Electric Motor Diagnostic FAQs

Electric Motor Diagnostic FAQs

Questions & Answers on How to Diagnose & Repair Electric Motors

- POST a QUESTION or COMMENT about how to troubleshoot electric motors such as air conditioning compressor motors, heating equipment burner or fan motors, swimming pool motors, water well pump motors

Electric motor test & repair diagnostic FAQs:

Questions and answers about diagnosing and fixing electric motors. The page top photo was taken of of an oil burner electric motor not an air conditioning blower fan motor or pump motor, but you'll see that all of these electric motors look a lot alike.

This article series describes A/C electrical motor troubleshooting: here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor problems for motors found on HVAC equipment in buildings such as air conditioners, furnace or air handler blower fans, oil burner motors, well pumps, and condensate return pumps.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

A/C Electric Motor Troubleshooting FAQs

at left our photo illustrates the motor as typically found in a direct-drive HVAC blower or air handler assembly.

at left our photo illustrates the motor as typically found in a direct-drive HVAC blower or air handler assembly.

These questions and answers were posted originally

at ELECTRIC MOTOR DIAGNOSTIC GUIDE - topic home. Be sure to check that article.

Article Contents

- MOTOR BLOWS FUSE / TRIPS CIRCUIT BREAKER

- MOTOR CAPACITOR WIRING

- MOTOR CONTROL SWITCH

- MOTOR CYCLES ON & OFF or SPEED VARIES

- MOTOR DRAWS HIGH CURRENT (AMPS)

- MOTOR OIL for ELECTRIC MOTORS

- MOTOR POWER SUPPLY CHECK

- MOTOR SPEED PROBLEMS, TOO SLOW, TOO FAST

- MOTOR WINDING REPAIR SUPPLIES

- MOTOR RUN DIRECTION

- MOTOR WON'T START / WON'T RUN

- OTHER ODD ELECTRIC MOTOR DIAGNOSTIC TROUBLES

...

Why is my motor drawing too much current unless I smack it?

Hey, I have a 9v dc motor with brushes. It is behaving weirdly. When I hook it up with no load to a power supply and start it, it draws about twice as much current as it should (0.6-0.7A). It also sounds bad.

When I hit it with my hand, the current goes back down to the normal range and it gets quieter. It does not do this behavior when it is under load.

What's going on? The commutator looks clean and the brushes aren't worn out so I don't think carbon buildup is an issue. Thanks. On 2022-07-28 by Tim

Guesses InspectApedia-911 (mod) -

@Tim,

Odd indeed.

Usually high current draw says a motor is having trouble starting, often because of a failing bearing or an excessive load.

But your high current draw is when there is a load. Could the load be tweaking the bearing at the motor's drive shaft?

Other guesses: there could be a failing bearing OR a winding that opens.

...

Electric motor won't start, drawing high amps but spins freely

Electric motor wont start, draws 27.5 amps and wont turn. Motor is free and can spin by hand. It is a 1/2 hp lifttech motor. Any ideas what could be wrong ?

Reply:

I suspect a bad start/run capacitor or an open start winding. If the amps draw you cite exceeds the starting amps on the motor data plate then it may be shorted internally. That seems most likely.

Table saw motor doesn't work when connected to power

I have a Delta 10" table saw motor that does not work.

I have pulled the motor apart: brushes are solid, the commutator is good, the windings appear to be intact, the electrical connections are good.

This motor does not have a capacitor that I can find. Off the saw, the motor being plugged in does nothing. Can you suggest anything or is this motor no good. On 2022-07-24 by Ernie

Tip by InspectApedia-911 (mod) - test the windings

@Ernie,

Have you actually tested the windings?If not I'd start there

Question: Spa pump motor won't run if stops in some positions

I have a 5 hp spa pump motor that fails to self start if the rotor is positioned anywhere within about a 90 Degree segment of the entire 180 degree rotation.

In other words if it stops at anywhere from 12:00 to 3:00 it will hang and not begin spinning without a manual assist.

Anything outside of this arc and it works fine.

We just rebuilt this motor with new bearings, start and run caps.

We even hooked another start cap in parallel with the original with no help. Any idea why this is happening? (June 16, 2015) Mike said:

Reply:

Mike

Do you think it's possible that the motor has an open start winding? Also, double check that the start / run caps are working - that the replacement parts were ok.

Update on trouble with re-built electric motor

We rebuilt two identical motors. The other is fine. We swapped all the caps between the motors also with no effect on the problem one. I thought we might have overheated the winding but it looks brand new and has no smell of burning inside.

If the start winding was open, why does the motor start as long as it doesn't start from that arc? I was wrong about that angle as it is 90 degree of 360 degree. I suppose we'll tear them down again and check resistance. Could the centrifugal start up switch be at fault? (July 3, 2015) Mike said:

Reply:

Very interesting Mike. Could a winding be opening when the motor spins - or some other part moves?

Those defects can be hard to spot by mere visual inspection.Mike said: motor's centrifugal switch failure caused start-up problems

I lost the link to here until now. The spa motor with the start problem (July this year).We tore it down again checking all we could and polished the kick out switch contacts with 2000 grit sand paper.

This reduced that 90 degree no start arc to about 10 degrees.I think it's resonable to assume that the switch is the problem. Now to figure out where to buy one. (July 3, 2015) Mike said:

How to fix a hard starting electric motor

My motor has a hard start and it was due to a high voltage what can I do ? On 2021-09-19 by Owen Kigula

by danjoefriedman (mod) - motor might have been damaged - hard start capacitor?

@Owen Kigula,

You can try and stalling a hard start capacitor kit but I'm not optimistic as it sounds as if your motor has been damaged.

Why my electric motor hums on start-up

I have a two speed electric motor for my wife's Spa/Hot tub, but it only has a single start capacitor. The issue is that the motor will start properly when power is applied to the high speed terminal, but won't start (just 'hums') when power is applied to the low speed terminal.

If I get the motor started with the high speed terminal and then switch power to low speed winding, it will continue to run just fine, but it won't start up on that winding.

