PVC / CPVC Cement Hold, Set & Cure Times

PVC / CPVC Cement Hold, Set & Cure Times

Glue set & cure times needed to avoid poor or leaky plastic pipe joints & connections

- POST a QUESTION or COMMENT about cement hold, set, and cure times for plastic piping

This article gives tables of hold, set & cure times that should be followed when cementing PVC (polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride) piping systems.

Included are definitions of plastic pipe gluing:

- Hold time (how long to hold the joint when gluing)

- Set time (how long before you can move the piping around)

- Cure time (how long before the piping can be exposed to pressure)

The article explains that movement or exposure to pressure in the piping system before the glued pipe joints & fittings have adequately set or cured risks damaged connections, leaks, pipe failures.

This article series describes the properties of polybutylene PVC & CPVC plastic piping and tubing used in buildings. We include information about failures and problems with some generations of CPVC or PVC plastic pipes and we describe good building practice installation details where plastic piping is being installed.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

PVC & CPVC Pipe Gluing Specifications, Joint Set & Cure Times

How long for a PVC pipe glue joint to dry before turning on the water

How long for a PVC pipe glue joint to dry before turning on the water

An accurate answer depends on knowing the diameter of the pipe you are gluing and other details as well as knowing the care taken in preparing and assembling the joints.

If we assume you are gluing a home water supply pipe that is no larger in diameter than 1 1/4" and at 20F, you need to wait a half hour before turning on your water supply.

That specification is good for typical conditions for pressures up to 160 psi.

Adding heat will indeed assist in curing of the glued joint. The risk of turning water on too soon is likely a failed glue joint.

Let's see what the glue manufacturers say about glue curing time.

Article Contents

- FACTORS AFFECTING CPVC & PVC PIPE SET & CURE TIMES

- GLUED PVC PIPE JOINT HOLD TIME

- GLUED PVC PIPE JOINT SET TIME with TABLE

- GLUED PVC PIPE JOINT CURE TIME with TABLE

- HIGH TEMP GLUING MANUFACTURER SUGGESTIONS

- COLD TEMP GLUING MANUFACTURER SUGGESTIONS

- SLOW SET TIMES FOR LONGER WORKING TIME

- HOW MUCH EXPOSED PIPE END IS NEEDED TO GLUE

- CAN YOU USE PVC GLUE ON CPVC PIPE AND FITTINGS?

- WARNING ABOUT GLUING DAMAGED PLASTIC PIPE & FITTINGS

- WHERE TO BUY CPVC & PVC PIPE SOLVENT-TYPE PRIMERS & CEMENTS

Portions of this text were adapted from information provided by Oatey®, Georg Fischer Piping Systems, and other manufacturers cited in this article and further at References or Citations.

...Factors Affecting CPVC & PVC Pipe Joint Set & Cure Times

Watch out: high and low temperatures, humidity, joint fit, pipe condition (new vs. old being repaired), and pipe size in diameter all have important effects on glued PVC pipe joints.

Cold temperatures mean that more time is needed for set and cure times.

And high temperatures can increase the softening effects of the solvents used in primers and glues used in PVC piping, potentially softening or damaging the piping if too much solvent is used.

Watch out: in damp or humid weather you need to increase the set and cure times by 50%!

Watch out: for an accurate figure on PVC glue drying time for your specific case, be sure to check the label of your particular CPVC or PVC pipe cement product.

Definition of Glued PVC Pipe Joint Hold Time:

The "hold time" is the period during which you should physically hold the newly glued pipe joint components in position immediately after assembling them. This is typically 30 seconds but in cold weather you will need to extend that time to perhaps a minute.

Definition of Glued PVC Pipe Joint Set Time

The "set time" for a glued PVC piping joint is the time that you should wait before handling the newly assembled and glued joints.

This is how long you should wait before moving the parts around. If you move the glued parts before the set time period the risk is that the glued joint will either fail or it will "set" into a position other than the one you intended.

The "set time" that you should wait before moving the assembled plastic piping that has just been glued is in addition to the "hold time".

PVC / CPVC pipe joint set times range from 2 minutes (1/2" - 1 1/4" pipe at 60-100°F) to 48 hours (16" - 24" pipe at 0-40°F).

At temperatures above 60°F, a generally "safe" set time for typical residential smaller sized plastic pipe (under 3") installations is 15 minutes before pressure testing to 180 psi, with increases needed for humid or cold conditions.

Watch out: Oatey warns "Do not test with air."

Typical PVC or CPVC Pipe Joint Cement Handling / Set Time Wait Periods |

||||

| Temperature At Time of Assembly | 60-100°F | 40-60°F | 20-40°F | 0-20°F |

Pipe Diameter |

||||

1/2" - 1 1/4" |

2 minutes | 5 minutes | 8 minutes | 10 minutes |

1 1/2" - 3" |

5 minutes | 10 minutes | 12 minutes | 15 minutes |

4" - 5" |

15 minutes | 30 minutes | 1 hour | 2 hours |

6" - 8" |

30 minutes | 1 1/2 hours | 3 hours | 6 hours |

10" - 16" |

2 hours | 8 hours | 12 hours | 24 hours |

18" & above |

4 hours | 16 hours | 24 hours | 48 hours |

Notes to the table above:

Watch out: in damp or humid weather you need to increase the set and cure times by 50%!

