BAT® Septic System Design, Maintenance, Repair

BAT® Septic System Design, Maintenance, Repair

- POST a QUESTION or COMMENT about BAT - Biologically Accelerated Treatment Septic Systems used for private onsite wastewater and graywater treatment & disposal

BAT - Biologically Accelerated Treatment Septic Systems:

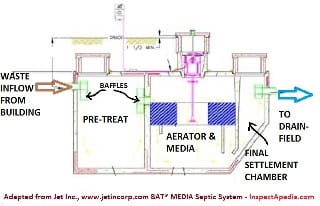

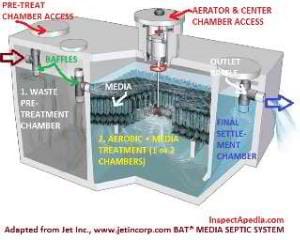

BAT septic systems use a combination of three-chambered or in some cases four-chambered septic tank consisting of an entry or pre-treatment chamber that separates large solid waste, one or two center chamber(s).

Each chamber contains an aerobic aerator system and a biologically-accelerated treatment media that increases the level of wastewater treatment, and a final settling chamber that permits final solid settlement before discharging effluent to the wastewater absorption system.

This septic system article series describes all of the types of batch, media & aerobic septic systems alternative septic system designs for difficult building sites such as wet sites, steep sites, rocky sites, limited space, bad soils with no percolation or sandy soils with too fast percolation, and other difficult site conditions.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Design, Maintenance & Troubleshooting for Biologically Accelerated Septic Systems - BAT Septics

Illustrated at the top of this page and in sketch at above/left and adapted from the manufacturer's illustration is the J-1500 Series BAT® [Septic] Media Plants (with Model 952 UV) is an onsite wastewater treatment system that combines an aerobic aeration pump (or two of them) in a three- or four-compartment septic tank along with a media located in the center tank(s) to achieve a high level of wastewater treatment.

Jet Inc.'s system is illustrated at the top of this page, and the Ohio state Department of Health has posted the company's BAT Plant owners manual online to encourage proper system maintenance.

The company provides two septic tank designs that accommodate a range of daily wastewater flow:

Jet BAT models 500-, 600, 750 or 800 gallon per day (gpd of wastewater flow) use a three-compartment septic tank comprised of a pretreatment chamber into which raw wastewater flows, a center treatment chamber that combines a septic media with an aerobic pump, and a third settling chamber to permit final floating solids settlement before clarified effluent is discharged from the septic tank to the absorption field.

The third (or fourth in some designs) settlement chamber is open at its bottom to allow settled solids to flow back into the center chamber (s) where the aerobic and media system is agitating and treating the wastewater. This design means that the final settling chamber is excluded from septic tank pumping during service.

[Click to enlarge any image at InspectApedia]

The BAT septic system may also include a final disinfection state using UV light or possibly the injection of a disinfectant, or both. A final effluent disinfection step in the Jet Bat Media septic system includes a UV light in some of these designs, Jet's Model 952 UV.

Some similar septic treatment units may use a disinfectant injection system instead of a UV lamp.

BAT systems may also require occasional addition of bacterial cultures used to repopulate the bacteria in the system if the system is left out of use for a prolonged period.

Jet BAT septic system models 1000, 1250, and 1500 handle gpd wastewater flow rates in those ranges and according to the company have been tested for conformity with NSF Standard 40 criteria for Class 1 NSF listed septic systems.

The combination of an aerobic septic pump (or two of them in the larger four-chamber design) provide higher levels of oxygen induced into the wastewater to accelerate the activity of microorganisms (principally bacteria) that in turn processes the biological component of sewage waste to provider "a high level of treatment" of the daily wastewater flow through the system.

A Jet - BAT septic system control panel is installed to monitor the condition of the system and includes both a visual alarm (red light) and an audible one (a buzzer) that warn the homeowner if the aerator pump electrical circuit has shut down (presumably by a tripped circuit breaker).

Watch out: This BAT control panel alarm is a critical warning that should not be ignored by homeowners, as without the aerator pump the system will stop successfully treating wastewater and with continued use, system failure may be imminent.

Contact your system dealer if the alarm sounds repeatedly.

