Septic Media Filters & Ruck Systems for Difficult Sites

Septic Media Filters & Ruck Systems for Difficult Sites

- POST a QUESTION or COMMENT about buying, installing, using types of septic media filter systems

Septic media filters:

This article series discusses the design and use of various types of septic media filter systems.

Media filter septic systems use a conventional septic tank followed by any of several methods to further filter and treat septic effluent before it is discharged to the soil, soil surface, or waterway.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Information about Media Filter & Ruck Septic Systems

When using a septic media filter system, effluent treatment is by both actual filtration and ultimately by a biochemical process as the

filter "matures" and includes its own biomass. Both natural media filter septic systems (such as sand, gravel, or peat)

and synthetic media filter septic systems (foam cubes, glass, slag) are used, and both single-pass and effluent

recycling systems may be employed.

When using a septic media filter system, effluent treatment is by both actual filtration and ultimately by a biochemical process as the

filter "matures" and includes its own biomass. Both natural media filter septic systems (such as sand, gravel, or peat)

and synthetic media filter septic systems (foam cubes, glass, slag) are used, and both single-pass and effluent

recycling systems may be employed.

These different septic media filter types are explained here. We include a list of product sources for various types of septic filters.

Citation of this article by reference to this website and brief quotation for the sole purpose of review are permitted. Use of this information at other websites, in books or pamphlets for sale is reserved to the author.

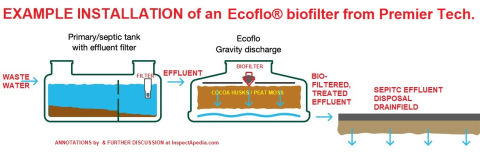

Illustration: Using the Ecoflo Biofilter (cited in detail below) this is one of several possible designs to prepare sewage wastewater for final disposal at a difficult site such as one with low-percolation-rate soil.

[Click to enlarge any image]

- Initial/Primary Wastewater Treatment:

In this example sewage enters the septic tank where, as with all septic tank systems, primary wastewater treatment occurs: settlement of solids, collection of oils and grease and floating solids at the tank top, first stage of bacterial treatment of the wastewater, followed by an initial filter - Secondary Wastewater Treatment:

Clarified sewage effluent is discharged, in this example, into Ecoflo's Biofilter where in a secondary or advanced secondary wastewater treatment step, additional bacteriological processing takes place in a bed that may use or combine coconut husk fibres and peat moss. - Wastewater Polishing Treatment:

Not shown in the illustration above, depending on site requirements disinfection or reduction in the levels of nitrogen and/or phosphorous may also occur in a final polishing treatment step. - Final Wastewater Effluent Dispersal:

In a final step, sewage effluent disposal, treated sewage effluent is discharged to a disposal drainfield where a combination of evaporation and dispersal into the soil occurs.

Septic media filters using textiles

Geotextiles are often used in septic effluent media filter systems; they can provide a large surface area and high water volume retention.

Fabric media is cut into squares and placed into a container, or hung in curtains in a container. Textile filters operate in a recirculating mode similar to that discussed above, but offer this advantage over sand and peat media: the larger effective surface area of the synthetic textile permits a much higher loading rate in gallons per square (or cubic) foot, thus permitting the media system to be designed into a physically smaller package.

Septic media filters using open celled foam cubes

Two-inch open-celled polyurethane cubes are placed into a container to form a packaged or "pre-fab" septic media filter system which is used in either single pass or recirculating effluent mode.

Packaged foam cube septic effluent (wastewater) treatment systems may be placed entirely above ground (but of course will not work in an area of hard freezing climate).

Septic effluent is passed into the foam filter in small doses (1/10 gallon to 1 gallon per cubic foot per dose) using spray nozzles which dose the system from its top. An advantage of this system is its easy maintenance as the (clog prone) top few inches of foam cubes are easily removed and replaced.

Septic Media Filter System Capacity

A typical media filter system is designed using a flow of 50 to 65 gallons per day per occupant of the building served by the system.