Watch out: for an accurate figure on PVC glue drying time for your specific case, be sure to check the label of your particular CPVC or PVC pipe cement product.

Adapted from

- Oatey Solvent Cements for PVC/CPVC piping, Oatey®, 4700 W. 160th St. I Cleveland, OH 44135 800.321.9532 I Fax: 800.321.9535 www.oatey.com

- Georg Fischer, "Design & Installation, Set & Cure Time [for solvent-cemented PVC piping glued joints]", Georg Fischer Piping Systems, Georg Fischer Harvel LLC, 300 Kuebler Road, Easton, PA 18040, USA, Tel: 610-252-7355, Website: www.GFPiping.com

- Also see additional citations at References or Citations

Table design © 2015 InspectApedia.com

Definition of Glued PVC pipe joint Cure Time

The "cure time" for a glued PVC piping joint is the time period that you should wait before pressure-testing the piping (for example in drain or supply piping) and before turning on water (in water supply piping) or in other words before pressurizing the piping system.

The risk is that if you pressurize the glued piping system before the completion of the glued joint curing, the system will fail, burst, leak, or come apart.

PVC / CPVC pipe joint cure times range from 15 minutes (1/2" - 1 1/4" pipe at 60-100°F) to 14 days (16" - 24" pipe at 0-40°F).

Typical PVC or CPVC Pipe Joint Cement Cure Time Periods |

||||

| Temperature At Time of Assembly | 60-100°F | 40-60°F | 20-40°F | 0-20°F |

Pipe Diameter |

Times are all in hours except as noted |

|||

1/2" - 1 1/4" |

1 | 2 | 6 | 8 |

1 1/2" - 3" |

2 | 4 | 12 | 16 |

4" - 5" |

6 | 12 | 36 | 2 days |

6" - 8" |

8 | 16 | 3 days | 4 days |

10" - 16" |

24 | 2 days | 8 days | 10 days |

18" & above |

36 | 3 days | 12 days | 14 days |

Notes to the table above:

Watch out: this data is for pressure testing up to 180 psi. Manufacturers warn "do not test with air". If pressure testing is to be conducted at pressures above 180 psi, the cure times before pressure testing is allowed will be considerably longer. Check the specifications of your specific PVC CPVC cement product.

Watch out: in damp or humid weather you need to increase the set and cure times by 50%!

Watch out: for an accurate figure on PVC glue drying time for your specific case, be sure to check the label of your particular CPVC or PVC pipe cement product.

Adapted from

- Oatey Solvent Cements for PVC/CPVC piping, Oatey®, 4700 W. 160th St. I Cleveland, OH 44135 800.321.9532 I Fax: 800.321.9535 www.oatey.com

- Georg Fischer, "Design & Installation, Set & Cure Time [for solvent-cemented PVC piping glued joints]", Georg Fischer Piping Systems, Georg Fischer Harvel LLC, 300 Kuebler Road, Easton, PA 18040, USA, Tel: 610-252-7355, Website: www.GFPiping.com

- See additional citations at References or Citations

Table design © 2015 InspectApedia.com

The cure time for PVC pipe cement joints will vary a bit by pipe size

The cure time for PVC pipe cement joints will vary a bit by pipe size, with larger sizes needing more time to set and cure. Temperature, pipe joint size, and cement formula are all factors.

That is, the PVC cement cure time also depends on which cement was used as there are some slow-set cements deliberately formulated to give more working time to assemble the joint and for use on large pipe connections.

You will see those in the table above on this page and in more detail in the Oatey and other PDF documents we provide.

Typically, as you'll see above, those are in minutes, not hours for smaller diameter PVC pipes such as on a residential building, but can be as long as 14 days for large diameter pipe joints in freezing weather.

Once the joint is cured as per the manufacturer's instructions you can turn on water or put the drain into use.

Watch out: don't turn on water to plastic piping that has been freshly glued before the glue cure time has completed. The concern is that if you pressurize the piping before the joints are fully cured, the piping could separate and leak.

For high temperature PVC gluing applications, manufacturers suggest

- Keep the solvent cement in a cool shaded area prior to use

- Keep the top on the solvent / cement

when you are not actively using it; leaving the container open when you don't have to will cause it to thicken, become stringy and difficult or impossible to use, and risks a bad glue joint. - Store the PVC piping and connectors in a cool, shaded area,

and if possible perform the gluing operations in the cooler time of the day (early morning in most cases) - Cool hot piping before gluing by wiping it with a damp rag, but be sure the surfaces are dry before applying the PVC cement

- Check cement wetness before assembling:

when assembling joints to be glued, be sure that the solvent cement coated surfaces of both sides of the joint are still wet with solvent cement before assembling them. Georg Fischer points out that puddling of solvent or cement in the pipe joint can cause excessive softening. - Wipe off excessive solvent or glue

from the joint exterior

For cold temperature PVC gluing applications manufacturers suggest

- Work indoors?

