Guide to Oil-Fired Hot Water Heaters - Inspection, Diagnosis, & Repair

Guide to Oil-Fired Hot Water Heaters - Inspection, Diagnosis, & Repair

- POST a QUESTION or COMMENT about diagnosing & repairing oil fired water heaters, calorifiers, geysers, hot water cylinders

This article explains how to inspect, diagnose, adjust, maintain, or repair oil-fired water heaters including the loss of hot water or inadequate hot water supply.

We include normal water heater maintenance, temperature adjustment, and improvements to hot water quantity as well as reduction in hot water heating cost. We also discuss important safety features and checks on oil fired heating equipment. And we describe how to restore a flood-damaged water heater to service.

This article series on oil hot water heat will answer most questions about oil-fired water heaters as well as many other building plumbing system inspection or defect topics. Our photo at page top shows an oil fired hot water system with the main components easily available, and with evidence of an oil burner operating problem.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Inspection, Diagnostic, & Repair Guide to Oil-Fired Hot Water Heaters

How do we identify an oil-fired water heater?

How do we identify an oil-fired water heater?

This page contains links to in-depth articles on inspecting, testing, and repairing problems residential hot water heaters of all types, including their parts, controls, and alternative sources for hot water as well as tips for improving hot water temperature, hot water pressure, and hot water quantity.

[Click to enlarge any image]

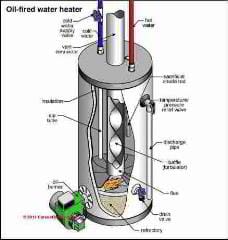

The sketch at left shows the basic components of an oil-fired residential hot water heater and is provided courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ]. It's easy to identify an oil-fired water heater:

- An oil burner will be mounted (usually) near the bottom of the hot water tank, fed by home heating oil from a local above ground or buried oil tank.

See OIL BURNERS

and

OIL BURNER NOISE SMOKE ODORS - A flue vent connector or "stack pipe" will leave the top or upper rear side of the water tank and continue on into a chimney (or directly outside if your water heater is a "direct-vent" or "power vent" system.

See CHIMNEY INSPECTION DIAGNOSIS REPAIR

and

see DRAFT REGULATOR, DAMPER, BOOSTER. - Two water pipes will be connected to the water heater: cold-water in, and hot water out. The hot water tank shutoff valve is normally installed only on the cold water supply line.

- A pressure and temperature relief valve should be installed right on the water heater, coming off of the tank top or upper area of its side.

See RELIEF VALVES - TP VALVES for details.

Watch out: sometimes an electric water heater is installed as an additional or backup hot water source, so you'll also want to see if you have other hot water heating equipment installed, such as

a TANKLESS COIL for HOT WATER. In our photo below an oil-fired water heater and an indirect-fired water heater are installed in tandem.

Here are a few things to check on your oil-fired water heater:

(WARNING: This is an INCOMPLE LIST and important water heater inspection topics may be omitted as we're working on this section. If you have comments, questions, suggestions, Contact Us.)

(WARNING: This is an INCOMPLE LIST and important water heater inspection topics may be omitted as we're working on this section. If you have comments, questions, suggestions, Contact Us.)

Check the pressure and temperature relief valve on your water heater: look for evidence of corrosion, leaks, improper installation, etc.

A missing, modified, blocked, or leaky pressure relief valve is extremely dangerous and can lead to a catastrophic BLEVE boiling liquid vapor explosion that can cause severe damage or even fatalities at a building.

Look for evidence of leaks in the hot water tank, or mechanical damage, or improper installation.

For example most water heaters are intended to be installed in a vertical position. Installing a hot water tank horizontally or in a hole in a crawl space is likely to cause early failure of the heater, violate the manufacturer's guidelines, and may be dangerous.

In our photo at left that puddle on the floor needs investigation.

Look for the draft regulator/barometric damper. If your conventional oil fired water heater does not have its own, personal draft regulator installed, it is impossible for the heater to have been tuned for optimum performance - you may be wasting money and heating oil.

See DRAFT REGULATOR, DAMPER, BOOSTER

Check the settings of the water heater temperature:

See WATER HEATER TEMPERATURE TOO COLD or TOO HOT

Look for insulation that has been improperly added to the water tank - it may be unsafe.

Look for signs of improper oil burner operation: such as sooting, draft problems, or back-pressure burns around the oil burner or around the combustion chamber inspection port.

Soot blowing out of the barometric damper or flue pipe, soot and burn marks, oil leaks, stumbling, rumbling, noisy oil burners, odors, are examples of improper oil burner operation that need prompt service.

