Chimney Rain Cap Clearance & Opening Dimensions

Chimney Rain Cap Clearance & Opening Dimensions

Chimney cap vent area requirements & codes

- POST a QUESTION or COMMENT about types of chimney rain caps & chimney caps / chimney crowns & their inspection, installation, troubleshooting & repair or replacement.

Chimney rain caps dimensions, clearances, or free venting area:

This article describes the distance between the under-side of the cap of a chimney rain cap and the top of the chimney flue.

We discuss the effective venting area provided by different rain cap designs and mesh or spark arrestor choices and we explain the possible safety hazards of using an un-listed chimney cap that does not provide adequate flue venting opening area.

The home made chimney rain cap and cover shown at the top of this page may not provide adequate flue exhaust area and if not, would be unsafe.

In this article series we illustrate common chimney cap & crown types, choices, & defects, and we cite pertinent chimney top cap / crown building defects, hazards, codes & standards for fire and other safety concerns.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Chimney Cap Clearance From Flue: Chimney Cap / Screen Vent Opening Dimensions

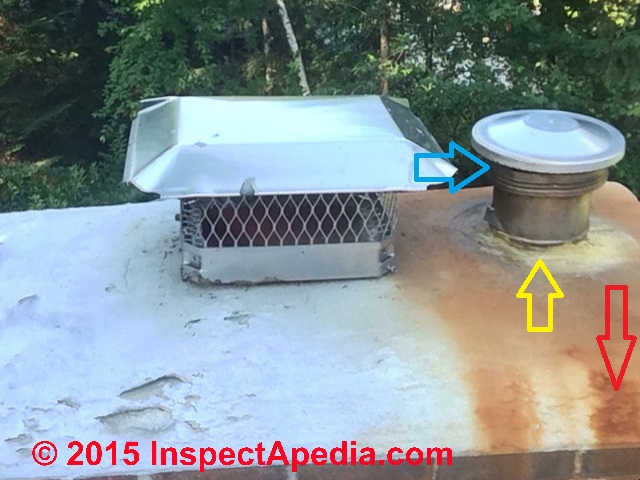

In the photo above left are two rain caps: a rectangular one over a rectangular clay flue tile and a round rain cap over a round metal flue venting an oil fired heating appliance.

Watch out: Below the photo shows a flat stone rain cap atop a stone or stone-veneer masonry chimney. If the installer left too little space between the under-side of this flat stone, or if the stone does not project sufficiently past the chimney top the chimney may be damaged by rain or wind-blown rain, making it unsafe.

Also, the chimney rain cap has no spark arresting screen, making it non-compliant where such spark arrestors are required (E.g. California in the U.S.).

Rain caps atop chimneys are defined and explained at CHIMNEY RAIN CAP / RAIN COVER INSPECTION. This article, beginning below, discusses a concern of inadequate venting through a chimney whose rain cap does not provide enough vent exit area or space.

Reader Question: red rust and yellow substance at chimney top

We replaced our chimney crown a year ago and had the chimney company seal it with crown seal. There is a fireplace flue (unused) and a oil furnace flue. There is a red rust color coming from the area of the oil flue and cap as well as what a pears to be a small circle of yellow substance surrounding the SS flue pipe.

The chimney sealant has now peeled leaving a real mess. Photos are available if you need them If you have any ideas on what is causing this that would be great. - T.W. 18 Jul 2015

Reply: blocked flue? Corrosive & yellow staining effects high sulphur in heating fuel?

Moderator said:

Watch out: Urgent: That cap doesn't look right. Is the flue blocked?

If the flue is obstructed there are possible fatal CO(carbon monoxide) hazards. Be sure you have working CO detectors or shut off the equipment.

See CARBON MONOXIDE - CO

(Oct 14, 2015) Paul said:

The yellow substance mentioned in the reader question may well be sulphur deposits. Two possible causes suggest themselves: 1)The heating oil supplier is providing a sub-standard product; or/and 2) The heating oil holding tank has collected sulphur over time.

The sulphur sinks to the bottom and accumulates with time, getting stirred up with each new delivery. The tank may need to be drained and cleaned.

Sulpher is corrosive. It would account for both the rusting and the yellowing.

Reader follow-up:

We have working CO detectors. The oil furnace company is here tomorrow and I will have them check the flue.

The flue was cleaned last July by the chimney people. What do you mean by the cap doesn’t look right? Also, what is the yellow substance near the pipe? - T.H. 19 Jul 2015

Reply:

I could not see that the chimney cap had adequate vent opening. Let me know what your oil heat tech thinks about the chimney top deposit. I'd be looking for a boiler leak or an odd combustion situation. We might see rust stains but not expect it at a stainless steel chimney and cap.