This number, cited by several authors including Jantrania, Minnis, and Kahn, Allen, and Jones, is less than other total wastewater load estimates but is considered by these authors to be realistic and is consistent with a number of studies performed on typical wastewater flow rates and quantities.

Septic Media Filter Maintenance

The system design maintenance required of the media filter system as well as its operating characteristics vary considerably depending on the media selected, with open cell foam and textiles providing higher gallons per day loading ability than peat and other media.

"Maintenance" in this case will refer to inspection of the media bed to determine when the media needs to be cleaned or replaced. Some systems, such as sand filter beds, are raked or agitated rather than replaced, but ultimately all filter systems will become clogged and face media replacement.

Septic filter media maintenance and replacement cost should be factored into estimates of alternative septic system costs when comparing alternative septic system designs.

Product Source List for Filters, Septic Filters & Wastewater Treatment Systems Using Filtration Methods

Illustration: the polyethylene Ecoflo® biofilter from Premier Tech cited below. The model shown combines a septic tank (with an effluent filter) and a biofilter in one configuration.

- Also see ALTERNATIVE DESIGN SEPTIC SYSTEM SUPPLIERS

- Also see SEWAGE TREATMENT PLANTS, RESIDENTIAL - Packaged onsite septic systems

- AMPHIDROME from F.R. Mahoney, Associates, is a "sequencing batch reactor" or effluent recycling system (approved in MA) cycling effluent between the septic tank and a reactor vessel.

- ADVANTEX- Onsite Wastewater Treatment Systems from Orenco uses a textile filter in a fiberglass basin.

- BIOMICROBICS wastewater treatment include BioSTEP, a screened pumping system, BioBarrier membrane bioreactor (MBR) which produces ultra-clean effluent Lixor, their submerged aeration system, SaniTEE wastewater screens and other wastewater treatment systems and products.

- BIOCYCLE WASTEWATER TREATMENTa BioCycle Unit, Tertiary Polishing Filter and Monitoring System.- Ireland

- BIOREN & LIVING FILTRER alternative wastewater treatment systems - Mass. USA

- BIOCLERE from AquaPoint (MA) is a trickle-filter effluent treatment system

- ECOFLO Biofilter® from Premier Tech is a passive filter system available in a polyethylene, concrete, or fiberglass tank. Illustrated above. Illustrated above.

Contact: PremierTech, 1 Avenue Premier Premier Tech Campus Rivière-du-Loup, Québec G5R 6C1 CANADA Tel: 1 800 632-6356 Website: https://www.premiertechaqua.com/en-us/septic-system/ecoflo

PremierTech also provides holding tanks, nitrogen reduction systems, pumping stations, UV disinfection systems, and commercial or municipal wastewater treatment systems for Canada and the U.S.

Website excerpt:

This energy-free treatment system gently removes wastewater pollutants with a filter made of coconut husk fragments or a combination of coco and peat moss. Both materials are natural and compostable, and coco is 100% renewable.

In the U.S. the majority of these systems use a 100% coconut fiber as the biofilter media.The company says that with proper care the filtering medium used in these systems (coconut fibre and peat) have a 10 to 15-year life.

Eccoflo Biofilter MEDIA LIFE for Coconut Husk Fragment Filters [PDF] retrieved 2021/11/24 original source: https://www.premiertechaqua.com/en-us/wastewater/why-does-ecoflo-use-coconut-husk-fragment-filter

In reply to our query the company said - ... we believe coco is an ideal filtering medium, even during lengthy periods of non-use.

Ecoflo Biofilter CERTIFICATIONS (North America) (NSF, BNQ, CAN-BNQ) retrieved 2021/11/24 original source: https://www.premiertechaqua.com/en-us/wastewater/ecoflo-biofilter-certifications-north-america

Accessed 2021/11/24 we read that for all of the common tests required for certification in North America, including CBOD5, TSS, Fecal coliforms, and pH, and NSF/ANSI Standards 40 and 245, the Ecoflo Biofilter systems tested met the requirements (and generally exceeded them - Ed)

Ecoflo® Biofilter OWNERS MANUAL [PDF] retrieved 2021/11/24 original source: https://www.premiertechaqua.com/sites/ptwe/files/prospace/Ecoflo_Owners-Manual_EN-CA-US.pdf

This manual provides helpful explanation of the operating principles of packaged septic processing systems such as the Biofilter, including a description of primary treatment, advanced secondary treatment, and polishing treatment of wastewater prior to its final disposal. The Ecoflo Biofilter diagram shown immediately below is one example of the three basic steps in wastewater treatment and disposal with this type of system.