Prefabricate (glue-up) as much of the piping system as you can while working inside a heated work area using components that have been stored in that area. - If you have to work outside,

store glue (and pipe components if possible) in a warm area before performing the actual gluing. - Remove snow, ice, water:

Be very careful that the glue joint surfaces are dry and free of snow or ice. I [DF] have noticed that a thin coating of ice on a section of PVC piping left outdoors can be easy to miss, though it may show up as a clue (ice shavings or hard to push parts together) when you try to assemble the joint. - Extra applications of PVC cement:

If necessary use more than one application of primer and solvent glue to be sure that the joint surfaces are adequately softened before assembly - Increase the set and curing time

as specified by the manufacturer of the solvent / cement you are using when the temperature is below 60°F.

PVC Pipe Cement Slow Set Times for Longer Working Time

In general, when choosing a PVC cement for an application where you need a longer initial set time, choose a "heavy bodied" PVC cement. You'll see that characteristic as I list the types of PVC cement from several manufacturers below.

Hercules makes a heavy duty long-working-time PVC cement, shown above, No. 60210, 8 oz. Heavy Body, Slow Set PVC Cement (Gray), described as PVC Cement, Gray Label, Low VOC - Gray, Heavy Body, Slow Set For PVC Types I & II, potable water, DWV, and SW pipe and fittings up to 15" diameter. Schedules 40 and 80. Meets ASTM D2564.

See details of the properties of all of Hercules' PVC primers and cements in

- HERCULES PVC PRIMERS & CEMENTS PRODUCT BROCHURE [PDF] Hercules Chemical Company, Inc.111 South Street, Passaic, NJ 07055-9100 USA, Tel: 800-221-9330 , Fax: 800-333-3456 E-mail: info@herchem.comwww.herchem.com or service@hercnet.co

Keep in mind that you can do all the prep, cleaning, de-burring, and application of a cleaner/primer without hitting a time snag.

Low temperatures and moisture will slow both the set time and the curing time of the PVC cement.

The Slow Set versions (Hercules makes both the gray and a clear slow set PVC cement) will give you about twice that, or 1 to 2 minutes of set time.

You might call for a more clear answer: contact Hercules customer service at the phone or email we give above.

- Gorilla PVC Clear PrimaGlue®, shown here, is also reported also to have a long set time, and can be cleaned up with water. I'm looking for details as I haven't seen a quote of set time in minutes vs. temperature etc. for this product.

Weld-on's Extra Heavy Body 719™ PVC Cement is described by the company as having a slow set time.

That product is described below.

That product is described below.

Weld-On has a chart of Weld-On(R) solvent cement average set and cure times that gives an idea of the effect of temperature on set time.

- Weld-On Adhesives, Inc., 455 W. Victoria Street,

Compton, CA 90220 U.S.A.

Main telephone: (310) 898-3300

Customer Service: Telephone (800) 421-2677 and Fax (310) 742-0164

Technical Support: (877) 477-8327 and (310) 898-3304

Weld-On 700 PVC (clear) cement, Weld-On 704 PVC, Weld-On 705 PVC, Weld-On 721 (blue) PVC Cement: Set time = Fast

Weld-On Heavy Bodied 711 PVC Cement, Gray, & Weld-on Heavy Bodied 717 PVC Cement, Clear or Gray, set time = MediumWeld-On Extra Heavy Bodied PVC Cement 719 Gray or White, set time = Slow.

Extra heavy bodied, slow setting, low VOC PVC cement for all classes and schedules with interference fit, including Schedule 80 through 30″ (800 mm) diameter.

Premium, high-strength formulation for large size industrial piping systems.

Ideal for fabrication of large fittings and applications requiring high gap filling properties. Also suitable for irrigation, conduit, other pressure and non-pressure applications.

See Weld On's table of PVC cement set and cure times given below.

- PVC SOLVENT CEMENT TIME & TEMPERATURE SET TIME TABLE [PDF] Weld-On Adhesives, Inc., 455 W. Victoria Street,

Compton, CA 90220 U.S.A.

Main telephone: (310) 898-3300

Customer Service: Telephone (800) 421-2677 and Fax (310) 742-0164

Technical Support: (877) 477-8327 and (310) 898-3304

retrieved 2020/05/02 original source: weldon.com/wp-content/uploads/2015/03/WeldOn_SetCure_TimeTable.pdf - Weld-On Solvent Cements Set and Cure Times, retrieved 18 March 2015, original source: http://www.weldon.com/pdf/weldon/WeldOn_SetCure_Timetable_Jul09.pdf

Set times for smaller diameter pipes (1/2 to 1 1/4") change from 2 minutes at 60 to 100 F, to 5 minutes at 40-60F to 10 minutes at 0 - 40 F.