Details:

The right-hand round metal chimney flue in the photo at above left is covered by what appears to be a squashed-down metal chimney cap. As you'll read in the email exchanges below, the homeowner recognized that there was trouble from the red stains on the chimney concrete crown or top seal and and from the yellowed melting, bubbling sealant around the penetration of the concrete top seal by the round metal flue.

We think that there was probably inadequate exhaust clearance between the chimney rain cap and the top of the flue opening (blue arrow) that may have had the effects of directing flue gases and heat down onto the chimney top seal, thus causing both the melting bubbling sealant (yellow material & arrow) and the red stains (flue gas products or rust from the flue interior - red arrows).

Reader follow-up:

The oil service company just left. The furnace is in good condition and clean. He removed the flue pipe

from the boiler into the chimney SS flue and it was clean. He looked inside the furnace for any water dripping

or buildup and saw nothing. These numbers don’t mean much to me but they may to you:

Efficiency: 82.5

Stack Temperature: Gross 490 Net 430

CO2 Reading: 11%

Smoke test: 0

Breach Draft: -.05

Over fire draft: -.01

Reply:

The heating system numbers measured at the oil burner and flue look fine except I like to see a small trace of smoke. If the temperatures were high (say 600 or more) I'd think the system was running too hot, sending too much heat up the chimney, and maybe generating orange crud - but you're ok on that score.

Either we're looking at a component of flue gas that is condensing out and staining or we're looking at actual metal rust.

Or there is some third material that I couldn't see that explains the staining.

Are you burning straight No. 2 heating oil?

Reader follow-up:

We are burning regular #2 heating oil. I have a call in to our chimney company.

The last time I spoke with them they suggested replacing the existing 304 flue cap with a 316 SS flue extension and a 316 SS Cap made with an insulated inverted cone to reduce staining similar to the photo at below left.

Reply: lack of specifications of chimney rain cover net vent free area in product specs and codes

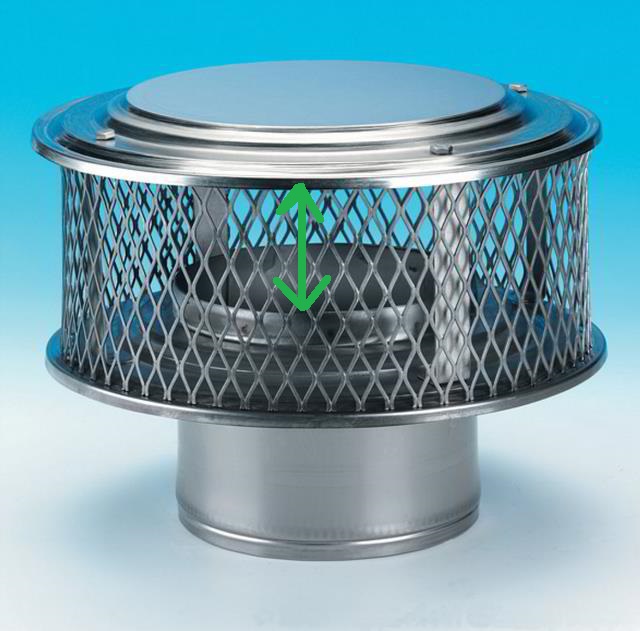

Above at left we see a double-insulated Class "A" chimney top rain lid or "rain cap" Enviro Stealth rain cover provided by Sleepy Hollow Chimney Supply, Ltd., a Brentwood New York company [Website: www.sleephhollowchimneysupply.com] .

This chimney top rain cover uses a 2x12" mesh (or in California a 2x2" mesh) to keep animals out of the flue while providing a minimal restriction of the exiting flow of flue gases through the cap assembly. A cap for a 6-inch round flue retails for about $200. USD.

A similar product shown at above right is a stainless steel chimney cap from HomeSaver using a 5/8" expanded metal lath type screen that meets fire safety spark-arresting specifications required by California and other areas and available from woodlanddirect.com for about $150. USD.

Interestingly, and perhaps because variation in actual chimney cap designs such as the inverted cone in the above left chimney cap (orange arrow) makes difficult the comparison of the vertical clearance distance "h" (green arrow) or more accurately, a specification of the effective free venting area afforded by the rain cover, this dimension is rarely given in the product specifications for rain caps. Some building codes also omit this dimension.

Yet the actual effective vent opening is a critical dimension for all rain caps and other chimney coverings.

5-inch Chimney Cap to Flue Clearance Space Recommendation

As you'll read below, in our opinion we think that 5" is a reasonable minimum dimension. Ideally every chimney cover or rain cap would include a specification of the net effective free opening for venting that the cap affords.

5-inches of opening space allows an extra safety margin for adequate venting that may be reduced by the mesh or screening, by the effects of the shape of the chimney cap, by variations in weather conditions, variations in stack temperature and other conditions.