It used to start up on either winding. What is the issue? I thought that if the capacitor was bad, it wouldn't start on either setting, but starts fine on one but not the other. On 2021-05-08 by noah

Answer by (mod) -

@noah,

It could be that the motor or a bearing in the motor is failing , binding the motor, causing it to hum rather than start;I prefer to measure the motor's starting current draw (amps) but a quick check that most service techs might make is to simply swap in a new start capacitor. That may give you some more life out of the motor.

Compressor motor hums, stops; reset button doesn't seem to work

Have an air compressue motor that will hum for a few seconds before stopp[ng. Has a reset button on motor, but doesnt seem to reset. Have a voltage supply of 123 volts now, but before I corrected the recepticle connection, it wasnt getting the 120 volts that it needed. On 2021-03-20 by Dennis E Strawn

Suggestions by (mod) -

@Dennis E Strawn, reset of a tripped motor safety switch can require some time to allow the motor and overheat sensor to cool down.

And yes, low voltage can prevent a motor from running or starting and might result in a humming motor.

Why has my electric motor lost torque and why does it trip the breaker?

I have 2hp motor that will start. However, the longer it runs the less torque it has. then it will pop the breaker, It goes on a compressor. On 2021-04-13 by Chjris

On 2021-04-13 by (mod) - causes of motor loss of torque and increased current draw

@Chjris,

Most-often the motor problem you describe, loss of torque and increased current draw (until it trips the circuit breaker) is caused by

1. overloading of the motor: for example if the compressor itself whose piston and other moving parts is failing due to wear or poor lubrication or a bad bearing, or due to backpressure load on the compressor, then the electric motor driving the compressor will face an abnormally high load that in turn can cause the motor to overheat or draw excessive current. Ultimately the compressor itself may seize or the motor driving it may seize.

2. failing bearings in the electric motor itself, again causing a resistance to turning or moving parts that leads to overheating of the motor itself, higher current draw, until the motor trips the circuit breaker; ultimately the motor itself may seize.

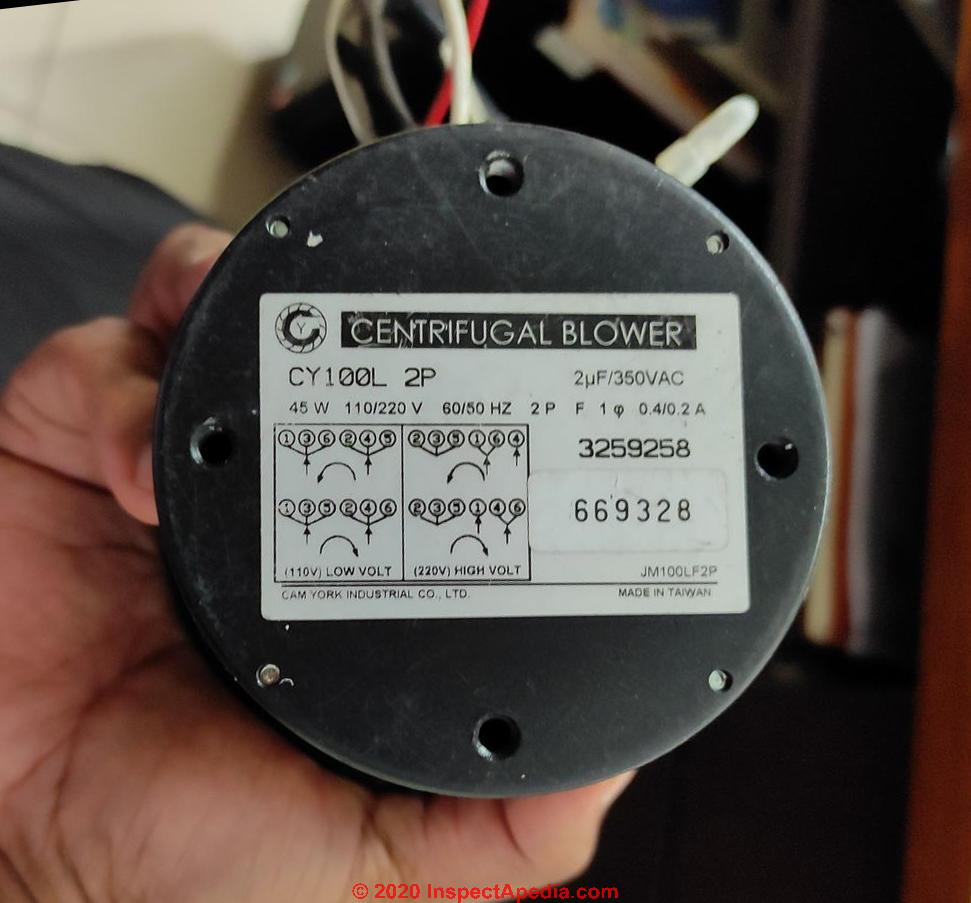

Diagnose why 1 or 4 new electric motors won't run

Hi we got 4 new motors and one also not working it's blower type ,

Hi we got 4 new motors and one also not working it's blower type ,

I am giving direct supply 220v not with blower set,

for checking purpose

but no one is rotating

mayI know the reason On 2020-06-11 by Lakshmipathi

by (mod) -

Lak

If that motor is new and came with three other identical motors, and if it was wired properly but does not run, then the motor is defective, perhaps seized or with a manufacturing defect - not something we can decide from photo alone.

However a ELECTRIC MOTOR DIAGNOSTIC GUIDE we describe diagnostic testing procedures for such electric motors.

Question: Blower Fan only runs 30 min and cuts off.

(Aug 22, 2014) Blower fan internal heat switch cuts motor after 30 min. said:

Had an HVAC CO provide a free inspection. A/C was working fine for prior 1 yr. Tech added refridg. and change dirty filter in attic. Now Blower Fan only runs 30 min and cuts off. Back on in 20 min.

After 4-5 more visits, Tech wanted to sell me a new A/c at $8-$10,000. Found bent blower door and improper/wrong filter. Also, refridg. was 2 lbs low so none had been added by Tech.

What type of Blower Fan filter provides "0" airflow resistance...?