This system is designed to operate properly with a six-month inspection or service interval. Periodic cleaning is needed and if the system is not used for a prolonged interval (presumably 3 months or longer) because it should be left running, the manufacturer may recommend the addition of a manufacturer-provided dry-pack of inoculating bacteria.

Watch out: some septic system designs use fragile media or media filters for which service should be performed only by properly trained or certified septic service companies.

The design and owners' manual for Jet's BAT Septic System include such a warning. Failure to properly protect media or filters from damage during septic tank pumping or cleaning can cause costly damage to the system and may prevent its proper operation.

Make sure you notify your Jet Distributor before you have your tank pumped. If the tank pumper is not familiar with Jet’s media and media has not been cleaned before pumping, severe damage to the media can occur.

This is

potentially costly to repair. - Jet Inc., 2016 cited below in the owners manual to which you referred in subsequent postings and that's provided online by the Ohio Department of Health.

Also see these articles on septic tank or system treatments, maintenance, and protection that have added advice for Jet's BAT septic system owners. .

- SEPTIC TANK BACTERIA BOOST found in SEPTIC TREATMENTS & CHEMICALS

- SEPTIC TANK DESIGN DEPTH - importance of proper tank lid access for service & importance of keeping surface runoff away from the tank & septic soakbed or drainfields

- SEPTIC TANK PUMPING PROCEDURE

- TOILETS, DON'T FLUSH LIST - home

- PLANTS & TREES OVER SEPTIC SYSTEMS - what's ok and what should be avoided

Reader Question: septic pumper says a BAT septic tank cannot be pumped without damage

2016/05/14 Matt said:

I have Jet 1500 Series Bat Media Plant. Was told by guy pumping tank that they wont pump tank with aerator because bat's fall in and its a defect in system. Is this true?

Reply:

Matt I don't quite understand the question. Certainly septic systems that use an aerator still need to be cleaned of settled sludge on occasion;

I don't know what you mean about "bat's fall in" nor what a bat is doing in the septic tank. I think you refer to Jet Inc.'s BAT septic system design - we'll include your question and our reply and discussion [here] in BAT MEDIA SEPTIC PLANTS

Watch out: As the Ohio Department of Health points out

Most sewage systems will fail sometime. Just like the roof on your house, a septic system is designed to have a lifetime of about 20-30 years, under the best conditions.

Eventually, the soil around the absorption field becomes clogged with organic material, making the system unusable.

But by far the most common reason for early failure is improper maintenance by homeowners. When a system is poorly maintained and not pumped out on a regular basis, sludge (solid material) builds up inside the septic tank, then flows into the absorption field, clogging it beyond repair. (Ohio DOH 2016, seeReferences or Citations )

Reader follow-up:

Matt said:

Sorry, I am referring to the baffles that are on the walls of the aeration tank.

www.odh.ohio.gov/~/media/ODH/ASSETS/files/eh/sts/P-Jet-1500%20Series%20BAT%20Media%20Plants-Ownman-952%20UV

I am being told if that tank is pumped out those baffles could fall in leaving the company that is pumping tank liable for the repair.

Meaning they would have to dig up tank to repair. I was told this is a defect in the design of this "Jet 1500 Series Bat Media Plant" system.

I was trying to research to see if this is true. I have to question if there is truly a design flaw, would there not be information somewhere on what is required to fix it?

Would there not be some sort of warranty for a 6 year old system? Or, am I being fooled by the company I called out to pump my system?

Moderator reply: BAT septic system maintenance must be done by a properly-trained pumper as the media is fragile

Matt:

Watch out: we may be snarled up in confusion about terminology. Take a look at the page top adapatation of Jet's BAT system tank.

- Septic tank baffles

are pipe tees (in this design) at tank or tank compartment entry and exit ports; baffles are usually cemented in place and have the job of keeping floating solids in the source compartment.

This is particularly critical in keeping solids from flowing out of the tank to the drainfield (causing clogging) and in the BAT design are probably critical in keeping large solids in the first tank chamber to avoid fouling up the BAT media itself or the aerobic pump. - Septic tank BAT Media (Biologically Accelerated Treatment)

shown in Jet's BAT design is a gride-like "media" component that is basically providing a large surface area to enhance bacterial action on the wastewater in the center treatment tank chamber(s).