As you'll read in a reader question and answer below where we do some calculations, a smaller cap to flue distance may still work and may still be safe provided there is objective data, not just arm-waving opinion to support that view.

Reader Question: minimum distance from chimney rain cap to top of flue

(Nov 8, 2012) Devon Bowman said:

(Nov 8, 2012) Devon Bowman said:

What is the minimum distance a Rain cap can be from the flu?

Reply:

Anon

The critical dimension is not only the distance from the under-side of a rain cap to the upper edge of the chimney flue. We must also consider the total opening space around the rain cap. For example, the masonry rain cap shown in my photo at left is rather enclosed and may be inadequate, depending on how this chimney is used.

Similarly for metal rain caps or rain covers the presence of and type of spark arrestor mesh or screening may be a factor in chimney performance, particularly if small-sized openings in the screen become clogged with soot or creosote as can occur on wood fired heating appliance flues.

Minimum chimney cap vertical cap bottom edge to flue upper edge clearance distance as described below is described by the cap manufacturers we surveyed as 5". Less may restrict chimney draft.

CHECK with your local state or provincial fire and chimney code and your building department as different specifications may apply where you live. Some states are silent on this detail: For example in New York State see Title 27 / Subchapter 15 Chimneys and Gas vents you'll find "[1501.10] 27-865 Chimney caps is silent on dimensions.

I think the reason this particular clearance distance has not come up is that factory rain caps for metal flues are pre-fabricated - one would not modify that device and it would provide its own clearance by its design. This is true for UL-Listed pre-fab chimney caps that fit into masonry flues as well.

The typical manufacturer's / distributor's chimney cap measurement instructions for ordering address the flue inner dimensions into which the cap mounting sleeve must fit (for non-extended flues) or the flue's outer dimensions (for extended flues) over which the cap sleeve fits.

Typically manufacturers who discuss the vent opening refer to the actual effective opening - which is more important than the actual distance about which you asked, as the chimney cap screen height.

Watch out: The required screen height is really the actual opening available for venting, and this height may need to be further adjusted depending on the screen mesh opening size as that in turn also obstructs venting both on its own and by its tendency to collect soot and debris (smaller mesh means faster clogging and more obstruction).

Watch out: a chimney cap is usually described just by the dimensions that fit the flue size - the actual screen height or venting area is often not given.

Again, look for AT LEAST 5" of vertical screen opening height. This is not quite what you asked but it's the best reply.

OPINION: I would like to see the greater of 5" unobstructed vertical screen opening height or for larger diameter chimney flues, a vertical opening height that equals the largest flue top horizontal opening (for rectangular flues) or its diameter (for round flues). And that opening may need further adjustment for smaller mesh screen openings that obstruct draft.

Watch out: we also don't want an excessive vertical clearance distance between the top of the flue opening and the lowest portion of the chimney cap cover, since if the opening were too all the rain cap no longer does a good job keeping rain out of the flue.

Safety warning: use only a listed chimney cap on your chimney flues.

Question: Chimney draft opening, chimney cap spacing vs. adequately hot chimney flue

2016/09/19 Ronald Snith said:

I read your thoughts on the 5 inch clearance for the chimney caps . My question is seeing a wood stove flue needs to be hot as possible to prevent creosote build up does lowering the cap raise flue temperature.But still maintain enough draft ? Thanks For Your Help

Reply:

I think that if you lowered a cap enough to restrict venting you'd raise flue temperature but I would not recommend that approach without one of us finding expert authority and/or research on the question.

If I need to restrict draft I think it's safe to do it at the intake end of the system where we can both keep an eye on what's happening at the fire and also adjust as needed without climbing up onto the rooftop in the middle of snowy icy winter when our woodstove is hard at work.

Consider that inappropriate or too much chimney draft constriction is unsafe on several counts including increasing the risk of a creosote fire.

Watch out: as we explain at CHIMNEY SHROUDS, use of an improperly designed or wrong-sized chimney cap or shroud can cause a dangerous chimney fire. Chimney caps for downdraft and rain protection must be installed according to either their listings (Such as U.L. in the U.S. or CSA in Canada) and must also be installed following the chimney cap manufacturer's instructions or the applicable building code where the building is located.

Chimney Cap Design & Sizing Research

- Also see CREOSOTE FIRE HAZARDS

- Bancroft, Robert M., and Francis J. Bancroft. Tall Chimney Construction: A Practical Treatise on the Construction of Tall Chimney Shafts... Constructed in Brick, Stone, Iron and Concrete. J. Calvert, 1885.

