Continuous Flow, Suspended Growth Aerobic Septic Systems

Continuous Flow, Suspended Growth Aerobic Septic Systems

- POST a QUESTION or COMMENT about CFSGAS Continuous Flow, Suspended Growth Aerobic Septic Systems, design, installation, maintenance, and repair

Continuous Flow, Suspended Growth Aerobic Septic Systems:

Here are designs and products CFSGAS for aerobic septic treatment units (ATUs) for onsite waste disposal, also called fine bubble aeration systems.

This document is based on US EPA EPA/625/R-00/008 Continuous-Flow, Suspended-Growth Aerobic Systems (CFSGAS) but includes expanding edits and comments. We address aerobic septic system design, features, inspection, repair, and maintenance. Product sources are also listed. Where we have reader or septic designer feedback on this and other septic system designs we add those comments to this and related documents.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Aerobic Treatment Septic Systems - Continuous Flow, Suspended Growth Aerobic Septic Treatment System Designs

Definition of Suspended Growth vs. Attached Growth Septic Systems:

Oxygen-supported (aerobic) bacteria in the mixed liquor perform the primary treatment in the system. As the bacteria themselves die off they remain suspended in the mixed liquor - a "suspended growth aerobic treatment system".

Alternatively, a media, such as synthetic fabrics, may be suspended in the treatment tank, permitting the bacteria to attach to the media surfaces - an "attached growth aerobic treatment system".

The Suspended-Growth type of aerobic septic system is detailed below.

AEROBIC Septic systems add oxygen using any of several types aeration or "fine air bubble" systems to increase the level of effluent treatment in the septic tank by encouraging aerobic bacteria. Aerobic systems produce a better-quality wastewater effluent for discharge into the absorption system for final treatment and disposal.

Citation of this article by reference to this website and brief quotation for the sole purpose of review are permitted. Use of this information at other websites, in books or pamphlets for sale, or in any other form is reserved to the author. Reviewers welcomed and are listed at "References."

What is an Aerobic Treatment Unit for Septic Effluent?

In residential use, aerobic treatment units (ATUs, also called "home aeration systems" or "septic tank aeration systems") are pre-packaged septic treatment systems which are in essence a mini-wastewater treatment plant for home use. "Aerobic" refers to the use of an air pump to add oxygen to the treatment tank to increase the level of treatment by the system.

Note: other types of packaged onsite wastewater treatment systems are

at SEWAGE TREATMENT PLANTS, RESIDENTIAL

AEROBIC Septic systems thus require electrical power and cost more to install and operate (more frequent tank pumping) than a traditional gravity septic tank and drainfield. Aerobic treatment, which can produce very high quality treated effluent, is used at sites where a conventional septic drainfield simply wont' work, perhaps because of wet soils or very rocky conditions.

ATUs are also used to restore a working septic system where a traditional septic system has failed and is difficult to repair. Other common reasons for installing aerobic septic treatment units include lots close to lakes and streams or lots which are too small to fit a conventional septic system.

Aerobic treatment may not entirely eliminate the requirement for a drainfield, but it can substantially reduce the drainfield area and capacity required. This is not a "new" idea. Aeration of wastewater as a means of septic effluent treatment has been in use for more than 100 years (using media filters according to Jantrania).

How do Aerobic Septic Treatment Units Work?

An aerobic treatment unit is basically an "oxidizer" which uses extra oxygen dissolved in the wastewater to support aerobic microorganisms which in turn decompose dissolved organic and nitrogen compounds into simple CO2 or into inorganic compounds.

As microorganisms die off they accumulate as a sludge of biological material, some of which supports the development of new cells or microorganisms to keep the system working. ATU's separate solid waste first in the "trash tank" and later, additional solids are separated in the clarifier or settlement tank from which they may be returned to the primary tank for more treatment. (See the sketch at the top of this page.)

