Install, Inspect & Test LP Gas Tank or Gas Cylinder Regulators

Install, Inspect & Test LP Gas Tank or Gas Cylinder Regulators

Gas regulator pressure & flow test procedure

- POST a QUESTION or COMMENT about LP gas tank or cylinder regulators & controls

This article explains LP Gas Pressure Regulators used on LP Gas or Propane tanks.

How to Inspect & Test LP Gas Valves Regulators, or Gas Controls and we provide descriptions and photographs of unsafe LP gas piping, LP gas regulators, or LP gas valves & controls on appliances or heating equipment.

We describe indications of unsafe or improperly operating gas appliances, gas meters, and other gas installation defects.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

LP or Natural Gas Tank / Cylinder Regulator or Control Inspection, Testing, & Defect Guide

Article Contents

Article Contents

- GAS REGULATORS for LP TANKS or CYLINDERS

- GAS REGULATOR SAFETY WARNINGS

- GAS REGULATOR TYPES

- GAS REGULATOR LOCATION & POSITION

- GAS CYLINDER / TANK SHUTOFF VALVE

- GAS TANK REGULATOR PROTECTION & POSITION

- GAS TANK REGULATOR DEFECTS

- GAS REGULATOR TEST PROCEDURES

- GAS REGULATORS & APPLIANCE / HEATER CONTROLS - separate article for natural gas systems

Watch Out: Immediate LP or natural gas safety hazards: If you smell gas you should leave the building immediately and should do so without doing anything that could create a spark such as operating a light switch or telephone.

From a safe location, call your gas company's emergency line and/or your fire department. The text provided here is a working draft and may be incomplete or inaccurate.

If there is evidence of an LP or natural gas leak at a building, gas odors, for example, you should:

- Do not do anything that is likely to cause a gas explosion,

such as lighting a match, operating an electrical switch, or even using a telephone in the building - Leave the building immediately

- Notify other building occupants

of the safety concern - Contact the local gas company

and/or fire department

Types of Gas Regulators Used at Gas Tanks, Cylinders, Appliances

[Click to enlarge any image]

Above: a first (and only) stage LP gas regulator installed on a gas tank (gas cylinder) in New York. In a better installation the vent on this regulator would have been aimed downwards.

Because of varying requirements, LP gas regulator types found at a typical residential or light commercial property may vary using:

- Separate first-stage and second stage LP gas pressure regulators

- Combined first and second stage LP gas regulators in the same device -

see GAS REGULATORS, TWO STAGE - Gas Appliance Regulators: Readers concerned with installing, inspecting, or testing LP or Natural Gas regulators which are found on appliances such as LP or Natural Gas fired boilers, furnaces, water heaters or appliances should also

see GAS REGULATORS & APPLIANCE / HEATER CONTROLS

Most gas-burning household appliances such as cooktops, ranges, and clothes dryers use an appliance gas regulator that can be converted for use with either natural gas or propane (LP GAS).

Watch out: be sure that your appliance, its regulator, and all other conversion or control adjustments specified by the manufacturer have been properly matched to the gas fuel type being used. Otherwise the appliance is unsafe and risks fire, burn, explosion, or other hazards.

See our safety warnings

at GAS APPLIANCE CONVERT LP-to-NATURAL GAS.

Also see THE TRUTH ABOUT GAS LEAKAGE COMPLAINTS and GAS VALVES [PDF] - original source: Honeywell Corporation (1994), www.graycoolingman.com/uploads/1/0/6/6/10667336/honeywell_gas_valve_leakage.pdf

Other regulators less likely to be found at a residential property include:

- High pressure LP gas pressure regulators

- Adjustable high pressure LP gas regulators

- Automatic changeover gas regulators

Watch out: improper installation and even improper inspection and testing methods involving natural or "LP" gas can involve dangerous conditions and risk fire or explosion.

Location & Position of the LP Gas Cylinder or Tank Regulator

An LP gas cylinder regulator should be mounted so that any moisture or condensate inside the regulator can drain out. Any drain openings should be facing downwards.

Otherwise water or in freezing climates ice can accumulate and damage the regulator, forming an unsafe condition.

