HVAC Ducts in Floor Slabs

HVAC Ducts in Floor Slabs

Problems, hazards, diagnosis, repair

- POST a QUESTION or COMMENT about HVAC air ducts placed in or below concrete floor slabs

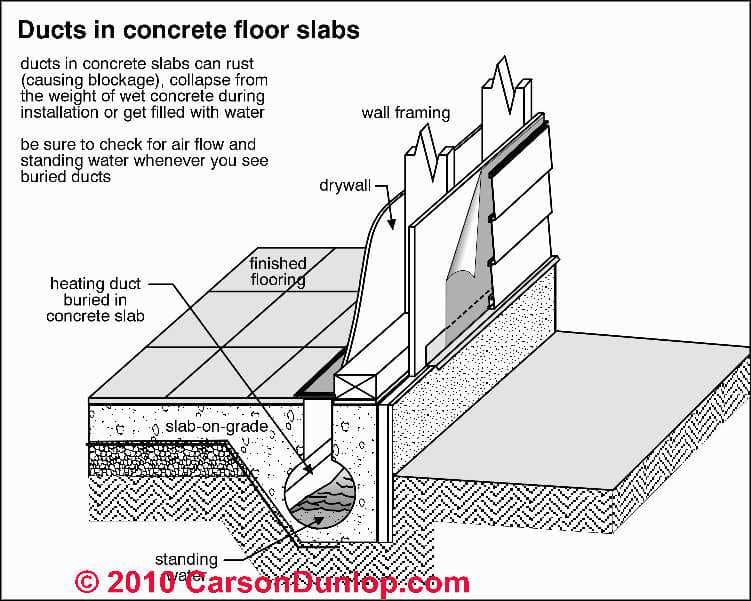

HVAC ductwork in floor slabs: this article describes heating and air conditioning ducts that have been placed in or beneath concrete floor slabs.

HVAC air ducts located inside concrete slab floors invite a surprisingly broad range of building problems that fall into two broad categories: functional troubles such as lack of air flow or collapsed ductwork, and environmental problems such as radon, odors, flooding, mold, insects, and where transite - cement asbestos - ductwork was used, asbestos particle contamination.

Here we catalog and illustrate the common problems found with in-slab ductwork & how those hazards may be recognized. We describe steps taken to repair or abandon in-slab air ducts.

The author, trained in mechanical systems repair and in environmental testing has inspected, installed, and repaired HVAC ducts and has performed environmental inspection and testing since the 1980s.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Problems with HVAC air ducts placed in or below concrete floor slabs

How to Recognize that heating or air conditioning ducts have been routed through or beneath a concrete floor slab

HVAC air ducts located inside concrete slab floors invite a surprisingly broad range of building problems that fall into two broad categories:

functional troubles such as lack of air flow or collapsed ductwork,

and

environmental hazards such as radon, odors, flooding, mold, insects, and where transite - cement asbestos - ductwork was used, asbestos particle contamination.

Sketch above was provided courtesy of Carson Dunlop Associates a Toronto Ontario home inspection educator and home inspection firm.

It's easy to recognize that in-slab or below floor slab HVAC ducts are or were used in the design of a building's heating or cooling air duct system, and it's not difficult to evaluate the condition of those ducts by a combination of visual inspection and observation of operating problems (lack of air flow) or environmental problems such as odors.

Here we'll describe how to determine if your air ducts are made of transite (asbestos-cement) and we'll discuss steps that should be taken to address the functional or environmental concerns we point out.

Article Contents

- DETECT THE PRESENCE of IN-SLAB DUCTS

- WHY IN-SLAB HVAC DUCTS ARE BAD

- FUNCTIONAL FAILURES in IN-SLAB DUCTWORK - Air Flow, Rust, Dirt & Debris, Condensation

- ENVIRONMENTAL HAZARDS in IN-SLAB DUCTWORK - Indoor Air Quality, Asbestos, Bacteria, Rodents, Mold, Radon

- RODENTS RATS MICE in IN-SLAB DUCTS - it's not your grandpa's "rat slab"

- SEWER GAS HAZARDS in IN-SLAB DUCTWORK - rare but possible sewage or sewer gas leaks into the ducts

- IN-SLAB DUCT 7 WORST INSTALLATION MISTAKES - avoid all of these

- HOW TO ABANDON IN-SLAB HVAC DUCTS - recommended in most cases

- HOW TO ABANDON IN-SLAB DUCTS in WET BUILDINGS - what to do if your basement or crawlspace keeps flooding through the old HVAC ducts

- IN SLAB DUCT SEALING PROCEDURES - possible but not recommended

- IN SLAB DUCTWORK CODES & STANDARDS

...

Steps in Detecting In-Slab HVAC Ductwork in Buildings

Here are the basic steps in determining that a building is using floor slab HVAC ducts:

Here are the basic steps in determining that a building is using floor slab HVAC ducts:

- Recognize that the building uses air ducts for heating, cooling, or both

- Observe the presence of air supply or return registers in the lowest floors of the building

- Observe that the lowest floors of the building were constructed as concrete slab on grade.

Note that in some buildings the lowest floor may have been constructed as a wood framed structure on-grade or over a very low, inaccessible crawl space rather than on a concrete slab.

Simply stomping on or tapping the floor may suggest that the floor itself is not set directly on concrete, or you may deduce the probable floor construction by inspection of the building exterior (presence of crawl space vents) or building dimensions (first floor is located more than a foot above grade level.

Using a hand-held camera for HVAC duct inspection

We have had good success inspecting the condition of in-floor and in-slab HVAC ducts using a simple digital camera that can be placed or held into the duct to take a quick look where a person's head cannot possibly fit for inspection.

Our photos just below demonstrate exploring the condition of an air duct in a concrete floor slab by inserting our camera (with wide angle lens) into the duct system through a floor register.

Naturally you won't see every inch of the duct this way and you could miss collapses or other in-slab duct problems.

Below our photo shows the seam of this HVAC duct was along its bottom.

We can see, along with cobwebs and insect debris, a tan stain from dirt and water that has at times lay in the bottom of this air duct.

And below, still more dirt and debris. At least some of this debris in any HVAC duct will include normal house dust, as air has been circulating through the building.

