Balanced Fresh Air Ventilation Systems

Balanced Fresh Air Ventilation Systems

Best IAQ Improvement

using Energy Recovery Ventilators ERVs HRVs

- POST a QUESTION or COMMENT about how to design, install, and use balanced fresh air ventilation systems in buildings

Balanced fresh air ventilation design, installation, & troubleshooting in buildings:

Tthis building ventilation design article explains the use of balanced fresh air ventilation systems, heat recovery ventilators, and energy recovery ventilators to improve indoor air quality in homes.

Lots of people consider dust, pollen, mold, animal allergens, pet hair as the main culprits in indoor air quality issues, allergies, and asthma aggravators. But many indoor contaminants are simply too small to see, or are not particles at all but rather gases or chemicals.

Balanced ventilation systems combine fresh air input with stale or contaminated air exhaust to improve indoor air quality while saving on building energy cost.

InspectAPedia tolerates no conflicts of Interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Balanced Ventilation Air for Improving Indoor Air Quality

As reported in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) :

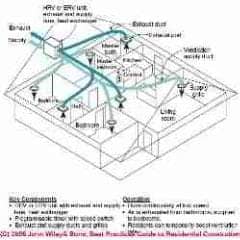

Balanced ventilation uses both a supply and exhaust fan to provide fresh air while keeping house pressures neutral. Linking a multiport supply system (described above) with a bathroom exhaust fan on the same switch is a form of balanced ventilation.

[Click to enlarge any image]

Article contents

Well suited to extreme climates, balanced ventilation provides optimal distribution of incoming fresh air and tempers it for comfort.

HRFs reclaim heat from the exhaust air while ERFs, recommended for hot humid climates, dehumidify and cool incoming air. For good performance, systems must be properly installed, balanced, and maintained.

Illustration Source: Recommended Ventilation Strategies for Energy-Efficient Production Homes, 1998, by Judy A. Roberson, et al., Lawrence Berkeley National Laboratory, appearing in the text cited above.

Most balanced ventilation systems, however, use a heat-exchanger to transfer heat and, with energy recovery ventilators (ERVs), humidity between the two air streams.

These systems, sometimes called air-to air heat exchangers, are the most expensive option for whole-house ventilation; but, if installed properly and well-maintained, provide optimal comfort and ventilation. Depending on the type of heat exchanger, balanced ventilators are referred to as either heat-recovery ventilators (HRVs) or ERVs.

Balanced Ventilation System Controls

One of our clients became so frustrated with problems balancing fresh air in her home that she simply cut out a window pane. This article discusses a better approach.

HRVs and ERVs are typically run continuously, but they also may be set to run 8 to 12 hours per day when people are at home.

In addition, most have a high-speed mode that can be manually activated for spot ventilation of kitchens and bathroom.

Some balanced ventilation systems also use dehumidistats to automatically turn on or increase ventilation when the air reaches a preset humidity level.

Balanced Ventilation System Ducting

While a dedicated ductwork system is the best approach for HRVs and ERVs, to save money they are often piggybacked onto the home’s HVAC ductwork. In one approach, the HRV or ERV draws exhaust air from the return ductwork and feeds fresh air into the furnace’s return plenum.

In a slightly better arrangement, the HVAC ductwork is used only for supply, while the exhaust side picks up stale air in bathrooms, laundry, and kitchen. Neither approach distributes fresh air as well as a dedicated duct system.

Also, since HRV/ERV fans operate at 100 to 200 cfm while air-handler fans are often sized at over 600 cfm, trying to integrate the controls, balance airflows, and provide the correct amount of ventilation air is challenging and rarely works well.

The most common approach is to run the ventilation system only when the thermostat calls for heating or air-conditioning, providing too little ventilation. Heat-recovery efficiencies are also compromised, typically due to unbalanced airflows.

Balanced Ventilation System Maintenance

One drawback of HRVs and ERVs is that they require more maintenance than other ventilation systems. Numerous studies have found that many of these systems significantly under perform in the field due to both installation errors and poor maintenance.