So if you can do your gluing on a cool morning, you'll have more set time to adjust your fittings.

And as larger pipes all have longer set times (a 15" or larger PVC pipe needs 4 hours to 48 hours depending on temperature), we can infer that the more generously the glue is applied the longer should be the set time.

Also see Oatey' Heavy Duty Clear PVC Cement as again, a heavier-body PVC cement will have a longer set-up time.

- Oatey, OATEY® SOLVENT CEMENTS SET UP / CURING TIMES Oatey®, 4700 W. 160th St. I Cleveland, OH 44135 800.321.9532 I Fax: 800.321.9535 www.oatey.com, retrieved 18 March 2015, anew 2 May 2020, original source https://images.homedepot-static.com/catalog/pdfImages/d2/d25ece3c-3e81-4223-9270-c18977273030.pdf

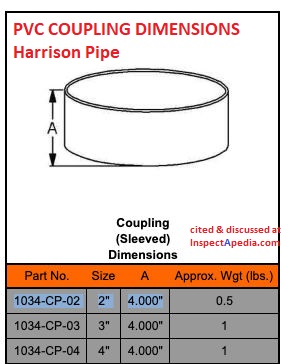

How much exposed pipe end is needed to glue a plastic pipe coupling?

If you measure your coupling depth you will typically see its 1/2 to 3/4 of an inch.

Adding an image from harrisonplastic.com (above), you can see that a typical 2, 3, or 4 inch PVC coupling is 4 inches in Dimension "A".

Can you use PVC glue on CPVC pipe and fittings?

CPVC (Chlorinated PolyVinyl Chloride) pipe cement such as the Oatey product shown here is an example confirming that at least some "PVC" glue is labeled for use on BOTH PVC and CPVC.

Bottom line:

for best results use both a primer and a glue and check the product label.

Warning about Gluing Damaged Plastic Pipe & Fittings

The following is an excerpt from a JM Eagle HDPE Water and Sewer Pipe Installation Guide:

5.1 Damage Assessment for Polyethylene Pipe

Damaged pipe or fittings should be inspected and evaluated.

Pipe, fittings, fabrications or structures with excessive damage should not be installed. Damage that occurs after installation may require that the damaged pipe or component be removed and replaced.

WARNING: scrapes or gouges in pressure pipe cannot be repaired by filling

in with extrusion or hot air welding.

The damaged section

should be removed and replaced.

WARNING: Improperly made fusion joints cannot be repaired.

Improper butt fusions must be cut out and re-done from the beginning.

Poorly joined socket or electrofusion fittings must be removed and replaced.

Poorly joined saddle fittings must be removed by cutting out the main pipe

section, or, if the main is undamaged, made unusable by cutting the branch

outlet or chimney off the saddle fitting, and installing a new saddle fitting on

a new section of main.

WARNING: Broken or damaged fittings cannot be repaired and, as such,

should be removed and replaced.

WARNING: Kinked pipe must not be installed and cannot be repaired. It

must be removed and replaced.

WARNING: Pipe damaged during an emergency squeeze-off cannot

be repaired. Squeeze-off damaged pipe must be removed

and replaced.

- source: HDPE_WATER_AND_SEWER_Installation_Guide_03-2011 [PDF] JM Eagle 5200 West Century Boulevard Los Angeles, CA 90045

800-621-4404

Where to Buy CPVC & PVC Pipe Solvent-type Primers & Cements

These and other PVC and CPVC pipe cement products are widely distributed by plumbing suppliers and building suppliers such as Home Depot & Loews.

These and other PVC and CPVC pipe cement products are widely distributed by plumbing suppliers and building suppliers such as Home Depot & Loews.

Illustrated: Oatey's Heavy Duty Clear PVC Cement discussed below as a product offering a longer initial set time.

[Click to enlarge any image]

- Oatey Solvent Cements for PVC/CPVC piping, Oatey®, 4700 W. 160th St. I Cleveland, OH 44135 800.321.9532 I Fax: 800.321.9535 www.oatey.com

- PVC Pipe Weld, Bostik Smart Adhesives,Bostik Ltd Ulverscroft Road Leicester LE4 6BW 01785 272727 U.K., Website: http://www.bostik.co.uk/, Technical Enquiries/Customer Service +44 (0)1785 272625

- Vinidex Pty Limited, A.B.N. 42-000-664-942, Email: sales@vinidex.com.au, offices in Queensland, Victoria, Western Australia, New South Wales, Tel: (02) 8839-9006 Quoting:

Vinidex has been Australia's leading manufacturer of PVC and polyethylene piping systems for over 50 years. - Weld-On® Adhesives, Inc., 455 W. Victoria Street

Compton, CA 90220 U.S.A.