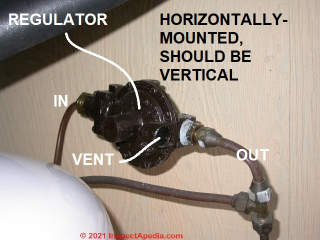

The photograph of an LP gas cylinder regulator above shows the regulator's vent opening.

In photo at above the red LP gas regulator can be seen installed in a tipped position in upper center of the photo.

The installer felt that the regulator would drain in this position, and that when the plastic cover was installed on the control well (this is a buried LP gas tank) the regulator would be protected from the weather.

Location of the Gas Cylinder On-Off Valve on an LP Gas Tank / Cylinder

The photograph at above left below shows at right the silver-colored LP gas tank on-off valve. An arrow on the valve will indicate the direction to turn the valve to close it or open it.

Normally you close the LP tank gas valve by turning it "clockwise" or as my daughter Mara says, "rightie-tightie, leftie-loosie" to help remember this important information.

The yellow cover on top of the valve is the connector for filling the LP gas tank.

The small-diameter copper tube leaving at the left side of the valve is the "high pressure" LP gas line carrying LP gas in vapor form from the top of the gas cylinder over to the LP gas regulator whose body you can just see in the upper left hand corner of this photo.)

Watch out: in addition to a gas supply shut off valve at the LP or propane gas cylinder or tank (or at the building gas main where piped-in natural gas is supplied), additional gas supply shutoff valves are required in the gas piping system at each gas-fired heating device or appliance.

How & Why to Protect an LP Gas Tank / Cylinder Regulator from Rain, Snow, Ice

An LP gas tank or cylinder regulator should be protected from the weather.

Water, particularly in freezing climates, can enter and block the safety vent on the gas regulator or ice can form preventing the regulator from properly controlling gas pressure. An iced or water-damaged gas regulator is unsafe.

Our photos above and below show how an existing LP gas tank regulator was protected from rain and weather by a simple rubber cover affixed to the building.

The protective cover was secured to the building wall and draped over the regulator. Despite formation of ice and icicles at the roof eaves and even atop the propane tank, the LP gas cylinder regulator was dry and functioning safely.

This option (adding a protective cover for the gas cylinder regulator) was elected when a new LP gas tank (shown in this photo) was installed and connected to an existing regulator difficult to relocate. Below: Bottini fuel delivering LP gas to this home in winter.

Watch out: It is important that any cover protecting an LP gas regulator does not block fresh air flow around the regulator. Otherwise leaking LP gas can accumulate and form an explosion or fire hazard.

LP Gas Regulator Installation Requirements

- Gas regulator ground clearance:

LP gas regulators should be installed at least eighteen inches above the surface of the ground. In areas of deep snow the regulator should really be above the snow level (or protected from weather) - Protect gas regulator from weather:

The LP gas regulator(s) should not be located where they are exposed to large amounts of water (or ice) such as below a roof eave with no gutter, or close to a downspout opening. - Gas regulator hoods:

The LP Gas regulator installed outdoors should [in best practice] have a protective hood to avoid damage from rain or (in freezing climates) ice.

If an LP gas regulator is being installed horizontally, that is without pointing it's vent opening down, it must be protected by a cover, and even under the cover the vent should slope down to avoid risk of accumulating condensate and frost blockage, an condition which would be unsafe as frost or ice can prevent safe operation of the gas pressure regulator. - Point gas regulator vents down:

Where a regulator is installed outside without such protection, it is very important that the regulator is placed with its vent pointed straight down so that rain and ice do not enter and possibly block the vent - a dangerous condition - Distance between LP gas regulator and building openings:

LP gas regulators should be installed at least five feet from any building window or vent or air intake (ten feet if a buried LP tank is in use).

LP Gas Regulator Inspection Procedure

The LP Gas regulator(s) should be inspected each time that the building receives an LP gas delivery.

- Turn off the LP gas service valve

at the tank and check for gas odors anywhere. If gas odors are present we suspect the main shutoff valve is defective and it may need replacement. - Check that the LP gas regulator is properly installed,

sloped so that its vent will drain, and that it is protected from the weather.

In the photo below the LPG regulator was positioned horizontally - leaving a risk of water entry into its vent opening. The installer, rather than re-pipe the regulator, provided a rubber cover over the whole gas piping installation - shown in winter, above.

