Condensate drains & pumps

Condensate drains & pumps

Codes & recommendations for HVAC Condensate Drainage

- POST a QUESTION or COMMENT about air conditioner or heat pump condensate drain installation, leaks, clogs, troubleshooting, repairs

A/C condensate drains & pumps: codes, installation, leaks, clogs, connections, troubleshooting & repair.

We discuss air conditioning, heat pump & condensing boiler or furnace condensate drain leaks, locations, causes, repairs. Air conditioning condensate drain clogging - how to de-clog the A/C condensate line or drain pump. Air Conditioning Condensate Handling defects lead to condensate spillage, leaks, mold.

Where should the air conditioner or heat pump condensate drain be connected - where are we permitted to dump condensate? Examples of Model Building Codes Condensate Disposal Regulations & Recommendations

Condensate leak health and safety concerns are reviewed.

Page to photo: improper connection of the AC condensate drain to a plumbing vent risks sewer gas leaks into the building air conditioning system.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

What are the Proper Locations for A/C or Heat Pump Condensate Disposal

This article discusses the inspection and repair or un-clogging of condensate disposal systems, including air conditioning, heat pump or condensing boiler/furnace condensate drains & condensate pumps, and their proper installation as part of our review of condensate piping, traps, drains, condensate pumps, and the detection and hazards of air conditioning system condensate leaks in buildings.

