Two Line Jet Pump FAQs-3

Two Line Jet Pump FAQs-3

Diagnostic Q&A on 2-line Jet Pump Repair

- POST a QUESTION or COMMENT about 2-line jet pumps on water wells

Questions & answers about installing or troubleshooting 2-line jet pumps on water wells. #3

This article series describes the components of a two-line jet pump water system, what the components look like, and what they do.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Two Line Jet Pump water pump diagnostic FAQs set #3

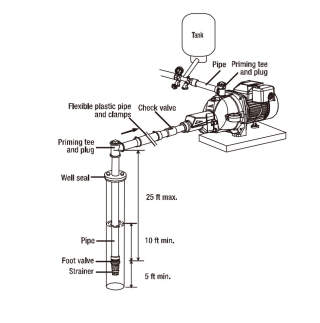

In the photo above you see an older installation of a two line jet pump that draws water from the well.

In the photo above you see an older installation of a two line jet pump that draws water from the well.

[Click to enlarge any image]

These questions about installing, troubleshooting, repairing two line jet pumps were posted originally

at WATER PUMP, TWO LINE JET - please be sure to review that article.

For help priming your jet pump see WATER PUMP PRIMING PROCEDURE

On 2020-02-19 - by (mod) - how do I prime my 2-line jet pump?

Anon:It's unusual to have no possible primer opening right on the jet pump - please tell me the brand and model and attach a photo of the pump.

But yes if there is a pressure gauge atop the pump impeller housing then you can (very tediously) prime through that opening.

See WELL PUMP PRIMING PROCEDURE for details - as we give options that work even if there is NO prime opening on the pump itself.

Or you might need to add a tee fitting on the well piping to use for priming.

Take care not to run the pump "dry" or it could be damaged.

On 2020-02-19 by Anonymous

there is no primer access on pump itself so do I just remove the pressure gauge and prime it through that pipe ?

Ive pulled the 2 lines to replace foot valve, should I fill the lines with water after returning them in casing to help yhe priming process /

On 2020-02-12 by Anonymous

who builds the 2 line jet pumps

On 2019-12-19 by Keerthi

180 -feet to 200-feet

On 2019-12-10 - by (mod) - pull out his Gould 1.5 hp Jet Pump out to replace the piping

Congratulations for being smarter than me by knowing when to stop.

I would be tempted, if there is space, to send a camera down the well to see exactly what's going on. It may be that you can juggle the pipe up and down sufficiently to Breakaway scale to retrieve things but I'm a little worried about pulling too hard and snapping off a pipe and then dropping stuff down what sounds like a rather small diameter Welborn. So let's inspect first.

On 2019-12-1 by Bill

I'm trying to help a friend pull out his Gould 1.5 hp Jet Pump out to replace the piping.

We removed the motor and everything down to the collar holding the pipe, but have pulled it seriously tight with a car engine hoist and it must be stuck around the foot valve with rust from the 2" well casing and/or that and possible small pieces of limestone from these aquifers here in Central Florida.

My only other thought was to lower the hoist and start raising it again with one of us trying to turn it with a pipe wrench.

Any thought?

Thanks

On 2019-07-18 by (mod) - Ejector keeps losing prime

Look for an air leak - it could be in a pipe, pipe connection, pump itself, or bad foot valve.

Isolate the building by turning off water into the building to assure it's not on the building side.

On 2019-07-18 by Norm

I have installed a shallow 2-pipe system and can't maintain prime. I have tested all of the piping, including suction, at 30 psi and there are no apparent leaks. I installed a check valve about one foot above water (a brook) and have a submerged slotted well screen assembly (nine feet of horizontal 2" slotted PVC well pipe with 10 mil slots).

The ejector is about 100 feet away from the brook, but only about four feet vertically above the water. In theory it should work but unless I continually add water at the pump (in the cellar, about 500 feet away from the ejector) it loses prime.

Any ideas?

Thanks.

On 2019-04-06 by (mod) -

Maybe an air leak?

On 2019-04-03 by Mike

Strange, I have a 2 pipe jet well, pump runs fine, doesn't lose prime, but no water comes out of discharge. Shop replaced pump impeller, I reinstalled and same thing, never loses prime, not water discharge. Packard jet problem or something else?