- Check the LP gas regulator for evidence that water has leaked

into it by looking into the regulator's cover-cap (a removable cap).

A service technician may also shut down the gas system and remove the regulator's adjusting screw to check the regulator interior for corrosion. It is particularly important to look for evidence of corrosion in the pressure relief valve area inside the regulator, since if this component is corroded the relief valve may not function safely. - Gas service experts recommend replacing an LP gas regulator if

it is more than fifteen years old.

- Check that the LP gas regulator vent has not become blocked.

We sometimes find that insects will nest in openings on these devices, blocking the vent screen with mud or insect nest materials. Make sure the regulator vent has not become blocked with anything whatsoever. - Check that the gas regulator vent does not exhaust close to a potential point of ignition.

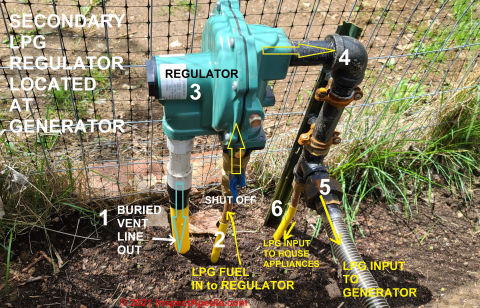

Below we illustrate a backup generator installation at which the installer made sure that the vent for the secondary regulator (installed at the generator) was piped back to a location (at the LP tank) well away from the generator itself - a potential source of ignition.

Separate LP Gas Regulator Vent Away from Sources of Ignition

Shown below, an LP gas powered emergency electrical generator installed in a New York home demonstrates gas regulator vent relocation.

[Click to enlarge any image]

A secondary LPG regulator is located close to the generator itself, to assure adequate pressure and flow of fuel to the the generator - photo above. This regulator feeds into the backup electrical generator and also down into the ground in a smaller copper line that brings LP gas to the home's gas appliances.

Shown in the photo above are

- The buried regulator vent line that carries any gas vented by the regulator away from the backup generator (up to the remote LP tank shown below)

- The underground LPG line bringing LP gas in to the regulator

- The gas regulator itself

- The gas regulator output line supplying the generator and home appliances

- Output of the regulator providing LPG input to the backup electrical generator

- Output of the regulator providing LPG input to the home appliances (buried line routed to the home)

Our photographs below show that the outlet vent for this LPG regulator was piped underground back to the LP fuel storage tank to be sure that any gases vented by the regulator would be released a safe distance away from a potential point of ignition: the electrical generator itself, and its controls.

Our photo below shows the separation of the LP tank and its primary regulator from the LP powered backup generator.

The photo just shows the vent opening for the secondary LP gas regulator that is installed next to the generator itself.

Typical LP Gas Pressures Found in Residential Systems

Example LP Gas or Propane Pressures:

- 10-200 psi in the LP gas storage tank

- 10" water column at the LP appliance gas regulator inlet - based on Maxitrol RV47CL US 1/2 psig Nat 6.0" LP 10.0"

- 0.4 psi at typical residential appliances

Details about the different pressures found or set for LP gas, propane, and natural gas including before and after different gas pressure regulators are

at GAS PRESSURES LP vs NATURAL GAS

What goes wrong with gas regulators on LP Gas Tanks?

Watch out: Immediate LP or natural gas safety hazards: if there is evidence of an LP or natural gas leak at a building, gas odors, for example, you should:

Watch out: Immediate LP or natural gas safety hazards: if there is evidence of an LP or natural gas leak at a building, gas odors, for example, you should:

- Do not do anything that is likely to cause a gas explosion, such as lighting a match, operating an electrical switch, or even using a telephone in the building

- Leave the building immediately

- Notify other building occupants of the safety concern

- Contact the local gas company and/or fire department

Gas pressure too high:

Adjustment of a gas regulator might also be necessary if the gas piping from source (meter or tank) to the appliance is long or is too small in diameter.

If the gas regulator delivers gas at too high a pressure the gas flame may be also too big (and too hot), which can accelerate

rusting and can warp the heat exchanger at its lower joints causing a "crack" to appear.

A cracked heat exchanger on a gas appliance is unsafe.

Our correspondent, Charles commented that:

After loosing three heat exchangers in two different homes that had routine maintenance inspections, I decided to look into it and check the gas regulator pressure myself. The same problem can occur with gas water heaters.