Thank very much,

New motor, cage bearings oiled and spinning freely. New fan belt.

I removed the "new" filter and motor is now running cool enough that it is not cutting off from overheating.

So I guess I am looking for a filter with no resistance.. any thoughts?

Reply:

Blower

I'm surprised that a tech would add refrigerant if the system was working properly - though we should keep in mind that a skilled HVACR tech may still not be an English major - so may not have explained what s/he was doing or why. Now I'm not sure what's wrong, but that offer of a costly new system is disturbing.

Ask to be shown and told what expensive parts are shot and how that diagnosis was made.

Then call a second HVAC company and ask for a second opinion before we accuse anyone of something further. If your system is an old one it might be at end of life, but working up until the time the tech touched the system is indeed worrisome.

A filter that gave zero air resistance would probably also not filter air passing through it.

A very very low air flow resistance air cleaner that is widely used is an electrostatic air cleaner. However usually we see these used in combination with a more conventional particle filter.

Kudos on getting the new motor going.

There are no zero-resistance air filters - since filtering will always create some resistance. But filters are rated for flow resistance.

About the lowest flow resistance type is an electrostatic air cleaner. Typically those are preceded by a washable filter and some by a low-resistance fiberglass or other paper filter.

Take a look at AIR FILTER OPTIMUM INDOOR

Question: cooker hood motor hums but runs if I give the fan a spin

Hi. I have a cooker hood motor that hums when fan speed is selected but does not turn. I have taken it out from the impeller casing, and if I give ithe shaft a quick turn whilst power is on, the motor spins, but as soon as turned off, does not restart on button. Any help please - June 16, 2014) Robert holt

Reply:

Robert,

It sounds as if the fan motor needs a new start or start-run capacitor.

...

Exhaust fan motor doesn't run at full speed

I just installed a brand new 1/2 hp 1725 rpm exhaust fan motor.

For some unknow reason, it doesn't seem to be running at full speed.

The capacitor is brand new on the motor, the wiring is perfect, the fan, bearings pulley, and belt are all new and running smoothly.

Just don't know why it isn't running as fast or strong as the same 1/2 hp motor we pulled out? Thanks for any suggestions... On 2022-04-01 by David Kruzona

Suggestions by Inspectapedia Com Moderator - First check the voltage supply to the motor

@David Kruzona,

Check the voltage supply to the motor and check the current draw or amps.Check for a bad run capacitor.

Check for a bad electrical connection or wire.

Check for a bad motor bearing.

Check for a bad run winding.

Diagnose why Adjustable speed electric hand tool loses power at higher speeds

I have an adjustable speed electric hand tool that loses power when I increase the speed via the control. Replaced control. no affect. What would cause the speed loss.? On 2021-11-09 by GLS Brian

Suggestion by Inspectapedia Com Moderator - adjustable speed electric hand tool loses power

@GLS Brian,

I don't know.

But it's possible that there is a winding that's opening when the motor tries to speed up or you simply have a defective switch or switch wiring.

I've also seen old Motors that would run at low speed but not at high speed because of a bad bearing

Why does my electric motor run more slowly than before?

My single phase electric motor tripped earth leakage and after remaking connections, runs again but at reduced speed - On 2020-09-13 by Eric Booth

by (mod) -

Could be a burnt winding or failing bearing or of course, low voltage.

Heat pump motor trouble getting up to full speed

I have a Waterco Aquanature 50xl heat pump for my pool.

After a normal cycle the fan stop, after the fan tries to start, but it takes 2-3 times before she gets going again at full speed.

I changed both capacitor (10uf 370v) and i still have the same problem. Anybody ever heard of that problem before ?