In addition to cleaning or changing intake, outtake, and internal filters, the homeowner or service person needs to clean the core once a year or more to prevent mold and bacteria growth. It is important to follow closely the manufacturer’s recommendations.

Unless the homeowner enjoys the responsibility of HVAC maintenance, the work is best handled by a professional service company.

Balanced Ventilation System Cost Effectiveness

For HRVs and ERVs to work properly and achieve the rated efficiencies, they must be installed correctly and balanced well, and the house must be very tight.

Even so, the added cost over a basic ventilation system will be recouped only in the most extreme United States climates with the highest energy costs. However, in very cold or hot climates where mechanical ventilation is needed during most of the year, the added cost may be justified by the comfort of tempered, filtered ventilation air, the effectiveness of the distribution, and the lack of pressure-related problems.

Heat Recovery Ventilation Systems - HRVs

Used primarily in cold climates, HRVs have two air streams that pass over one another in a plastic or aluminum heat exchanger.At left we show a photograph of a heat recovery ventilator.

Used primarily in cold climates, heat-recovery ventilators (HRVs) pass two air streams by one another within a plastic or aluminum heat exchanger, recapturing 60 to 75% of the heat from the outgoing air stream. This unit, installed in an attic, is hung from chains to reduce noise and vibrations.

Recovery of heat from the exhaust air typically ranges from 60 to 75%, if properly installed and balanced.

During the summer, if air-conditioning is used, the heat transfer reverses, cooling the incoming hot air. Systems generally have exhaust ports in rooms that generate moisture or pollutants, including bathrooms, laundry, and kitchen and supply ports in bedrooms, living rooms, and other main living spaces.

Because they have both supply and return ducting, HRVs provide the best distribution, exhausting air from bathrooms and other wet areas and providing fresh air to primary living space. The kitchen typically has its own range hood, so grease does not get into the HRV system.

Original Best Construction Practices Guide photo source: courtesy of David Hanson, memphremagog Heat Exchangers, appearing in the text cited above.

Defrost cycle for heat recovery ventilators

In cold climate applications, a defrost cycle is required. It usually switches on at about 20°F to keep frost from building up in the core as condensation from the exhaust stream begins to freeze. Systems either recirculate indoor air or preheat incoming air to prevent freeze-ups.

Energy Recovery Ventilators - ERVs for Indoor Air Ventilation

Energy-recovery ventilators are primarily used in air-conditioned homes in hot, humid climates. They are generally recommended for climates where the cooling load exceeds the heating load and where sustained freezing temperatures are rare. Sustained temperatures below 10°F can damage the permeable core material used in many ERVs.

ERVs either use a dessicant-coated plastic wheel or a special “enthalpic” core material to move moisture (latent heat), as well as sensible heat, between the two air streams. In summer, incoming air is cooled and dehumidified. Since dehumidification is the biggest component of air-conditioning costs in humid climates, it is important to find a unit with a high TRE (total recovery efficiency) rating, indicating that it can transfer large amounts of moisture.

To achieve the rated efficiencies, the units must be run at the recommended airflows.

In cold weather, an ERV will tend to humidify the incoming air, since the moisture transfer is always toward the less humid air stream. This is rarely a problem, however, since the cold incoming air holds so little moisture to begin with that the net effect of the air exchange is to remove humidity from the house.

This article includes excerpts or adaptations from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , by Steven Bliss, courtesy of Wiley & Sons.

Question: are fiberglass fragments or unidentified-dust on the exterior heat recovery ventilator ductwork an indoor air quality hazard?

We recently exchanged a few replies in the page bottom Comments section of

We recently exchanged a few replies in the page bottom Comments section of

this InspectApedia article: ASBESTOS in DRYWALL

Regarding glass fibers around a ventilation unit in a spare room we plan to store cooking supplies in etc., in a home we just started renting. The room is directly off our living room/kitchen. The building was built roughly 10 years ago.