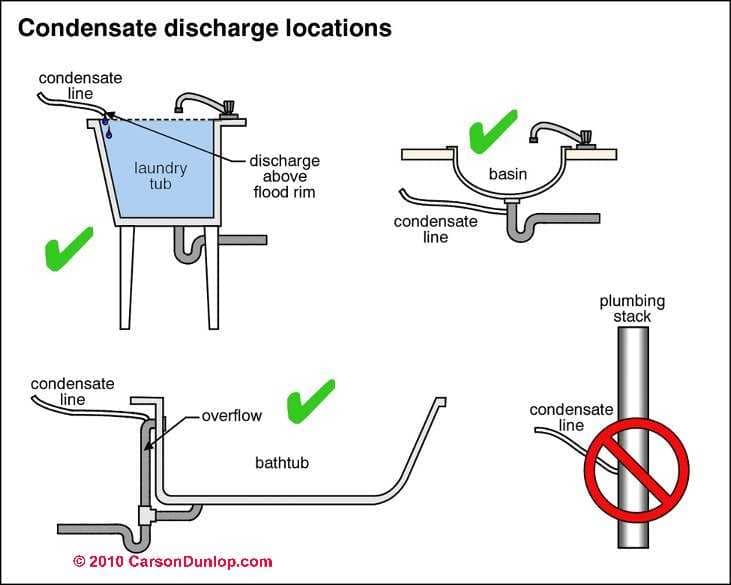

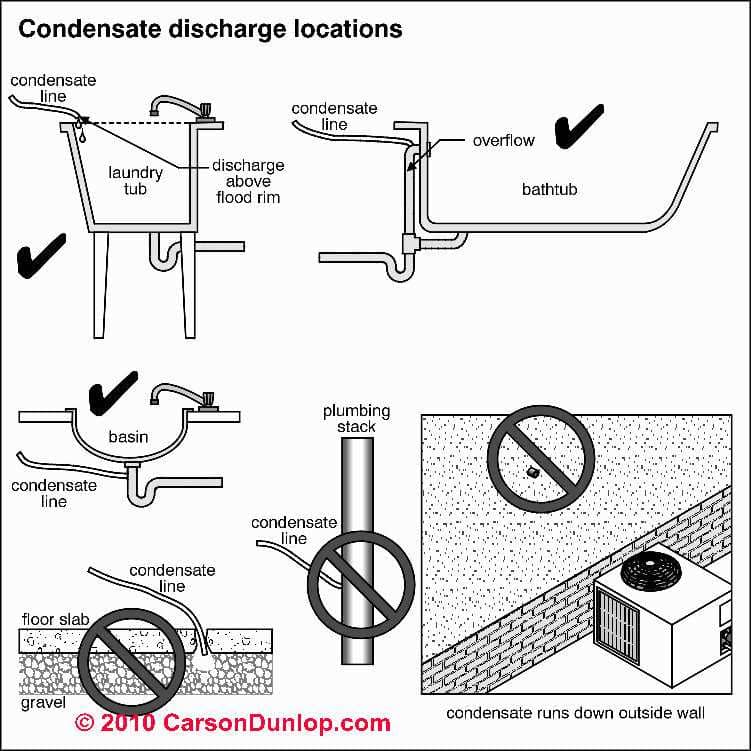

Carson Dunlop's sketch shows the proper locations for disposal of air conditioner or heat pump condensate.

Notice that one of the most common condensate disposal locations, connection to a plumbing stack vent pipe, is not recommended and is prohibited by building code in some jurisdictions.

Article Series Contents

- CONDENSATE DRAINS, CODES - this article

- LOCATIONS for CONDENSATE DISPOSAL - proper locations

- PLUMBING CODE for CONDENSATE DRAINS - code citations

- CONDENSATE DISPOSAL, IMPROPER

- CONDENSATE DRAIN CLEAN & DE-CLOG

- CONDENSATE DRAIN INSULATION REQUIREMENTS

- CONDENSATE DRAIN PAN CLEANING

- CONDENSATE RETURN PIPES, PUMPS, STEAM

- CONDENSING BOILER/FURNACE CONDENSATE DRAIN

- DIRECT VENTS / SIDE WALL VENTS

Plumbing Code Citation for Installation of Air Conditioning Condensate Drain Piping

Carson Dunlop Associates sketches (left) illustrate both acceptable and not-recommended locations for the discharge of an air conditioner or heat pump condensate drain line discharge.

Carson Dunlop Associates sketches (left) illustrate both acceptable and not-recommended locations for the discharge of an air conditioner or heat pump condensate drain line discharge.

Uniform Mechanical Code Section 310.0, 310.1 Condensate Disposal

Here is an excerpt from the Uniform Mechanical Code pertaining to the disposal of air conditioning condensate:

Condensate from air washers, air cooling coils, fuel-burning condensing appliances, the overflow from evaporative coolers and similar water supplied equipment or similar air conditioning equipment shall be collected and discharged to an approved plumbing fixture or disposal area.

If discharged into the drainage system equipment shall drain by means of an indirect waste pipe.

The waste pipe shall have a slope of not less than 1/8 inch per foot (10.5 mm/m) or one percent slope and shall be of approved corrosion-resistant material not smaller than the outlet size as required in either Section 310.3 or 310.4 below for air-cooling coils or condensing fuel-burning appliances, respectively.

Condensate or waste water shall not drain over a public way.

To clarify, an indirect waste pipe is something that is upstream of a trap. That means we cannot dump into anything downstream of a trap. That would include the main plumbing vent stack. -- [Thanks to Al Carson, Carson Dunlop Associates, Toronto]

ICC Model Building Code, Section 307: Condensate Disposal Regulations & Recommendations

Note: new in 2015 is the ICC IMC 307.2.5 & IRC M1411.3.3 Drain Line Maintenance code for 2015

The ICC, under "Drain Line Maintenance" requires that

Condensate drains shall be configured to permit the clearing of blockages and performance of maintenance without having to cut the line. - ICC IMC 307.2.5 & IRC M1411.3.3 Drain Line Maintenance code for 2015, original source: http://www.iccsafe.org/

Devices or methods for providing condensate drain cleaning or de-clogging are discussed in this companion

article: CONDENSATE DRAIN CLEAN & DE-CLOG

The following HVACR condensate disposal recommendations summary cites, paraphrases, & comments on the widely adopted 2006 ICC model building code section on condensate disposal, section 307 [7]