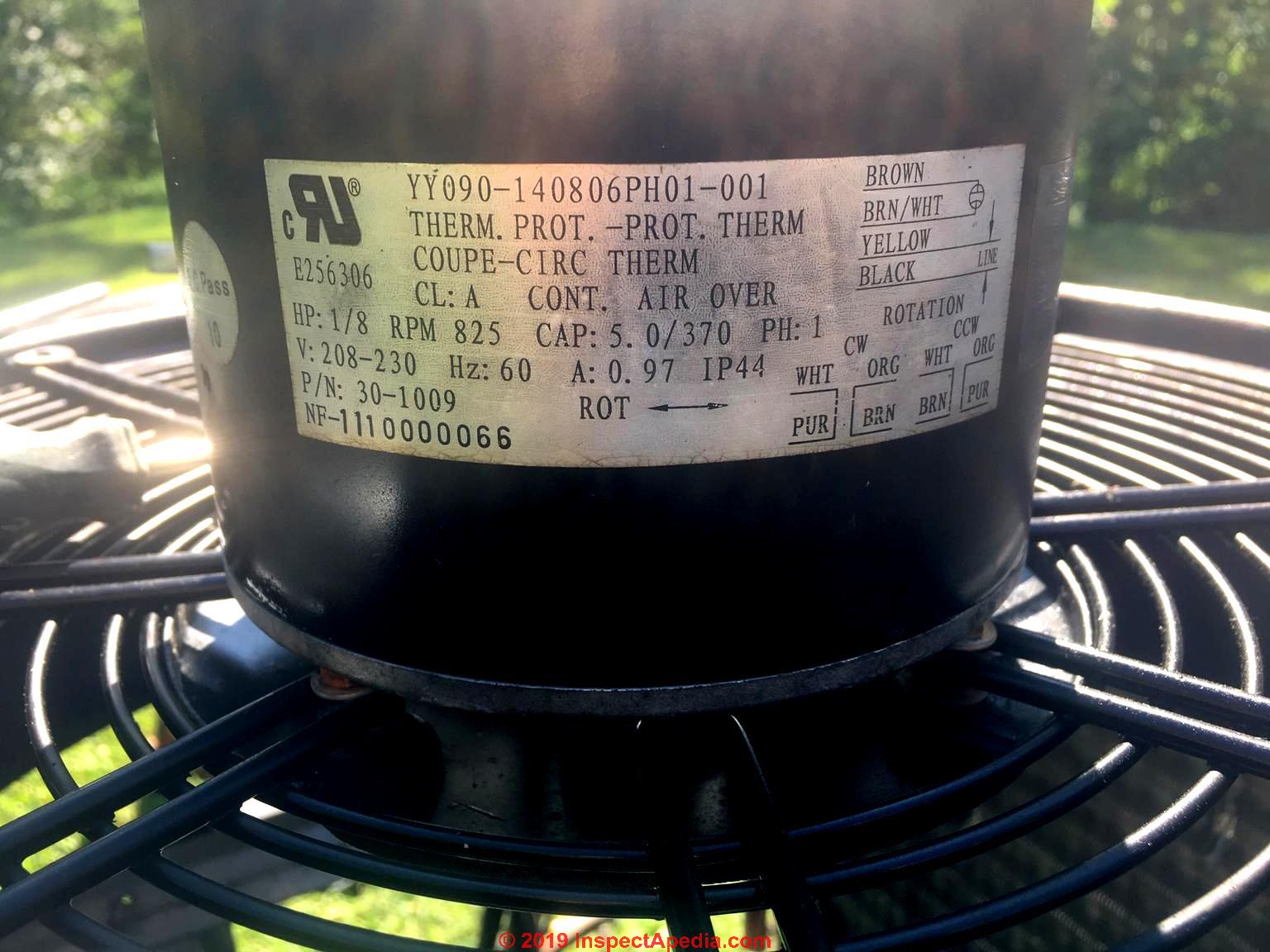

(relay good too) i thing it could be the motor but it's very expensive for just a test ? any help (motor 1/8hp 825rpm 208-230) Thnx for your help On 2019-07-30 2 by Tommy

by (mod) - how to check for bad electric motor bearings

It sounds to me like you want the motor tested.

That's really would be less than the cost of arbitrarily replacing the motor. There is something you can do first which is to remove the motor completely and simply confirm that the motor drive shaft will spin freely.

If the drive shaft doesn't spin easily or if it wiggles in its bearings, or if there is a lot of end play when you move the motor drive shaft parallel to its axis then the motor is probably damaged or its bearings are shot.

A motor rattling noise or vibration may also be a sign of failed motor bearings.

See details at RATTLING & VIBRATION noises from A/C or Heat Pump System

Pottery wheel motor speeds up when I apply load

I have taken a properly operating treadmill apart to repurpose the motor ,circuit board, sliding speed controller to operate a pottery wheel, the project is successful except as I'm putting a drag on the spinning wheel while shaping the pottery the motor seems to try and compensate for the reduction of rpm ,

and as I ease pressure on the pottery ie reduce drag the wheel speeds up much faster than the speed controller is set at , then slows to original set speed, this doesn't work for pottery as it slings the clay everywhere, I hope you have an answer for me, thx On 2019-04-25 by Dave N.

by (mod) -

It sounds to me as if the motor was designed to increase its output torque under load. That's something that you would expect a motor for a treadmill to do. Have you tried an independent speed controller?

Heat pump air handler motor speed varies every 20 seconds

Heat pump air handler variable speed works, warm air comes out vents. here's the serious problem though. when i go to high speed it runs for 20 seconds, then it goes to low speed for 20 second or so. this cycle continue and lately the high speed act like it wants to quit. any help would be appreciated. (Jan 31, 2015) Anonymous said:

Reply:

Anon I'm not sure if the problem is in the motor itself - sounds more to me like a control or relay problem.

See BLOWER FAN OPERATION & TESTING

...

Motor capacitor leads are both black: can I ignore polarity when connecting it?

A capacitor 250vac at 10 micro farad blew a hole in the side of my motor.

I order a new onne and there is no polarity marked on it.

It has two black leads comming from it and no polarity markings. Can this be installed disconcering the polarity ? On 2022-05-23 by Dwight

Answer by InspectApedia-911 (mod): yes

@Dwight,

Yes that's right

Do new motor capacitors come pre-charged?

I have purchased 2 capacitors for a 5 hp 220 v motor that hums. I assume they do not come charged. How do I do it? Spin the motor? 2021-07-17 by Bob R

Answer by inspectapedia.com.moderator - NO, but watch out!

@Bob R,

If you install the proper capacitor - correct size and specs - and wire it properly, and IF the capacitor was all that's needed, then turning on power to the motor will charge the capacitor and start the motor. You don't have to give it a spin.

If that doesn't work then there's another problem with wiring or with the motor itself.

Watch out: if you are not familiar with proper and safe electrical wiring you could be shocked or killed .

What are synonyms for electric motor capacitor: condenser, and other terms

Can a condenser be called a capacitor in case of water pump? - (Feb 11, 2015) Soham

Reply:

Yes Soham in some areas people use the term "condenser" where in most articles at InspectApedia we use the term "capacitor"

Synonyms for capacitor include: condenser and electrical-condenser.

Also I'd include

electrolytic capacitor

electrolytic condenser

Leyden jar, (and mis-spelled Leiden Jar)

trimmer or trimming capacitor

Capacitors store an electrical charge and release it in a nice big zap.

Other electrical storage devices are various types of batteries or storage cells.

Other "synonyms" posted at some thesaurus websites are nonsense and include very generic terms like CRT AC and Circuit that simply do not pertain.

...

Motor blows breaker after replacing bad bearing in electric motor

My 100v induction motor was squealing but running and starting fine. I found a bad bearing on the front so I change both front and rear bearings.

Everything turns very smoothly by hand but when I plug it in it now only buzzes and blow the breaker.

Can't figure what I did wrong. All went back together as originally. Finding it hard to believe it is the capacitor or centrifugal switch or contact since it ran before the bearing change. Ideas? On 2020-03-05 by jimbo -

Reply by mod

Jimbo

*IF* you can confirm that the new bearings were properly sized and installed and that the motor can spin freely if not connected to powerTHEN that sounds to me like a wiring error, damaged or shorted wire, or perhaps a lost or bad start capacitor.

It's possible that dis-assembly and re-assembly nicked a wire or connector belonging to the start cap.