Gas pressure too low: if the gas regulator is not properly adjusted or if there are other problems in the gas piping or supply system the gas pressure may be too low, providing an inadequate and possibly unsafe flame.

Depending on the cause of the problem, it may be possible to correct this at the regulator, but don't try boosting pressure at a gas regulator unless the pressure has always been too low. Otherwise when the underlying cause for low gas pressure is corrected elsewhere, the flame will be too big and pressure too high at the burner - an unsafe condition.

Disassembly of gas meters, regulators, valves & controls for inspection, testing, calibration

Watch out: SAFETY WARNING: If you lack the training and equipment, do not attempt to disassemble or mess with a gas regulator as you could create a very dangerous or even fatal problem.

What are the Typical LP Gas, Propane Gas, or Natural Gas Pressures Found in Residential Systems

Details about the different pressures found or set for LP gas, propane, and natural gas including before and after different gas pressure regulators are

at GAS PRESSURES LP vs NATURAL GAS

LP Gas or Propane Pressures:

- 10-200 psi in the LP gas storage tank

- 0.4 psi at typical residential appliances

Natural Gas pressures:

- Natural gas in the natural gas service line in the street will be found at pressures from 60 psi down to as low as 0.25 psi.

- At individual natural gas appliances the gas pressure will be regulated to about 0.25 psi [1]

Gas Regulator Pressure & Flow Test Procedures

Question: How do I check the gas coming out of my regulator for LP ? I

Question: How do I check the gas coming out of my regulator for LP ? I

2018/01/18 Anonymous said:

How do I check the gas coming out of my regulator for LP ? It is for a commercial deep fryer on a Mobil truck.

Illustration: a typical gas pressure gauge reading in inches of water or Inch H2O as sold on eBay. Other gas pressure gauges and manometers are available in both digital and analog format.

[Click to enlarge any image]

Reply: How to test or check the gas pressure provided by an LP gas regulator:

Watch out: do not try testing nor adjusting your gas regulator output pressure unless you are equipped and trained to do so. A mistake can lead to a fire, explosion, injury, or death.

A plumber who is familiar with gas piping might use a pressure gauge and would, of course, check system piping safety including for leaks.

The plumber attaches a pressure gauge or a manometer to the regulator output side where she can see what pressure the regulator is delivering. Most 2-psi output gas regulators include a test port intended specifically for this purpose.

Other installations include a test-tapping upstream from the shutoff valve for your gas-burning appliance, in this case your deep fryer.

Or the plumber will install such a fitting to permit gas pressure testing.

LP Gas Regulator Pressure & Flow Test 5-step Procedure

- Install a water column manometer

or a suitable low-pressure gauge or measuring device in the second-stage regulator outlet test tap or in a test tap in the appliance gas shutoff valve at the gas appliance that is most-distant from the gas regulator being tested. - Re-light all of the gas appliance pilots

and turn the appliances on, confirming that the gas burners are all operating at their highest setting. - Read flowing gas pressure:

With all of the gas-using appliance pilots lit and appliance gas burners operating (in your case maybe that's just one appliance), the flowing gas pressure (or "in-use" pressure rather than static pressure) is read at the pressure gauge or manometer. - Compare to desired pressure:

On a manometer, with at least half of the gas appliances working you have to see a total of 11 inches of water (pressure) on the readout scale. You may need to adjust the supply regulator to achieve that pressure. If so,

see GAS REGULATOR ADJUSTMENT PROCEDURE. - Check delivery gas pressure:

Check the required LP or propane gas delivery pressure specified on the data tag that you will find attached to your deep fryer.

If the supply regulator cannot maintain the required flowing gas pressure, the problem may be any of the following:

- The regulator output capacity is inadequate -

a larger output capacity regulator is needed - The upstream main gas regulator

may be the wrong size or capacity - The gas supply piping may be under-sized

(too small diameter) for the piping distance, number of elbows and fittings, or for the flow requirements of the appliances being served or for the regulator being tested

LP Gas Regulator Lock-Up Test Procedure

An important additional gas pressure regulator safety check is for the "lock-up" gas pressure in your system.