Our page top photo and our photo at left show examples of improper oil burner operation on an oil fired water heater: both systems show soot blow-out at the water heater's combustion chamber inspection port. Our photo at left also shows that the discharge tube is missing from the relief valve - a safety concern.

Often these soot marks are a symptom of excessive pressure or "back pressure" inside the combustion chamber.

This problem can be caused by an oil fired water heater that is way past due for cleaning (soot blocks the exhaust flue), by a blocked chimney, by improper draft regulator adjustment, or other defects.

See OIL BURNERS

and OIL BURNER NOISE SMOKE ODORS

Check the hot water piping and control valves connected to the water heater for leaks, support, and for proper location of shutoff valves.

An improperly installed shutoff valve on a water heater can be very dangerous, risking an explosion. Usually the "hot water tank shutoff valve" is installed only on the cold water pipe coming into the water tank. There should be no shutoff valve installed on the hot water line leaving the water tank.

Check for leaks at the water heater drain valve. Most water heater manufacturers recommend that their water tank be drained periodically. This process will help remove sludge and debris or mineral deposits that may have accumulated at the bottom of the water heater tank.

Removing this debris can extend the life of the hot water tank, especially where electric and gas fired water heaters are involved. But since few people remember to open and drain the tank it may be that the drain valve does not open easily, or worse, it won't close.

- Tips On Draining the Oil-Fired Water Heater Tank: Don't try opening the hot water tank drain valve without first noting these warnings and tips:

- The water heater heat source should be turned off and the water tank cooled down (or run hot water out through building fixtures) before attempting to drain the tank - there can be a serious scalding hazard otherwise

- You can connect a garden hose to drain the water heater tank to a suitable destination

- If it's a Sunday - you may have trouble obtaining spare parts or emergency plumbing service if a problem occurs

- Be sure to have a spare garden hose cap to install over the end of the drain valve in case it drips and won't shut off completely

- If you have trouble turning the water heater tank drain valve to open it - don't force it - if break off the valve stem you may have a leak that you cannot shut off except by turning off cold water supply to the water heater

- After opening the heater drain valve, if you forgot to turn off the cold water supply coming into the water heater, you may find that water just shoots out of the drain forever - you'll need to turn off the cold water supply to the water heater.

- You will probably need to open a nearby hot water tap to let air into the plumbing system and through it into the water heater tank so that water can drain out at the tank's bottom. We don't recommend opening the pressure/temperature relief valve for this purpose as you may find that the TP valve won't shut successfully afterwards.

Check for heating oil leaks and oil piping defects:

see OIL TANK PIPING & PIPING DEFECTS

If plastic water piping is installed, such as polybutylene water supply piping, it should be at least 18" from the water heater.

Vacuum relief valves are required at water heaters in some communities, to protect against collapse of the water storage tank and to prevent backup of hot water into the cold water piping should cold water pressure drop. Here is Carson Dunlop's sketch of

A Guide to Oil Fired Water Heater Controls & Operation

The principal controls on an oil fired water heater include the following water tank and oil burner parts and controls:

- BOILER CONTROLS & SWITCHES (many controls on oil fired heating boilers are the same on oil fired water heaters)

- AQUASTAT FUNCTIONS - simple aquastats may be used as upper and lower limit controls on oil fired water heaters

- CAD CELL RELAY SWITCH FLAME SENSORS - turns off the oil burner if it does not achieve proper flame ignition

- CIRCULATOR PUMPS & RELAYS - may be used if the water heater is connected to a continuous hot water loop plumbing system or in (more rare) cases where an oil fired water heater is being used as a building area heating device (usually not code-approved)

- LIMIT SWITCHES, BOILERS combination aquastats or single-limit simple aquastats may be used as upper and lower limit controls on oil fired water heaters

- MIXING / ANTI-SCALD VALVES - used to permit keeping the water heater at high temperature (more total hot water will be available) without risking scalding the building occupants

- OIL HOT WATER HEATER TEMPERATURE CONTROL - how to adjust the hot water temperature

- RELIEF VALVES - TP VALVES - required on every pressurized tank, including oil fired water heaters

- STACK RELAY SWITCH - an older safety switch used to turn off the oil burner if successful burner flame ignition does not occur

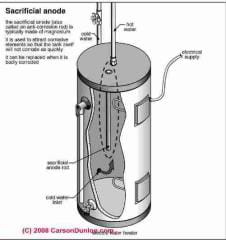

Check the Sacrificial Anode & Dip Tube of Your Oil Fired Water Heater Tank

The dip tube on many water heaters functions as a sacrificial anode, as we show here.