The company warns against damaging the BAT Media during pumping, and it might be that this is what your septic pumper is worried about.

But if there is actually a problem of the BAT Media collapsing or falling out of its proper position in the septic tank simply when the wastewater is removed during tank cleaning that would be a serious concern that needs to be addressed. I've asked Jet for technical comment in hopes we can clarify this question.

In any case, taken at face value your septic pumper is partly correct. The owners' manual for your BAT system does not prohibit pumping and in fact pumping or cleaning of the tank at intervals is recommended; rather it warns that if the system is pumped by someone who is not expert in the care of this system design the media in the tank can be severely damaged and require costly repair.

Here is what the Ohio Health Department's copy of Jet Inc.'s BAT Owners Manual (cited below) describes:

- 6-Month Service: This comprehensive service call includes collection and assessment of a post-treatment sample, inspection, servicing, cleaning, removal, reinstallation and testing of the aerator by a trained service technician.

- 12-Month Service: This call provides all elements of the 6-Month service as well as media cleaning.

- 3-Year Service: This service provides all steps in the 6- and 12-month service and tank pumping, if necessary. If you have not renewed your Inspection/Service Policy, you will be charged for the 30- and 36-month service calls. Tank pumping is not included under your Jet Distributor’s Inspection/Service Policy. It is charged to you by your tank pumper. If you have kept your service policy active, there will be no charge for aerator service.

- Make sure you notify your Jet Distributor before you have your tank pumped. If the tank pumper is not familiar with Jet’s media and media has not been cleaned before pumping, severe damage to the media can occur. This is potentially costly to repair. - (Jet Inc., 2016)

From the manual I infer that your pumper may have used confusing language in discussing the concern with you.

The "BAT" media is what seems to be fragile - not the "baffles" that are found at the tank inlet and outlet ports. This is a multi-compartment septic tank with an aerator and a UV light.

Septic tank baffles

in this design using PVC piping Tees - are a critical component in all septic tanks that keeps floating solids in the proper tank or tank compartment. Usually the baffles are cemented or sealed in place in the tank opening, and don't "fall out". But there might be a loose baffle problem with this tank.

Watch out: As I am not closely familiar with this septic tank and as the company's instructions and contact information have been published by the Ohio DOH, I would be very reluctant to disagree with your septic pumper about specific septic system design problems with which they are familiar. I would never ask a contractor to do something that they don't want to do and of which they warn of a damage concern.

Instead I suggest that you contact the company to ask for advice about this question.

There are indeed special instructions required for pumping the system and particular care is taken when pumping the media section of the tank.

You will read that the tank is indeed to be pumped from two of its three sections, but that special care is taken not to damage the media during pumping. If the pumper believes that she or he simply cannot pump the tank without touching the media with the pumper hose, the certainly you should not ask that company to do so. Here are excerpts from the instructions to which you referred:

- Media Compartment Pumping 500 Thru 1500 GPD Plants:

Jet service technicians must air clean the media tank prior to tank pumping. Pumping must take place within two weeks after media cleaning. - Remove tank access covers. Remove aerator(s). Always place aerator so shaft and foam restrictor do not contact any surface. You can lean aerator against the mounting casting as long as the shaft does not come into contact with hard surfaces. Even a small bend in the shaft will shorten the aerator’s lifespan.

- Always pump the Pretreatment Compartment (access 1) first, then pump the Treatment Compartment (access 2) second. Pumping from the Settling Compartment (access 3) is not required.

- The opening in some media is very small. Take extreme care not to touch any part of the media with the pump hose or the tip of the pump hose - serious damage can occur if the media is stressed by the vacuum or the hose.

- The opening in the media center can not be seen from the surface. Carefully lower the hose down the center of the mounting casting, through the opening in the media, and down to the bottom of the tank.

- Pump tank until empty and carefully remove hose. Use caution not to touch the media with the hose as the hose is being removed. Rinse out all compartments and pump out residual water. Reinstall aerator(s) and access covers.

- There are three access covers. Pump from access cover one and two.