"Typical organic materials that are found in residential strength wastewater include carbohydrates, fats, proteins, urea, soaps and detergents. All of these compounds contain carbon, hydrogen, and oxygen. Domestic wastewater also includes organically bound nitrogen, sulfur and phosphorus.

During biochemical degradation, these three elements are biologically transformed from organic forms to mineralized forms (i.e., NH3, NH4, NO3, SO4, and PO4)." -- Reference #3 at page bottom.

In contrast, an example of an anaerobic process involved in the breakdown of wastewater would be fermentation, the exothermic, enzymatic breakdown of soluble organic compounds which does not depend on the presence of dissolved oxygen. Methane and CO2 are both products of wastewater fermentation.

Onsite Wastewater Treatment Systems Technology Fact Sheet 1 - EPA 625/R-00/008

Description of Continuous-Flow, Suspended-Growth Aerobic Systems (CFSGAS)

The activated sludge process is an aerobic suspended-growth process that maintains a relatively high population of microorganisms (biomass) by recycling settled biomass back to the treatment process. The biomass converts soluble and colloidal biodegradable organic matter and some inorganic compounds into cell mass and metabolic end products. The biomass is separated from the wastewater through settling in a clarifier for recycling or wasting to sludge handling processes.

Preliminary treatment to remove settleable solids and floatable materials is usually provided by a septic tank or other primary treatment device. Most onsite designs are capable of providing significant ammonia oxidation and effective removal of organic matter.

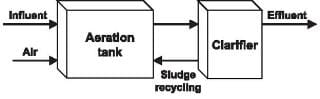

The basic system consists of a number of interrelated components (as shown in figure 1):

- An aeration tank or basin.

- An oxygen source and equipment to disperse atmospheric or pressurized air or oxygen into the aeration tank at a rate sufficient to always maintain positive dissolved oxygen.

- A means to appropriately mix the aeration basin and ensure suspension of the biomass (usually accomplished by the aeration system).

- A clarifier to separate the biomass from the treated effluent and collect settled biomass for recycling to the aeration basin.

Figure 1. A basic Continuous-Flow, Suspended-Growth Aerobic Systems CFSGAS configuration

Several modifications of this basic process are commercially available.

Several modifications of this basic process are commercially available.

These include different aeration devices; different means of sludge collection and recycling to the aerator; the use of coarse membrane filters in lieu of, or in addition to, the clarifier; and process enhancement through the addition of an inert media area on which biofilms can grow.

The addition of surfaces where biota can become attached and grow increases the capacity of the system (increased organic loading possible). This last modification is the most significant enhancement and is described below.

The combined fixed-film/suspended growth process is sometimes referred to as a class of treatment processes called coupled contact aeration, enhanced, or high biomass systems. To enhance performance and increase the capacity of the aeration tank, an inert support medium is added to the aeration tank.

This allows a fixed film of biomass to attach and grow on the medium to augment the suspended microbial population, providing more biomass to feed on wastewater constituents (figure 2).

Synthetic trickling filter media, loops of fiber bundles, and a variety of different plastic surface configurations can be suspended in the aeration tank.

Advantages of CFSGAS septic systems include increased active microbial mass per unit volume, enhanced potential for nitrification, reduced suspended solids loading to the clarifier, improved solids separation characteristics, reduced sludge production, and resilience under variable influent conditions.

Figure 2. An enhanced Continuous-Flow, Suspended-Growth Aerobic Systems CFSGAS or "high biomass" system

Typical Continuous-Flow, Suspended-Growth Aerobic System application

These systems are usually preceded by a septic tank and followed by a subsurface wastewater infiltration system (SWIS). Despite some claims of reduced SWIS sizing when compared to the conventional septic tank pretreatment, the designer is cautioned to consider ground water protection. These systems should be applied only where onsite system management services are available.

For surface water discharge, the system must be followed by disinfection at a minimum to consistently meet discharge standards.