Excerpt: Heavy and large caps are often the source of great danger, inconvenience and expense (see Brooks & Son's Chimney, page 48), as the cap at top in a gale of wind acts upon the shaft as a weight at the end of a long lever. - Chimneys - Accessories - Part 7: Rain caps - SS-EN 16475-7:2016

- Requirements and test methods (Swedish Standard)

This European Standard specifies requirements and test methods for rain caps that are used as components, subject to flue gas, in order to protect against rain entry into the chimney flues. Rain caps which are part of components of a system chimney or other components of a chimney such as terminals, are not covered by this European Standard.

It also specifies the requirements for marking, manufacturers instruction, product information and attestation and verification of constancy of performance (AVCP). NOTE Rain caps according to this standard are suitable for both dry and wet chimney applications. - Chimneys - Accessories - Part 7: Rain caps - DIN EN 16475-7:2016

- Requirements and test methods; German version EN 16475-7:2016

(Foreign Standard)

This European Standard specifies requirements and test methods for rain caps that are used as components, subject to flue gas, in order to prevent rain entry into the chimneys.

Rain caps already tested together with system chimney products or other chimney components, e. g. terminals, are not covered by this standard. It also specifies the requirements for marking, manufacturers instruction, product information and assessment and verification of constancy of performance. - Farías, Oscar, Françoise Jara, and Róbinson Betancourt. "Theoretical and experimental study of the natural draft in chimneys of buildings for domestic gas appliances." Energy and Buildings 40, no. 5 (2008): 756-762.

Note: includes discussion of the effect of wind over the chimney cap. - Farshadmanesh, Pegah, Mehdi Modares, and Jamshid Mohammadi. "Impact of Chimney-top Appurtenances on Flue Gas Flow." (2014).

- Helwig, Lawrence L., and Mary Ann Sward. Wood Stove and Fireplace Safety and Maintenance. Cooperative Extension Service, South Dakota State University, 1979.

- ICC/IRC CHIMNEYS AND FIREPLACES, SECTION R1001 MASONRY CHIMNEYS, [PDF] - 2003 IRC, original source http://www2.iccsafe.org/states/seattle/seattle_residential/PDFs_residential/Chapter%2010.pdf

- OREGON BUILDING CODE, CHAPTER 10, CHIMNEYS AND FIREPLACES, SECTION R1001 MASONRY FIREPLACES [PDF]

- Peacock, Richard D. "Wood heating safety research: an update." Fire technology 23, no. 4 (1987): 292-312.

Abstract: The Center for Fire Research at the National Bureau of Standards has been involved in research related to wood heating safety for more than seven years.

Areas of interest have included: typical operating conditions of modern heating appliances, intensity and duration of chimney fires in factory-built and masonry chimneys, clearance reduction systems for protection of combustible walls and ceilings, and wall pass-through systems for connection of appliances to chimneys through combustible walls.

This paper presents a review of research at NBS and elsewhere related to wood heating safety and provides an assessment of the impact of the research on the fire safe use of wood heating appliances.

Extensive references of research related to solid fuel heating safety are included. - Siddhartha Bhatt, M. "Towards the design of high efficiency woodstoves." International Journal of Energy Research 14, no. 6 (1990): 629-649.

Abstract:

The paper describes the various methods that lead to the development of high efficiency woodstoves. The main design constraints that need to be adhered to are the reduction in fuel consumption, keeping the power output higher than, or the same as, that of the traditional system, and the incorporation of user friendly aspects such as low weight, low floor area, low cost, etc.

The parameters that affect the stove performance most are the combustion chamber parameters, the fuel parameters and the self-draught parameters. The effects of these are discussed in detail.

Some design considerations, such as matching of the heat transfer coefficients, matching of the heat source and the heat exchanger, maximization of the area of contact between the vessel and the flame, and the choice of chamber diameter are also described.

Discouraging the use of clay vessels and encouraging the use of grates in traditional stoves can alone decrease the fuel consumption to about half of the present consumption besides increasing the power output. The results of this study will provide working information for stove designers towards the development of high efficiency woodstoves. - Stone, Richard L. FIREPLACE OPERATION DEPENDS UPON GOOD CHIMNEY DESIGN [PDF] ASHRAE Journal 63 (1969). Retrieved 2016/09/20, original source: http://www.whysanity.net/richardstone/OPERATION.pdf

Note: includes engineering calculations of draft & chimney details.

Question: is 2-3" enough space between the chimney cap and the flue opening? How to Calculate Chimney Top Vent Area Size.

I have recently had my chimney company install a liner for my oil burning appliance.

The top of the top of the flue liner is about 2-3 inches from the chimney cap. Is this enough clearance?

Reply: gut feel, opinion, vs. calculation vs. objective measurement data

Carlo:

Thank you for asking. My gut feel is that 2" is probably not enough, but my gut may be wrong. Let’s try to get past general opinion (that 2” between cap underside and flue vent top edge) would be insufficient - which is my general view.