- These systems have two sets of media, use caution when pumping from riser one and two. There is also a separate pre- treatment tank that will require pumping.

- Note: Tank pumping should only be preformed by a properly equipped professional service provider. Check with your local health department for current tank pumping regulations. - (Jet Inc., 2016)

Watch out: If your septic pumper does not know how to pump and clean this system following the manufacturer's instructions, you might want to contact Jet Inc., to ask for a referral to a local service company who does know their system.

Jet Inc 750 Alpha Dr. Cleveland, OH 44143 USA Phone: (440) 461-2000 Fax: (440) 442-9008 email@jetincorp.com www.jetincorp.com

This information has been adapted from the Ohio health department's public information and from Jet Inc.'s BAT system owners' manual as published in the public domain by the Ohio department of health and cited just below.

InspectAPedia is an independent publisher of building, environmental, and forensic inspection, diagnosis, and repair information provided free to the public - we have no business nor financial connection with any manufacturer or service provider discussed at our website.

BAT Septic System Costs, Research & Information Sources

- BAT SEPTIC SYSTEMS GUIDE to OPERATION & MAINTENANCE [PDF] Maryland DOH, Washington County, retrieved 2018/12/04, original source: https://health.maryland.gov/washhealth/Documents/BAT%20Educational%20Information%20Flyer%20Oct%202015%20(1).pdf

- J 1500 Series BAT® Media Plants with Model 952 UV Owners Manual [PDF] Jet Inc., 750 Alpha Dr., Cleveland OH 44143 USA, Tel: 440-461-2000, email: email@jetincorp.com Website: jetincorp.com retrieved 2016/05/15, original source, Ohio health department, U.S.A., http://www.odh.ohio.gov/~/media/ODH/ASSETS/files/eh/sts/P-Jet-1500%20Series%20BAT%20Media%20Plants-Ownman-952%20UV

Excerpt from the company's website:

Founded in 1955, David S. MacLaren acted on an innovative idea. While working closely with his father, Albert MacLaren, they designed and patented an aerator for family homes that would more effectively treat and dispose of residential wastewater, changing the technology in the wastewater treatment business forever!

A close look at our competitors will highlight how much of an innovator we are as most of the competing concrete tanks are modeled after our design, but they can’t copy another Jet innovation, our patented BAT® media.

Contact Us: in the USA Tel: 440-461-2000 or email@jetincorp.com. - Davis, H.E. and Bullock, D.C., Davis, Harold E., Bullock and Donald C., 1995. Batch biological treatment by microorganisms; circulating loop; aeration; submerged growth filters. U.S. Patent 5,454,949.

Vancouver

Abstract:

The invention is directed to a sewage treatment system comprising a tank in which biological treatment by microorganisms occur in mixed liquor and a circulating loop for removing mixed liquor from the tank and returning oxygen enriched aerated mixed liquor to the tank.

The mixed liquor is removed and returned to the tank through a pair spaced apart submerged filters. One alternative construction is to use a pressure tank in the circulation loop to increase the percentage of dissolved oxygen in the aerated mixed liquor. - "Home Sewage Treatment Systems Rules Update", Ohio Department of Health, Address: 246 N. High St., Columbus, Ohio 43215 Website: http://www.odh.ohio.gov/ Tel: (614) 466-3543 - retrieved 2016/05/15, original source: http://www.odh.ohio.gov/homesewagerules"

Excerpts:

Without proper maintenance and good system design, your sewage could go into your neighbor’s yard (and their sewage could come into your yard) contaminating the ground water with disease-causing germs like E.coli, Salmonella, Shigella, polio, hepatitis, Cryptosporidium.

In addition to the diseases themselves, mosquitoes and flies that spread some illnesses can breed in areas where liquid waste reaches the surface.

The problems of a failing septic system don’t stop at your property line. Sewage and disease can impact the health of your neighbors and your community.

In addition to creeping into the yard next door, contaminates such as E.coli can get into our beaches. The Ohio Department of Health has identified home sewage system discharge as a contributing factor to unhealthy bacteria levels at Ohio’s beaches.