Here is a picture. [Click to enlarge any image]

The taped areas used to have white/grey insulation sticking out but we had the landlord tape it up before we started moving in.

However, I notice on the unit and black wrapping/sleeving on the duct (pipes?) that there are dozens, if not 100+, shiny fibers all over it. Most of them are short, ~1-2 mm long. The pictures are unable to pick it up, so I didn't try getting a close-up.

There doesn't seem to be any in the other rooms or anywhere else, so I'm assuming none of it ever got into the actual air flow of the unit, or at least not a noticeable amount.

I've damp wiped some of the unit, but there are areas hard to get into and I'm unsure how to try cleaning off the black pipe sleeving. I'm also unsure how much of an issue this actually is and whether I should be even concerned.

I just want to make sure if it is an issue, I don't spread it and clean it properly. Some google searches of fiberglass hazards don't seem too helpful and have me worried, bringing up anything from it being just a nuisance dust all the way to cancer/mesothelioma links and blindness.

I look forward to your thoughts, thank you very much for your time.

Sincerely, - Anonymous by private email 2017/04/29

Reply: simple cleanup and cover-up for exposed fiberglass at flex duct ends

Got it - so the ventilator is a Venmar system and we're seeing dust on the duct exterior.

At FIBERGLASS FRAGMENT HAZARDS in AIR or DUST we explain that expert research indicates that while large fiberglass fragments found in buildings are not likely to be a carcinogen nor serious health concern, very small fiberglass fragments might indeed be a serious health risk.

I add that without expert forensic microscopy very small fiberglass fragments are hard to spot and I suspect they have been missed in various studies.

Still small fiberglass fragments are not the normal product of fiberglass insulation or ductwork installation. Rather these tiny particles are made when fiberglass insulation or ductwork is damaged by foot traffic, grinding, chopping of existing insulation, or by running a mechanical duct cleaner inside of un-lined fiberglass ducts - or by similar events.

If you want to be most-meticulous, the easiest cleanup of dust that will also avoid aerating (and breathing) it is to use a HEPA-rated vacuum cleaner.

While in my OPINION the amount of fiberglass fragments of any size that will be released into the air from the edges of the flex-duct where it is banded to the connection ports on your Venmar heat recovery ventilator will be close to or below the limits of detection in the air in your home, even anxiety itself can be unhealthy, so you can certainly, if you wish, use foil adhesive tape to cover-over the edges of the flexduct at its connections.

This will make any future service or repair that requires removal of the flexible ductwork more difficult but certainly not impossible.

I can't see which Venmar model you have but as you may know Venmar produces air-to-air heat-exchanging ventilation systems to provide fresh air to a building without increasing heating or cooling costs. I have the company's product specifications and installation manuals if you need more information.

Venmar heat recovery ventilators (HRVs) or more currently called Venmar energy recovery ventilators (ERVs) are installed using standard third-party flex-duct that's standard, in a diameter that matches the HRVs connection ports. Beginning

at DUCT ROUTING & SUPPORT

you will find a series of articles on flex duct that includes naming some problem brands, deterioration, contamination.

Generally the flexible ducts are made of a plastic or mylar liner, a coiled wire spring, fiberglass insulation, and a plastic exterior.

(A few problem brands had exposed interior fiberglass and others suffered from plastic that disintegrated when exposed to heat and time). As long as the flex-duct is lined and undamaged, fiberglass shedding into the air path into the building is not likely to be a concern.

Dust and debris on the duct exterior won't affect the ventilator's nor ducts' peformance. If there's a significant amount of fiberglass or other house dust in an area, perhaps left over from construction or accumulated over time, you can remove that by damp wiping and HEPA-vacuuming.