As you might read at HOUSE DUST COMPONENTS , the two dominant ingredients in normal house dust are fabric fibers and skin cells (human skin). Those are organic in nature and provide food for mold growth as well as, in some cases, bacterial growth.

Also notice that water has been deeper in this duct and it's also rusted along its upper left side.

Check the air handler and other mechanical system components

An additional and important indicator of a building HVAC duct design that makes use of in-slab air ducts is illustrated at our photo and is explained in more detail just below.

Take a close look at the air handler (blower unit) located on the lowest floor of the building, often in a basement or on occasion in a crawl space.

Inspecting the warm air furnace shown in the left side of our photographs, we noticed that both the bottom of the furnace itself and an air duct appeared to penetrate the floor slab of the building.

Our further investigation at this home found that the return air plenum of this furnace was also located below slab and below ground, as well as return air ductwork - both had been flooding.

...

Why HVAC Air Ducts in Concrete Floor Slabs Are Trouble

Our photo just above and our investigation photo (shown at left) illustrate how you may spot an air duct routed through the building floor slab and how you may spot trouble too.

In this case the furnace return air plenum was also located below the concrete floor. The air duct system in this building had been subject to periodic flooding, as illustrated in our second photo (below right).

A description of the health and functional problems that may be traced to air ducts that were routed in a concrete floor slab as well as our advice on how to properly abandon and seal in-slab air ducts are found

There we describe concerns with ductwork run in floor slabs in the article above, including risks of air duct collapse that interferes with air flow through the system, water leaks into the in-slab duct system (not a problem unique to transite ducts), and rodent or insect infestations or even mold contamination.

Odor complaints may be traced to the duct system because of these problems.

See details at DUCT & AIR HANDLER ODORS.

Hopefully needless to say, flex duct should never be buried underground nor set into concrete slabs. [13]

...

Functional Problems Found in In-Slab HVAC Ductwork

Air Flow Problems in HVAC Ducts Due to Collapsed in-Slab Ductwork

Air flow rates of heating or cooling air delivered by in-slab ductwork can become substantially reduced and ultimately blocked completely by

- rodents or other animals that may invade the ductwork, nesting or even dying therein

- crushed or collapsed ducts in the slab

- debris loaded in-slab ductwork

- water flooded in-slab ducts

Above and below, reader-contributed photographs of problems in spiral metal ductwork routed in a concrete floor slab illustrate collapsed blocked ductwork (photo at left) and severe rust, and HVAC duct flooding history (below left) .

In both of these spiral metal ductwork photos (left and below left) you can see actual holes in the duct bottom - admitting ground water, vermin, other contaminants.

We discuss and illustrate disconnected heating or air conditioning duct defects

at DUCT CONNECTIONS. We also show additional images of the interior of crimped or squashed flexduct

Rust flakes

from rusty heating or air conditioning ducts themselves are unlikely to be much of a health hazard - these particles are pretty big, not easily airborne, and probably won't be found at high levels in indoor air except in unusual circumstances.

But rust in ducts is a problem indicator, showing quite clearly that the duct system has been wet.

Dust & normal air duct debris

The chief components of house dust, which will certainly collect within a duct system include fabric fibers and skin cells, often also including starch fragments and other organic debris.

Watch out: The combination of organic debris within a duct system and water (indicated by rusty ducts or duct registers) indicates a possible risk of mold or bacterial hazards within the air conditioning or heating system.

Since blowing air through the system can pick up and distribute these hazards

to occupants of the building, wet or previously-wet duct work is a potential health hazard to building occupants.

Condensation, Water & Flooding Problems in HVAC Ducts Placed In or Below Concrete Floor Slabs

Water accumulates in in-slab or below-floor air ducts from

- condensation during the cooling season, exacerbated if the ductwork is being used for air conditioning and more so if it is inadequately insulated

- leaks into the duct system from ground water seeping under the floor

- leaks into the duct system from nearby plumbing drain defects

- actual area flooding of the home (photo below)

In addition to blocking air flow, moisture or water in the duct system invites allergenic or pathogenic mold growth therein as well as bacterial or other health hazards that can be transmitted to the occupied space in the building as air moves through the duct system.

Inspect in-slab ductwork first through the floor registers (above left) and better, using a good light or mirrors or a camera system such as the Chim-Scan or plumbing drain camera.

The mud in the air duct shown above confirmed a history of building flooding that sent flood waters inside the HVAC duct system. Remarkably, this rectangular duct was below the basement ceiling of a home we inspected. We found flood lines indicating that the basement had been flooded to a depth nearly reaching the top of the foundation walls.

Also see WET CORRODED DUCT WORK. Water flooding in ductwork also ruins it and is discussed in detail

at WATER & ICE IN DUCT WORK.

...

Environmental Problems Found in In-Slab Air Ducts

Indoor Air Quality Problems Traced to In-Floor Slab HVAC Ducts

Air quality hazards of in-slab duct systems include rodent infestations in ductwork, dirt and debris accumulation which then is returned to the building indoor air or that serves as a breeding ground for pathogens, radon gas hazards, and water leaks into the duct system which can in turn generate a mold or bacterial hazard or can cause softening, collapse, and blockage of the in-slab transite pipe duct. All of these are described individually and in greater detail within this article.

While there are companies offering duct cleaning and duct sealing services, we remain cautious that such a "sealing" project creates a false sense of confidence that no remaining duct issues exist, causing the occupants to miss the discovery of future leaks and in-duct problems.

A description of the health and functional problems that may be traced to air ducts that were routed in a concrete floor slab are found

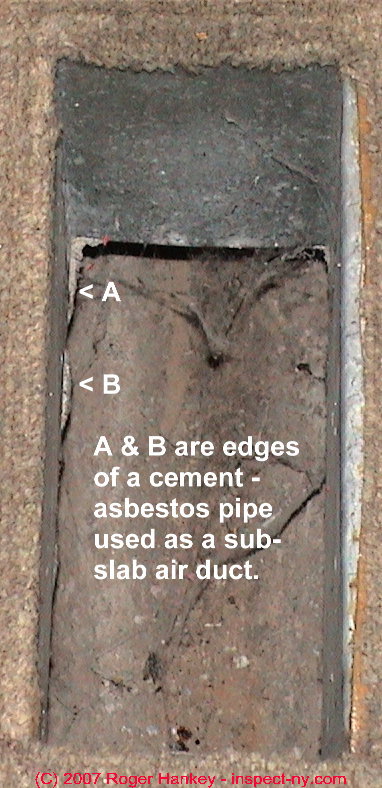

Asbestos Hazards Found at In-Slab HVAC Ductwork

Transite pipe, which contains significant percentage of asbestos fibers, was often used for heating ducts and on occasion heating and cooling ducts in older buildings.