To read Lock-up (or static) gas pressure,

- Turn off all of the gas-fueled appliances

- Turn off the gas supply at all of the individual gas appliances

individual shutoff valves. Illustration: a gas valve with a test port, from Industrial Valve Co. - Leave the LP gas tank gas valve open

or "on" to keep providing gas pressure to the gas delivery system. - Check the gas pressure:

You should see the gas pressure increase slightly (above the 11 inches of water column read before) and then the pressure rise should stop. This is the lock-up gas pressure.

The lock-up gas pressure can be no more than 30% higher than the flow pressure.

Example: with a flow pressure of 11" WC, the lock-up pressure can be no higher than (11 + .3 x 11) = 14.3" W.C.

Converting inches of water column to psi for pressure gauge users and where 1" WC = 0.03609 psi we have:

11" WC = 0.397 psi

14.3" WC = 0.516 psi

Watch out: Document the regulator measurements made in both of these tests, including the date, location, test operator, test pressure results, and results of leak tests performed.

Watch out: if after a brief initial pressure rise the gas pressure continues to increase with all appliances off, the LP regulator is defective and must be replaced.

On a typical gas regulator an adjustment screw is turned clockwise, increasing pressure on the regulator's diaphragm, to thus increase the pressure of the gas being delivered.

Gas Regulator Test Procedures

Illustration: a gas pressure manometer reading in inches of water column or In. W.C.

Illustration: a gas pressure manometer reading in inches of water column or In. W.C.

This device is provided by Dwyer Instruments, cited below. Gauge type instruments (shown earlier on this page) reading in inches of W.C. or psi can also be used provided that the gauge is within the proper low-pressure range.

- ACCESSORY KIT INSTALLATION MANUAL GAS VALVE & PRESSURE TEST KIT (S1-1PK0601 & S1-1PK0602) FOR USE WITH MODELS: ALL SINGLE STAGE 40” & 45” FURNACES [PDF], Johnson Controls, retrieved 2018/01/18, original source: http://www.upgnet.com/PdfFileRedirect/035-18780-001-B-0610.pdf

- Alabama Propane Gas, CONDUCTING GAS REGULATOR PERFORMANCE TESTS [PDF] (2012), Retrieved 2018/01/18, original source: http://www.alabamapropane.com/uploadedFiles/State/Alabama/Dealer-Supplier/Safety_Topics/october2012.pdf

This procedure describes LP gas regulator flow test procedures and adjustments - Bosch, GAS PRESSURE REGULATOR PRESSURE TEST PROCEDURE [PDF], Models 520HN, 520PN, 330PN, Bosch Climate U.S., Tel: 800-283-3787 Website: https://www.bosch-climate.us/ Retrieved 2018/01/18, original source: https://www.bosch-climate.us/files/201008292118090.THERM_CheckingGasPressure.pdf

- Bosch, MEASURING GAS PRESSURE [at a tankless water heater] [PDF] Service Bulletin G3-)3 Models: 715ES, C800ES, C920ESC, 2400ES, 2700ES, Retrieved 2018/01/18, original source: https://www.bosch-climate.us/files/201109161543270.G3-03_Measuring_gas_pressure.pdf

- Dwyer Instruments, 1213 Series gas pressure gauge, retrieved 2018/01/18, original source: http://www.dwyer-inst.com/Product/Pressure/Manometers/Stationary/Series1213

Website Excerpt:

Obtain a visual indication of the pressure with the 1213 series gas pressure gauge. Designed for use with natural gas, the pressure gauge can also be used to monitor any compatible gas up to 15 inches of water column. Tap water is used as the sensor medium, and a magnetic clamp allows temporary or permanent assembly. - Farthing, David, CHECKING FUEL TRAIN SAFETY SHUTOFF VALVES [PDF] , retrieved 2018/01/18, original source: http://www.federalcorp.com/tech/fueltrain_shutoff.pdf

This document includes a model ASME ANSI 21.21 Safety Valve Leak Test Record useful for documenting gas system leak testing. - Maxon, FUNCTIONAL TESTING of MAXON SHUT-OFF VALVES & Recommended Leak Testing [PDF] retrieved 2018/01/18, original source: http://www.lesman.com/unleashd/catalog/valves/Maxon-shut-off-valves/Maxon-Shut-off-Valve-leak-testing.pdf

- Maxitrol® LINE PRESSURE REGULATOR GUIDEBOOK [PDF] 7th Ed., retrieved 2022/03/19, original source:https://www.gastite.com/downloads/pdfs/LPROPD_GB_EN.pdf for 2 and 5 psi systems.