When the levels reach a certain point, the beach must issue an advisory and the beach manager can even close it to the public. Your septic system won’t last forever, but you can extend the life of it and delay expensive replacement with maintenance and replacement of broken parts. Ohio’s new sewage system rules DO NOT require everyone to automatically replace their system with new technology.

You will have to replace your system WHEN it fails- but that’s been the law in Ohio since 1977.

These new septic system rules give you more options to fix it before it fails and more ways to prevent sewage from making you, your family, your neighbors and your community sick from the germs of septic waste. - Laak, Rein. "Sewage system for the treatment of segregated domestic waste water." U.S. Patent 4,465,594, issued August 14, 1984.

- Maryland DOH, Anne Arundel County, NITROGEN REDUCING [SEPTIC] SYSTEMS – Frequently Asked Questions, (2017) retrieved 2018/12/04 original source: https://www.aahealth.org/nitrogen-reducing-systems-frequently-asked-questions/

Excerpts:

Code of Maryland Regulations, COMAR 26.04.02, established new requirements for on-site sewage disposal systems within the Chesapeake Bay Watershed.

Nitrogen-reducing units approved by the Maryland Department of the Environment as Best Available Technology (BAT) are required for:

new construction applications countywide;

building addition applications that require an upgrade to the existing septic system for building permit approval;

and repair or replacement applications for existing on-site sewage disposal systems located in the Critical Area

...

How does a nitrogen-reducing system work?

A nitrogen-reducing system consists of the advanced pretreatment unit and the sewage disposal field. The advanced pretreatment units used in Anne Arundel County typically replace or work in combination with the septic tank.

The units may use aeration or recirculation to promote biological action.

Through this action, nitrogen is released as a harmless gas to the atmosphere.

Advanced pretreatment units include electrical and mechanical components such as pumps, blowers, floats, alarms, diffusers and electronic control panels.

What maintenance is required for nitrogen-reducing systems?

Since advanced pretreatment units have electrical and mechanical components, periodic maintenance and inspections by a qualified contractor are essential.

The frequency of inspection and maintenance will vary based on the type of unit.

Manufactured units should follow the manufacturer’s maintenance requirements.

Engineer-designed units should follow inspection and maintenance requirements recommended by the installer.

An operation and maintenance service contract with a certified service provider is required for properties with nitrogen-reducing units in the Critical Area. An operation and maintenance service contract is recommended for all other properties with a nitrogen-reducing unit.

Property owners who install a nitrogen-reducing system must enter into an agreement with the County, which is recorded against the deed of the property.

This agreement will specify the amount of square footage and number of bedrooms approved for the property, along with the maintenance responsibilities associated with the nitrogen-reducing unit.

The overall effectiveness of a nitrogen-reducing system and its level of wastewater treatment depend upon the use of the system.

Bleach, detergents and household chemicals should be used sparingly. According to County Code, garbage disposal units are prohibited on properties served by on-site septic systems.

All leftover food and grease should be discarded as solid waste in garbage cans.

- Norton, John W. "Decentralized systems." Water Environment Research 81, no. 10 (2009): 1440-1450.

Note: Norton uses the term "BAT" to refer to "Best Available Technology" - Podella, Carl W., and Nils Siegfried Hauptmann. "Fermenting yeast culture and recovering peptides and surface active agent for use in enhancing metabolic rates in biological systems and increasing nutrient uptake of cells; bioremediation and waste water treatment." U.S. Patent 7,476,529, issued January 13, 2009.

- Vandervelde, Don M., and Glenn J. Helm. "Sewage treatment." U.S. Patent 4,997,568, issued March 5, 1991.

Excerpt from patent description abstract:

A system and method to remove pathogenic organisms and other suspended and dissolved containments from sewage or other contaminated water by an inexpensive, nearly maintenance free device. Principles of operation include new effective methods which combine synergistically, suspended and fixed film biological reactor, settling chamber, physical filter, and composting technology, to achieve tertiary sewage treatment and equivalent treatment of other contaminated water without outside energy input being required.

Contaminated water flows into the apex or center of a large circular, wedge or conic chamber, then radially through precisely shaped layers of medium which provide progressive treatment by reduced pore size and increased surface area as the flow proceeds to the periphery. Oxygen can be diffused into the final treatment stage by providing large surface exposure to ambient air.