ECOFLO Biofilter CANADA GUIDE for PROFESSIONALS [PDF] retrieved 2021/11/24 original source: https://www.premiertechaqua.com/sites/ptwe/files/PDF/Ecoflo-Rewatec_Professional-Guide_CA_EN-CA.pdf

ECOFLO Biofilter CANADA: ONTARIO-SPECIFIC GUIDE FOR PROFESSIONALS [PDF] (2021) retrieved 2021/11/24 original source: https://www.premiertechaqua.com/sites/ptwe/files/PDF/Ecoflo-Rewatec_Professional-Guide_ON_EN-CA.pdf

ECOFLO Biofilter CANADA: QUÉBEC-SPECIFIC GUIDE FOR PROFESSIONALS [PDF] (2020) retrieved 2021/11/24 original source: https://www.premiertechaqua.com/sites/ptwe/files/PDF/Ecoflo_Professional-Guide_QC_EN-CA.pdf

ECOFLO Biofilter USA GUIDE FOR PROFESSIONALS [PDF] retrieved 2021/11/24 original source: https://www.premiertechaqua.com/sites/ptwe/files/prospace/Ecoflo-Rewatec_Professional-Guide_US_EN-US_1.pdf

WHY SEPTIC FILTER REPLACEMENTS ARE NEEDED [PDF] retrieved 2021/11/24 original source https://www.premiertechaqua.com/en-us/wastewater/advantages-ecoflo-filter-replacements

- JET INC., 750 Alpha Dr., Cleveland OH 44143 USA, Tel: 440-461-2000, email: email@jetincorp.com Website: jetincorp.com retrieved 2016/05/15, original source, Ohio health department, U.S.A., http://www.odh.ohio.gov/~/media/ODH/ASSETS/files/eh/sts/P-Jet-1500%20Series%20BAT%20Media%20Plants-Ownman-952%20UV

Also see BAT MEDIA SEPTIC PLANTS - biologically accelerated treatment septic systems - PEAT FILTERS for septic effluent treatment, University of Minnesota Information Article on Peat Systems

- RUCK SYSTEMS (in MA) "Traditional RUCK- [Residential Septic] Systems are passive innovative septic systems that are designed to remove nitrogen and provide excellent treatment for an on site septic system." Commercial products are also available. This is an in-ground filter system installed between the septic tank and the absorption field.

- SEPTI TECH Residential and Commercial Wastewater Pretreatment Systems include a fixed film effluent trickling filter and a patented effluent treatment media.

- WATERRLOO BIOFILTER trickle type wastewater filter and systems using aeration combined with foam filter media; effluent is sprayed over foam.

- Product listing submissions are welcome; there is no listing fee.

InspectAPedia is an independent publisher of building, environmental, and forensic inspection, diagnosis, and repair information provided free to the public - we have no business nor financial connection with any manufacturer or service provider discussed at our website.

Ruck Septic System Information

Question: where to find care & maintenance information for Ruck type Septic Systems

2015/11/23 David Ambrose wrote:

I live in the New Jersey Pine lands, and I have a RUCK System.

I have been unable to find info on the Care & Maintenance of this system. I know, that at one point, it was required in my area, but that is not the case now. I've lived in this house for 20 years and had only minor problems.