1. Requirement for a drainage system

For the two Types of Condensate: Fuel burning devices vs Evaporators & cooling coils

- 307.1 requires that liquid condensation from fuel burning appliances be collected and discharged "to an approved plumbing fixture or disposal area in accordance with the manufacturer's instructions"

- 307.2 requires a condensate drain system for appliances containing evaporators or cooling coils, conducted from the appliance drain pan to an approved destination

2. Types, sizes, slope of Condensate Drain Piping

- 307.1 Condensate drain piping must be corrosion resistant for condensate from fuel burning appliances. using "corrosion-resistant material" and sized "no smaller than the drain connection on the appliance"

- 307.2.2 Condensate drain piping materials can be "... cast iron, galvanized polybutylene, polyethylene, ABS, CPVC or PVC pipe or tubing"

- Piping shall be at least 3/4" in diameter and ... shall not decrease in size ... [throughout its run from the condensate drain pan to its final disposal destination - no constructions by diameter]

- Horizontal runs of condensate drain piping slope at least 1/8" per foot in the direction of discharge. There is also a requirement for "uniform slope" and "uniform alignment"

4. Acceptable Condensate Drainage Terminations

- 307.2: "... Condensate shall not discharge into a street, alley or other areas so as to cause a nuisance." [i.e. do not discharge HVACR condensate over a sidewalk

5. Requirements for a Backup Condensate Drain System & Backup Condensate Drain Options

- 307.2.3 A secondary condensate drain system is required not in every installation instance, but in every installation at which "where damage to any building components will

occur as a result of overflow from the equipment drain pan

or stoppage in the condensate drain piping".

This backup condensate system requirement refers for example to an indoor air handler installed in an attic or in living space where leakage into the attic ceiling or onto a floor system could cause damage to the structure.

Typical damage includes cosmetic leak stains, mold infections of wet drywall or insulation, structural damage from rot or inviting insect attack, and even, as one reader reports, unsafe collapse of a ceiling fan mounted below the leak area. - 307.2.3 recommends any of the following methods for handling a backup condensate overflow protection system:

- 1. An auxiliary drain pan with separate drain:

an auxiliary condensate drain pan at least 1.5" deep and at least 3" larger than the length & width of the appliance beneath which it is placed, using corrosion-resistant material of adequate thickness (0.7mm galvanized metal or 1.6mm non-metallic e.g. plastic) with a separate drain installed under the equipment and discharged to a conspicuous point that will alert building occupants to a blocked primary condensate drain - 2. A separate or secondary condensate overflow drain line

connected to the primary or OEM equipment's drain pan at a higher level than the main drain, and discharged as in 1. above. - 3. An auxiliary drain pan without a separate drain line but instead provided with a water-level detection device

(a switch that senses the presence of water in the drain pan) conforming to UL 508. The water or condensate detection switch in the drainless condensate overflow pan is wired to shut down the equipment. - 4. A water detection device (UL 508)

that will shut off the equipment in event of blockage of the primary condensate drain can be installed in any of several locations that in essence detect that the primary drain is backing up: in the primary condensate drain pan, in the primary condensate drain line, or in the condensate overflow drain line, positioned to detect and shut down the equipment before the primary drain pan would overflow. - An exception to this condensate backup or overflow protection requirement is made for

fuel-fired appliances that already include features that automatically shut down the device should the condensate drain become blocked. This feature is found, for example, on some condensing heating boilers or furnaces.

- 1. An auxiliary drain pan with separate drain:

6. Other requirements for a condensate water-level monitoring device

- Section 307.2.3.1 requires use of a water-level monitoring device to provide condensate overflow protection on equipment where there is no secondary condensate drain and no ability to install an auxiliary condensate drain pan. Quoting

"This device shall shut off the equipment served in the event that the primary drain becomes restricted. Externally installed devices and devices installed in the drain line shall not be permitted."