However, some subsurface (non-human-contact) reuse may be implemented without further treatment. High biomass systems can be a low-cost means of upgrading existing overloaded CFSGAS units that currently do not meet BOD or nitrification goals.

They can also compete directly with conventional designs because they have greater stability in handling highly variable loadings.

Continuous-Flow, Suspended-Growth Aerobic System Design assumptions

The extended aeration type of CFSGAS is the most commonly used design. At present there is no generic information on design parameters for fixed film activated sludge systems. Package plants are delivered based on design flow rates. A conservative design approach for extended aeration systems is presented in table 1.

The inert medium should support additional biomass and add to the total system microbial mass. Because the increase in microbial population is difficult to measure, any "credits" for this addition would have to be based on empirical observation.

Claims for significantly decreased sludge production, increased oxygen transfer efficiency, and improved settleability of the sludge have not been universally proved. However, a number of successful installations for onsite and small municipal systems have been in operation throughout the world for more than 10 years (Mason, 1977; Rogella et al., 1988; Rusten et al., 1987).

Table 1-1. Design parameters for CFSGAS extended aeration package plants |

|

| Parameter | Extended Aeration |

| Pretreatment (if needed) | Septic tank or equivalent |

| Mixed Liquor Suspended Solids (mg/L)a | 2,000 - 6,000 |

| F/M Load (lb BOD/d/MLVSS)b | 0.05 - 0.15 |

| Hydraulic Retention Time (h) | 24 -120 |

| Solids Retention Time (days) | 20 -40 |

| Mixing Power Inputc | 0.2-3.0 hp/1,000 ft3 |

| Clarifier Overflow Rate (gpd/ft2) | 200 - 400 avg., 800 peak |

| Clarifier Solids Loading (lb/d/ft2) | 30 avg., 50 peak |

| Dissolved Oxygen (mg/L) | >2.0 |

| Residuals Generated | 0.6 - 0.9 lb TSS/lb BOD removed |

| Sludge Removal | 3 - 6 months as needed |

Notes to the table above

a TSS in aeration tank.

b Organic loading (pounds of BOD per day) to aeration tank volatile fraction of MLSS.

c Power input per cubic foot of tank volume.

Onsite package treatment units (see figure 3) should be constructed of noncorrosive materials, such as coated concrete, plastic, fiberglass, or coated steel. Units may be stand-alone or manufactured to drop into a compartmented septic tank. Some units are installed aboveground on a concrete slab with proper housing to protect against severe climatic conditions.

Units may also be buried underground as long as easy access is provided to all mechanical parts, electrical control systems, and water surfaces. All electrical components should follow NEC code and be waterproof and/or housed from the elements.

If airlift pumps are used, large-diameter units should be provided to avoid clogging. Blowers, pumps, and other mechanical devices should be designed for continuous use because they will be abused by climatic conditions and the corrosive atmosphere within the treatment environment.

Easy access to all moving parts should be provided for routine maintenance. An effective alarm system should be employed. Typical land area requirements for package plants are modest.

Figure 3. Components of a typical aerobic treatment unit

For engineered package plants, final clarifier designs should be conservative for high MLSS and poor settleability of biomass.

Because of the potential for bulking sludge, secondary clarifiers should be equipped with surface skimming devices to remove greases and floating solids, as well as efficient screens.

Performance of Continuous-Flow, Suspended-Growth Aerobic Systems

Well-operated CFSGAS extended aeration units that are well operated can achieve BOD concentrations ranging from 10 to 50 mg/L and TSS concentrations ranging from 15 to 60 mg/L. Some studies (Brewer et al., 1978; Hutzler et al., 1978) have indicated poorer performance owing to surge flows, variable loading, and inadequate maintenance. Nitrification can also be significant in these aeration units during warmer periods.