You checked that that fireplace top mounted damper still works OK right? And when it's open, the two flue openings are not at the identical height, right?

Looks like 2 or 3 generations of repairs to the masonry chimney. Be sure your chimney sweep confirms that the fireplace flue is also intact and safe to use.

Here’s some objective data about chimney opening size controlled by the space between the cap underside and the top of the flue opening.

Let’s calculate the actual chimney vent opening size by computing its area.

Chimney vent area with no chimney cap

The area of a 6-inch round flue is A=πr2=π·32≈28.27433 or about 28 square inches.

Watch out: we are not recommending leaving off a chimney cap, as you can read in this article series.

Chimney vent area with a chimney cap with 2" between Cap & Flue Opening

Now let’s cap the flue and raise the cap 2-inches above the very top edge of the flue.

The area of an entire cylinder that’s 6” round and 2” tall is

A=2 π r h + 2 π r2

where

A = area available for venting out flue gases via the chimney top

π or pi is 3.1416

r = the radius of the circle or 1/2 the diameter or in our case 3”

h = the height of the cylinder wall or in our case 2” - the open space between chimney cap underside and flue vent top edge.

For a 6-inch diameter round flue with a 2-inch space between the chimney top and the flue opening, the available exit vent area is

A=2 π r h + 2 π r2 = 2·π·3·2 + 2·π·32 ≈ 94.24778 or about 94 square inches minus the areas of the top and bottom of the cylinder. That's because this 94" is the area of the entire 2-inch tall cylinder, including its sides, top, and bottom. For chimney venting we want to know just the area of the side of the cylinder of space given by the chimney cap:

From the 94 we subtract back out the area of the flat circle so that we can see just the area provided by the 2” tall x 6” diameter opening space under the chimney cap.

That space, the size of the opening between the cap and the flue top will be 94.2 minus 2 x the flat area of the 6-inch circle (the top and bottom of a cylinder)

That’ll be

94.2 - (2 x 28.2) = about 37 square inches. That's how much vent opening is given by a 2-inch opening between the chimney cap underside and the top of the chimney flue.

[Really? Yeah I know, we could have simplified our starting formula but I included the whole cylinder formula to help avoid other readers from falling into the trap of too-hasty use of online calculator web pages. - Ed.]

The 2-inch space between chimney cap and flue top is giving us more space (37”) than was given by a 6-inch flue that just opened to the air with no cap at all (28”). The chimney cap is giving us 1.3 times (37 / 28 ) the flue vent cross section in opening size.

So your installer is probably right that based just on vent opening area size, your chimney cap is probably OK. That’s before considering other cap benefits such as preventing downdrafts and it’s before considering whether the chimney size and height are giving adequate draft to the particular heating system being vented in the first place.

Watch out: A vent opening outlet size is important in its control over chimney draft, but other factors such the obstruction or draft reduction due to the screening on a chimney cap, spark arrestors, and variations in fuel, temperature outdoors, temperature inside the flue, wind, chimney height, use of a barometric damper, and use of a draft inducing fan would also be important.

Make an objective, actual measurement of chimney draft

A smarter objective measurement would be done by a trained, qualified heating service technician who measures the actual draft at your heating system both over the fire and in the breech (that's above the heater, below any barometric damper or draft hood) when the heater is up to operating temperature, and under various weather conditions. (Hot weather, downdraft, and other conditions change the draft).

You don't say what fuel is being burned to be vented by your chimney. Earlier in this article we give as an example that for a typical residential oil fired boiler or furnace, we want the draft to be

Breach Draft: -.05

Over fire draft: -.01 to 0.2

See CHIMNEY DRAFT & PERFORMANCE

Since inadequate combustion air can also show up as poor draft, also

see COMBUSTION AIR REQUIREMENTS

Watch out: as we explain at CHIMNEY SHROUDS, use of an improperly designed or wrong-sized chimney cap or shroud can cause a dangerous chimney fire and a blocked chimney flue or inadequate draft can also risk fatal carbon monoxide poisoning of building occupants.

As a separate functional and safety check, to evaluate the size of the newly-lined chimney flue itself, you can also compare the input BTUH of what's being vented into the chimney along with the fuel type (perhaps natural or propane gas?) and look up the required chimney size accordingly.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question:

(Dec 3, 2014) Tony said:

We installed a triple walled metal chimney 12'run of pipe straight up from the top of our woodstove to 3' above the roof line. We burn our stove almost constantly at 250F-400F.We don't see any creosote buildup when inspecting and cleaning the chimney, but are plagued by soot collection in the top 3'-5' of the chimney.