Heat Recovery Ventilator - Balanced Ventilation Equipment Sources, Manuals, Guides for ERVs & HRVs

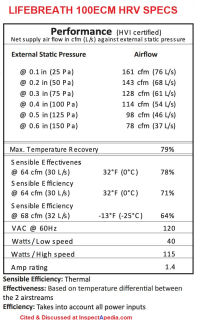

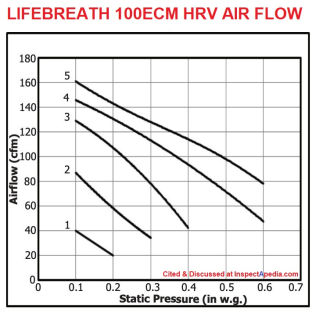

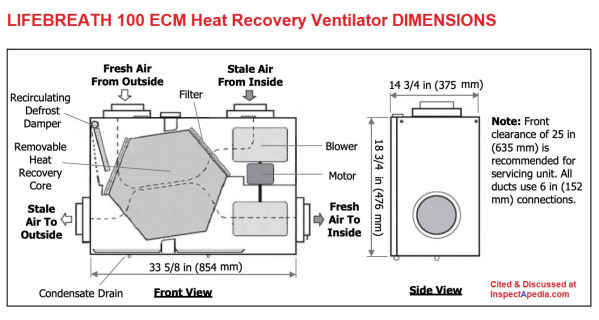

Illustrations above: Using the Lifebreath 100ECM Heat Recovery Ventilator as an example of HRV specifications they (and we) illustrate that the CFM or air flow delivery capacity of heat recovery ventilator will be affected by external static pressure.

[Cick to enlarge any image]

- AirCycler g2-k WHOLE HOUSE SUPPLY-EXHAUST VENTILATION SYSTEM [PDF] Product Literature [note: this is not a supply-only system]

Excerpt:

The AirCycler® g2-k Whole House Mechanical Ventilation System includes the AirCycler® g2 Furnace Fan Timer, FanConnect™ Bath/Fan Light Switch with remote fan control, and a motorized fresh air damper (available in four

sizes). This system provides balanced and hybrid whole house supply-exhaust ventilation.

- Lennox HRV & ERV VENTILATOR SYSTEMS INSTALLATION & OPERATION MANUAL [PDF] Lennox Corporation, Te;" 1-800-9-LENNOX, Website:www.lennox.com, retrieved 2021/05/26 original source: https://resources.lennox.com /fileuploads/24e49ec7-a076-4e63-98a4-a041921f2b4fLennox_HRV_ERV_IOM.pdf

Product Application Excerpts:

The Healthy Climate® Heat Recovery Ventilator (HRV) and Energy Recovery Ventilator (ERV) are designed to provide fresh air while exhausting an equal amount of stale air.

Refer to application map on page 42. The HRV unit is equipped with an aluminum core. The device uses the stale air that is being exhausted to condition the fresh air as it is being brought in. The ERV unit is equipped with an enthalpic core.

This device is designed for use in warm, humid climates with heavy air conditioning loads. The ERV unit transfers both sensible (temperature) and latent (moisture) heat from incoming fresh air to the stale air as it is being exhausted; thus, reducing the air conditioning load.

The ERV unit is not suitable for use in climates where the temperature drops below 25ºF (−4ºC) for more than 5 days continuously.

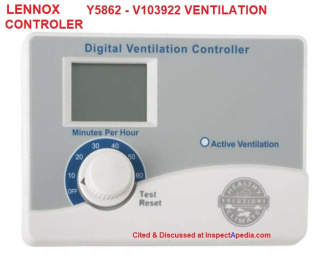

- Lennox LCVS VENTILATION CONTROL SYSTEM IO MANUAL [PDF], Lennox Corp., Op.Cit.,

Excerpts:

Application:

Healthy Climate LVCS Ventilation Control System provides fresh air intake which can be used with any furnace or air handler. Fresh air is brought into the return air system, where it can be filtered. The controller allows fresh air intake using a motorized damper when outdoor conditions are appropriate.

In very cold climates, balanced ventilation is recommended. LVCS Ventilation Control System can be used with an exhaust fan to provide balanced ventilation.