I'm now selling the house and would like to have some kind of "Care & Maintenance" info for the new owner. Can you help me with this? - anonymous [by private email]

Reply: where to get Ruck® septic system information & design or maintenance help

Sure; here are some resources for Ruck septic systems:

- Costa, Joseph E., George Heufelder, Sean Foss, N. P. Millham, and B. L. Howes. Nitrogen removal efficiencies of three alternative septic system technologies and a conventional septic system. [PDF] Environment Cape Cod 5, no. 1 (2002): 15-24. Retieved 2015/11/23, original source: http://buzzardsbay.org/etistuff/results/costaenvccarticle2.pdf

Abstract:

At a septic system testing center, conventional design onsite wastewater disposal (“Title 5”) systems, were found to have a net nitrogen removal capability of 21-25% when data from the base of the Soil Absorption System (SAS) was considered, after accounting for an assumed precipitation recharge dilution of 10%. This reduction occurs principally in the soil absorption system, a component that is often overlooked in comparative studies.

Nitrogen losses in the septic tank ranged from 1% to 3%. Successful proprietary nitrogen removal systems tested like the Waterloo Biofilter trickling filter and MicroFAST Model 0.5 systems had a net nitrogen removal capability of 60% and 55% respectively, thus discharging slightly more than half the nitrogen discharged by a conventional system. In these technologies, most nitrogen reduction occurred prior to discharge to the SAS.

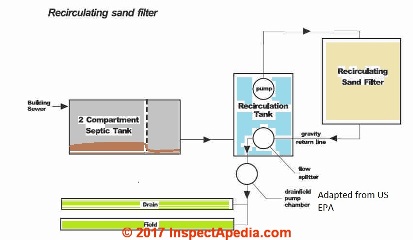

The recirculating sand filter (RSF) designs tested removed approximately 41% of influent nitrogen, but we did not examine SAS losses, and overall system performance may be slightly better than this with a SAS installed. Without the SAS, the RSFs tested discharged 25% less nitrogen to groundwater than the Title 5 systems.

Conventional septic systems with a Geoflow Wasteflow Drip Line system in the SAS removed 42% of influent nitrogen overall, showing that the performance of a SAS can be improved by injecting discharge near the topsoil, to allow nitrogen uptake by grass and other vegetation.

This Drip Line design, combined with another septic tank technology could result in very high overall system nitrogen removal rates. One experimental design (ECORUCK) had a nitrogen removal ability less than a conventional system and was withdrawn after one year of testing. - Ruck® Systems® Manual Design and Installation [PDF], RUCK A FINS - R1032C (patented), Connecticut (2009), Rein Laak, Ph.D., P.E.

149 Browns Rd., Storrs, CT 06268 Vox: 860 423 7294

Fax: 860 456 0803

EMail: rein@rucksystems.com URL: http://www.rucksystems.com/ , retrieved 2015/11/23, original source: http://www.rucksystems.com/docs/manual_2009.pdf

Abstract excerpted from the document introdction:

The RUCK ACCORDION system is a cost effective, treatment based upgrade from conventional stone and other leach field systems. The ACCORDION system is based on proven enhancements. Evapotranspiration, oxygen transfer, biodegradation, soil treatment and longterm operation are accomplished by using biotextile prefiltration and controlled soil loading.

Biofabric technology is based on 25 years of published research work and field experience.

Multiple vertical infiltrating surfaces of biofabric and sand is provided per square foot of trench bottom area. ACCORDIONS are installed on top of 6” of sand by stretching the unit to specified length in 42INCH wide trench and filling with sand. The accordion modules are interconnected using PVC pipes.

The primary biomat layer forms within the biofabric. The ACCORDION leach field is sized for the longterm acceptance rate (LTAR). RUCK ACCORDION leach fields are designed to operate indefinitely, not for a halflife of 25 years as with other systems. The soil directly below the sand and accordion module develops only a minor secondary biomat layer. The result is a greater longterm infiltration capacity. - Innovative RUCK Systems, Inc. 205 Worcester Court, Suite A-4 Falmouth, MA 02540

Phone: (508) 548-3564, Website: RUCK® systems http://irucks.com/ . Here is an excerpt from the company's website:

Innovative RUCK Systems, Inc. (IRUCKS) designs alternative innovative on-site septic systems called RUCK® systems. The RUCK® wastewater treatment system is a proven cost-effective innovative septic system that uses a proprietary design to obtain significant removal of nitrogen from wastewater.