By constructing the dip tube of a metal which is more readily corroded than the steel of a steel hot water tank, the anode protects the hot water tank from early failure due to corrosion.

Here Carson Dunlop Associates' sketch shows the location of the sacrificial anode on an electric water heater.

If your water supply happens to be highly conductive or corrosivehen the dip tub/sacrificial anode in the water tank may indeed corrode away until it leaks (dropping the hot water temperature) or disappears entirely.

If your hot water smells like rotten eggs, you should definitely check the condition of the sacrificial anode on the hot water heater, no matter what kind of water tank you've got installed.

For details of how to inspect or replace the sacrificial anode or dip-tube on a water heater, please

see WATER HEATER ANODES & DIP TUBES

Check the Oil-Fired Hot Water Tank Temperature and Pressure Safety Relief Valve

Please see TESTING THE WATER HEATER TEMPERATURE PRESSURE RELIEF VALVE

How to Restore a Flood-Damaged Hot Water Heater To Save Service

Question: How do I get my oil fired water heater running again after building flooding?

I am having problems restarting the water heater ever since hurricane irene slammed into New Jersey and my basement flooded. We changed the motor and oil filter, but are having problems getting oil to feed through the lines I was wondering if there were suggestions. - Antoinette

Reply: recommended inspection & repair points for flooded oil fired water heaters, heating boilers, furnaces

When an oil fired water heater has been flooded, such as by hurricane Irene that flooded the Northeastern U.S. in August 2011, there are a number of concerns that need to be addressed.

Before addressing flooded water heaters, boilers, or furnaces, if your building has been flooded,

see FLOOD DAMAGE ASSESSMENT, SAFETY & CLEANUP for advice about priorities of entry, diagnosis & repair of homes or other buildings after flooding from any cause.

Now to the flooded water heater: you report having taken two important post-flood steps by changing parts (motor and oil filter) but below we have listed suggestions that might help get the water heater (or a flooded heating boiler or furnace) running again and also assure its safety and forward life.

The extent of disassembly, inspection, and replacement of parts of any heating appliance (water heater, furnace, boiler) after building flooding depends on the height reached by floodwaters and perhaps also the duration of flooding.

Our flood damage photo (above left) shows our client pointing to flood water markings on the heating system expansion tank - water had nearly filled the basement of this home - the heating boiler had been completely under water.

Certainly any component that was under-water or soaked needs to be inspected, and as appropriate, cleaned or replaced. On the other hand, basement flooding that did not even reach the level of the oil burner assembly may have left that component intact, but still may have entered and damaged the heating appliance combustion chamber.

We list some key post-flood inspection and repair points for water heaters, boilers, furnaces, just below.

What oil fired water heater parts are replaced after a building flood?

Chimneys & flues: In addition, a thorough inspection of the combustion chamber for damage and debris must be conducted before the equipment is returned to service.

Mud, sludge, debris anywhere inside of the heating appliance (combustion chamber, heat exchanger, chimneys, flues) has to be removed and the appliance cleaned. In addition, if area flooding sent flood waters inside of chimneys or flues (don't forget the chimney base and cleanout door) those areas need to be opened, inspected, cleaned.

Combustion chamber & chamber liner: most oil fired water heaters use a masonry (fire brick) or synethetic fabric combustion chamber liner. The liner heats to very hot during oil burner operation - a condition that helps assure complete combustion of fuel oil being sprayed into the combustion chamber.

Watch out: Firing up a flooded oil fired heating appliance before the combustion chamber liner has been dried or replaced risks damaging that component and possibly damaging the heater itself. Ask your service technician about the condition of the combustion chamber.

Controls on heating appliances: heating appliance (water heater, boiler, furnace) safety and limit switches and controls that have been flooded, in our OPINION, should be replaced. Other electrical components such as electrical wiring may be re-usable after inspection.

Electrical panels and circuit breakers that have been flooded should be replaced as even if they "look" fine, we're not confident that internal working parts have not been damaged by water, corrosion, or even silt and debris.

Heat Distribution: Ductwork: The inspection points listed above pertain to oil fired heating devices that have been exposed to flooding or sewer backups. In addition, for building heating systems, the heat distribution system may also have been flooded, damaged, or require repairs and cleaning.

See FLOOD DAMAGE in DUCT WORK for examples.

Oil burner assembly: First, you said that the "motor" was replaced. If you are not sure whether just the electric motor on the oil burner was replaced or whether the whole oil burner assembly was replaced,

see OIL BURNERS

for an illustration of the different parts involved. If the oil burner was submerged, and if only the oil burner's driving electric motor was replaced, additional disassembly and cleaning are probably in order to be sure that the oil burner nozzle, blower assembly, and other parts are clean and working properly.