Main telephone: (310) 898-3300

Customer Service: Telephone (800) 888-8312 and Fax (901) 853-5008

Technical Support: (877) 477-8327 and (310) 898-3304

EDI Support: edi@ipscorp.com

US & Canadian Sales Inquiry: tncustserv@ipscorp.com

International Sales Inquiry: international@ipscorp.com

General Inquiry: info@ipscorp.com

- IPS Weld-on P70 primer and IPS Weld-On #717 / #719 (for use with Schedule 40 / Schedule 80 PVC piping)

- IPS Weld-on P70 primer and IPS Weld-On #714 (for use with Schedule 40 / Schedule 80 CPVC piping)

- Wurth White PVC Glue 200G, U.K., Tel: 03 300 555 444 Website: http://www.wurth.co.uk/ offices in North America, South America, the U.K., Europe, Asia, Australia, New Zealand

- Gorilla PVC Clear PrimaGlue®, shown here, is also reported also to have a long set time, and can be cleaned-up with water. I'm looking for details as I haven't seen a quote of set time in minutes vs. temperature etc. for this product.

- HERCULES PVC PRIMERS & CEMENTS PRODUCT BROCHURE [PDF] Hercules Chemical Company, Inc.111 South Street, Passaic, NJ 07055-9100 USA, Tel: 800-221-9330 , Fax: 800-333-3456 E-mail: info@herchem.comwww.herchem.com or service@hercnet.co

- Oatey, OATEY® SOLVENT CEMENTS SET UP / CURING TIMES Oatey®, 4700 W. 160th St. I Cleveland, OH 44135 800.321.9532 I Fax: 800.321.9535 www.oatey.com, retrieved 18 March 2015, anew 2 May 2020, original source https://images.homedepot-static.com/catalog/pdfImages/d2/d25ece3c-3e81-4223-9270-c18977273030.pdf

- PVC SOLVENT CEMENT TIME & TEMPERATURE SET TIME TABLE [PDF] Weld-On Adhesives, Inc., 455 W. Victoria Street,

Compton, CA 90220 U.S.A.

Main telephone: (310) 898-3300

Customer Service: Telephone (800) 421-2677 and Fax (310) 742-0164

Technical Support: (877) 477-8327 and (310) 898-3304

retrieved 2020/05/02 original source: weldon.com/wp-content/uploads/2015/03/WeldOn_SetCure_TimeTable.pdf

- Weld-On Adhesives, Inc., 455 W. Victoria Street,

Compton, CA 90220 U.S.A.

Main telephone: (310) 898-3300

Customer Service: Telephone (800) 421-2677 and Fax (310) 742-0164

Technical Support: (877) 477-8327 and (310) 898-3304

Weld-On 700 PVC (clear) cement, Weld-On 704 PVC, Weld-On 705 PVC, Weld-On 721 (blue) PVC Cement: Set time = Fast

Weld-On Heavy Bodied 711 PVC Cement, Gray, & Weld-on Heavy Bodied 717 PVC Cement, Clear or Gray, set time = MediumWeld-On Extra Heavy Bodied PVC Cement 719 Gray or White, set time = Slow.

Extra heavy bodied, slow setting, low VOC PVC cement for all classes and schedules with interference fit, including Schedule 80 through 30″ (800 mm) diameter.

Premium, high-strength formulation for large size industrial piping systems.

Ideal for fabrication of large fittings and applications requiring high gap filling properties. Also suitable for irrigation, conduit, other pressure and non-pressure applications. - Weld-On Solvent Cements Set and Cure Times, retrieved 18 March 2015

Additional citations and solvent cement set & cure times:

See also our RECOMMENDED ARTICLES list at the bottom of this page.

...

...

Continue reading at PVC & CPVC PIPE INSTALLATION STEPS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- PLASTIC PIPING ABS CPVC PB PEX PPR PVC - home

- CPVC & PVC PLASTIC PIPING

- PVC & CPVC PIPE INSTALLATION STEPS

- PVC & CPVC PIPE GLUING SET & CURE TIMES

Suggested citation for this web page

PVC & CPVC PIPE GLUING SET & CURE TIMES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Georg Fischer, "Design & Installation, Set & Cure Time [for solvent-cemented PVC piping glued joints]", Georg Fischer Piping Systems, Georg Fischer Harvel LLC, 300 Kuebler Road, Easton, PA 18040, USA, Tel: 610-252-7355, Website: www.GFPiping.com - retrieved 18 March 2015, original source: http://www.envirokinguv.com/design-installation/set-cure-times

The company has offices in the U.S. in Connecticut, Hawaii, Illinois, Indiana, Iowa, Kentucky, Maine, Massachusetts, Michigan, Minnesota, Missouri, Nebraska, New Hampshire, North Dakota, Ohio, Rhode Island, South Dakota, Vermont, Wisconsin, Wyoming,

and

in Canada in Ontario, Quebec, Alberta, Manitoba, Saskatchewan, New Brunswick, British Columbia. Canada Tel: +1-905-670-8005, Email: Kuno Lischer, President, kuno.lischer@georgfischer.com - Vinidex, "Technical Note VX-TN-10D, Do's and Don't of Solvent Cementing Pressure Pipes", retrieved 18 March 2015, original source: http://www.vinidex.com.au/technote-parent-page/dos-and-donts-of-solvent-cementing-pressure-pipes/

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- [7] PB Technology Center (information about PB Pipes) Tel: 800-338-7732, also see the 1990 PB Pipe recommendations published by the Polybutylene Product Line Committee of the Plastic Pipe and Fittings Association.