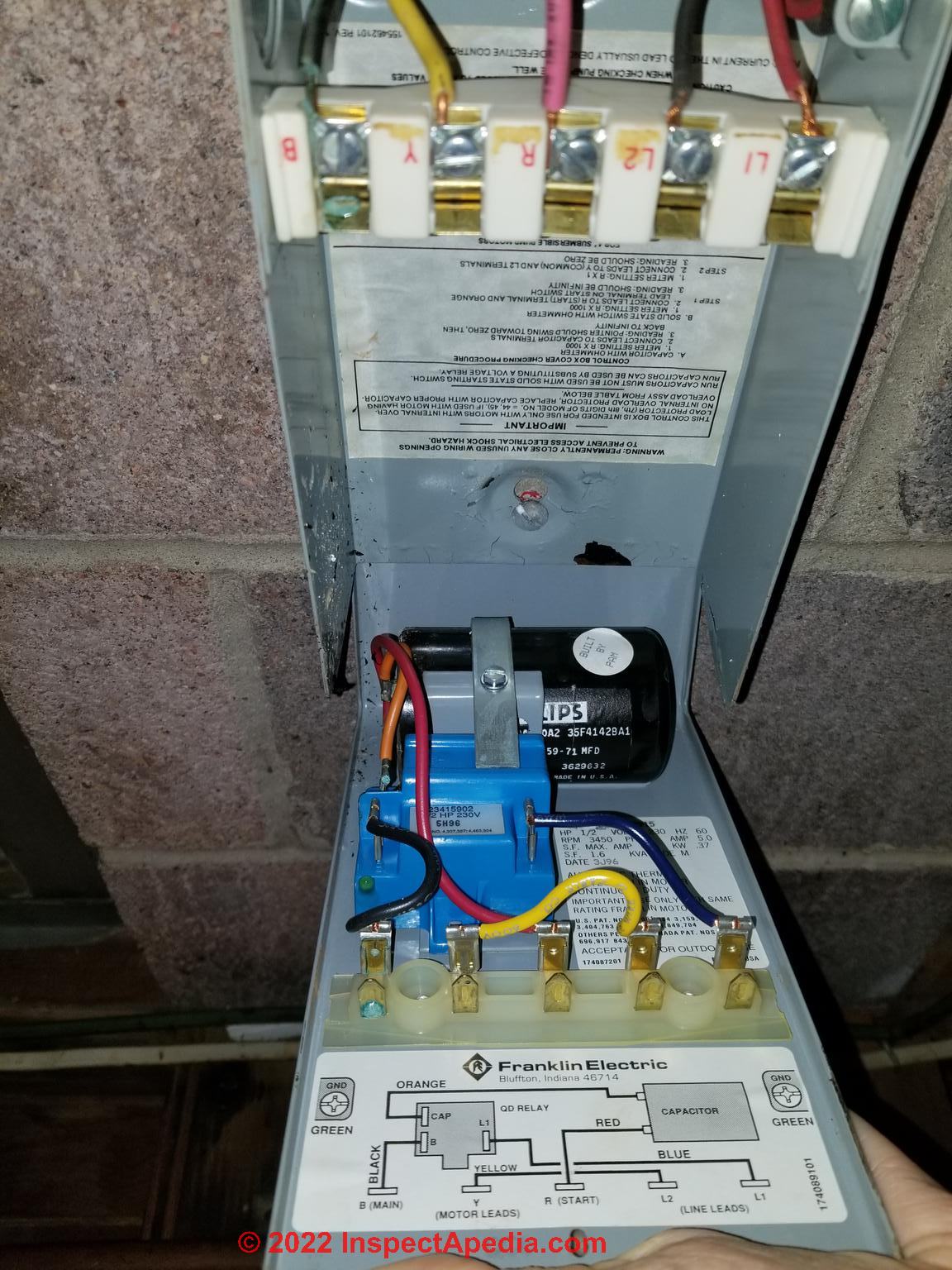

Diagnose well pump motor or conrol box: capacitor hole, control box sparks, circuit breaker trips

Here's a desription of the problem I am seeing with my well pump motor

Here's a desription of the problem I am seeing with my well pump motor

3 years ago the water was shut off with a water valve. Well pump was replaced in 1996. The well pump motor circuit was left on, but presumably no pumping was required, as no water was being used. I'm now trying to troubleshoot the system.

It's a two phase motor. When I first looked at it, one of the two 120 volt circuits had its breaker tripped, the other didn't. at the regulator, you could see 120 V. If I pushed in the other breaker, the first would immediately trip.

If I open up the box containing the wiring for the pump and the starting capacitor, I could get both breakers pushed in. If I then close the wiring box, I get a spark and the breaker blows.

Suspecting a short, I tested the winding resistances on the motor, and get non zero values across. Not exactly what's on the chart inside the box, but not far off.

Looking at the starting capacitor, it looks like there's a hole in it on the bottom where fluid leaked out, so I replaced it with a smaller one with the same microfarads (59-71).

This doesn't change anything. In fact, even with the capacitor not in the system, the breaker flips as soon as the circuit is connected (I suspect if I understood the circuit better this would not be a meaningful statement, but I'll say it here anyway because I'm fuzzy on it).

At the regulator, I see 120 volts to ground on all the leads with both breakers connected.

With one breaker pressed, one of the leads says 29 to ground rather than 0, which I found confusing. shouldn't it have said 0?

I'm a little bit lost on how to proceed, I have a couple ideas:

1. The breaker trips immediately when connected.

perhaps I need to somehow connect the capacitor to the circuit before the motor starts for it to charge, so the initial current draw doesn't flip the breaker?

Is there some procedure I've missed for replacing the capacitor that does this? or does a 59-71 uF capacitor not have a real charging time? Perhaps having the capacitor blown also can break the blue circuit assembly thing for the capacitor in the circuit box and I need to replace that?

2. Combine circuit breakers?

I know this idea is probably stupid. the breakers used are 2 independent 20 amp breakers. I could use a different circuit to test using a combined 40 or combined 60 amp breaker instead. maybe it needs a little more current, but is not actually shorted?