There is no chase surrounding the exposed section of the chimney, would an insulated chase eliminate this problem? Or are there other solutions? I'm getting too old to keep climbing up on the roof all winter.

Reply:

Tony I'm not confident I can safely diagnose and recommend for this concern. Light soot from a woodstove at a chimney top may be ok but if soot blocks the cap, screen or flue there are indeed safety hazards. I agree that depending on the chimney height, enclosing the flue increases its temperature - but in wood burning I'm not sure what that does to soot at the cap.

I would feel that you are safest getting onsite advice from a certified chimney sweep. Do keep us posted.

Question:

(Feb 2, 2015) Eva said:

Do you need licence to produce Chimney caps in nyc?

Reply:

I'm not sure Eva, if you need a special license to produce chimney caps but selling them would be another question: certainly you'd need to get your chimney caps listed by UL or another accepted authority before they'd be code-approved and thus legal to install.

...

Continue reading at CHIMNEY POTS & DECORATIVE TOPS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CHIMNEY CAP / CROWN CONSTRUCTION

- CHIMNEY CAP & CROWN DEFINITIONS

- CHIMNEY "CAP" CROWN / TOP SEAL INSPECTION

- CHIMNEY INSPECTION DIAGNOSIS REPAIR - home

- CHIMNEY INSPECTION at ROOFTOP

- CHIMNEY RAIN CAP / RAIN COVER INSPECTION

- CHIMNEY RAIN CAP / RAIN COVER DIY

- CHIMNEY RAIN CAP VENT OPENING SIZE

- CHIMNEY POTS & DECORATIVE TOPS

- CHIMNEY SHROUDS

- CHIMNEY STAINS & LEAKS

- CHIMNEY TOP MASONRY DAMAGE

Suggested citation for this web page

CHIMNEY RAIN CAP VENT OPENING SIZE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to CHIMNEYS & FLUES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] ...

- [2] ...

- [3] Wood Heating Alliance, "BUILDING INSPECTOR'S CHECKLIST FOR FACTORY BUILT FIREPLACES [PDF] ", appearing in Baird, David J., C.B.O., "Factory-built Chimney Chase Fires: A case for More Detailed Inspection", Building Standards, March-April 1991, pp. 14-17. Note: The Fireplace Institute (FI) and the Wood Energy Institute (WEI) united to form the Wood Heating Alliance in 1980. The name was then changed again in 1983 to the Hearth Products Association (HPA) a non-profit organization, in order to better reflect the diversity and range of products and services within the industry. The name was changed once more to, Hearth Patio and Barbecue Association (HPBA) in 2001. Pacific HPBA, 2304 Huntington Dr., Suite 218, San Marino, CA 91108

(626) 237-1200 or (888) 332-2472

Fax: (626) 237-0721- info@hpbapacific.org, Website: http://hpbapacific.org/

Fireplace Safety Tips - Barbecue Safety Tips from the HPBA - see http://hpbapacific.org/pdfs/safetytips.pdf - [4] Baird, David J., C.B.O., "Factory-built Chimney Chase Fires: A case for More Detailed Inspection", Building Standards, March-April 1991, pp. 14-17.

|

- Stephen Werner

General Manager

Chimney King, op cit, personal communication 3/26/2013 w/attachments:

- CHIMNEY KING INSTALLATION INSTRUCTIONS FOR CHIMNEY CROWN, [PDF]

- Purdie, Roger K., "CHIMNEY FIRE SAFETY BULLETIN", Vista Fire Protection District, 2001, report of house fire related to the home's metal chimney. Contains advice for chimney * fire safety & sketches of approved and not-code-approved metal chimney tops, caps & crowns. [PDF]

- See also CHIMNEY SHROUD FIRE - technical article contribution by Mr. Werner

- [6] Residential Masonry Fireplace and Chimney Handbook, James E. Amrhein, S.E., MIA, Masonry Institute of America, 2d. Ed., 1995, ISBN 0-940116-29-4. The MIA is in Los Angeles, CA 213-388-0472. This manual reflects the 1994 Uniform Building Code, Energy Conservation Requirements of California, and the U.S. Department of Housing and Urban Development - HUD. The complete UBC is available from the International Conference of Building Officials (ICBO), Whittier CA 310-699-0541.

- [7] NFPA 211 - Standards for Chimneys & Fireplaces, NFPA 211: Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances, 2006 Edition (older editions and standards are found at the same bookstore)

- [8] NFPA 211 - Standards for Chimneys & Fireplaces, NFPA 211: Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances, 2006 Edition (older editions and standards are found at the same bookstore), NFPA #211-3.1 1988 -

Specific to chimneys, fireplaces, vents and solid fuel burning appliances.