- Polybutylene Plumbing Failures: Spencer Class settlement, Web: spencerclass.com, 10% of replacement cost/damages, only for acetal (plastic)fittings

- [8] Polybutylene plumbing info at U. Arizona

- [9] Polybutylene piping lawsuit settlement website

- [10] Polybutylene plumbing lawsuit proposed settlement-old site

- [12] Zurn Manufacturing, Web: zurn.com , Zurn Pex, Inc., Highway 11 East, Commerce, TX 75428, Tel: (903) 886-2580

provides information about installing and using PEX piping including Type b PEX through their website. Quoting from the company's website

Zurn was founded in 1900 in Erie, PA. It originally manufactured a patented backwater valve, and it now manufactures and distributes one of the largest plumbing products packages in the world! Zurn includes: the Specification Drainage Operation, AquaFlush flush valves, AquaSense sensor-operated plumbing products, AquaSpec commercial faucets, Wilkins, Zurn Light Commercial, Flo-Thru, the Chemical Drainage Systems, Zurn PEX Plumbing Systems and Zurn Radiant Heat. - [13] Zurn PEX PLUMBING DESIGN AND APPLICATION GUIDE [PDF] - web search 2023/04/06 & 12/23/2010, original source zurn.com/operations/pexrh/pdfs/installation/PEXDesApplGuide.pdf

- [14] Zurn Pex Plumbing

Products Liability Litigation, United States Court of Appeals

FOR THE EIGHTH CIRCUIT, No. 10-2267, Filed 6 July 2011, Quoting:

Minnesota homeowners brought this action1 against Zurn Pex, Inc. and Zurn Industries, Inc (Zurn) alleging that brass fittings used in the company's cross linked polyethylene (PEX) plumbing systems are inherently defective.

In pretrial motions the homeowners sought class certification for their consumer protection, warranty, and negligence claims, and Zurn moved to strike the testimony of two of the homeowners’ experts.

After denying Zurn's motion to strike the expert testimony, the district court2 granted the homeowner requests for class certification for their warranty and negligence claims, but denied it for their consumer protection claims

. Zurn appeals from the district court's certification order. We affirm.

Web search 4/12/12, original source: www.ca8.uscourts.gov/opndir/11/07/102267P.pdf - [15] Uponor, Inc., F1807 Plumbing Court File No. - United States District Court, District of Minnesota, In Re: Uponor, Inc., F1807 Plumbing Court File No. 11-MD-2247 ADM/JJK

Fittings Products Liability Litigation

Order Granting Motion to Certify Class for Settlement Purposes and for Preliminary Approval of Class Action Settlement and Form and Dissemination of Notice to the Class" Quoting:

The Motion for Preliminary Approval of Class Action Settlement was heard on January 12, 2012.

After review of pleadings and briefing, and having heard the arguments of counsel for good cause shown, it is hereby ORDERED that:

(1) the Motion for Preliminary Approval of Nationwide Class Action Settlement Agreement;

(2) preliminary and conditional certification of a settlement class;

(3) approval of the form and content of Notice and Settlement; (4) an injunction and stay of all claims and actions against the RTI Defendants

Web search 4/12/12, original source: http://www.mnd.uscourts.gov/MDL-Uponor/ - [16] Bonnie Ransom Stern & Gustavo Lagos, "Are There Health Risks from the Migration of Chemical Substances from Plastic Pipes into Drinking Water? A Review", Human and Ecological Risk Assessment: An International Journal

Volume 14, Issue 4, 2008, Abstract:

Plastic pipes used to convey hot and cold drinking water are synthetic polymers containing numerous additives that enhance durability, impact strength, and toughness, and resist material degradation. Although some research studies have been conducted to evaluate the type and levels of chemical substances migrating from polymeric materials into drinking water, the potential adverse health effects associated with these compounds in potable water have not been described.

This review evaluates the literature on the occurrence of regulated and unregulated substances in drinking water related to the use of plastic pipes, characterizes potential health hazards, and describes uncertainties associated with human health and exposure in need of further research.

Of particular public health concern is the potential for sensitive populations to be exposed to short-term elevations in leachates during critical periods, and for co-occurring leachates targeting the same organ(s) and/or sharing a common mode of toxic action to have additive or synergistic effects.