Appreciate any insight you guys might have.

Thanks,

- 021-12-11

by Dan This question, photo, and our reply waere first posted at

Reply by Inspectapedia Com Moderator - low resistance and developing short in the pump motor run winding or main winding.

@Dan,

Do you think we've simply got a dead short - in the pump motor or pump wiring?

Have you tried disconnecting from power (first turn power off) and then checking the resistance between the leads to the pump?Watch out: do NOT just combine circuit breakers to give more amps to the pump; you risk a dangerous or fatal electrical shock, short circuiting, electrical wire burn up, building fire.

by Dan

@Inspectapedia Com Moderator,

I did test the winding resistances and compared to the chart. The sticker on the motor says 'Model 2801054915' HP 1/2, volts 230The chart in the box for 1/2 hp 230 volts says "Main BLK-YEL - 4.2-5.2 Ohms" My ohm meter says 1.3 ohms for this. It also says "Start RED-YEL - 15.5-19.6 Ohms"

my meter says 13.3 for this, so both are low, that first one could be a lot too low. It also says the current motor running loaded amps is 5.9 (not sure that's useful)

What do you make of those numbers?Followup by Inspectapedia Com Moderator

@Dan,

That sounds like you might have a low resistance and developing short in the motor run winding or main winding.

Keep in mind that when the motor starts to spin conditions in the windings can change and a break can open up or short circuit can close.

As a point of comparison, a dead short will show zero or close to zero resistance.

Another test point is measuring the current strong when the motor is attempting to start. For example, if a motor's bearing has seized, the motor will draw High Currentmore information by Dan

@Inspectapedia Com Moderator,

I see. I appreciate your insight on this. My understanding is we're at 'the motor needs to be replaced'? Is it worth trying giving it a higher amp circuit?If the well is toast, I think the shortest path to getting water to this house is connect to municipal water rather than repair the well, but if there's something I can do with just the electrical end of this to get it going, that'd be ideal.

Is that a fair assessment? Is there anything else to give a try before declaring this thing shot?Suggestion by Inspectapedia Com Moderator - how to diagnose an electric motor such as a well pump

@Dan,

Take a look at ELECTRIC MOTOR DIAGNOSTIC GUIDE

and keep in mind that if you're not trained in safe electrical work and testing you could be shocked or killed - just sayin'

Or you could take the pump out and ask for its motor to be tested by a local electrical motor repair company who provides that service - compare the estimate of that testing with simply replacing the pump.

Watch out: When a motor is blowing a breaker, and provided it was wired and given the proper amperage to start with, I would never simply try a higher-amp circuit. Doing so invites an electrical fire or injury.

- stay safe

Daniel

Motor stops after 10 minutes, buzzes

Small AC capacitor start motor. 1/2 hp. It runs fine for ten minutes, then stops running. Then buzzing trying to start again, but it cant. The start capacitor was burned out when I got it, but I replaced it. On 2019-05-23 4 by Ron

by (mod) -

Ron, if we assume the motor isn't overloaded then it sounds as if the motor is overheating, perhaps from a bad bearing. Check first, though, for low voltage.

Motor smokes and shuts off when run at high speed

I have a single phase 220 Dual speed pump and when I hook the high speed side up it runs for about 5 seconds and then starts to smoke and shuts off but if I hook up the low side it runs fine why is this? On 2020-03-04

by Jessie Higgins

by Mod - what to check when electric motor overheats and shuts off

Jessie

I can't say with certainty but I think your electrician will look at

- actual voltage being delivered to the high speed terminals

- pump wiring connections

- pump loading, bearings, water supply

Meanwhile, don't hook it up as you risk a fire (and may have damaged the pump)

...

Diagnose rapid on-off cycling in a 12V motor

I have a 12 volt electrical motor which goes start/stop/start/stop and so on in very rapid succession when connected to the battery. what is wrong with it? On 2021-05-02 by Peter Tozer \

by (mod) -

@Peter Tozer,

I would look for a loose electrical connection,

an excessive load being applied to the motor,

A bad bearing,

For if the motor is being controlled by a relay, a bad relay

What causes cyclic variation in electric motor speed?

What is the cause of motor undulating? On 2021-01-02 by Luis Martinez

by (mod) -

Luis

If by undulating you are describing a motor whose speed seems to keep speeding up then slowing down,

I would first check the stability of the supply voltage to the motor.

Other possibilities are a failing bearing, overheating, a poor electrical connection, or a winding that opens when the motor gets up to higher speed.

...

After I cleaned it my electric motor spins backwards

I stripped and cleaned an electric motor on reassembly it spins backwards Why?

Reply:

Please see ELECTRIC MOTOR RUN DIRECTION to diagnose and repair an electric motor that is running backwards.

Why an Electric lawnmower motor runs backwards

My lawnmower, which I bought on eBay, is rotating the wrong way.

The single phase domestic electric motor has two terminals/spades which I swopped over but no change.

The motor should rotate clockwise, looking on the spindle, which ties in with motor fan and grass impeller configuration. There is a capacitor adjacent to the manual switch, if this item was faulty could it have any effect on rotation?

The mower does cut the grass, throws most of the cuttings into collection box but also scatters some around!

Would be grateful for any suggestions/solutions, thanks On 2020-06-02 by Bob Abbot -

by (mod) -

Bob

Let's start with diagnosing the cause and then we can select the cure for an electric motor that runs backwards. It may be that the motor was damaged or it may simply be a wiring error.

See details at ELECTRIC MOTOR RUN DIRECTION - backwards

after checking there let me know you you're progressingby Bob Abbot

I guess a replacement capacitor will be a lot cheaper than a motor, so I'll try that first and let you know. Thanks.

by (mod) - why the service tech tries replacing the start or run capacitor

Right, Bob, that's why a service tech often "shotguns" a repair guess by swapping in a new cap.

Let me know how that works.by Bob

hi and thanks for your reply. I have read the linked article and noted the possible reasons for my single phase motor going ACW rather than CW.

It may be that the fault/damage had already been done before I bought it but I can't see how the motor's start widing connections could have been reversed, as being one suggested possibility.