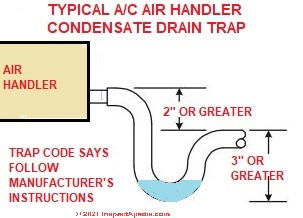

7. Model building code requirements for a P-trap on the HVACR condensate drain system

Bottom line: The model building codes require a P-Trap on all plumbing waste lines that is connected to a sewer.

The model same model building codes contain these very minimal requirements for traps on condensate removal lines for HVAC equipment:

1. a trap shall be installed in accordance with the unit manufacturer's installation and operating instructions

2. the condensate drain line slope towards its final drainage point shall be at 1/8" per foot [or, of course greater, where vertical drains are used - Ed.]

OPINION: your local building code compliance inspector/officer is the final legal authority on HVAC condensate drain trap requirements.

- IMC 407.2.4, Traps, requires that "Condensate drains shall be trapped as required by the equipment or appliance manufacturer." We interpret this provision to defer to the equipment manufacturer's installation instructions.

Watch out: in our OPINION and as we discuss in these articles, while a trap on a condensate drain line, usually provided quite close to the condensate collection pan itself, can reduce the chances of sewer gases backing up from a condensate drain that has been connected to the building DWV vent piping (not a procedure we recommend),

a conventional P-trap in the condensate drain will not protect against all sewer gas backup possibilities.

In particular, when an air conditioner is shut down for long periods of time (say during the heating season) it is common for the water condensate contents of the trap to dry out, thus losing protection against sewer gas leaks backing up through that system. Solutions often proposed are for a trap of sufficient depth that water in the trap will not evaporate sufficiently to lose the trap seal during periods when no condensate is being produced.

Special trap product can also provide a seal against sewer gas back-drafting through a dry trap. See detail

at DRY PLUMBING TRAP CAUSE & PREVENTION

- Canadian CMC 310.3: condensate waste pipes must be made from materials designed to work with that type of condensate drainage.

- U.S. IMC 307.2. 2: an A/C condensate drain inside diameter should not be smaller than 3/4″ and should not be smaller than the drain pan outlet diameter.<

3/4" condensate drain diameter is sufficient for up to 20 tons unless the drain outlet size on the unit itself is larger than 3/4″

Condensate Drain Insulation Code?

Moved to CONDENSATE DRAIN INSULATION REQUIREMENTS

Condensate Pan, Overflow Pan or Base Pan Cleaning Recommendations

We did not find cleaning requirements for condensate drip trays cited in the model building codes surveyed to date. However a read of manufacturer's installation instructions can provide further advice. For example:

"In some installations, dirt or other debris may be blown into the unit from the outside and settle in the base pan (the bottom of the unit).

In some areas of the United States, a “gel-like” or “slime-like” substance may be seen in the base pan.

Check it periodically and clean, if necessary." General Electric Zoneline® instructions [8][9]

Watch out: see the warnings and advice about health hazards in HVAC systems and condensate handling systems

See

- CONDENSATE DRAIN CLEAN & DE-CLOG - cleaning the condensate drain trap and drain line

- DIRTY HVAC COIL CLEANING PROCEDURES

- Legionella BACTERIA & HVAC EQUIPMENT

HVAC Condensate Drain & Condensate Drain Trap Installation Instructions

- Also see CONDENSATE DRAIN INSULATION REQUIREMENTS [Web Article] where we provide condensate handling codes & standards

- AIR CONDITIONER SLEEVE OUTDOOR DRAIN KIT INSTALLATION INSTRUCTIONS [PDF] Lowes Building Supply 2021

Note:

These instructions specifically warn to avoid drain hose traps or kinks that may otherwise block successful condensate drainage disposal to the building exterior - Also see: specific condensate drain installations for your specific air conditioner, heat pump, or condensing gas furnace

Examples discussing the code and manufacturer's statements on the requirement for a condensate drain line trap are below: - Amana, ARUF & ASPT AIR HANDLER INSTALLATION & OPERATING INSTRUCTIONS [PDF] (2017)

Excerpts:

NOTE: When units are installed above ceilings, or in other locations where damage from condensate overflow may occur, it is MANDATORY to install a field fabricated auxiliary drain pan under the coil cabinet enclosure. The installation must include a “P” style trap that is located as close as is practical to the evaporator coil.