Transite pipe used as HVAC ducts or air ducts for heating and air conditioning was often installed buried in a concrete floor slab - methods that placed the asbestos-cement transite piping below or in a building floor slab.

Asbestos-containing transite pipe HVAC ducts were also used in exposed areas such as shown in the crawl space photograph at the top of this page. And transite pipes were also used as flues or chimneys for some heating equipment, usually where gas fired heaters were installed.

Transite Duct Asbestos Hazards: if used for air ducts transite pipe may be a an asbestos hazard, particularly where the ducts become softened by water exposure (such as air ducts located in floor slabs), potentially releasing asbestos fibers into the building air. [21][22][23][24][25][26][27]

See TRANSITE PIPE AIR DUCT ASBESTOS RISKS for details.

Readers concerned with ice or water leaks into or out of HVAC ductwork should also s

see WET CORRODED DUCT WORK and

see WATER & ICE IN DUCT WORK as well

as FROST BUILD-UP on AIR CONDITIONER COILS where we describe build-up of ice on the cooling coil in air conditioning air handler units.

Photo of transite duct material shown above is provided courtesy of Thomas Hauswirth, a Connecticut home inspector.

Also see:

- ASBESTOS DUCTS, HVAC - Guide to Identification of Asbestos Materials On or In Heating and Cooling Duct Work: carbon monoxide hazards of transite chimneys and vents

- TRANSITE PIPE AIR DUCT ASBESTOS RISKS - (continued below) Hazards of Asbestos-containing Transite Pipe HVAC Ducts: duct collapse, mold, radon, asbestos fiber release

- TRANSITE PIPE CHIMNEYS & FLUES - Guide to Identifying Asbestos Transite Chimneys & Flues & their Hazards in buildings

Dirt & Debris Collection Hazards in HVAC Ducts Placed in Floor Slabs

Our photos below illustrate very dirty, debris-laden HVAC air ducts.

In our photo below you will also see evidence of rodent infestation in the duct - a collection of seeds probably left by a squirrel or mouse. At below right the fiberglass-duct was invaded by plant roots and appears to be collapsing.

Don't panic about dirt or debris in HVAC ducts. It is normal for some dust and debris to collect within the air handling system, though by installing and maintaining air filters at the air return registers you can minimize debris and dirt in the ducts themselves.

See details at AIR FILTERS for HVAC SYSTEMS.

"Normal" dust and debris we find inside of air ducts is dominated by fabric fibers, skin cells shed by human occupants, perhaps some food or starch granules, and if the ducts are made from fiberglass, fiberglass particles will be present.

Watch out: however if these duct debris materials are wet from any water source they may become a breeding ground for mold or other pathogens, and of course if the ducts are invaded by rodents or flooded by sewage they are unsanitary and are a health hazard to building occupants.

Mold Hazards Occurring in Slab-Routed Heating or Cooling Ducts

This photo of moldy and dirty insulation in an HVAC system has been provided courtesy of Tampa Florida home inspector and prior ASHI president Mark Cramer.

Because an air duct routed through a floor slab is more likely to contain moisture from condensation or water from leaks or floods, that moisture, combined with normal organic dust and debris found in ductwork can increase the chances of mold contamination in slab-ductwork.

At AIRBORNE PARTICLE & MOLD LEVELS in DUCTWORK we describe how to measure the level of mold or other airborne contaminants found in HVAC ducts.

Also see WHY DOES MOLD GROW in INSULATION?.

Watch out: don't assume that because mold has been detected in an HVAC duct system that the mold is the principal source of IAQ hazards in the building.

Modest amounts of Cladosporium sp. are quite common in air handlers where condensate blows off of the cooling coil.

And mold isolated from a duct system may have entered from a far more serious mold reservoir located elsewhere in the building. Expert investigation may be warranted.

See MOLD / ENVIRONMENTAL EXPERT, HIRE ?.

Odor & Smell Problems Traced to HVAC Ducts Routed in or below floor slabs

The catalog of odors and gases in buildings that may be traced to an origin in the ductwork is lengthy and includes both odors/gases that originate within the duct system itself and odors or gases that are transported between building areas by the HVAC system.

In addition to the aesthetic issues of mold, rodent, or sewer gas smells, these, along with odorless gases such as carbon monoxide can be serious even potentially fatal

Take a look at the dirt and black sludge on the bottom of the air duct visible through this floor register. We suspected that the duct system had been repeatedly flooded by ground waters, possibly including organic debris or even sewage that could contribute to an indoor odor complaint.

Odor complaints may be traced to the duct system because of these problems

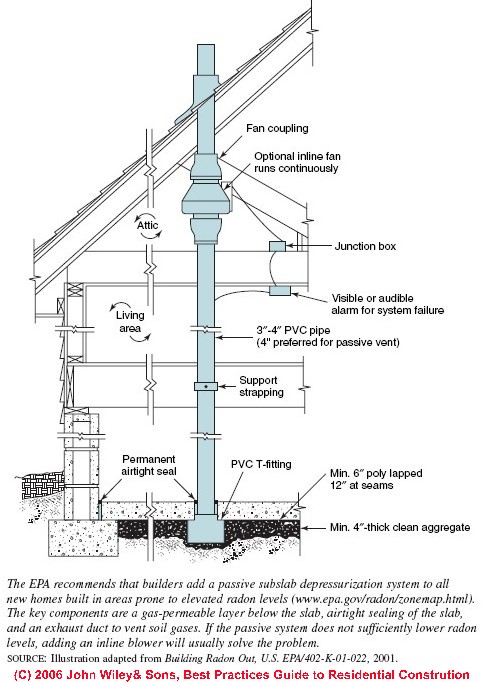

Radon Hazards Occurring at In-Slab HVAC Duct Systems

Radon entry through in-slab duct systems: can occur in areas where radon is present at problem levels in the soils. In particular, because a return air duct is often at negative pressure (when the blower is operating), the movement of radon gas from the soil into the building air through a leaky in-slab duct can be significant, certainly greater than the movement into the building from other openings such as through a basement slab crack.