As regards a failed electric motor starting capacitor, there is a small square capacitor close to the manual switch.

If this was faulty, could it influence the motor direction?

by (mod) - motor runs backwards

Yes that's possible.

Why Electric bed-lift motor no longer will reverse direction

I have an electric motor for a bed to lift and lower but now it only goes one direction what could be the problem On 2020-11-19 by Mike

Answer by (mod) -

Since your motor is working it sounds as if the problem is with the wiring or a switch or with the bed movement direction control itself.

...

Where do I buy insulation material for just one motor rewinding?

Where do I buy all the insulation material for just one motor rewinding?

hendricksonbruce399@yahoo.com On 2020-10-16 by bruce

- >

Answer by (mod) - electric motor repair: re-winding, varnishing, etc.

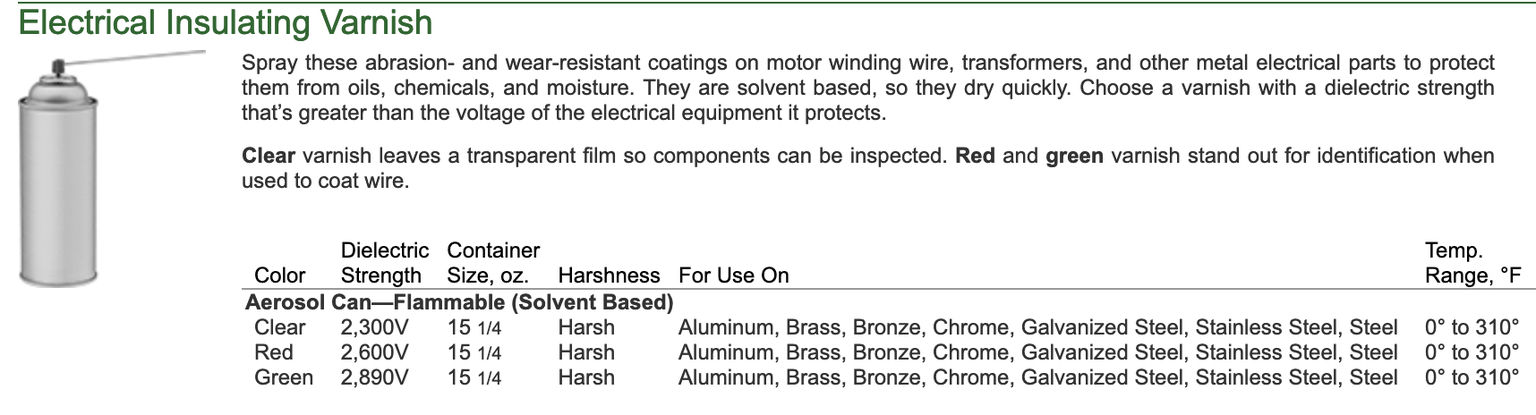

Bruce:

Companies who are expert in or who provide electric motor re-winding services describe use of either varnish or a resin used to insulate the motor rewinding wire after repair.

Dreisilker describes four types of electric motor winding insulation methods; you'll want to see that guideline before buying anything. You'll want to match your winding insulation method and material. The four methods are

1. Dip and bake: electric motor windings are dipped in varnish and then baked in an oven

2. Trickle varnishing: the motor windings are heated and spun to distribute the varnish

3. Vacuum Pressure Impregnation (VPI) a vacuum pressure tank filled with varnish is used to fully impregnate motor windings and insulation with resin or varnish.

4. Ultra-Seal - the electric motor windings are impregnated with high molecular weight thermoset polymer resin.

- https://dreisilker.com/blog/4-types-of-motor-winding-insulation-methods/

You can see that some of these methods for electric motor winding insulation are pretty sophisticated and require special equipment. So you need to choose the method before buying varnish, another resin material, or thermoset polymer resin sealant.

Once decided there are quite a few suppliers of resins and varnishes for sealing motor windings, and nearly 500 products among which to choose, including some simple spray-on products; which and where you buy depend as well on the country in which you're working.

Just one example is a spray-on motor winding varnish from

- McMaster-Carr, 9630 Norwalk Blvd. Santa Fe Springs, CA 90670-2932, USA Website: www.mcmaster.com Email: la.sales@mcmaster.com Tel: (562) 692-5911

...

How to check that the electric motor is getting power?

I have the following fan motor model # SFC1-500B, 120V 60HZ 1.35A 162W. I am trying to figure out how to repair it. This is a learning project and not sure how to get past this part.

The red color wire has no continuity getting to the windings.

I checked it from one of the prongs on the power cord.

The power cord is connected to a red wire that goes to a white wire that goes to the windings.

There is continuity to the white wire as you can see under the insulation that disrepair into the windings. I check the winding to see if there is continuity and I get none. I should be able to touch it with the multi-meter and get low resistance correct?

How do I check to see if the coil can receive power from the power cord? This seems like the most obvious way. If there a copper wire broken from the white wire located under the insulation? On 2020-06-27

by lindylex

Suggestion by (mod) -

Lindy

Have you checked to be sure that there are no switches that could be out of order.

E.g. a start winding power may be turned off by a centrifugal switch.

...

Table saw motor runs regardless of switch ON or OFF Position

The 230V Rockwell motor on my table saw runs with the switch on or off. What could be the problem? On 2019-11-23 by Les

by (mod) - Bad swith and dangerous saw

Les

Watch out: What you describe is very dangerous risking an electrical shock injury or worse.You should unplug that motor immediately. Most likely the switch has either failed internally or is shorted internally. It's possible that the wires to the switch have become shorted together.

Motor doesn't start - is it the reset switch?

Motor doesn’t start when relay closes. Sometimes fan moves ever so slightly. Changed capacitor but no changed. I haven’t pulled the motor assembly out from the enclosure yet. Could it possibly have a resetable overload switch?On 2019-10-11 by Wally

Answer by (mod) -

Wally

If the problem wear a switch that needed to be reset then I don't think you would see any movement in the fan when you turn power on

...

Other Electric Motor Troubleshooting FAQs

Question: Weather King Furnace motor trouble vs cycling on and off?