See [above, as edited for clarity-Ed] for details of a typical condensate line “P” trap. NOTE: Units operating in high static pressure applications may require a deeper field constructed “P” style trap than is shown in Figure 12 to allow proper drainage and prevent condensate overflow.

NOTE: Trapped lines are required by many local codes. In the absence of any prevailing local codes, please refer to the requirements listed in the Uniform Mechanical Building Code.

A drain trap in a draw-through application prevents air from being drawn back through the drain line during fan operation thus preventing condensate from draining, and if connected to a sewer line to prevent sewer gases from being drawn into the airstream during blower operation.

Use of a condensate removal pump is permitted when necessary. This condensate pump should have provisions for shutting off the control voltage should a blocked drain occur. A trap must be installed between the unit and the condensate pump.

IMPORTANT NOTE: The evaporator coil is fabricated with oils that may dissolve styrofoam and certain types of plastics. Therefore, a removal pump or float switch must not contain any of these materials.

- Amana CONDENSING GAS FURNACE SERVICE MANUAL [PDF] Models GUCA, GCCA & Accessories (1998) source: Questar Gas https://www.questargas.com/ForEmployees/qgcOperationsTraining/Furnaces/Amana_GUCA_GCCA.pdf

Excerpts:

[Exhaust flue/vent] Piping must be adequately secured and supported to prohibit sagging, joint separation, and/or detachment from the furnace. Horizontal runs of vent/flue piping must be supported every three feet and must maintain a 1/4 inch per foot downward slope, back towards the furnace, to properly return condensate to the furnace’s drain system.

... Precautions should be taken to prevent condensate from freezing inside the vent/flue pipe and/or at the vent/flue pipe termination. All vent/flue piping exposed outdoors or in unheated areas must be insulated with 1/2” thick closed cell foam such as “Armaflex” or “Insultube.” Inspect piping for leaks prior to installing insulation.

A vent termination shall not terminate over public walkways or over an area where condensate or vapor could create a nuisance or hazard or could be detrimental to the operation of regulators, relief valves, or other equipment...

See in this document excerpted from the manual:

AMANA GUCA GCCA CONDENSATE DRAIN LINES AND DRAIN TRAP INSTRUCTIONS (1998) pp. 29-32 - Intertek CVC96 7 MVC96 TWO STAGE GAS FURNACE INSTALLATION INSTRUCTIONS (2016), Amana, Goodman Manufacturing, 5151 San Felipe Suite 500, Houston, TX 77056 USA Web: www.goodmanmfg.com • www.amana-hac.com

- Rectorseal Co., RECTORSEAL EZ TRAP CONDENSATE DRAIN LINE INSTRUCTIONS [PDF] RectorSeal® 2601 Spenwick Drive, Houston, TX 77055 (800) 231-3345

www.rectorseal.com - Also see CONDENSATE PUMPS for details about when, where, & how to use a condensate drain pump

Improper Disposal of Air Conditioning or Heat Pump Condensate Disposal

This topic has moved to CONDENSATE DISPOSAL, IMPROPER

...

...