- NFPA 211 - 3-1.10 - Relining guide for chimneys

- NFPA 211 - 3-2 - Construction of Masonry Chimneys

- NFPA 211 - 3-3 - Termination Height for chimneys

- NFPA 211 - 3-4 - Clearance from Combustible Material

- NFPA 54 - 7-1 - Venting of Equipment into chimneys

- [9] NFPA # 54-7.1 1992 - Specific to venting of equipment with fan-assisted combustion systems.

- [10] GAMA - Gas Appliance Manufacturers' Association has prepared venting tables for Category I draft hood equipped central furnaces as well as fan-assisted combustion system central furnaces.

- [11] National Fuel Gas Code, an American National Standard, 4th ed. 1988 (newer edition is available) Secretariats, American Gas Association (AGA), 1515 Wilson Blvd., Arlington VA22209, and National Fire Protection Association (NFPA), Batterymarch Park, Quincy MA 02269. ANSI Z223.1-1988 - NFPA 54-1988. WARNING: be sure to check clearances and other safety guidelines in the latest edition of these standards.

- [12] Fire Inspector Guidebook, A Correlation of Fire Safety Requirements Contained in the 1987 BOCA National Codes, (newer edition available), Building Officials and Code Administrators International, Inc. (BOCA), Country Club HIlls, IL 60478 312-799-2300 4th ed. Note: this document is reissued every four years. Be sure to obtain the latest edition.

- [13] Uniform Mechanical Code - UMC 1991, Sec 913 (a.) Masonry Chimneys, refers to Chapters 23, 29, and 37 of the Building Code.

- [14] New York 1984 Uniform Fire Prevention and Building Code, Article 10, Heating, Ventilating, and Air Conditioning Requirements

- New York 1979 Uniform Fire Prevention & Building Code, The "requirement" for 8" of solid masonry OR for use of a flue liner was listed in the One and Two Family Dwelling Code for New York, in 1979, in Chapter 9, Chimneys and Fireplaces, New York 1979 Building and Fire Prevention Code:

- [15] "Top Ten Chimney (and related) Problems Encountered by One Chimney Sweep," Hudson Valley ASHI education seminar, 3 January 2000, contributed by Bob Hansen, ASHI

- [16] Chimney Inspection Checklist, Carson Dunlop, Associates, Toronto, Ontario

- [17] "Rooftop View Turns to Darkness," Martine Costello, Josh Kovner, New Haven Register, 12 May 1992 p. 11: Catherine Murphy was sunning on a building roof when a chimney collapsed; she fell into and was trapped inside the chimney until rescued by emergency workers.

- [18] "Chimneys and Vents," Mark J. Reinmiller, P.E., ASHI Technical Journal, Vol. 1 No. 2 July 1991 p. 34-38.

- [19] "Chimney Inspection Procedures & Codes," Donald V. Cohen was to be published in the first volume of the 1994 ASHI Technical Journal by D. Friedman, then editor/publisher of that publication. The production of the ASHI Technical Journal and future editions was cancelled by ASHI President Patrick Porzio. Some of the content of Mr. Cohen's original submission has been included in this more complete chimney inspection article: CHIMNEY INSPECTION DIAGNOSIS REPAIR . Copies of earlier editions of the ASHI Technical Journal are available from ASHI, the American Society of Home Inspectors.

- [20] Natural Gas Weekly Update: http://tonto.eia.doe.gov/oog/info/ngw/ngupdate.asp Official Energy Statistics from the U.S. Government

- [21] US Energy Administration: Electrical Energy Costs http://www.eia.doe.gov/fuelelectric.html

- [24] Ceramic Roofware, Hans Van Lemmen, Shire Library, 2008, ISBN-13: 978-0747805694 - Brick chimneys, chimney-pots and roof and ridge tiles have been a feature of the roofs of a wide range of buildings since the late Middle Ages. In the first instance this ceramic roofware was functional - to make the roof weatherproof and to provide an outlet for smoke - but it could also be very decorative. The practical and ornamental aspects of ceramic roofware can still be seen throughout Britain, particularly on buildings of the Victorian and Edwardian periods. Not only do these often have ornate chimneys and roof tiles but they may also feature ornamental sculptures or highly decorative gable ends. This book charts the history of ceramic roofware from the Middle Ages to the present day, highlighting both practical and decorative applications, and giving information about manufacturers and on the styles and techniques of production and decoration. Hans van Lemmen is an established author on the history of tiles and has lectured on the subject in Britain and elsewhere. He is founder member and presently publications editor of the British Tiles and Architectural Ceramics Society.