[Click to enlarge any image]

As reported in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) :

The EPA and the U.S. Geological Survey have rated every county in the United States as Zone 1 to 3 for radon risk. Links to state maps with county by- county risk levels can be found at www.epa.gov/ radon/zonemap.html.

The EPA recommends that all homes in Zone 1 counties be built with radon-resistant features, which can be easily upgraded to a radon remediation system if needed.

Seal ducts and air-handling units Where Radon Gas is Present. Placing any return-air ductwork under the concrete slab is not recommended, since this will tend to draw radon into the ductwork and distribute it around the house.

If supply ductwork must pass through a subslab space, it should be seamless or sealed airtight with durable aluminum tape or duct mastic.

Details are at HOW to REMOVE INDOOR RADON

and at DEFEATING RADON part 3 - Key spots to seal, to stop radon gas leaks into buildings. [28][29][30]

...

Rodent Problems: Rats, Mice, Snakes, other Animal Contamination in HVAC Ducts Routed in or Below Floor Slabs

During a careful site inspection you may find reason to look further into the air duct system interior for contamination rodents.

Below our photograph illustrates such an example: the presence of maple leaf seeds and other organic debris entering the HVAC duct chaseway.

Below is one of the (dead) mice along with mouse droppings found in an HVAC air duct and air handler system.

Potential health concerns from mice and rats include not only fleas or odors, but potential pathogens such as hantavirus.

What about Rat Slabs?

For clarity and completeness we include this note that a "rat slab" is not what we're discussing here.

Definition: A rat slab is a thin layer of concrete, usually just two or three inches, poured over dirt in a crawlspace or possibly a dirt floor basement, in an effort to keep rodents from finding an easy path into the building.

Rat slabs are not structural, don't contain steel mesh or re-bar, are thin, and are just there as a practical aid to make the crawlspace or basement cleaner and easier to sweep out.

Don't expect to find an HVAC duct under a rat slab.

Really? You would never expect to find HVAC ducts under a rat slab, though our six decades of construction experience warn that people do all sorts of unexpected things in building construction.

...

Sewer gas leaks into HVAC ducts located in or below floor slabs

Sewer Gas entry into the HVAC duct system through in-slab transite asbestos ductwork:

A reader (Conrad) provided us with the photographs and case history of the successful track-down of sewer gas odors in a building.

The case began with a complaint of sewer gas odors in the building's heating duct work system.

As reader Conrad discovered while tracking down the odor of sewer gas that was appearing in a home's in-slab ductwork, placing in-slab ducts close to sewer piping (or septic system piping ) invites any future sewer gases leaking out of the piping right into the HVAC duct system.

The owner tracked the sewer gas odor that was coming out of the building's heating ducts to a break in the sewer piping located in the same floor.

The repair of the sewer gas odor involved jack-hammering out the floor slab, removing and replacing the leaky cast iron sewer pipe, and repairing the floor. Because of the inconvenience and cost of relocating these air ducts or converting to an alternate heating distribution method, the owner elected to retain the transite in-slab floor ducts.

This case of cast iron drain leaking sewer gas into a transite asbestos heating air duct is illustrated in more detail

at CAST IRON DRAIN PIPING and details about the case including more pictures and notes on how the building owner tracked the sewer smell to the basement floor slab (and transite heating ducts in the slab) can be read

at CAST IRON DRAIN LEAK, ODOR, REPAIR.

Watch out: sewer gases may include multiple hazards including the risk of exploding methane gas and possible bacterial pathogens as well as VOCs that can be a respiratory irritant.

Also see SEWAGE CONTAMINATION in BUILDINGS

If you think sewer gas is coming through your HVAC ducts, also

see SEWER GAS ODORS

...

7 Worst Installation Mistakes in HVAC Ducts in Slabs

Common Original Installation Mistakes for In-Slab Ductwork

Based on a history of complaints of contaminants entering in-slab HVAC ducts, the choice of this design is at best a higher-risk approach to heating and air conditioning duct installation in buildings and at worst, a catastrophe that should have been avoided entirely.

A review of in-slab ductwork installation guidelines from several manufacturers and HVAC contractors can inform us about what goes wrong from the start with in-slab duct systems. Here are some errors during original in-slab ductwork installation that show up as trouble later. You'll notice that most of these address water entry or condensation in the duct system.

- Too-Deep In-Slab HVAC Duct Installations:

the HVAC duct system must always be located above the high water table for the soils below the building.

Otherwise duct flooding and contamination are likely. - Too-Fast Disasters in Duct-Slab Installation:

experts warn that the weight of thick slab pours onto metal and some other duct materials can cause the duct to partially or even totally collapse during pouring and construction of the surrounding concrete slab.

Concrete around in-slab ducts needs to be poured in a sequence of layers or steps with allowance of intervening time to permit each layer to set up and harden. - In-slab HVAC Duct Float-Up:

if the duct slab system is not tied down before a concrete pour it may float-up causing high and low spots, water accumulation spots, or even disconnection of the duct segments leading to partial blockages and future leaks into the system. - In-Slab HVAC Duct Vapor Barriers:

in laying out the in-slab duct system vapor barriers must be provided between the ductwork and the surrounding gravel fill, insulation, and concrete;

Omitting the vapor barrier invites moisture into the in-slab duct system. In more than 40 years of building inspection, disassembly, and forensic investigation, I [DF] have not once encountered the presence of a vapor barrier nor even insulation around an in-slab duct system built in the 1940s through the 1980's. - In slab HVAC duct slope:

In-Slab duct system trenches that are not sloped to a drain point will permit water to accumulate in the duct at low spots where it breeds mold, bacteria, or other pathogens.