Contaminants are measured in the distribution system, not at the tap where human exposure actually occurs. For increased health protection, it is important to identify compounds that migrate from plastic pipes into drinking water and to better quantify human exposures and health hazards to these substances and their degradates. - [17] Andrew J. Whelton, Andrea M. Dietrich, Daniel L. Gallagher, "Chapter 6 Impact of Chlorinated Water Exposure on Chemical Diffusivity and Solubility,

Surface and Bulk Properties of HDPE and PEX Potable Water Pipe", in Advancing Potable Water Infrastructure through an Improved Understanding of Polymer

Pipe Oxidation, Polymer–Contaminant Interactions, and Consumer Perception of Taste, Andrew James Whelton

Dissertation submitted to the Faculty of the Virginia Polytechnic Institute and State University In partial fulfillment of the requirements for the degree of DOCTOR OF PHILOSOPHY In Civil Engineering Andrea M. Dietrich, Chair Daniel L. Gallagher Marc A. Edwards Brian J. Love James M. Tanko, April 2, 2009 Blacksburg, Virginia. Abstract:

While more than 100 years of research has focused on removing acute and chronic health threats from water, substantially less study has focused on potable water infrastructure and water quality deterioration, monitoring technologies, and relationships between water taste and consumer health.

These knowledge–gaps have left infrastructure users, owners, regulators, and public health professionals largely unaware of how premise and buried polymer water pipes deteriorate and sorb/ desorb organic contaminants during normal operations and following water contamination events.

These knowledge–gaps also prevent infrastructure managers from producing drinking water that optimizes mineral content for both water taste and health benefits, and employing a monitoring tool capable of immediately detecting water contamination or equipment failures.

Research was conducted to address these challenges using analytical chemistry, environmental engineering, food science, polymer chemistry, public health, and material science principles. This work was enhanced by collaborations with sixteen American water utilities and the National Institute for Standards and Technology. These efforts were funded by the National Science Foundation, American Water Works Association, and the Water Research Foundation.

Research results are unique and provide important scientific contributions to the public health, potable water, and material science industries. Particular achievements include the:

(1) Evaluation of linkages between minerals, water palatability, and health useful for water production and public health decisions;

(2) Creation of a novel infrastructure and water quality surveillance tool that has begun water utility implementation in the USA;

(3) Development of an accelerated chlorinated water aging method with stable water pH, free chlorine, and alkalinity concentration that enables interpretation of polymer pipe surface and bulk characteristic changes;

(4) Discovery that polar compounds are 2–193% more soluble in PEX than HDPE water pipes;

(5) Finding that several polymer and contaminant properties can be used to predict contaminant diffusivity and solubility during sorption and desorption in new, lab aged, and water utility PE pipes; and the

(6) Discovery that chlorinated water exposure of HDPE and PEX pipes increases polar contaminant diffusivity during sorption by 50–162% and decreases diffusivity during desorption as much as 211%. Outcomes of this work have domestic and global significance, and if engaged, can greatly improve public health protection, potable water infrastructure operations, water quality, sustainability, and regulation. - [18] Chemax, "Cross-Linked Polyethylene Tubing and Water Contamination", retrieved 2/17/2013, original source: http://www.chemaxx.com/polytube1.htm [copy on file as [Water Contamination chemical investigation.pdf]

- [19] Ingun Skjevrak, Anne Due, Karl Olav Gjerstad, Hallgeir Herikstad "Volatile organic components migrating from plastic pipes (HDPE, PEX and PVC) into drinking water", Water Research Volume 37, Issue 8, April 2003, Pages 1912–1920

Abstract: High-density polyethylene pipes (HDPE), crossbonded polyethylene pipes (PEX) and polyvinyl chloride (PVC) pipes for drinking water were tested with respect to migration of

volatile organic components (VOC) to water.

The odour of water in contact with plastic pipes was assessed according to the quantitative threshold odour number (TON) concept. A major migrating component from HDPE pipes was 2,4-di-tert-butyl-phenol (2,4-DTBP) which is a known degradation product from antioxidants such as Irgafos 168®.

In addition, a range of esters, aldehydes, ketones, aromatic hydrocarbons and terpenoids were identified as migration products from HDPE pipes. Water in contact with HDPE pipes was assessed with respect to TON, and values ⩾4 were determined for five out of seven brands of HDPE pipes.

The total amount of VOC released to water during three successive test periods were fairly constant for the HDPE pipes.

Corresponding migration tests carried out for PEX pipes showed that VOC migrated in significant amounts into the test water, and TON ⩾5 of the test water were observed in all tests. Several of the migrated VOC were not identified. Oxygenates predominated the identified VOC in the test water from PEX pipes. Migration tests of PVC pipes revealed few volatile migrants in the test samples and no significant odour of the test water. - [20] Andrew J. Whelton, Ph.D., M.ASCE; Andrea M. Dietrich, Ph.D., Aff.ASCE; and Daniel L. Gallagher, Ph.D., P.E., M.ASCE, ”Contaminant Diffusion, Solubility, and Material Property Differences between HDPE and PEX Potable Water Pipes.” J. Environ. Eng., 136(2), 227–237.

doi: 10.1061/(ASCE)EE.1943-7870.0000147

Abstract: the objectives of this work were to identify differences between the composition, bulk properties, contaminant diffusivity and solubility for new high-density polyethylene (HDPE) pipe and crosslinked polyethylene (PEX) pipe, as well as determine which contaminant and polymer properties are useful for predicting contaminant fate in water pipe.