- [25] Chimney Inspection Checklist, Carson Dunlop, Associates, Toronto, Ontario

- [26] Chimney & Stack Inspection Guidelines, American Society of Civil Engineers, 2003 - These guidelines address the inspection of chimneys and stacks. Each guideline assists owners in determining what level of inspection is appropriate to a particular chimney and provides common criteria so that all parties involved have a clear understanding of the scope of the inspection and the end product required. Each chimney or stack is a unique structure, subject to both aggressive operating and natural environments, and degradation over time. Such degradation may be managed via a prudent inspection program followed by maintenance work on any equipment or structure determined to be in need of attention. Sample inspection report specifications, sample field inspection data forms, and an example of a developed plan of a concrete chimney are included in the guidelines. This book provides a valuable guidance tool for chimney and stack inspections and also offers a set of references for these particular inspections.

- [27] Fireplaces, a Practical Design Guide, Jane Gitlin

- [28] Fireplaces, Friend or Foe, Robert D. Mayo

- [29] Principles of Home Inspection: Chimneys & Wood Heating, in (Principles of Home Inspection), Carson Dunlop, Associates, Toronto, Ontario

- [30] U.S. vs. Canadian Unlined Masonry Chimney Flue Requirements & Case Study

- [31] Brick Institute of America - Flashing Chimneys

Brick Institute of America - Proper Chimney Crowns

Brick Institute of America - Moisture Resistance of Brick - [32] American Gas Association - New Vent Sizing Tables

- [33] Chimney Safety Institute of America - Chimney Fires: Causes, Effects, Evaluation

- [34] National Chimney Sweep Guild - Yellow Pages of Suppliers

- [35] "Building Codes that Regulate Decorative Chimney Shrouds", provided by Stephen Werner [5], [copy on file as Chimney_Decorative_Shroud_Regs.pdf] cites:

- International Mechanical Code IMC (2000), M74-98 806.6, ratified 9.98, model building code for the United States,

806.6 Decorative Shrouds. Decorative shrouds shall not be installed at the termination of factory-built chimneys, except where such shrouds are listed and labeled for use with the specific factory-built chimney system and are installed in accordance with section 304.1. Reason: Decorative shrouds have been the cause of roof and chase fires - International Residential Code (IRC) (2000), R1002.2 ratified 9/99, 1000.2 Decorative Shrouds. Decorative shrouds shall not be installed at the termination of factory-built chimneys, except where such shrouds are listed and labeled for use with the specific factory-built chimney system and are installed in accordance with the manufacturers installation instructions. Reason: Decorative shrouds often allow for the creation of temperatures in excess of those permitted in UL 103 and UL 127. Decorative shrouds have been the cause of chase top fires ...

- International Fire Code (IFC) (2000), IFC 603.6.3, 603.6.3 Decorative Shrouds. Decorative shrouds installed at the termination of factory-built chimneys shall be removed, except where such shrouds are listed and labeled for use with the specific factory-built chimney system and are installed in accordance with the manufacturers installation instructions. Reason: Decorative shrouds have been the cause of dozens of chase fires. As a non-listed part to a listed assembly, their use should not have been allowed in the first place.

- International Mechanical Code IMC (2000), M74-98 806.6, ratified 9.98, model building code for the United States,

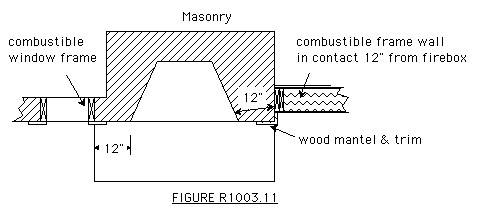

- [36] International Residential Code IRC R100.11 - Fireplace Clearance:

International Residential Code was recently amended:-

R1001.11 Fireplace clearance. Combustible material shall have a clearance of not less than 2 inches (51 mm) from the front faces and sides of masonry fireplaces and not less than 4 inches (102 mm) from the back faces of masonry fireplaces. The air space shall not be filled, except to provide fire blocking in accordance with Section R1003.12.

Exceptions:1. Masonry fireplaces listed and labeled for use in contact with combustibles in accordance with UL 127, and installed in accordance with the manufacturer's installation instructions, are permitted to have combustible material in contact with their exterior surfaces.

2. Combustible materials, including framing, wood siding, flooring and trim, shall be permitted to abut the sides and hearth extensions, but not the backs, of masonry fireplaces, in accordance with FIGURE R1003.12, provided such combustible materials are a minimum of 12 inches (306 mm) from the inside surface of the nearest firebox lining.

3. Exposed combustible mantels or trim may be placed directly on the masonry fireplace front surrounding the fireplace opening provided such combustible materials shall not be placed within 6 inches (153 mm) of a fireplace opening. Combustible material within 12 inches (305 mm) of the fireplace opening shall not project more than 1/8 inch (3.2 mm) for each 1-inch (25 mm) distance from such opening.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com 11/06

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.