Curiously none of the installation procedures we reviewed included a detail on how water was to be removed from the in-duct slab low point much less how its presence was to be detected. - In-slab HVAC duct reinforcement:

Inadequate structural reinforcement around in-slab duct systems can result in crushing or settlement and thus breaks and leaks into and out of the duct system. - In-Slab HVAC Duct Sealers:

the interior surfaces of some in-slab air duct systems is coated with a sealant after placement or installation; experts advise that a water-based sealant should not be used in underground duct installation, presumably because the designers know perfectly well that future water entry or condensation is likely to occur - an event that will damage the sealant inviting further leaks and contamination.

...

How to Abandon In-Slab HVAC Ducts

We recommend abandoning in-slab HVAC air ducts, including transite asbestos cement HVAC ducts, reasoning that there are usually multiple indoor air quality and potential health as well as functional concerns with such installations.

We described concerns with ductwork run in floor slabs in the article above, including risks of air duct collapse that interferes with air flow through the system, water leaks into the in-slab duct system (not a problem unique to transite ducts), and rodent or insect infestations or even mold contamination.

Our starting point for proper abandonment of the in-slab air duct system shown above was this floor register in the home's garage.

Years of accumulated organic and other debris (odors, IAQ complaints) combined with a modest radon gas concern to lead a prior owner to begin abandonment of this duct system.

But he had left floor registers open to the building - failing to close them off and inviting ongoing IAQ problems.

Below: because this was a rather deep penetration into the slab and because we didn't want to have to mix many cubic feet of concrete just to seal off this in-slab air register, we used whatever scrap metal was at hand to raise the "floor" of the register up closer the slab surface. (Details are below.)

The photos below illustrate the additional steps in abandonment of the in-slab air duct whose floor register was illustrated at the start of this section.

Our photos above illustrate how we prepared for sealing of ductwork run in a concrete floor slab.

Working at the air supply register we used metal scrap to form a support for a section of drywall cut to fill the air supply register.

We pushed this assembly down about 2-inches into the register in order to allow for a 2-inch thick concrete plug (shown below).

Even if the in-slab transite air duct system appears to be in "good condition" there is risk of asbestos fiber release (though in our OPINION the fiber release from intact cement asbestos materials is probably quite low).

Even if the transite air ducts look ok now, the risk of future leaks, infestations, and damage remain, and risk exposure of the building occupants to the problems described here. In addition, where the transite ducts have become softened by water entry or have suffered mechanical damage, there is a risk of increased level of airborne asbestos in the building served by the ductwork.

Our photo (left) illustrates the last stage of an in-slab heating system air duct that we abandoned and sealed, using concrete. Rather than try to fill the entire in-slab duct, we used the combination of metal scraps and drywall to provide a backer for concrete (shown in photos above).

We then poured into the air register opening in the concrete floor slab.

In other sections of this home the concrete floor, originally covered with carpeting, was re-covered using ceramic tile, adding a final layer of sealant as well as a cosmetic improvement.

More examples of duct routing & support troubles are provided

at DUCT ROUTING & SUPPORT.

We discuss and illustrate disconnected heating or air conditioning duct defects

at DUCT CONNECTIONS.

We also show the interior of crimped or squashed flexduct

at DUCT DAMAGE, MECHANICAL.

When abandoned, in-slab ductwork of any material can usually be left in place. However where radon gas is an issue, we seal the ducts at the air delivery registers in the building floor slab, as well as sealing any slab cracks that may allow radon gas to enter the building at increased levels.

...

How to abandon in-slab ducts when there are water leaks up through the slab or foundation

Reader Question: Wow!! We finally found someone who understands our struggles with in floor ducts. I'm really hoping you can help.

Bought a house 8 years ago built in 1960, thought it was great that the basement had in floor ducts so it would be warmer in the winter.

[Photo of an in-slab duct supply register is from InspectApedia.com files and shows an in-slab duct system that had been abandoned and that was later sealed by the author (DF). ]

That winter we purchased two furnaces, one for the main floor and one inverted one for the basement. Spring thaw came and we heard water bubbling in the ducts and it was overflowing on the floor.

The previous owners didn't disclose of this problem but anyhow, it was our problem now.

For the past eight years we've had water in the ducts during spring thaw or when we've had torrential rain.

We've been the human sump pumps with our shop vac that has an aspirator that takes the water out of the ducts out the window to our yard.

We didn't want to fill it in we like the feature and we just bought a new furnace. But fast forward to our current state and we are finally waving the white flag. We've added two sump pits in the house and we're still getting water in the ducts.

We've had quite a winter season with significant snow fall, we're getting older and don't want to keep pumping out water not including the health risk we've been exposed.

Good thing we're not in the basement too often and the furnace is set at 57 degrees so it only turns on when it's really cold.

We would like to fill it in with concrete, we've had a structural engineer look at our basement and he recommended a certain mix of concrete but didn't mention about the metal rebar. Do you insert that only on the vents or the whole area?

There is no one in our area that is an expert on this so we're hoping you can help or direct us to someone that can.

Also, do you think that when we fill the ducts with concrete, would the water seep through our walls instead?

Thank you for your time and we look forward to your reply, - S. & G. L. 3/13/2013

Moderator Reply: here are more "how-to" details of the procedure for abandoning an in-slab air duct

Let's divide your question & our comments into some subtopics:

- Best procedure for filling in an in-slab duct system - you don't usually have to fill the whole duct system

- Structural reinforcements when filling in a duct-slab: shouldn't be needed

I'll discuss both of these just below.

Best way to abandon in-slab HVAC ducts where water leaks are a concern

Indeed in our photo examples of HVAC duct abandonment I have focused just on sealing up in-slab HVAC ducts at the supply and return registers in the building floors.

I showed this procedure in a location (a dry garage floor) where there was no evidence that I might be leaving a dangerous reservoir of sewage, mold, dead rodents, bacteria under a floor up through which (via other cracks or openings) contaminants might enter the home.

But what about the problems of leaving a reservoir of water or contaminants in the remaining ductwork under a building, and what about buidings where the in-slab ducts themselves seem to be forming a conduit that sends water up into the building above? Here are the issues:

- Fill in the duct passage?

This more costly procedure may be necessary in homes with water entry problems (or in our opinion in all homes) as over the life of the building we expect to find the in-slab duct problems discussed here).

