarad) option is set (on its dial or selector) to MFD and with the capacitor disconnected from any other wiring the VOM probes are touched to two terminals on the capacitor.

A standard digital VOM or multimeter that includes a MFD (microfarad) option is set (on its dial or selector) to MFD and with the capacitor disconnected from any other wiring the VOM probes are touched to two terminals on the capacitor.

- For a two-terminal start capacitor touch the probes to the only two terminals that will be present.

- For a standard two-terminal run capacitor just touch the probes to the only two terminals that will be present.

- For a dual-run capacitor select the common and herm (for the compressor circuit), or in a separate test, the common and fan (for the fan motor circuit).

If the uf/mfd reading on the meter is close to the rating stamped on the capacitor label then the device is in normal condition. For example on a 45MFD (or uf) capacitor your meter should read close to 45.

Watch out: do not attempt to touch or measure equipment with power on and wires in place. You could be injured or killed or could cause a fire or explosion. Watch out that capacitors can store energy and deliver a shock even after power has been turned off.

General advice: Electrical Tests to Check HVAC Blower Fan Motor or Outdoor Compressor Fan Motor Winding on Heating or Cooling Equipment or on Other Electrical Motors

Example: testing a blower fan motor winding: referring to the electrical diagram for your equipment, unplug electrical connectors at the fan motor. Measure the resistance between each lead wire with a multimeter or VOM. The multimeter should be set in the X1 range. For accuracy, don't measure when the fan motor is hot, allow it to cool off.

When the resistance between each lead wire are those listed in the specifications for your equipment the fan motor should be normal. Zero resistance or infinite resistance are indicators of a problem.

More examples of checking wiring:

see BURNED-OUT COMPRESSOR.

See HARD STARTING COMPRESSOR MOTORS

also TIGHT or SEIZED AC COMPRESSORS for more details about old or failed compressor motors.

Make These Simple A/C Compressor Checks Before Adding a Hard-Start Capacitor

Most electrical problems in air conditioning systems are in the compressors and their relays or motor overload switches.

Most electrical problems in air conditioning systems are in the compressors and their relays or motor overload switches.