Oil filter: it makes sense to replace an oil filter cartridge after a building has been flooded; the cartridge canister is normally air tight and thus water tight. But repair steps, movement of equipment, or other events may have contaminated the canister itself or oil tank or piping, sending more debris into the canister and filter.

For this reason it makes sense to not just replace the filter, but inspect and clean the canister that holds the filter.

Oil pump (fuel unit) internal filter screen: Debris, sludge, water, rust particles are often found in the bottom of the oil filter canister. If these enter the oil burner's oil pump (properly, the fuel unit), its internal filter screen may also be clogged - I'd be sure that the fuel unit has had its filter screen replaced.

Debris in the fuel unit will clog its internal check valves and the oil burner nozzle too, damaging the pump and leading to improper, even unsafe oil burner operation or total loss of heat later on.

Also a clogged filter screen can prevent the fuel unit from being able to pump oil from the tank - and could be mistaken for a blocked oil line.

Oil piping: if oil piping has become contaminated with sludge, it may be possible to blow the lines clear, but if not, oil line replacement will be needed. Details about unclogging a blocked heating appliance oil line are found

at OIL TANK PIPING & PIPING DEFECTS

Water heater (or boiler or furnace) insulation: most heating appliances (water heaters, furnaces, boilers) include an insulated outer jacket or "skin" that helps keep heat and noise inside the device and that improve its operation.

If the insulation on a flooded appliance is still wet when the appliance is turned back on you might get lucky and dry it out during the next operating cycle. Or equipment might be damaged, or the insulation might need replacement. Ask your service technician about the condition of the appliance insulating jacket.

Oil piping on flooded water heaters

Oil lines between an oil tank and the water heater can become blocked with sludge, silt, mud, and even water or sewage if the lines are open to the flooding environment. But normally an oil line between the oil tank and oil burner, say at a water heater, is always full of fuel oil, and sealed against oil leaks out and air leaks in to the piping system.

So dirt or water from outside the system would not easily enter the piping system. Details about spotting oil or air leaks in oil piping are found

at OIL SUPPLY LINE PIPING LEAKS and also

at OIL FILTERS on HEATING EQUIPMENT.

Other oil piping defects and oil line clogging are detailed

at OIL TANK PIPING & PIPING DEFECTS.

Check the oil tank: So how might debris enter and clog oil piping after a building flood? If the oil tank itself were flooded you might have water and mud or silt and dirt on the tank bottom - if your oil line feeds from the tank bottom all of that crud would enter the oil line. So a further check of the condition of the oil tank is in order.

A buried oil tank should, like the oil piping, be sealed against outside water entry (though in times of area flooding a partially empty oil tank might float-up and break lines or cause leaks).

An above ground oil tank should be ok IF flood waters never rose high enough to enter the oil tank vent or fill piping.

If your oil tank itself checks out as not contaminated with water and dirt, and provided we are sure that the oil burner assembly was itself entirely replaced and that the oil pump (fuel unit) is working properly, and if you are unable to draw oil from the tank, the usual step employed by the service tech is to use a CO2 gas cartridge and special "gun" assembly that connects to the oil line and attempts to "blow out" an obstruction.

If you are unable to make the line usable following that procedure, and provided we remain convinced that the line is the culprit, I'd have the service company run a new fuel line between the oil tank and the burner.

Check the oil supply valves: fusible link oil piping shutoff valves should be found at the oil burner (just before the oil filter) and perhaps also at the oil storage tank.

A valve at the oil tank is often used for service convenience if the oil piping exits at the tank bottom. If oil piping or the oil tank were open to floodwaters debris often collects right at the control valve.

See FIRE SAFETY CONTROLS for a discussion of oil piping fire safety valves.

Bleed the oil piping properly:

Also be sure the service tech was following proper procedure for bleeding air out of the oil piping during service restoration.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-02-04 - by (mod) -

That's puzzling, George; what might be freezing up?

If your oil storage tank is outdoors there's the common problem of waxing or of water in the tank freezing in the tank or line or filter.

I'd check the oil filter canister for signs of crud and rust and water.

On 2021-02-04 by GeorgeBaxter

When it is below freezing outside my oil water heater quits and won't start until air outside is above the freezing mark.

Oil flow is good.

On 2021-01-13 - by (mod) -

Another possibility is that the valve itself is damaged and leaking putting could have lost its internal washer. With the water heater turned off in pressure drained first thing attacked by do is replace the valve.