Some nitrogen removal can be achieved by denitrification, which can remove 30 to 40 percent of the total nitrogen (TN) under optimum conditions. Average total nitrogen effluent concentrations in residential extended aeration units range from 17 to 40 mg/L. Fecal coliform and virus removal has been reported in the range of 1 to 2 logs.

High biomass systems have produced BOD and TSS effluents of 5 to 40 mg/L. Although they are less dependent on temperature than the extended aeration CFSGAS, temperature does have an impact on their seasonal capability to nitrify the influent ammonium-nitrogen to nitrate-nitrogen. All CFSGAS systems do an excellent job of removing toxic organics and heavy metals. Most CFSGAS systems do not remove more than a small percentage of phosphorus (10 to 20 percent) and nitrogen (15 to 25 percent).

Management requirements for Continuous-Flow, Suspended-Growth Aerobic Systems

CFSGAS systems must be managed and maintained by trained personnel rather than homeowners to perform acceptably. Power requirements vary from 2.5 to 10 kWh/day. They should be inspected at least every 2 to 3 months. During these inspections, excess solids pumping should be based on the mixed liquor measurements.

It is estimated that an effective program will require between 12 and 28 person-hours annually, in addition to analytical testing of the effluent, where required. Management contracts should be in place for the life of the system.

Common operational problems with extended aeration systems are provided in table 2. Residuals generated will vary from 0.6 to 0.9 lb TSS per lb BOD removed, over and above the normal septic tank sludge produced.

Table 1-2. Common operation problems of extended aeration package plants |

||

| Observation | Cause | Remedy |

| Excessive local turbulence In aeration tank |

Diffuser plugging Pipe breakage Excessive aeration |

Remove and clean Replace as required Throttle blower |

| White, thick, billowy foam on aeration tank | Insufficient MLSS | Avoid wasting solids |

| Thick, scummy, dark tan foam on aeration tank | High MLSS | Waste solids |

| Dark brown/black foam and mixed liquor in aeration tank | Anaerobic conditions Aerator failure |

Check aeration systems, aeration tank DO |

| Billowing sludge washout in clarifier | Hydraulic or solids overload Bulking sludge |

Waste sludge; check flow to unit See EPA, 1977 |

| Clumps of rising sludge in clarifier | Denitrification Septic conditions in clarifier |

Increase sludge return rate to decrease sludge retention time in clarifer Increase return rate |

| Fine dispersed floc, turbid effluent | Turbulence in aeration tank Sludge age too high |

Reduce power input Waste sludge |

| Poor TSS and/or BOD removal | Excess flow and strength variations | Install flow smoothing system |

| Poor nitrification | Low temperatures Excessive biocide use |

Insulate, upgrade to high biomass, etc. Reduce biocide loading |

Continuous-Flow, Suspended-Growth Aerobic System Risk management issues

CFSGAS systems require effluent disinfection at a minimum to meet surface discharge or any surface reuse water quality requirements. They are quite sensitive to temperature, interruption of electric supply, influent variability, or shock loadings of toxic chemicals. The septic tank helps protect these units from the latter problems.

Aesthetically, noise from the blowers is the major irritant, while odors can be significant during power outages or organic overloading periods.

High biomass units are more resistant to the above impacts. The systems are not well suited to seasonal use because of long start-up times.

[DF note: we agree, and this is the chief complaint that we have heard from readers. As a start in addressing aerobic treatment unit noise, we advise checking with the manufacturer of your unit to be sure that it is properly installed and maintained.]

Continuous-Flow, Suspended-Growth Aerobic Systems Costs

The installed costs of package plants are highly variable but are usually less than $10,000. Operation and maintenance (O/M) costs are primarily dependent on local power and labor costs, varying from $400 to $600 per year in most cases.

Other Aerobic Septic System Designs:

Simplest Two-Chamber Aerobic Treatment Unit Design

Waste from the occupied building is fed into a septic tank primary treatment chamber where it is kept agitated and aerated (oxygenated) by an air pump and rotor or mixer. By increasing the oxygen level in the effluent, we increase activity by the tank's aerobic bacteria and other naturally occurring microorganisms such as fungi, protozoa, rotifers, and other microbes.