Per ASHRAE 62.2-2003, very cold climates are those that have more than 9000 annual heating degree-days based on 65°F day

Operation Principles:

Working in conjunction with a normally closed motorized damper, the Ventilation Controller makes decisions regarding when – and how long – to ventilate. It does this through continuous monitoring of indoor relative humidity, outdoor temperature, and user-adjusted timer settings.

Ventilation time may be satisfied by a heating, cooling, or fan call initiated by the thermostat, or from a fan call initiated by the Ventilation Controller itself. Indoor relative humidity is monitored to help prevent high humidity conditions inside your home.

The Ventilation Controller will not allow ventilation when indoor relative humidity rises above 55% RH.

If the outdoor air temperature is below 0°F or above 100°F, the normally closed motorized damper to the outside will not be opened. This feature can be disabled at installation if the installer chooses not to use outdoor air temperature as a parameter.

- LifeBreath 100ECM HRV HEAT RECOVERY VENTILATOR SPECIFICATIONS [PDF] Airia Brands, Inc., 511 Mccormick Blvd., London, Ontario Canada N5W 4C8, Tel: 519 457-1904, Website: www.lifebreath.com Sales: 1.855.247.4200

Air flow output varies with this (and other) HRVs and ERVs depending on external static pressures. Example data showing these variations, excerpted from this proudct specification are shown just above.

The company produces several versions of HRVs including the Lifebreath RNC-Series Heat Recovery Ventilators, ERV Energy REcovery Ventilators, HRV/ERV Intake Exhaust Hoods, and air supply grilles and adapters. - Lifebreath MAX SERIES HEAT RECOVERY VENTILATOR INSTALLATION MANUAL [PDF]

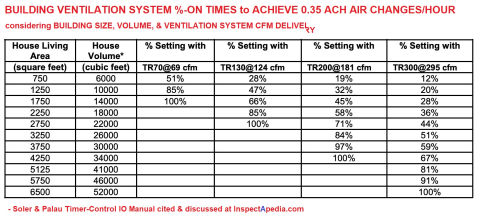

- Soler & Palau, VENTILATION FAN RUN PERCENTAGE TIMER SWITCH, # 6XAU2 INSTRUCTION SHEET [PDF] Soler & Palau

USA: Tel (800) 961-7370, Fax (800) 961-7379, www.solerpalau-usa.com

Canada: Tel (866) 733-0233, Fax (866) 358-5346, www.solerpalaucanada.net

Mexico: Tel 52 (222) 2 233 900, Fax 52 (222) 223 3914, www.soler-palau.com.mx

This device is shown just above. The "percent run time" guidelines for a house ventilation system depend on the total area and total volume of the building being ventilated, and are designed to provide 0.35 ACH or air changes per hour, in accordance with ASHRAE recommendations. These and most ventilation guidelines assume that the building rooms have eight-foot ceilings.

You will note in the ventilator run time table given below that the controller and HRV / ERV manufacturer will relate building size and volume to ventilator CFM capacity to give recommended "percent-on" settings for the building ventilation controller.

Watch out: the recommended percentage "on-time" for your building's ventilation system will vary depending on building size, area, climate, leakiness, and the particular brand and model of HRV or ERV ventilation system you have installed.

Excerpt: The Percent Timer Control-Lighted (SPTL) automatically turns on your TR70, TR130, TR200 or TR300 Total Recovery for All Climates unit every hour, ensuring proper ventilation for your home around-the-clock

. When the “Runtime %” light is on, the control is telling your Total Recovery for All Climates unit to operate.

Set the control and your ventilator will run once every hour. How long it runs depends on the runtime percentage setting.