We said earliler that if we don't have a flooding building problem we can usually abandon the duct system simply by filling in and blocking the supply and return registers in the building floors.

And before going to the trouble of filling in the entire duct system under your slab be sure to review

WET BASEMENT PREVENTION

Other approaches to sealing or abandoning in-slab HVAC ducts are discussed at HOW TO ABANDON IN-SLAB HVAC DUCTS but overall, in my OPINION best if we have a building where water is coming up through the slab and where the usual simple outdoor steps to keep water away from a building are not working, would be to fill the entire in-slab duct channel with concrete.

Use a high-portland cement mix that will be most-resistant to water passage. But we'd best keep the following limitations in mind so you're not disappointed by this repair:

- Debris can prevent a complete concrete seal in old ductwork

On the sides and bottom of the in-slab ducts debris will most likely prevent a really good water-tight bond between the four sides of the new concrete (or round sides if your ducts are round) that is poured through the duct system. - Water leaks may continue

Your building may still suffer from water entry and basement or crawl space flooding, depending on other building details such as the height of the upper surface of the floor slab above ground, water pressure and quantity in soils around the home, and surely some other factors I haven't yet thought-of.

It is possible that once you fill this channel running through the slab the same water problem will simply reappear at other slab penetrations or even higher up on the building foundation walls (if the building foundation also is partly below grade-level).

Therefore worry about an ongoing water problem is appropriate.

Without more details about your specific home, its site, roof drainage, surface contours, the actual sources of water that has been entering the home through the in-slab ductwork, I can't be confident I've got a complete understanding of your situation, but here are some additional points that you should consider when abandoning the slab ductwork:

Make sure water does not come into the building through the slab or foundation.

In addition to filling the entire slab duct passage (because we expect that to significantly reduce leak openings into the slab from below even if it won't fully seal them) you may need a sump system to lower the water level below your slab.

Fix the Water Sources Outdoors!

It is almost always most effective to find and fix the water entry source from outside the building, rather than waiting for it to enter and then pumping it away.

That means paying attention to roof runoff, surface grading, and any other sources of outdoor water and snowmelt.

Watch out: when ground is frozen it is almost entirely the top surface contouring that determines where surface water, roof runoff, and for homes in a snow-climate, control where snowmelt water goes.

Don't pile snow up against the house where it forms a water trap.

See WATER ENTRY in BUILDINGS - our home page for this topic.

For Wet-Site Buildings: Install a sump pit and sump pump?

For a building with persistent basement or crawl space water entry,

at the low-end of the ductwork, making sure that the bottom of the sump opening is well below the bottom of the slab. Pipe the sump pump discharge to a location where when it disposes of water that water won't just run back around the foundation. If you have frequent power outages you may need battery backup or even generator backup for your sump.

Watch out: You are balancing the risk of water flooding the building through the sump pit (during a power loss) with the benefit of lowering the water table under the ducted and leaky slab.

This is not the best choices for all cases like yours (it depends in part on the assessment of whether or not you can seal the slab and don't risk other water entry), and in general sumps are not my first choice for de-watering a basement or floor slab. Butt sometimes the cost-benefit of a sump pump is appealing.

Of course don't bury the sump - make a safe cover and keep this system accessible for inspection & repair.

The sump can provide extra insurance against water leakage up through the remains of the filled-in slab ductwork; also depending on site conditions and building construction, a sump can actually lower the water table under an area of building leakage.

See SUMP PUMPS for details.

Structural reinforcement requirements when filling in-slab ducts with concrete?

I cannot imagine why it would be necessary to install re-bar or any other structural reinforcement into the in-slab duct openings before filling the ducts with concrete.

I cannot imagine why it would be necessary to install re-bar or any other structural reinforcement into the in-slab duct openings before filling the ducts with concrete.

You may have been misled by a photo I used in the article above

at HOW to ABANDON IN-SLAB & OTHER TRANSITE ASBESTOS HVAC DUCTS.

But the purpose of this material was not at all structural.

Rather it was to hold in place a backer (I used a section of drywall) to place about 3-inches down into the floor register opening so that I wouldn't need much concrete to fill and seal just the floor opening itself.

As you will read below, the decision about whether to just seal the register openings in the slab or to fill in the entire duct passage depends on several variables.

In the example home to which my photo (at left) pertains, no area of the original concrete slab was left with cracks or openings that made us worry about contaminants entering the building through the duct passage.

The finish flooring (other than in the garage) was ceramic tile as you can see in our photo.

We filled the HVAC ducts at the supply registers and then sealed that surface by installation of a new ceramic tile floor. There were not worrisome slab cracks, the slab upper surface is above grade, and there was no history of water entry coming up through the slab ducts into the building. Your case and your worry are different.

...

Seal HVAC Ducts Routed In or Below a Floor Slab?

Application of an internal sealant to the air ducts to keep using them?

Application of an internal sealant to the air ducts to keep using them?

Because there is a whole industry of folks who offer to "seal" HVAC ducts in slabs by spraying a coating therein, we address that topic here but first:

Bottom line: We do not recommend this approach because there are serious questions about its thoroughness, durability, and longer-term reliability.

For most buildings it's sufficient to simply close off all of the slab openings formed by supply or return air openings. We describe those steps

at HOW TO ABANDON IN-SLAB HVAC DUCTS

For buildings subject to flooding or water entry up through the slab owners may need to take more aggressive steps taht we describe

at HOW TO ABANDON IN-SLAB DUCTS in WET BUILDINGS

Watch out: if you are planning to seal in-slab ducts and then keep using them, keep in mind that continuing to use in-slab ductwork, if it makes people in a building sick, may have a much greater cost than the cost of abandoning the system. .

Duct Interior Sealants: apply an internal HVAC air duct sealant

There are spray coating duct-sealants that some contractors offer as an in-duct sealant/spray.

The contractor extends a spray wand into the HVAC ducts to deliver a coating that, if perfectly successful, can prevent or at least reduce the risk of asbestos fiber release into the building air.