On 2019-02-12 by (mod) - two line jet pump that has been submerged when the basement flooded.

Bruce

Between failed bearings and having flooded the pump motor I'd replace the whole unit.

Often an electric motor that was flooded can be dried out and it'll run, but having been soaked, especially with nasty floodwater, it's going to see ongoing corrosion and future failure. I'd rather fix the situation just once.

Watch out: floodwaters are not sanitary; if your building was flooded from sewage or area floodwaters you may need to do more cleaning, sanitizing, and inspections for mold reservoirs.

On 2019-02-1 by Bruce Frauman

We have a two line jet pump that has been submerged when the basement flooded. Now there is a constant high pitched squeal. I suspect the bearings are going. Is the bearing replaceable or do we need to replace the whole pump. I have some mechanical skill. Is this a job for a plumber? It looks just like the one in the "what is the capacity of a two line jet pump" section. I can add an image late

Thank you

On 2019-02-11 by (mod) -

Damaged pump, piping leaks, lack of water in the well, even low voltage to the pump, are examples of why a pump may produce only a weak output.

On 2019-02-11 by neville..

why the pump delivers small amount of water to the durface

On 2018-11-27 by (mod) -

Don

I don't know for certain but it seems to me that since the small diameter line is sending water under pressure down to the ejector a small leak in that line while the pump is running should not caused a failure to lift water.

Have you checked to make sure you're not losing Prime through a leak in your piping?

On 2018-11-26 by dondon simon

i had properly install a 2 inches ejector in a 2 inches drilled casing, but it did not suck the water below . it is just a 35 feet water from the ground. i uses 1 inch for my suction pipes and properly attach the 2 inches ejector. if my 1 inch pipes has a small leak at 1 joint does it cause the deep well not to suck water below?

On 2018-11-25 by (mod) -

I don't think that the difference in Horsepower would explain getting no water at all. You're talking about a two-line jet pump that can lift from considerable depth. So more likely you haven't adequately primed the system or there's a bad check valve or foot valve.

On 2018-11-22 by gary

i had a 3/4 horsepower in the basement...my son called me and said he didnt have any water..the pump was ccontinually running.I was told that the pump is probably shot....i changed it out with a 1/2 horsepower....i called a plumber out...

he said there is probably a break ib one of the pipes going to the well...I had the pipes dug up...found that the steel pipe was connected to a plastic pipe and the steel pipe had a hole in it....I replace the steel with a plstic pipe...i tried primming the pump....no prime.....would the 1/2 horsepower not work....

it used to have a 3/4 horsepower....maybe its not enough to pull the water....dont know.....

On 2018-10-2 by (mod) -

Kirk,

A review of the Everbilt pump manual for your pump shows the pump mounted horizontally - not vertically.

See https://inspectapedia.com/water/Everbilt-DP370C-DP550C-Pump-Manual.pdf

and also the illustration I will show just below.

Image lost, please re-post

On 2018-10-29 by kirk

i just bought a everbilt mod. dp550c pump it shows a vertical installation can i install it horizonally

On 2018-10-21 by (mod) -

Frankly I don't have a clear understanding of your pump and well set-up;

But it appears that your pump can be configured in either of the two ways you understand;

Your photo shows, on the left, what looks like the front end of a 2 line jet pump - the blue casing; that gets removed and the two pipes connect to the small and larger fittings repectively on your new jet pump.

You need either to put an injector down near the bottom of your well, or if you are going to use the pump without a down-well injector it can only lift 25 ft. so that's where your foot valve will have to hang.

On 2018-10-21 by shawn parker

Yes I understand that. I'm asking....

---- if my problems are because I'm not mounted on the pump?

--- to use this ejector, what do i need to change?how do I change from a vertical pump 2 pipe system to vertical ejector mount 1 pipe system ?

--do i even need to do this?

--- why won't it work installed in the well at foot valve as it was?

-- do i need to find an ejector that can be put 49feet down a 56 foot well with a water table at 19 feet in a 2 pipe well pump? unlike this one that can't... even though it seems it can be put in a well much

deeper?

--- why did i seem to get 40# pressure ...then nothing? on 2 separate times?