Effluent passes out of the primary treatment tank into a settlement chamber where sludge settles out for recycling into the primary treatment tank.

Clarified effluent passes to an absorption or further treatment system. An alarm system is usually installed to tell the building owner if the equipment has stopped working.

Three-Chamber Aerobic Septic System ATU Design

- AEROBIC Septic Trash Tank: Waste from the occupied building is fed into a "trash tank" (similar to a septic tank);

septic solid waste and scum are retained in the "trash tank" and as with a conventional septic tank, must be periodically

removed by a septic pumping company. (ATU's require more frequent septic tank pumping than a conventional

septic system.)

The ATU tank works like a septic tank but can be smaller because the system does not depend on a long "settlement time" to remove solids and grease as occurs in a conventional septic tank. - AEROBIC Septic System Aeration Chamber & Aeration Pump: An aerator or air pump, normally installed

in a chamber atop or close to the septic tank, pumps air into the septic tank's aeration compartment using any of

several methods to aerate the wastewater.

A mixing device or rotor may be used to further agitate the wastewater in the aerobic treatment tank to increase the oxygen level in the effluent and to support treatment by aerobic bacteria in the tank.

Speaking slightly more technically, the aerobic process in the treatment tank provides for biochemical oxidation of the soluble organic compounds found in domestic wastewater.

AEROBIC Septic Aeration Chamber: Septic effluent moves out of the "trash tank" to a separate aeration chamber. In the aeration chamber air (oxygen) is pumped through the system to provide oxidation and waste treatment using a variety of designs.

The added level of oxygen permits a variety of microbial life forms (bacteria, fungi, protozoa, and others) to oxidize or otherwise process pathogens and nitrogen compounds in the discharged septic effluent. The aerated, or oxygenated wastewater is called the "mixed liquor". - AEROBIC Septic System Clarification Chamber: After having been aerated and mixed in the aeration chamber, the effluent flows to a clarification chamber.

Solids settle out of the effluent and stay inside the ATU. In some designs the sludge is recycled to the

aeration chamber.

The settled sludge and solids support the formation of additional microbial growth which in turn is used to process pathogens as we just described. The ATU may, depending on its design, also remove nutrients, solids which were not retained in the trash tank, and pathogens.

Suspended Growth vs. Attached Growth Septic Systems: Oxygen-supported (aerobic) bacteria in the mixed liquor perform the primary treatment in the system. As the bacteria themselves die off they remain suspended in the mixed liquor - a "suspended growth aerobic treatment system".

Alternatively, a media, such as synthetic fabrics, may be suspended in the treatment tank, permitting the bacteria to attach to the media surfaces - an "attached growth aerobic treatment system". The Suspended-Growth type of septic system is detailed above.

Saturated vs. Non-Saturated Wastewater Treatment Systems: An aerobic treatment unit (ATU), because it involves a tank filled with wastewater and forced oxygenation of that wastewater, is a type of saturated wastewater treatment system. Other non-saturated wastewater treatment systems such as trickling filter beds use passively-infused air to support their oxygen-supported microorganisms.

Unlike ATUs, non-saturated systems allow passive air contact with effluent as it moves through the media. Air is not being pumped. Both types of systems make use of aerobic microorganisms.

Four-Chamber Aerobic Systems - 4-chamber ATU Design

Four-chamber Aerobic Treatment Units are also designed for and used in some areas, though how we count chambers may be confusing - some designers may not design or count a separate aeration chamber. A four-chamber aerobic tank uses

- AEROBIC Septic Tank Sewage receiver: a compartment to receive sewage and collect sludge;

- Aerobic Treatment Unit Aeration Chamber: an aerobic chamber to pump air and thus oxygen through wastewater to assist in the aerobic treatment process;

- AEROBIC Septic Effluent Settling Chamber: a clarifying or settling chamber which permits remaining solids to settle out of the wastewater; disinfection may take place in this chamber;

- AEROBIC Septic Effluent Pumping Chamber: a pumping chamber to receive treated effluent for discharge to an absorption system or other destination.