And Andrew Oberta has described standards methods for repairing asbestos-cement products including underground transite piping.[5]

A down-side with in-slab ductwork is the difficulty in accessing for application of the spray and difficulty in inspection in the future to see what's going on inside the duct: collapsing walls, sealant falling off of duct interior, flooding, mold, asbestos-releasing scraps, rodents, etc.

Our in-slab air duct photo shows evidence of a history of floods in the duct system as well as rodents (the rodent poison).

Watch out: rodent poisons themselves can be a hazard to building occupants or pets, particularly if not properly applied by a licensed, trained pest control officer or PCO expert.

Watch out: rodent poisons themselves can be a hazard to building occupants or pets, particularly if not properly applied by a licensed, trained pest control officer or PCO expert.

A second concern is that even if the coated transite air duct interior surfaces appear to have been treated successfully, especially with in-slab ducts we are not assured that the in-slab ducts remain clean, dry, and undamaged in the future nor that the transite duct interior coating remains bonded to the duct surfaces.

But given the history of concerns with the product, in particular with in-slab ducts, we would give strong consideration to abandoning in-slab ductwork entirely.

Reader Question: best way to seal in-slab ducts when abandoning them - how to minimize radon hazards in the slab ductwork

Rod

Dan, I have Sub Slab air returns in my Tucson home (my delivery ducts are above slab) which appear to be rectangular metal ducting.

I have Radon levels of about 5.5+ if I leave the air handler fan always on and about 3.5 if I leave it off (we're not into the cooling season yet so I have the option of having it not run at all for now).

I don't have a problem abandoning the returns as I can raise the air handler and build a new plenum below and make returns that vent directly into the room.

However sealing for Radon, I'm thinking I'd like to put a high density plastic sheet or panel in the vent and then pour concrete over that rather than just using concrete, less permeable to gas. Have you seen anything like this done?

Reply:

Rod,

I agree with your plan to abandon the in-slab ducts. Not only are there the issues we've discussed in the article above, but where radon gas is a concern, the fact that the ducts are at negative air pressure when the HVAC system is running increases the risk of radon gas entry into the home.

I appreciate too your interest in making a well-sealed abandonment procedure for the slab ductwork.

I'm not sure of the practicality of placing a plastic sheet or panel in the vent. If you mean simply covering the vent opening into the building with plastic in the process of filling the whole duct, that's reasonable.

And I don't think it'd be easy to line the entire duct in that manner - because of what I usually find is limited access.

You could alternatively hire a duct sealing company to spray the whole duct interior with a plastic coating/sealant before filling the entire HVAC duct with concrete throughout its run.

My OPINION, which is just that as we have no data, is that the lining step is unnecessary. If you fill the duct completely with concrete it ought to be at least as well sealed as the rest of the basement floor slab where there are no ducts.

Further, 5.5 pCi/L is a very low level, as the action level is just 4 pCi/L - I'm not sure that added and costly measures would be justified. (We realize the true radon level number varies by weather, season, and more significantly air movement patterns in the building.)

I would:

1. completely fill the return ducts with concrete

2. seal any other basement slab cracks or other obvious radon entry points

3. perform a long term measurement, for a year, or else for shorter intervals representing seasons when there are likely to be more upwards air currents in the home (upstairs windows open, heating season, exhaust fans in use).

4. Based on the results of 3, do nothing else, or if necessary, install a mitigation system (sub-slab suction exhaust)

Rod continued:

No, it would be to cover the opening of the duct, not to try and line the duct. Do you really have to fill the whole thing?

If I felt like I had a more serious radon problem, I'd be tempted to try and plug each end of the returns and stub a 4 - 6" pvc pipe through the plug so I could use the existing duct space as part of the slab depressurization system, since it's obviously leaky.

Anyway I was hoping to construct plugs in the duct not fill it.

Reply: why fill the whole in-slab duct?

Rod, a reason for filling the whole duct is to prevent other duct cavity areas from taking up radon from the soil below and leaking it into the home.

But sure, if a duct runs under a sound, un-cracked slab, you could just fill the duct opening.

See "How to Abandon in-slab and other transite asbestos HVAC air ducts" and the accompanying photos in the article above. With a good seal of concrete and no cracks, the addition of a plastic sheet isn't helping and might be a source of cracks.

Also see PVC HVAC DUCTS

Rob continued:

What would you do once the ducts are sealed? How would you run heat to the closed off areas?

Reply: getting heat into areas of abandoned in-slab ducts

We describe various alternatives in this article series - the best solution to getting heat into the areas no longer served by in-slab duct depend on the building and what's most convenient:

- new ducts through walls, ceilings

- conversion to forced hot water

- spot heat using electric baseboard

...

Codes, Standards, Guidelines for In-Slab HVAC Duct Design

- 2015 IRC CHAPTER 26 DUCT SYSTEMS [PDF] Section M1601 DUCT CONSTRUCTION as adopted by the state of Utah, retrieved 2019/10/03 original source: https://up.codes/viewer/utah/irc-2015/chapter/16/duct-systems#16

Excerpt:

M1601.1.2 Underground Duct Systems

Underground duct systems shall be constructed of approved concrete, clay, metal or plastic. The maximum duct temperature for plastic ducts shall not be greater than 150°F (66°C).

Metal ducts shall be protected from corrosion in an approved manner or shall be completely encased in concrete not less than 2 inches (51 mm) thick.

Nonmetallic ducts shall be installed in accordance with the manufacturer's instructions. Plastic pipe and fitting materials shall conform to cell classification 12454-B of ASTM D 1248 or ASTM D 1784 and external loading properties of ASTM D 2412.

Ducts shall slope to an accessible point for drainage.

Where encased in concrete, ducts shall be sealed and secured prior to any concrete being poured.