Excerpt:

This Handbook contains information from national heating and plumbing ordinances or codes that may have been adopted or incorporated by local authorities. The Handbook should only be used as a guideline and should not be considered as a supplement or replacement of the existing ordinance or code for a particular area or industry. The color yellow on tags depicted herein is a trademark of the Maxitrol Company and all rights are reserved.

Maxitrol Company recommends that all installation contractors refer to their local requirements and applicable ordinances or codes, such as those found in the International Mechanical Code, International Plumbing Code, National Electrical Code, American Gas Association Standards, and National Board of Fire Underwriters.

The Maxitrol Line Pressure Regulator Guidebook [PDF] 6th edition (2018) is also available at https://inspectapedia.com/plumbing/Line-Pressure-Regulator-Guidebook-Maxitrol-6thEd.pdf

Gas Cylinder Regulator Codes, Standards, Research

See

- GAS METER CODES

- GAS PIPING CODES

- GAS REGULATOR CODES

- International Fuel Gas Code (2003), Chapter 4 GAS PIPING INSTALLATION CODE [PDF], retrieved 2017/11/12, original source: https://www2.iccsafe.org/states/seattle/seattle_fuelgas/PDFs_fuelgas/Chaper%204.pdf

- NFPA 54, ANSI Z223.1 NATIONAL FUEL GAS CODE [PDF] contents & sections (2012), American Gas Association and NFPA, 1 Batterymarch Park, Quincy, MA 02169-7471

See Chapter 8, Gas Pressure Testing and Inspection, and Gas Piping System Leak Check procedures. - NFPA 54, ANSI Z223.1 NATIONAL FUEL GAS CODE [PDF] (2006) Complete Text, retrieved 2018/01/18, original source: http://bcpad.net/Code%20Books/NFPA%202006.pdf

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-12-10 by InspectApedia (Editor) - is a 24 volt thermostat required in the line between the transformer and the valve

@CaptTPT,

Thanks for the interesting discussion.

Most residential HVAC except for electric baseboard heat runs using a 24VAC thermostat and control boards.

I'm out speculating from left field here but I would think that if a control wants to see 24VAC power - and you fed it 120V or more I'd expect it to be damaged, and probably to burn-up.

When a flame burns normally for a while then the burner shuts down I expect there is one of the common safety concerns:

- flue gas spillage

- supply plenum temperatures too high (dirty blower fan or dirty filter or duct blockage or some other reason that air flow is reduced)

- a damaged fan limit control or improper control settings

On 2022-12-10 by CaptTPT

@InspectApedia (Editor), Yes I do. The supply sizing info I used appears to be based on black pipe. At an inlet pressure of 11” wc, 1/2” pipe will provide about 250K BTU LP at around 15 ft length. One half inch black pipe is approximately 0.622” ID.

I made the mistake of assuming 1/2” HomeFlex was the same, without measuring it. Unfortunately, the HomeFlex is only about 0.41” ID, so it will obviously provide less propane over that length. Lesson learned! They say it’s 1/2” but it’s not.

Thanks for the suggestion on the Thermocouple. I don’t think that is the issue but I am open to more info. The pilot will light normally and remain lit indefinitely if I do not call for heat.

If I call for heat, the burner will fire normally. If I turn the temp down in 30-60 seconds the burner will shut off and the pilot will remain lit. All good there. It’s only when I keep the thermostat on (call for heat) that the problem occurs. In a few minutes the valve closes and the pilot and burner both shut down.

So, does that info not suggest the thermocouple is working properly? I’m now focusing on wiring. I initially wired in an electronic 120volt thermostat supplying the hi limit switch switch and then the transformer.

Don’t recall where I heard this but someone told me I must have a 24 volt thermostat in the line between the transformer and the valve. Does the valve require this? Is it not possible to use a 120 volt thermostat? If the valve has 24 volts shouldn’t it remain open?

On 2022-12-10 by InspectApedia (Editor) - check the the temperature monitoring equipment

@CaptTPT,

Have you checked the the temperature monitoring equipment such as a thermocouple and its connection of a gas valve and have you checked for flu gas spillage and a flue gas sensor switch that would shut the system off ?