...

Continue reading at AEROBIC SEPTIC EFFLUENT SPRAY HEAD REPAIR or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- AEROBIC SEPTIC SYSTEMS, ATUs - home page for Aerobic Septic Systems

Suggested citation for this web page

AEROBIC SEPTIC CONTINUOUS FLOW, Suspended Growth at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to SEPTIC SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about CFSGAS Continuous Flow, Suspended Growth Aerobic Septic Systems, design, installation, maintenance, and repair.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Ayres Associates. 1998. Florida Keys Onsite Wastewater Nutrient Reduction Systems Demonstration Project. Contract no. LP 988. Florida Department of Health Onsite Sewage Program, Tallahassee, FL.

- Brewer, W.S., J. Lucas, and G. Prascak. 1978. An evaluation of the performance of household aerobic sewage treatment units. Journal of Environmental Health 41(2):82-84.

- Converse, J.C., and M.M. Converse. 1998. Pump Chamber Effluent Quality Following Aerobic Units and Sand Filters Serving Residences. In Proceedings of the Eighth National Symposium on Individual and Small Community Sewage Systems. American Society of Agricultural Engineers, Orlando, FL.

- Englehardt, J.D., and R.C. Ward. 1986. Operation and maintenance requirements for small flow treatment systems. Journal of the Water Pollution Control Federation 58(10).

- Hutzler, N.L., L. Waldorf, and J. Fancy. 1978. Performance of Aerobic Treatment Units. In Proceedings of the Second National Home Sewage Treatment Symposium. American Society of Agricultural Engineers, Chicago, IL.

- Kellam, J.G., et al. 1993. Evaluation of Performance of Five Aerated Package Treatment Systems. Bull. 178. Virginia Water Resources Research Center, Blacksburg, VA.

- Mason, D.G. 1977. A Unique Biological Treatment System for Small Plants. Paper presented at the 50th Water Pollution Control Federation Conference, Philadelphia, PA.

- Midwest Plan Service. 1982. On-site Domestic Sewage Disposal Handbook. Midwest Plan Service, University of Minnesota, St. Paul, MN.

- Otis, R.J., and W.C Boyle. 1976. Performance of single household treatment units. Journal of Environmental Engineering Division, ASCE, 102, EE1, 175.

- Otis R.J., et al. 1975. The Performance of Household Wastewater Treatment Units under Field Conditions. In Proceedings of the Third National Home Sewage Disposal Symposium. American Society of Agricultural Engineers, Chicago, IL.

- Rogella, F., J. Sibony, G. Boisseau, and M. Benhomme. 1988. Fixed Biomass to Upgrade Activated Sludge. Paper presented at 61st Annual Water Pollution Control Federation Conference, Philadelphia, PA.

- Rusten, B., M.J. Tetreault, and J.F. Kreissl. 1987. Assessment of Phased Isolation Ditch Technologies for Nitrogen Control. In Proceedings of the Seventh European Sewage and Refuse Symposium, pp. 279-291, Munich, Germany.

- Tchobanoglous, G., and F. Burton. 1991. Wastewater Engineering. 3rd ed. McGraw-Hill, Inc., New York.

- U.S. Environmental Protection Agency (USEPA). 1978. Management of Small Waste Flows. Small Scale Waste Management Project. EPA/600/2-78-173. National Technical Information Service PB 286 474.

- U.S. Environmental Protection Agency (USEPA). 1980. Design Manual: Onsite Wastewater Treatment and Disposal Systems. EPA 625/1-80-012. U.S. Environmental Protection Agency, Office of Water Programs, Washington, DC.