[Click to enlarge any image]

- VENMAR AVS ERV INSTALLATION GUIDE [PDF] for Venmar AVS units AVS S10 ERV, S10 ERV ECM, S10c ERV, S10 ERVplus, S10n ERVplus and VanEE 70E, 70E ECM, 70Ec, 70E+ & 70 En+ Units Model Numbers 417xx, 418xx residential ventilators

- VENMAR Energy Recovery Ventilators ERV USERS GUIDE [PDF] Venmar AVS S10ERV series, Model No. 417xx series HRVs ERVs

- VENMAR CONSTRUCTO AIR EXCHANGER # 41000 SPECIFICATIONS [PDF] basic ventilation system for excess humidity & small areas

- VENMAR CONSTRUCTO 1.0 HRV Heat Recovery Ventilator SPECIFICATIONS [PDF]

- VENMAR CONSTRUCTO 1.5ES HRV Heat Recovery Ventilator SPECIFICATIONS [PDF]

- VENMAR AVS CONSTRUCTO 2.0 HRV Heat Recovery VEntilator SPECIFICATIONS [PDF]

Excerpt:

The Venmar AVS Constructo Series is an entry level product that offers all the basic features for the new construction market, such as a small-sized housing, integrated balancing damper and a no negative pressure defrost that ensures quick installation and trouble-free operation. M

oreover, its operation can be interlocked with an existing furnace without adding an extra relay. Best price for builders and contractors requiring simple, affordable and reliable products. - Contact Venmar: Residential Product Group, 550 Lemire Blvd., Drummondville, Qc, Canada J2C 7W9 - Tel.: 1-800 -67-3855 Fax: 1-800-567-1715, Website: www.venmar.ca

- Air-to-Air Heat Exchangers for Healthier Energy-Efficient Homes, Kenenth Hellevang, PH.D., P.E., Extension Engineer, and Carl Pederson, Energy Educator, North Dakota State University, AE-1393, NDSU Extension Service, North Dakota State University, Fargo ND 58108, March 2009. Web search 02/04/2011, original source: http://www.ag.ndsu.edu/pubs/ageng/structu/ae1393.pdf, reproduced for non-commercial use, with permission.

- Energy Recover Ventilation Systems for buildings, U.S. Department of Energy

- Energy Savings Methods: Whole House Systems Approach, U.S. Department of Energy

- Whole House Ventilation Systems, U.S. Department of Energy

- Whole-House Balanced Ventilation Systems, U.S. Department of Energy

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at it's page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question:

(Sept 10, 2011) Brion Black said:

We have been asked by a person who is acutely effected by multipul toxics illness to create a very low VOC and allergens interior air environment within a studio apartment that is located in an 80 year old NYC apartment building. We plan to start by sealing all existing finishes with a special VOC containment paint and varnish.

However, it seems likely a fare amount of contaminated air will be entering from the rest of the building. Yes, we are sealing the envelope as much as possible. QUESTION: how can we bring in fresh air from outside (window opening) to exchange 30% of air by volume an hour, WHILE maintaining a small interior pressure (say 5 pa) to avoid building infiltration?

Any ideas would be very welcome. This may have to be a custom made (home made) unit.

Reply:

Brion

I imagine you will want to do a blower door test to measure the actual building area air leakage rate. That measurement, combined with a careful survey of all of the vents and fans in the apartment to be sure you're not going to upset the balance, will let you specify the net air inflow rate to maintain a positive pressure with respect to the rest of the building.

I'd consider adding a manometer or similar air pressure gauge such as those used on radon mitigation systems to compare apartment air pressure to air pressure outside the apartment but inside the building. That lets the occupant as well as designer keep an eye on the proper air pressure balance.

...

Continue reading at BALANCED VENTILATION, HEAT COST SAVINGS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- FIBERGLASS FRAGMENT HAZARDS in AIR or DUST

- LEED GREEN BUILDING CERTIFICATION

- VENTILATION in BUILDINGS - home

Suggested citation for this web page

VENTILATION, BALANCED at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING VENTILATION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see " Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectApedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use I llustrations from The I LLUSTRATED HOME .

Carson Dunlop Associates provides extensive home Inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.