Metallic ducts having an approved protective coating and nonmetallic ducts shall be installed in accordance with the manufacturer's instructions. - [16] ACCA: Manual D—Residential Duct Systems – Air Conditioning Contractors of America (ACCA)

- American Concrete Institute, "Guide for Concrete Floor and Slab Construction" [at Amazon.com], (2004), ISBN-10: 0870311514 ISBN-13: 978-0870311512

- Bauman, Fred, and Tom Webster. "Outlook for underfloor air distribution." [PDF] Center for the Built Environment (2001). - Note: this article is about using crawl spaces not under-slab ductwork. The authors, arguing for the benefits of this system, in our opinion, fail to address any of the common problems found with HVAC ducts routed through rarely-entered, less rarely-inspected spaces. Abstract:

Underfloor air distribution (UFAD) is an innovative technology that uses the underfloor plenum below a raised floor system to deliver space conditioning in offices and other commercial buildings. The use of UFAD is increasing in North America because of the benefits that it offers over conventional ceiling-based air distribution. - Carino, Nicholas J., and Mary Sansalone. "Detection of voids in grouted ducts using the impact-echo method." ACI Materials Journal 89, no. 3 (1992).

Abstract:

The impact-echo method was used to detect simulated voids in grouted post-tensioning tendon ducts cast in a 1-m (39.4-in.) thick concrete wall specimen. The study was part of a program sponsored by CANMET (Ottawa) to evaluate nondestructive test methods based on stress wave propagation.

The locations of the voids in the ducts were not known until after their results had been reported to the principal investigator of the project.

The impact-echo method successfully located most of the voids. The study provided impetus for additional experimental and analytical studies to better understand the interaction of stress waves with voids in cylindrical duct. It also highlighted the need to increase testing speed and develop a method to automate signal interpretation. - [19] Florida Mechanical Code, Section 610: Air Distribution Systems

- JLC Online, "Abandoning Old Underslab Ductwork", Journal of Light Construction, Retrieved 12 Sept 2015, original source: http://forums.jlconline.com/forums/forum/jlc-online-expert-forums/building-science/839-abandoning-old-underslab-ductwork

- Koschenz, Markus, and Viktor Dorer. "Interaction of an air system with concrete core conditioning." Energy and Buildings 30, no. 2 (1999): 139-145.

Abstract: In Europe, hydronic concrete core systems are being increasingly used for room conditioning systems. The concrete slab acts as heat accumulator and permits dissipation of the load using, for instance, cooling towers.

When using such systems the external climatic conditions limit the achievable water temperature. The convective loads, however, directly affect the room air temperature and reduce the storable part of the load.

The ventilation system also has a large influence on the energy related operation of such a system. Moreover, the dimensions of the concrete slab and the layout geometry of the water pipes, especially the spacing, are important factors for the design of the system.

A model is described which can be used to illustrate the transient two dimensional heat flow in such a construction.

This method is suitable for simple hand calculations, but can also be integrated into existing building simulation programs without having to modify the program code. Thus, the complete system can be designed for practical applications to ensure optimum operation.

In addition, this paper describes the interrelationship between heat storage capacity and pipe geometry.

Finally, criteria are listed for suitable application of concrete slab cooling and further aspects are listed that need to be considered in connection with these systems. - McGill Air Flow, LLC., "Uni-Coat™ Installation Guidelines for Installing Underground Duct", McGill AirFlow, LLC, McGill AirFlow Headquarters One Mission Park Groveport, Ohio 43125 614/829-1200, Email: marketing@mcgillairflow.com, Website: mcgillairflow.com, the U.S. Company has offices in many U.S. states, - retrieved 12 Sept 2015, original source: http://www.mcgillairflow.com/textDocs/uniCoat/uc_install.htm

- Park, Robert, and William L. Gamble. Reinforced concrete slabs. John Wiley & Sons, 2000.

- Schickert, Martin, Martin Krause, and Wolfgang Müller. "Ultrasonic imaging of concrete elements using reconstruction by synthetic aperture focusing technique." Journal of Materials in Civil Engineering 15, no. 3 (2003): 235-246. Abstract:

The main purpose to use ultrasonic pulse echo techniques for concrete are the following testing B;problems: Injections faults in tendon ducts because they lead to a loss of the basic protection of the tendon steel and can result in corrosion damage Compaction faults or honeycombing because they reduce the concrete strength. They influence the static stability beginning from a diameter of about 50 mm. - Sullivan, John F. "Air duct boot." U.S. Patent 4,773,197, issued September 27, 1988.

- [18] Uniform Mechanical Code, 2003 Edition, Appendix A: Standard for Installation of Factory-Made Air Ducts

- Werner, Henry H., "Concrete slab and embedded duct structure." U.S. Patent 2,783,639, issued March 5, 1957.

- partial excerpt:

Heretofore in building constructions employing reinforced concrete slabs as structural units for the floors and the like, in order to provide the necessary services for the building, such as electric lighting, telephones, radio, inter-communications, radiant heating and cooling, air conditioning and soundproofing and the like, many expedients have been followed.

Some have resorted to the installation of an underfloor duct system in afill on top of the structural concrete slab for distribution of the wiring.

Such ducts are necessarily shallow in order to avoid excessive fill and because of the cost they are spaced considerable distances apart, for example, four to six feet.

Thus they cover only a minimum of floor space, and allow minimum flexibility. - Zhu, Jinying, and John S. Popovics. "Imaging concrete structures using air-coupled impact-echo." Journal of engineering mechanics 133, no. 6 (2007): 628-640.

Thank you to our readers for their generous comments

What a terrific article with so much sharing of issues and helps. Thank you - On 2016-07-08 by Barry

Great info here; it makes me feel much better to read - On 2021-12-15 by Steve - I appreciate all the info here - what a wealth of knowledge! about in-slab HVAC ducts

Great information on duct work in concrete, - On 2020-02-19 by Aaron Burnham - Great information on duct work in concrete - what can be done with respect to air-conditioning in the summer if I abandon in slab ducts?

...

...

Continue reading at WATER & ICE IN DUCT WORK or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see SLAB DUCTWORK FAQs - questions & answers posted originally at this page.

Or see these

Recommended Articles

- ASBESTOS TRANSITE DUCTWORK

- DUCT & AIR HANDLER ODORS

- PVC HVAC DUCTS

- SLAB DUCTWORK

- TRANSITE PIPE AIR DUCT ASBESTOS RISKS

- WATER & ICE IN DUCT WORK

- WET CORRODED DUCT WORK

Suggested citation for this web page

SLAB DUCTWORK at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HVAC DUCT SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [20] Thanks to Indoor Air Care Corp., for their photograph of flooded flex-duct. The Southhampton NY company can be reached at 866 580-MOLD

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.