Also check your building's water pressure level and the heater's temperature setting.

On 2021-01-13 - by (mod) -

If that is a pressure temperature relief valve that is flushing it may be that the system is unsafe with temperature too high or pressure too high.

I'm not trying to close or block that valve or the water tank could explode.

You may need to turn off the water into the water heater and turn off the water heater itself.

On 2021-01-13 by Lance

The valve on the side of the tank won't shut off seems that it is spring loaded

The valve on the side of the tank won't shut off seems that it is spring loaded

On 2020-11-14 by Anonymous

who works on oil fired water heaters in cincinnati

On 2020-02-17 - by (mod) -

Angel,

The Bock 51PPC water heater (shown below) - used as a water heater - has itself nothing to do with heating a home, but it's possible that to service the heater a tech turned off oil supply to your heating system - or of course there's an independent problem.

Give the service company a call and let me know what is found as that will assist others.

On 2020-02-17 by Angel

Our bock model 51ppc heater is not wirking, we have hot water but no heat to the house. And it just got service

On 2015-08-25 - by (mod) -

No.

Putting an oil fired heater in a clothes closet is risking setting the building on fire; there are fire clearance issues, combustion air supply issues, and code concerns with a heater in a closet of a bedroom.

On 2015-08-25 by steve

Can i put a oil fired on-demand water heater in a clothes closet?

On 2015-07-03 - by (mod) -

Cindy:

Check first that the oil fired water heater is in fact on and runs in response to a call for hot water.

You may need to ask your plumber to drain debris and silt from the heater tank bottom and to check that the water heater dip tube is intact.

Typically when warm water comes out of the cold faucet then turns cold I think that the hot and cold piping are either close together in their routing (cold picks up heat from the hot pipe) or they both reside in a ceiling or other warm area near heating equipment.

So it may be that both cold and hot pipes are picking up a little heat from a boiler room but no hot water is actually being delivered by the water heater tank.

On 2015-07-03 by Cindy

I just had a water pressure tank replaced. Now my oil hot water heater is not working right. There was a lot of sandy black water that came throw the lines when we ran out the air in the lines. But when you run the hot water it will come out hot for about a min or so then go warm for a while then cold. The cold dose the same running hot for a bit then to cold. If you shut them off and wait about 1 to 2 min. This happens all over again with the hot but not the cold. I have flushed out the heater and all the lines, but it still dose it. What could this be. Nothing was done to the hot water tank just replaced the pressure tank for out well water.

On 2015-01-01 - by (mod) -

Joe

If you are talking about a tankless coil on a heating boiler, clogged tankless coil tubing will slow the flow rate through the tankless coil and might reduce heat transfer into the water, but it would not cause you to run out of hot water. IN fact since it would make you use hot water more slowly, it would last longer rather than run out sooner.

If the aquastat is not properly set on either a heating boiler or a water heater that could be the trouble.

On 2015-01-01 by JOE

The burner and hydrostat seem to be working fine. but for some reason after about 15 minutes i run out of hot water? this has just start over the past month or so. someone suggested the tubing inside the take might be bad, but no way to check this with out cuting the connection and pulling the tubes

any thoughts

On 2014-10-31 - by (mod) -

Paul G

Absolute: any oil fired heater needs annual service that includes cleaning, replacement of oil filter, oil fuel unit screen, nozzle, then burner adjustment, and typically vacuuming of the sooty interior of the heater and a complete check of the flue for soot - that may also need cleaning.

Sounds as if you are past due for service.

On 2014-10-31 by Paul G

Our oil-fired water heater shuts of about every 2 weeks , All I do is press the reset button (hold for 6 seconds) and it works for a few weeks before shutting off again. No other apparent problems...the water heats up quite quickly and to a good temperature. We do have to drain of the scale buildup quite often though. Any idea? Do these burners need any regular or cleaning?

...

Continue reading at OIL BURNER INSPECTION & REPAIR or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see OIL FIRED WATER HEATER FAQs - Q&A posted originally on this page

Or see these

Recommended Articles

- OIL BURNER INSPECTION & REPAIR

- OIL BURNER WONT RUN

- OIL FIRED WATER HEATERS

- OIL HOT WATER HEATER TEMPERATURE CONTROL

- WATER HEATER TEMPERATURE ADJUSTMENT CONTROLS - home

- WATER HEATERS - home

- WATER HEATER PROBLEM DIAGNOSIS

- WATER HEATER SAFETY

Suggested citation for this web page

OIL FIRED WATER HEATERS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.