Weather King furniae outside unit & fan run continuously . Inside the lower cycles on & off but it does not cool the house ( June 15, 2015) jim dyson

Reply:

Sounds like a refrigerant or a control problem. You need an on-site service technician to sort this out, Jim.

We give diagnosis and repair steps

Question: HVAC motor keeps switching between heating & cooling modes

(June 21, 2015) robert said:

my fan motor on my central heating and air conditioner keep witching back and forth. the air flows out the top to cool the compressor but the next time it come on the motor turn the other way and pull the air in causing the compressor to over heat

Reply:

This is a control problem not a problem with the electric motor, Robert

Question: are there different test procedures for DC electric motors?

ELECTRIC MOTOR DIAGNOSTIC GUIDE describes a lot of diagnostic test procedures for A/C electric motors such as those found in air conditioners, heat pumps, washing machines, clothes dryers, condensate pumps, well pumps, even garage door openers. But what about direct current motors such as used by hobbyists and in some automotive or boat applications?

Reply:

Hobbyist LB Miller has described the design and function of a simple test fixture useful for determining the electrical resistance of DC motors by providing a 1A current to the motor and measuring the voltage drop across the motor, thus giving motor resistance in milli-ohms. Note that his approach is for DC motors. [33]

Question: AC not working to cool the home - Install a more-powerful blower motor?

(May 14, 2014) Jaime (from Huntington WV) said:

Hi! In 2010 we replaced our outside central air unit, without replacing the furnace inside. The forced gas heating inside works great for heat in the winter, but in the summer when it gets humid, or newer AC in combination with our older fan/motor inside the house do not work well together.

I have very cold air coming out, but by the end of the day when the thermostat is set on 69, it just keeps going up and up to about 71.

From what I have been told, the humidity makes the air thicker which in turn the old fan/motor in the furnace part can't handle the cool air from the new AC, which in turn my duct work under the house sweats terrible.

Can I replace the motor in the house with a newer/more powerful motor without replacing the entire furnace inside? I hope you understand what I meaning. =) Thank you! Email me or comment back BillandJaime2004@gmail.com

Reply:

First I would look for an operating problem, possibly improper refrigerant charge, or dirty filter, that is causing the coil to freeze - that could explain the reduction in cooling capacity as the day wears on. Look for frost or ice on the cooling coil.

Another direction of diagnosis: if the system is oversized then it will cool the home too quickly, failing to adequately dehumidify.

...

Question: Oil the blower motor: Carrier air handler blower motor repairs - noisy, intermittent run

Hey guys - I'm having a problem with the blower motor in my carrier air handler. I keep it oiled regularly every yr to 2 yrs as equipment suggests. Started squeaking on me when we turned our ac on this summer.

After cleaning / lubricating the motor, restarted ac and it ran fine for 4-6 hours then wouldn't not kick on when tstat showed a higher inside temp then set at. I check ed the motor and all was clear and well lubed and restarted.

Ran OK for a period then same issue. Motor became noisy again and will only run intermittently and then get noisy and shut itself down. Is this a case of bad bearings / windings in the motor or could it be a wiring issue? Any helps would be great. Thanks in advance. (July 23, 2014) B said:

Reply:

B

Check first that the blower assembly itself is spinning freely, not binding, and doesn't have worn bearings.

Then consider that the motor may be failing internally, possibly a bad bushing or bearing.

You might extend its life with a hard start capacitor kit.

Question: how to oil an Emerson K55hxkwa-9803

Can you oil a Emerson K55hxkwa-9803 ? (July 23, 2014) Jeff Wilmsmeier

Reply:

Jeff I had trouble finding a manual for this fan motor online too - so I don't know the answer.

Look closely at the motor assembly.

Oil ports will be obvious, often capped with a hinged cap or a hole facing up marked "OIL" on the steel body of the motor.

Or send us some sharp photos of all sides of the motor and we'll comment further.

See ELECTRIC MOTOR LUBRICATION for detailed advice

...

...

Continue reading at ELECTRIC MOTOR DIAGNOSTIC GUIDE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see ELECTRIC MOTOR DIAGNOSTIC FAQs-2 - more questions & answers about fixing electric motors

Or see these

Recommended Articles

- ELECTRIC MOTOR DIAGNOSTIC GUIDE - home

- A/C ELECTRIC MOTOR COMPONENTS

- BURNED-OUT COMPRESSOR

- CAPACITOR TYPES, for MOTORS

- CAPACITORS for HARD STARTING MOTORS

- CHATTERING RELAY CONTROL SWITCHES

- COPELAND ELECTRICAL HANDBOOK [PDF]

- ELECTRIC MOTOR 3-PHASE MOTOR SELECTION

- ELECTRIC MOTOR 3-PHASE TROUBLESHOOTING

- ELECTRIC MOTOR CENTRIFUGAL SWITCH or PTC PRD

- ELECTRIC MOTOR DATA TAG

- ELECTRIC MOTOR HORSEPOWER & CIRCUIT WIRE SIZE

- ELECTRIC MOTOR LUBRICATION

- ELECTRIC MOTOR NOISE DIAGNOSIS

- ELECTRIC MOTOR OFF on RESET

- ELECTRIC MOTOR OVERHEATS

- ELECTRIC MOTOR OVERLOAD RESET SWITCH

- ELECTRIC MOTOR RUN DIRECTION

- ELECTRIC MOTOR START SWITCH

- ELECTRIC MOTOR TESTS

- ELECTRIC MOTOR WIRING DIAGRAMS & GUIDES

- ELECTRIC MOTOR WON'T START / RUN

- HARD STARTING COMPRESSOR MOTORS

- HARD STARTING ELECTRIC MOTOR CAUSES

- OIL BURNER NOISE DIAGNOSTIC INDEX

- RESET BUTTON, ELECTRIC MOTOR

- TIGHT or SEIZED AC COMPRESSORS

- WATER PUMP PROTECTION SWITCH

Suggested citation for this web page

ELECTRIC MOTOR DIAGNOSTIC FAQs at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.