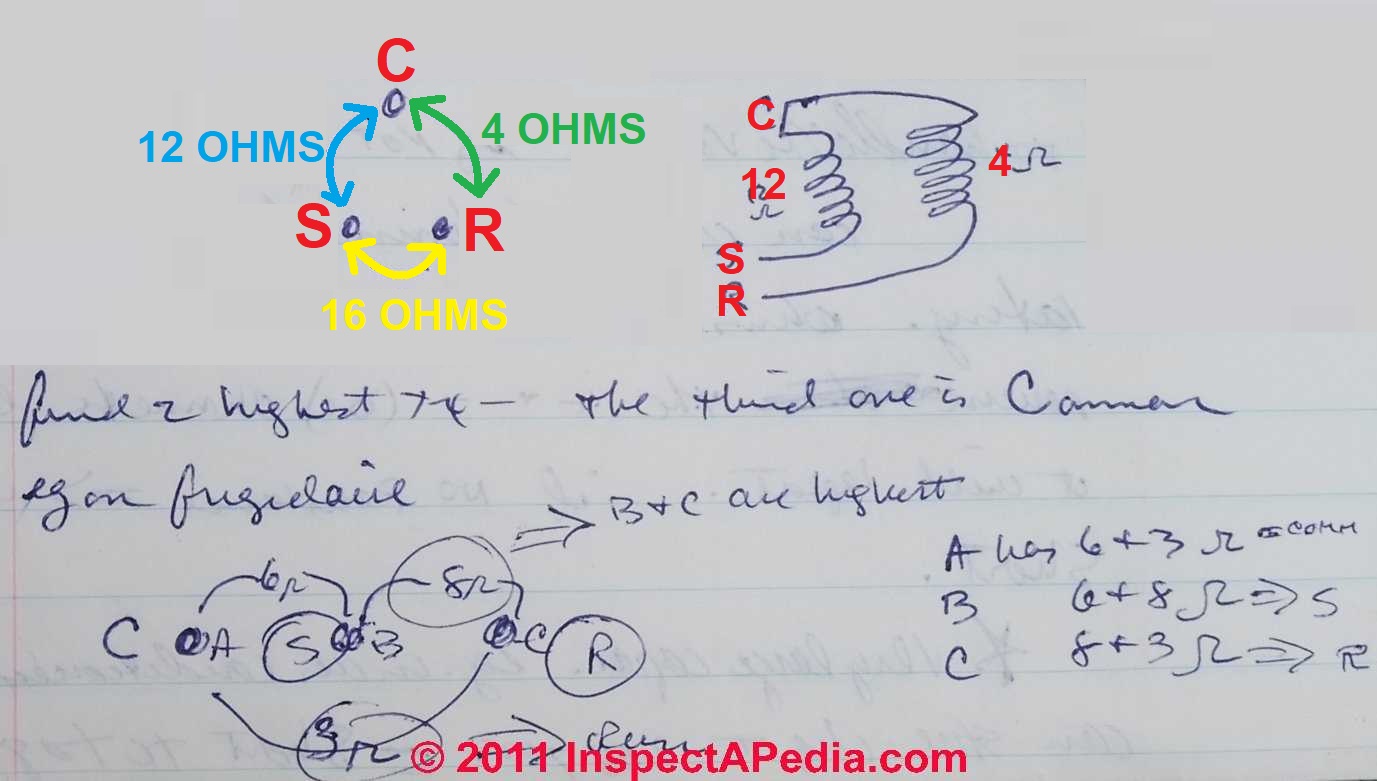

In a single phase (common residential A/C) compressor you can verify with an ohmmeter whether or not the A/C compressor is bad.

[click to enlarge the image at left]

A fractional horsepower electrical motor should show different electrical resistance between the three terminals (Start, Run, and Common) as we illustrate just below.

Find the two highest resistance terminals.

The third one will be the common terminal.

Our example is for a Frigidaire compressor motor.

In our capacitor testing and wiring sketch at left, you note we use the letters S, C, and R to identify the usual terminals to which a start/run capacitor is wired. On many systems these terminals may be labeled so that the three leads on a start/run capacitor can be wired correctly:

- S = start wire connector

- R = Run wire connector

- C = common connector

At MOTOR CAPACITOR WIRING GUIDE we show how to hook up a typical capacitor.

Electric Motor run speed side note: Incidentally while most electric motors are marked with a data tag indicating the motor run speed (in RPMs) it's worth noting that the number of run coils is what determines the run speed of the motor.

Two-coils marks a motor that runs at 3450 rpm (3600 rpm "nominal"),

while 4 coils marks a 1725 rpm motor. (120V, 60 cycle/sec x 60 sec/min = 3600 rpm).

Electric Motor Start / Run Capacitor Testing & Selection References

- AFCAP MOTOR START and RUN CAPACITORS [PDF] AFCAP (African Capacitors Limited), Metallized polypropylene film capacitors for

motor running applications, These capacitors are designed for general A.C. applications and particularly for:

- starting and running of mono-phase induction motors.

- single-phase supply of three-phase asynchronous motors.

- series and parallel power factor correction of fluorescent and discharge lamps. web search 08/05/2011, original source: http: //www.afcap.co.za /manual/Part2.pdf; 2018/07/11 update: the original source link is no longer valid - Ed. - Emerson, COPELAND ELECTRICAL HANDBOOK [PDF] free download from Emerson Climate Controls, at InspectApedia.com

- NPTC ELECTRIC MOTOR CAPACITOR TEST PROCEDURE [PDF] Alabama A&M & Auburn Universities Extension, National Poultry Technology Center, Duncan Hall

Auburn University, AL 36849 USA, Tel: (334) 844-4444 - retrieved 2023/10/25, original source: aces.edu/blog/topics/farming/nptc-tools-of-the-trade-testing-a-motor-capacitor/

This PDF gives a detailed step by step procedure for performing simple electrical tests of a start or run capacitor. - Sears, Kenmore model 580. 75121 room unit air conditioner wiring diagram", Sears Roebuck window air conditioner wiring diagram for a typical room or window air conditioner