Variations in PE pipe density (0.9371–0.9547 g/cm3) , crystallinity (69–72%), crosslinking (60 and 76%), and oxidative induction time (33 to >295 min .) were detected. While numerically these differences seem minor, results show that slight material differences have a notable effect on contaminant diffusivity and solubility.

Nonpolar contaminant diffusivity and solubility were best predicted by bulk density. Polar contaminants were more soluble and diffused faster through PEX than HDPE pipes because PEX pipes contained a greater amount of oxygen.

For all materials, dipole moment and Log Kow were good predictors of contaminant fate and molecular volume was only useful for predicting diffusivity and solubility values for haloalkane and nonpolar aromatic contaminants. - [21] Jia Tang, Daniel L. Gallagher, and Andrea M. Dietrich. (2013) Predicting Permeation of Organic Contaminants into Polyethylenes. Journal of Environmental Engineering 139:2, 205-212

Online publication date: 1-Feb-2013.

Abstract:

A model was developed and validated for predicting solubility and diffusion coefficients for contaminants permeating polyethylene (PE) materials used for water pipes and geomembranes. Model development was based on diffusivity and solubility of 13 contaminants and six PE materials that were new and/or aged in chlorinated water.

Physical and chemical properties of the contaminants and PEs were included as variables in the model. Tree regression was used to select variables, and multiple linear regression was used to develop predictive equations for contaminant diffusivity and solubility in PE.

Organic contaminant properties, especially dipole moment and octanol-water partition coefficient, had greater predictive capability than PE properties. Coefficients of determination (R2)>0.8 were obtained for the multiple linear regressions.

Model coefficients changed slightly between new PE materials and chlorine-aged PE, but these changes were not statistically significant. Good agreement was demonstrated between model predictions and measured data from an independent data set. These results provide guidance for material selection for both water pipes and geomembranes and assessing contamination potential. - [22] Andrew J. Whelton, Andrea M. Dietrich, and Daniel L. Gallagher. (2011) Impact of Chlorinated Water Exposure on Contaminant Transport and Surface and Bulk Properties of High-Density Polyethylene and Cross-Linked Polyethylene Potable Water Pipes. Journal of Environmental Engineering 137:7, 559-568

Online publication date: 1-Jul-2011.

Abstract:

The aim of this work was to determine if the aging of polyethylene (HDPE, PEX-A and PEX-B) water pipes by exposure to chlorinated water altered polar and nonpolar contaminant diffusivity and solubility by analyzing new, laboratory-aged, and exhumed water-distribution system polyethylene (PE) pipes.

After 141 days of aging in pH 6.5 water with 45 mg/L free chlorine, the surface chemistry and bulk properties of PEX-A pipe were unaffected. Carbonyl bonds (σ=1,713 cm−1) were detected on the surfaces of HDPE and PEX-B pipe, and these oxygenated surfaces became more hydrophilic, resulting in statistically significant increases in diffusion rates.

All 10 contaminant and four pipe material combinations had diffusivity increases on average of 50% for polar contaminants and 5% for nonpolar contaminants. Contaminant solubility was slightly increased for aged PEX-A and slightly decreased for PEX-B pipes.

Toluene and trichloromethane diffusivity and solubility values for 7- to 25-year-old buried water utility pipes were similar to values for new and laboratory-aged HDPE-based materials. Because chlorinated water exposure alters how polar contaminants interact with aged PE pipes, results of this work should be considered in future health risk assessments, water quality modeling, pipe performance, and service-life considerations. - [23] ANDREW J. WHELTON & TINH NGUYEN, "Contaminant Migration from Polymeric Pipes used in Buried Potable Water Distribution Systems: A Review", Critical Reviews in Environmental Science and Technology, February 2012 posted online,

Abstract: Polymeric pipes are increasingly being installed in water distribution systems because of their many advantages.

Contaminant migration from polymer pipes into drinking water is a growing concern in the United States and environmental engineers are evaluating the role of these materials on water quality, system operation, and regulatory compliance.

To aid these efforts and serve as a source of background information, this paper critically reviews available literature on polymeric potable water pipes in use, known contaminants released from in–service and new piping, their perceived sources, and outlines future challenges in the U.S. and abroad. - [24] Andrew James Whelton, "Advancing Potable Water Infrastructure through an Improved Understanding of Polymer Pipe Oxidation, Polymer–Contaminant Interactions, and Consumer Perception of Taste", Dissertation submitted to the Faculty of the Virginia Polytechnic Institute and State University In partial fulfillment of the requirements for the degree of DOCTOR OF PHILOSOPHY In Civil Engineering, April 2, 2009 Blacksburg, Virginia, retrieved 2/17/2013, original source http://scholar.lib.vt.edu/theses/ available/etd-04162009-113815/unrestricted/ FINALWheltonDissertationMay09.pdf#page=158

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.