- Pennsylvania State Wastewater Treatment Fact Sheet SW-161, Septic System Failure: Diagnosis and Treatment

- Pennsylvania State Wastewater Treatment Fact Sheet SW-162, The Soil Media and the Percolation Test

- Pennsylvania State Wastewater Treatment Fact Sheet SW-l64, Mound Systems for Wastewater Treatment

- Pennsylvania State Wastewater Treatment Fact Sheet SW-165, Septic Tank-Soil Absorption Systems

- Document Sources used for this web page include but are not limited to: Agricultural Fact Sheet #SW-161 "Septic Tank Pumping," by Paul D. Robillard and Kelli S. Martin. Penn State College of Agriculture - Cooperative Extension, edited and annotated by Dan Friedman (Thanks: to Bob Mackey for proofreading the original source material.)

- "International Private Sewage Disposal Code," 1995, BOCA-708-799-2300, ICBO-310-699-0541, SBCCI 205-591-1853, available from those code associations.

- "Manual of Policy, Procedures, and Guidelines for Onsite Sewage Systems," Ontario Reg. 374/81, Part VII of the Environmental Protection Act (Canada), ISBN 0-7743-7303-2, Ministry of the Environment,135 St. Clair Ave. West, Toronto Ontario M4V 1P5 Canada $24. CDN.

- Onsite Wastewater Treatment Systems, Bennette D. Burks, Mary Margaret Minnis, Hogarth House 1994 - one of the best septic system books around, suffering a bit from small fonts and a weak index. While it contains some material more technical than needed by homeowners, Burks/Minnis book on onsite wastewater treatment systems a very useful reference for both property owners and septic system designers.

- Septic Tank/Soil-Absorption Systems: How to Operate & Maintain, Equipment Tips, U.S. Department of Agriculture, 8271 1302, 7100 Engineering, 2300 Recreation, September 1982, web search 08/28/2010, original source: http://www.fs.fed.us/t-d/pubs/pdfimage/82711302.pdf

- US EPA ONSITE WASTEWATER TREATMENT SYSTEMS MANUAL Top Reference: US EPA's Design Manual for Onsite Wastewater Treatment and Disposal, 1980, available from the US EPA, the US GPO Superintendent of Documents (Pueblo CO), and from the National Small Flows Clearinghouse. Original source http://www.epa.gov/ORD/NRMRL/Pubs/625R00008/625R00008.htm

- Water Wells and Septic Systems Handbook, R. Dodge Woodson. This book is in the upper price range, but is worth the cost for serious septic installers and designers.

Quoting Amazon: Each year, thousands upon thousands of Americans install water wells and septic systems on their properties. But with a maze of codes governing their use along with a host of design requirements that ensure their functionality where can someone turn for comprehensive, one-stop guidance? Enter the Water Wells and Septic Systems Handbook from McGraw-Hill.

Written in language any property owner can understand yet detailed enough for professionals and technical students this easy-to-use volume delivers the latest techniques and code requirements for designing, building, rehabilitating, and maintaining private water wells and septic systems. Bolstered by a wealth of informative charts, tables, and illustrations, this book delivers:

* Current construction, maintenance, and repair methods

* New International Private Sewage Disposal Code

* Up-to-date standards from the American Water Works Association

- The NSFC Products List has an excellent list of design manuals/modules National Small Flows Clearinghouse (NSFC) now (2019/12/13) hosted at http://www.nesc.wvu.edu/ Tel: 304-293-4191 e-mail info@mail.nesc.wvu.edu.

The National Small Flows Clearinghouse (NSFC) was funded by the U.S. Environmental Protection Agency (EPA) to help America's small communities and individuals solve their wastewater problems through objective information about onsite wastewater collection and treatment systems. NSFC products and information are the only national resource of its type, dealing with small community wastewater infrastructure. or by telephone 800-624-8301 - In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.