- SUPCO, Sealed Unit Parts Company, PO Box 21, 2230 Landmark Place, Allenwood, New Jersey, 08720, Tel: 732-223-6644, 201-449-3300, email: info@supco.com, Website: http://www.supco.com/ provided the compressor starting capacitor and packaging information (purchased by the author from an air conditioning parts supplier in New York) - our example uses a Sealed Unit Parts Company Solid State part No. RSC 10 115V starting capacitor which was designed for installation on refrigerators and freezers. See www.supco.com/

- [1] "The E Class Advantage", Supco (op cit), describes the company's advanced start/run capacitor products. Web search 08/04/2011, original source: http://www.supco.com/eclassadvantage.htm Quoting from that article:

The SUPCO E-Class Series comprise the most advanced developments in start device technology:

1. Voltage sensing technology that monitors for motor start (current sensing devices require internal fuse protection).

2. A 2-wire connection that simplifies installation

3. A secondary timing circuit that ensures that the capacitor is not permanently left in the start winding circuit

4. A fully electronic device - minimizing the limitations of mechanical devices and secondary fusing associated with triac devices

5. A start device matched with an appropriately sized capacitor to cover the range of compressors for the intended application (one size does not fit all)The use of compressor start devices results from a need to ensure that a compressor (usually air conditioning) will start under voltage conditions that are less than ideal.

As discussed, several options exist in the market to address compressor start concerns. Start devices exist in many forms for specific applications. SUPCO provides a full range of products in all relevant technologies to effectively match the proper start device to the application.

Care should be taken to utilize a device that meets the requirements of the job.

Extra caution should be observed when employing the "one-size-fits-all" and "a bigger capacitor is better" approach to applying a start device.

Consult SUPCO, a manufacturer with a complete product range, to ensure the greatest success in the start device application.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-01-22 by (mod) - My ceiling fan will run if I push it to get it going

If your fan motor uses a start/run cap that would explain what you describe,

I'd also look for

- trying to start a muti-speed fan with the speed control set at its slowest speed position

- a loose wire connection

- bad switch

- failing fan motor

On 2020-01-21 by Don

My ceiling fan will run if I push it to get it going, but won't start up by itself. What is failing?

On 2018-04-26 by (mod) -

Thank you for the comment, Freddy. Can you point us to a specific product or manufacturer's instructions that describe the procedure you describe for testing capacitors?

On 2018-04-25 by Freddy

I disagree with instructions or at least needs clarification. You will see almost a short as you touch the DMM leads (in ohms function) to the terminals.

Depending on the value of capacitance it may take a while (or never) reach "infinite"

Some caps have bleeder resistors and some large electrolytic s and start caps have inherent DC leakage...

On 2017-12-28 by (mod) -

RE-Posting:

Tibcon Capacitors said:

Nice Blog about...good information .

Editor's note: Tibcon, a company located in India, sells motor run capacitors and can be contacted at

Tibcon

Corporate Office

803, Manjeera Trinity Corporate, KPHB, Phase III, Kukatpally, Hyderabad, Telangana - 500 072, INDIA

Phone:

+91 40 48194444 Email : sales@tibcon.net

On 2016-12-20 by (mod) -

Jim:

sounds to me as if the motor is failing, perhaps with a binding bearing.

On 2016-12-19 by Jim

I have a craftsman 6 hp air compressor. Motor starts, runs a few seconds then trips the breaker. Compressor is about 12 years old, and has been running fine until 3 days ago. Removed motor from compressor and bench wired a plug to it, when it runs wire gets hot.

On 2016-07-29 by (mod) -

An ammeter, properly connected, will read the current draw on the wire being sampled; If the bad cap is preventing the motor from starting you might still see current draw on the wire.

On 2016-07-29 by Anonymous

can you read amps on a ammeter on a running motor with a bad capacitor

On 2015-12-12 by (mod) -

Joe:

We have published details on using and buying DMMs

See the DMMs we list at

https://inspectapedia.com/electric/Electrical_Measurement_Tools.php#DMMSources

On 2015-12-10 by Joe W.

Anyone know a good source for a cheapo Digital Multimeter (DMM) with µF (micro-Farads) measurement capability using its test probes?

My cheapo from Harbor Freight ($20) measures capacitance, but only through special test points located next to the dial/selector, rather than using the test probes. I'm thinking this requires a higher-end DMM due to the capacitance of the test probes themselves affecting the measurement?

On 2014-10-06 by Diane

I hope someone can help me fix my goodman 3 ton heat and air unit heat pump.