There are two different RUCK® system designs – a Traditional RUCK® system for flows less than 2000 gallons per day and a RUCK® CFT System for flows greater than 2,000 gallons per day, but less than 10,000 gallons per day. RUCK® systems generally include the addition of supplementary components to a traditional soil absorption system.

Treatment occurs through the creation of a series of alternating environments in which bacteria first nitrify wastewater and then perform denitrification. Design of a RUCK® system is done on an individual basis.

Plans and specifications are prepared by a consulting engineer trained in RUCK ® system design. In Massachusetts the traditional RUCK® System has been issued a General Certificate by the Department of Environmental Protection as an innovative and alternative septic system. RUCK® CFT Systems has been issued Piloting Approval by the Department. Contact the designers for the status in other states.

I'd appreciate seeing details of your system and photos of any components you can access.

Reader follow-up:

Thank you Very Much, but I cant see Any Components without digging.

I know there's an Extraction Pump that I had to replace because someone took a shortcut by installing a 1 1/2" - 2" fitting in order to buy a cheaper pump! And I had to dig up the area where the pipe goes into the house because it was the wrong Schedule pipe! Grrrrr, What some People will do to save about a hundred bucks huh?

The good news is that besides getting it pumped every 2-3 years, these are the only problems I've had.- Anon

Reply:

I've read a Costa (2002) study about one Ruck system design that was dropped (ECORUCK) from the study because of its poor reduction of nitrogen. Is your Ruck septic system currently permitted in new construction where you live or is your system "grandfathered" in?

Reader follow-up:

From what I heard, It was So Expensive that they had to stop requiring it. Heard it cost $25,000 in My house! Never heard anything about not being able to have it, or getting Grandfathered.

It's All Septic here. I see lawns getting dug up all the time, but mine is just fine.

The reason for the RUCK is to lessen the Nitrogen, and it didn't work as well as expected, but better than regular systems. Again, I think it was mainly Costs

...

Continue reading at DOSING CONTROL for SEPTIC MEDIA SYSTEMS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- FILTERS SEPTIC & GREYWATER for an explanation of septic filter devices for tanks and drywells

- MEDIA FILTER SEPTIC SYSTEMS - home

- BAT MEDIA SEPTIC PLANTS

- DOSING CONTROL for SEPTIC MEDIA SYSTEMS

- FOAM CUBE SEPTIC MEDIA FILTERS

- PEAT SEPTIC MEDIA FILTERS

- POD SEPTIC SYSTEMS

- RUCK® SEPTIC MEDIA FILTER SYSTEMS

- SAND FILTER SEPTIC DESIGN SPECIFICATIONS

- SAND SEPTIC MEDIA FILTERS

- SANDY SOIL SEPTIC DESIGNS

- SEPTIC MEDIA FILTER CAPACITY & MAINTENANCE

- SEPTIC MEDIA FILTER SOURCE LIST

- SEPTIC MEDIA FILTER SYSTEM OPERATION

- SINGLE PASS vs RECIRCULATING SEPTIC MEDIA FILTER DESIGNS

- TEXTILE SEPTIC MEDIA FILTERS

- TYPES of SEPTIC MEDIA FILTER MATERIALS

- SAND BED SEPTIC SYSTEMS

- SEPTIC FILTER / GRAYWATER FILTER SOURCES

- SEWAGE TREATMENT PLANTS, RESIDENTIAL - Packaged onsite septic systems

Suggested citation for this web page

MEDIA FILTER SEPTIC SYSTEMS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to SEPTIC SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about buying, installing, using types of septic media filter systems.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- New York State Department of Health, APPENDIX 75-A WASTEWATER TREATMENT STANDARDS - INDIVIDUAL HOUSEHOLD SYSTEMS , [PDF] New York State Department of Health, 3 February 2010, retrieved 3/1/2010, original source: https://www.health.ny.gov/regulations/nycrr/title_10/part_75/appendix_75-a.htm

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.