The treated effluent has a benign health and aesthetic quality to permit disposal as normal surface run-off, used for irrigation and landscaping or allowed to percolate into subsurface soil without clog mat formation. - Vought, Allan, "New state rule will make septic systems, many new homes more expensive" The Baltimore Sun, 24 December 2012,

Excerpt:

The cost of new homes using on-site sewage disposal systems will increase significantly in Harford County and elsewhere in Maryland after Jan. 1, when a controversial new state regulation takes effect.

The required installation of what is referred to in the law as "Best Available Technology," or BAT, is spurring owners of undeveloped lots to get well and septic permits before the law takes effect, a county health official said.

Most of those affected are in the northern half of the county where there are still hundreds of undeveloped, but platted building lots.

The deadline to receive a septic permit and be grandfathered from the law is this Friday, Dec. 28. County offices will not be open on Monday, Dec. 31, because of the New Year's holiday.

The additional cost is estimated at between $11,000 and $14,000 per individual septic system, Kevin Barnaba, director of the health department's Bureau of Environmental Health, said last week. - Weaver, Lloyd, James C. Monroe, and James R. Gray. "Waste water treatment process and system with filtering media." U.S. Patent 6,187,183, issued February 13, 2001.

Abstract:

A waste water treatment method and system including a recirculating treatment zone and a filter/treatment zone.

The recirculating zone has a treatment medium that includes aerobic microbes and small beads that create interstices within, and extensive surface area on, which active microbes dwell and through which dead microbes and treated water are permitted to easily pass.

The filter/treatment zone has a filter/treatment medium that includes peat and small beads that create interstices through which filtered water is permitted to pass.

The recirculating treatment zone is designed to be coupled to a settling unit, such as a septic tank.

The filter/treatment zone may be coupled to a leach field, with ultraviolet disinfection for coupling to a secondary water user, a soak hose system, etc.

The present invention is sufficiently effective so as to reduce to desirable levels the TSS, BOD, E-Coli, nitrogen-containing compounds, phosphorus-containing compounds, and bacteria of waste water in a manner that is cost-effective and that permits water recycling for many applications. - Also seeReferences or Citations

Reader Question: On 2018-05-29 by Richard Laird - what does a BAT septic cost?

I am looking for prices for a BAT septic system and if it can be used in Allegheny County, Pa.

This Q&A were posted originally

On 2018-05-29 by (mod) - prices for a BAT septic system

Richard

Take a look at BAT MEDIA SEPTIC PLANTS where there are some sources and citations in the article and in that article's REFERENCES section.

Typical additional costs for a BAT media septic plant start at around $10,000 to $15,000 above a conventional septic system that fits your site. The base cost that you have to add to those numbers vary so considerably by country and city or province or state that I'm reluctant to promise a more-specific estimate when we know nothing about your specific site.

Really? well yes and no. A typical septic tank cost is around $1200. U.S. for the tank - before installation costs that vary by site conditions. The costs we give above for BAT septics are for a complete system including effluent disposal.

...

Continue reading at MEDIA FILTER SEPTIC SYSTEMS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- AEROBIC SEPTIC SYSTEMS, ATUs - home

- AEROBIC SEPTIC CONTINUOUS FLOW, SUSPENDED GROWTH

- DISINFECTION SEPTIC SYSTEM

- MEDIA FILTER SEPTIC SYSTEMS - home

- BAT MEDIA SEPTIC PLANTS

- DOSING CONTROL for SEPTIC MEDIA SYSTEMS

- FOAM CUBE SEPTIC MEDIA FILTERS

- PEAT SEPTIC MEDIA FILTERS

- POD SEPTIC SYSTEMS

- RUCK® SEPTIC MEDIA FILTER SYSTEMS

- SAND FILTER SEPTIC DESIGN SPECIFICATIONS

- SAND SEPTIC MEDIA FILTERS

- SANDY SOIL SEPTIC DESIGNS

- SEPTIC MEDIA FILTER CAPACITY & MAINTENANCE

- SEPTIC MEDIA FILTER SOURCE LIST

- SEPTIC MEDIA FILTER SYSTEM OPERATION

- SINGLE PASS vs RECIRCULATING SEPTIC MEDIA FILTER DESIGNS

- TEXTILE SEPTIC MEDIA FILTERS

- TYPES of SEPTIC MEDIA FILTER MATERIALS

- SEPTIC SYSTEM DESIGN BASICS - home

- SEPTIC SYSTEM TYPES - home

- ALTERNATIVE DESIGN SEPTIC SYSTEM SUPPLIERS for directory lists of other septic system component suppliers for sources of septic effluent spray system repair parts and sprayers.