The trouble I'm having is I heard this clicking noise like the fan trying to come on, but never did until

I took a stick and pushed the blades and they started moving than I went inside the house and the air coming out was not cool could anyone tell me where to start checking, I,m going to try to fix this myself .

Question:

(Feb 21, 2014) Anonymous said:

is it possible to rebuild a submersible well pump

Reply:

Yes ... maybe; it depends on the condition of the pump casing, parts, an in my opinion, an accurate diagnosis of the trouble; at some point rebuilding is not cost effective. Indeed there are specialists (H Shreck in Poughkeepsie used to be one of them) who rebuild electric motors of all kinds.

There are also many water pumps whose design makes it quite reasonable to replace pump impellers.

So to answer your question, I dunno - it depends on what's broken.

Question: fan will start but won't keep running.

(June 1, 2014) Anonymous said:

The fan on my Conquest 80 will not stay on (interior fan). It starts and then stops after a few seconds. It was installed in 2005. Help.

Reply:

Anon,

The start capacitor is for getting a motor started, not keeping it running.

Often motors have two windings, a start winding and a run winding. Your motor's run winding may be damaged.

Or your fan motor may require a dual capacitor (start and run) or a separate run capacitor to keep it spinning.

Or your system may have a faulty control.

Question: will a hard start capacitor reduce current drawn and stop tripping a breaker

(June 7, 2014) Joel said:

I have a commercial hood & exhaust fan (120v) running in a food truck that is used for catering. We occasionally need to run off a generator (3000w) and we've found that the fan cause the generator overload to trip. The fan has been tested and observed to draw 8 amps running at full speed. Given this, would it be possible to add a hard start kit, such as SUPCO SPP4E? Will need to confirm the motor size, just wondering if this would help.

The total draw of all items is less than 20 amps and the generator is capable of supplying 25 amps constant.

Thanks for the advice.

Reply:

Joel I think the problem lies elsewhere and needs some further diagnostics. I suspect that your total current draw is exceeding the ability of the generator - you may be running more than the fan, such as lighting, a cooler, toasters, other electrical appliances. If it were just the fan, drawing 8A, it has no business tripping the breaker.

Put another way if the problem is the fan and there are NO other appliances running, then there is a failing fan motor drawing high current, or an electrical short circuit or other unsafe condition to find and fix.

A start capacitor or a run capacitor won't change the current drawn by the motor.

...

Continue reading at HOW to TEST the MOTOR to ID TERMINALS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BASIC ELECTRICAL TESTS for BURNED OUT COMPRESSOR MOTORS

- CAPACITOR TYPES, for MOTORS

- CAPACITORS for HARD STARTING MOTORS

- CAUSES of HARD STARTING ELECTRIC MOTORS

- CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS

- COPELAND ELECTRICAL HANDBOOK [PDF]

- HARD STARTING COMPRESSOR MOTORS

- HOW a STARTING CAPACITOR WORKS

- HOW to TEST the MOTOR to ID TERMINALS

- LOCATE the STARTING CAPACITOR

- MOTOR CAPACITOR WIRING GUIDE

- STARTING CAPACITOR SAFETY

- TEST a MOTOR START or RUN CAPACITOR

- ELECTRIC MOTOR CENTRIFUGAL SWITCH or PTC PRD

- ELECTRIC MOTOR DIAGNOSTIC GUIDE

- HARD STARTING ELECTRIC MOTOR CAUSES

Suggested citation for this web page

TEST a MOTOR START or RUN CAPACITOR at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- George Fazio, reader, contributed comments on failed starter capacitor diagnosis by noting the bulged capacitor ends. 09/25/2009

- Troubleshooting Compressor Problems," Henry Puzio, Fuel Oil & Oil Heat with Air Conditioning Magazine, June 1993, p. 39

Tom Morris, Engineer, capacitor discussion and correction to the original data. Email to D Friedman 5/29/2006 - Thanks Tom for critical editing. The text above explaining about capacitors was suggested by Mr. Morris. The original text of the 1993 compressor diagnosis article had the resistance explanation backwards. - Thanks to reader Diane McGivney for asking about air conditioner compressor motor starting capacitor costs and typical air conditioner service call fees - (May 2010)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.