Continue reading at CONDENSATE DISPOSAL, IMPROPER or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see CONDENSATE DRAIN CLEAN & DE-CLOG FAQs questions & answers about how to handle HVAC condensate drainage, posted originally on this page

Or see these

Recommended Articles

- BUILDING CODE DOWNLOADS - free downloadable PDF files of building codes & standards

- CONDENSATE HANDLING, HVAC - home

- CONDENSATE LEAKS

- CONDENSATE PUMPS

- CONDENSATE DISPOSAL, IMPROPER

- CONDENSATE DRAINS, CODES

- CONDENSATE DRAIN CLEAN & DE-CLOG

- CONDENSATE DRAIN INSULATION REQUIREMENTS

- CONDENSATE DRAIN PROBLEMS

- CONDENSATE DRIP TRAY DEFECTS

- CONDENSATE PAN SWITCH LOCKOUT

- Legionella BACTERIA & HVAC EQUIPMENT

- CONDENSING BOILER/FURNACE CONDENSATE DRAIN

- DUCT SYSTEM DESIGN SIZE & DEFECTS - home

- SLAB DUCTWORK

- WATER & ICE IN DUCT WORK

- WET CORRODED DUCT WORK

Suggested citation for this web page

CONDENSATE DRAINS, CODES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see this

INDEX to RELATED ARTICLES: ARTICLE I NDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- ICC, International Code Council, 500 New Jersey Avenue, NW 6th Floor, Washington, DC 20001 [P] 888-ICC-SAFE (888-422-7233) [F] (202) 783-2348 International: (202) 370-1800, Website: http://www.iccsafe.org/, Electronic / Digital products including copies of the ICC codes: 888-ICC-SAFE (888-422-7233), ext. 33822 eCodes@iccsafe.org

- [3] Reader Stuart Oakner suggested the Mighty Pump (below) as a method for clearing clogged or blocked air conditioning or heat pump condensate drains.

- [6] Simpson Strong-Tie, "Code Compliant Repair and Protection Guide for the Installation of Utilities in Wood Frame Construction", web search 5/21/12, original source strongtie.com/ftp/fliers/F-REPRPROTECT09.pdf, [copy on file as /Structures/Framing/Simpson_Framing_Protectors.pdf ]. "The information in this guide is a summary of requirements from the 2003, 2006 and 2009 International Residential Code (IRC), International Building Code (IBC), International Plumbing Code (IPC), International Mechanical Code (IMC), 2006 Uniform Plumbing Code (UPC) and the 2005 National Electrical Code." broad. Puerto Rico and the U.S. Virgin Islands enforce one or more of the I-Codes.

- [7] 2006 ICC Model Building Code Chapter 3, General Regulations, New Jersey Mechanical Code, web search 8/2/2012, original source: http://www2.iccsafe.org/states/newjersey/NJ_Mechanical/PDFs/2006_Chapter%203-General%20Regulations.pdf

Quoting about the ICC:

The International Code Council (ICC) was established in 1994 as a non-profit organization dedicated to developing a single set of comprehensive and coordinated national model construction codes.

The International Code Council is a member-focused association dedicated to helping the building safety community and construction industry provide safe, sustainable and affordable construction through the development of codes and standards used in the design, build and compliance process. Most U.S. communities and many global markets choose the International Codes.

The International Codes, or I-Codes, published by ICC, provide minimum safeguards for people at home, at school and in the workplace. The I-Codes are a complete set of comprehensive, coordinated building safety and fire prevention codes. Building codes benefit public safety and support the industry’s need for one set of codes without regional limitations.

Fifty states and the District of Columbia have adopted the I-Codes at the state or jurisdictional level. Federal agencies including the Architect of the Capitol, General Services Administration, National Park Service, Department of State, U.S. Forest Service and the Veterans Administration also enforce the I-Codes. The Department of Defense references the International Building Code for constructing military facilities, including those that house U.S. troops, domestically and a ... - [8] "GE Zoneline® Owners Manual and Installation Instructions, Heat/Cool Model 2900, Heat Pump Model 3900", General Electric Corporation, [copy on file].

- [9] "GE Zoneline® Owners Manual and Installation Instructions, Heat Pump Model 5800", General Electric Corporation, [copy on file].

- [10] "Whirlpool WGPH45 Packaged Heat Pump, Product Specifications", Whirlpool Corporation, [copy on file].

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.