-- is there a way to determine if injector is bad? it spins freely and not noisy

--- can i fix and re use old ejector with new screen ft valve? at least i knew it worked in my system

My system was fine until booster pump manifold blew apart...losing 1100 g of water and lost prime

Image lost, please re-post

On 2018-10-20 by (mod) - booster pump manifold blew open and I lost 1100g and totally lost prime.

Shawn

Regarding

the instructions for new ejector placement state this...depth to water 25-60 ft ejector placed in well

If the ejector is placed at the pump rather than in the well, it can't lift more than 25 ft.

On 2018-10-20 by shawn parker

3/4 hp 2 line jet pump, well 56 ft..... foot valve set at 49 ft....water table approx. 19 ft. 1100g holding tank with booster pump and 2 bladder tanks.

Full lengths 1" and 1.25" 160psi poly pipe

My booster pump manifold blew open and I lost 1100g and totally lost prime. The usual method of priming did not work, so I lifted the pump and filled the reservoir and both pipes, and watched... he water dropped in both slowly but gradually..

I figured my foot valve was failing, as this would also explain why pump would run with no water being used, I just replaced the foot valve , ejector, and pipe, filled the reservoir and pipes , no loss of water, set pump and topped off the prime @ pressure gauge.

Turned on well circuit and jumped to 40# for a few seconds then dropped to 0. Re primed thru air vent hole til it spit, tightened it then turned on pump..... nothing.

Removed pressure gauge, very small splash of water to top off, tightened gauge, turned on pump, sounds fine, but 0# pressure. Tried with gauge removed and I didn't get soaked.

Removed pump and impeller cover to inspect. Impeller seems fine and spins freely. Dressed up where impeller cover seats into pipe and made sure gasket was compressed. Power to motor and watched impeller spin, quietly.

Reset pump, filled for prime and hit switch. Jumped to 40# for a few seconds then dropped to 10# and ran at holding 10#, but barely a trickle going into holding tank. Turned off then on....still running 10#. Turn off...Wait.... clik....0, clik clik, nothing nothing .check prime ...no water needed...turn on... nothing.

Here I am now. Every thing below pump is new and in same configuration. But......

T

HIS MIGHT BE MY PROBLEM.... the old ejector with foot valve was 49 ft down, water at 19-20 ft.

I put new ejector in same place and used the right nozzle and tube as per instructions... and you saw all the luck I had.

THE PROBLEM- the instructions for new ejector placement state this...depth to water 25-60 ft ejector placed in well...... Water at less than 25 ft. ejector mounted on pump.

My old set up is not that way, and is that the way it needs to be? My pump is vertical and sits atop casing. piping going thru cap. I don't see how that could work in a 2 pipe configuration.

Yet... here we are.... any logical ideas concerning any of this surely would be appreciated.

Image lost, please re-post

On 2018-03-22 by (mod) - water was flowing like Normal then it just stopped then seconds later made a loud weird noise

I'm not sure, as I have so little information, K. The problem could be an electrical connection, pump control switch, impeller damage, motor damage, or even simply that your well ran out of water or had a frozen water line. After waiting 3 hours (as you now have) try turning on the pump

. If it sounds unusual again, shut it off and call your plumber for repair. If it works normally your system may have been out of water.

On 2018-03-22 by k

Have a jet pump about 2-3yrs old this morning water was flowing like Normal then it just stopped then seconds later made a loud weird nosie any idea what could be causing it we shut it off so it wouldnt burn up

On 2018-01-20 by Je

What would happen if will not use the water down pipe. Instead, i will put cap plug to it? Will the pump function as normal one pipe shallow well pump?

On 2017-11-10 by Anonymous

How do I remove the moter from a two line jrt pump GE

...

Continue reading at WATER PUMP, TWO LINE JET - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- SHORT CYCLING WATER PUMP

- WATER PRESSURE PROBLEM DIAGNOSIS TABLE

- WATER PUMP DIAGNOSTIC TABLE

- WELL PUMP PRIMING PROCEDURE if you need to re-prime your jet pump.

- WELL CAPS & COVERS - requirements for sealed well caps & covers, requirements for vents & exclusion of vent requirements for some jet pump installations.

Suggested citation for this web page

WATER PUMP TWO LINE JET PUMP FAQs-3 at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.