- SEQUENCING BATCH SEPTIC SYSTEMS

Suggested citation for this web page

BAT MEDIA SEPTIC PLANTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to SEPTIC SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Beal, C. D., E. A. Gardner, and N. W. Menzies. "Process, performance, and pollution potential: A review of septic tank–soil absorption systems." Soil Research 43, no. 7 (2005): 781-802.

Abstract:

On-site wastewater treatment and dispersal systems (OWTS) are used in non-sewered populated areas in Australia to treat and dispose of household wastewater. The most common OWTS in Australia is the septic tank–soil absorption system (SAS)—which relies on the soil to treat and disperse effluent.

The mechanisms governing purification and hydraulic performance of a SAS are complex and have been shown to be highly influenced by the biological zone (biomat) which develops on the soil surface within the trench or bed. Studies suggest that removal mechanisms in the biomat zone, primarily adsorption and filtering, are important processes in the overall purification abilities of a SAS.

There is growing concern that poorly functioning OWTS are impacting upon the environment, although to date, only a few investigations have been able to demonstrate pollution of waterways by on-site systems.

In this paper we review some key hydrological and biogeochemical mechanisms in SAS, and the processes leading to hydraulic failure. The nutrient and pathogen removal efficiencies in soil absorption systems are also reviewed, and a critical discussion of the evidence of failure and environmental and public health impacts arising from SAS operation is presented.

Future research areas identified from the review include the interactions between hydraulic and treatment mechanisms, and the biomat and sub-biomat zone gas composition and its role in effluent treatment. - Cogger, C. G., and B. L. Carlile. "Field performance of conventional and alternative septic systems in wet soils." Journal of Environmental Quality 13, no. 1 (1984): 137-142.

- Grimshaw, Derald E. "Waste treatment system." U.S. Patent 3,662,890, issued May 16, 1972.

Abstract:

A system and method of treating contaminated liquid, such as domestic waste liquid in a septic tank, by progressively withdrawing part of the liquid into a closed chamber and aerating it under pressure to permeate it extensively with clean ambient air, and discharging the saturated liquid into the septic tank, or other type of tank if different waste liquid from domestic waste is being treated, to enhance the reduction of B.O.D. and/or C.O.D. of said liquid prior to discharge from the tank. - Takigami, Hidetaka, N. Taniguchi, T. Matsuda, M. Yamada, and S. Matsui. "The fate and behaviour of human estrogens in night soil treatment processes." Water Sci. Technol 42 (2000): 45.

- Tobey Jr, James Francis, and Raymond D. Stapleton Jr. "Enzyme and bacterial combination in a slowly dissolvable matrix for septic tanks, grease traps and waste treatment." U.S. Patent 6,325,934, issued December 4, 2001.

Abstract:

Sewage waste digestive bacteria and enzymes are incorporated into a slow release material and delivered to the site of the waste to digest the solid waste. The slow release material is made heavy so the enzymes and bacteria will be delivered to the sludge in the bottom of a sewage digester chamber and made fat soluble so that the enzymes and bacteria will be delivered to the grease in the waste system to be digested. This selective delivery system prevents the enzymes and bacteria from being diluted in grey water rendering them less effective and discharged from the sewage system without digesting waste. - Advanced Onsite Wastewater Systems Technologies, Anish R. Jantrania, Mark A. Gross. Anish Jantrania, Ph.D., P.E., M.B.A., is a Consulting Engineer, in Mechanicsville VA, 804-550-0389 (2006), Advanced Onsite Wastewater Systems Technologies. Outstanding technical reference especially on alternative septic system design alternatives. Written for designers and engineers, this book is not at all easy going for homeowners but is a text we recommend for professionals--DF. I>

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.