On 2022-12-09 by CaptTPT

@InspectApedia (Editor), unfortunately the unit is still is not working properly, despite my last post. I have plumbed a new 3/4” black pipe line to the heater, which is about 14 ft in length. The static gas pressure input to the valve is 14” wc.

When the unit fires and is running, the pressure now drops to 12.5” wc. Both pressures are within the specs called for by Resideo for this valve. The transformer is providing 26 volts to the valve. The burner again runs for a few minutes and then shuts down both the burner and pilot.

When the unit shuts down, 26 volts remain at the valve from the transformer, and the input gas pressure remains 12.5”wc. Remember from a previous post, I have replaced the valve once. I’m stumped at this point.

On 2022-11-29 by InspectApedia (Editor)

@CaptTPT,

Good going on that work and thank you for the update as that will help other readers. Do you think that the size of the line and run length are factors at all in this problem?

On 2022-11-29 by CaptTPT

@InspectApedia (Editor), I have bypassed the line in the wall with a 75 ft line consisting of 50 ft of 3/4” ID line and 25 ft of 5/8” ID line. Then refired the furnace. Now it runs properly and without the previous shutdown.

Since 14 ft of 1/2” line from the second stage regulator should provide about 250K BTU of gas there is obviously an obstruction in the line. I’m going to try to diagnose without pulling the wall apart first.

If I’m unsuccessful, I’m going to re-plumb with 3/4” black pipe outside the wall. Then reset pressures and should be good to go. Tom

On 2022-11-23 by InspectApedia (Editor) - suspicion of a blockage in the gas line

@CaptTPT,

Thank you for the question and the excellent detail. We've had this question before and the suspicion of a blockage in the gas line but honestly it's not something I have any confidence we can diagnosed by text.

Before you start tearing apart piping or doing more things to the gas line let's double check that the thermocouple and flame sensor are working properly on this system.

Simple mistakes such as the flame sensor not located exactly correctly or the other end of the thermocouples flexible copper tubing not properly secured in the gas valve can cause exactly the symptoms that you described.

So check that first and let me know what you find.

On 2022-11-22 by CaptTPT

@InspectApedia

Modine PA 105 A

Resideo valve w/standing pilot

Old/New Shop Heater. New Install

Modine PA105 A. All new parts. New Resideo valve w/standing pilot.

Input rating 105K BTU

Tank supply press 70 psi at 40 degrees F

Supply Lines:

Tank to 1st stage reg = 3/4” 4 ft

1st stage reg to 2nd stage reg = 3/4” 30 ft

2nd stage reg to wall = 3/4” 2 ft

Wall to valve = 1/2” (less than 15 ft - Home Flex SS 4 curve bends. No elbows.

Line and valve Pressures:

1st stage input = 70 psi

1st stage out 10 psi static and with burner on

2nd stage in = 10 psi static and with burner on

2nd stage out = 14” wc static and with burner on

Valve input = 14” wc static

= 8” wc with burner on

Valve output = 6.5” wc with burner on

Unit fires normally, runs for about 2 minutes, then valve closes, and unit shuts down, including pilot.

I pulled everything apart again to inspect. All lines clean. Valve screen is clean. Passed a 1/4” plastic cable through the 1/2” Home Flex in wall easily. Blew out line with 130 lbs air. No debris found. Reassembled everything. Same pressures. No change. Unit shuts down in 2 minutes.

Forgot to mention. System is new. It has never worked. The heater is the only appliance. There was a 1/2” shut off valve present but when I took the system apart last week I replaced with a 3/4” valve. I think all the info you mentioned is present here. Thanks. Tom

On 2022-11-15 by InspectApedia (Editor) - make sure that system piping and regs are designed for the flow required by equipment

@CaptTPT,

Apologies; I've looked at this discussion multiple times and have hesitated about posting a reply as it felt as if we just don't have a clear understanding of your whole system, making an "answer" too speculative and thus maybe even dangerous.

I would start this diagnosis with a collection of all of the basic data in one place:

- List all of the gas-using appliances and their input or flow or volume or lpm or similar requirements

- List of all of the gas piping components to include both diameter and lengths

- add the elbows, bends, valves or other restrictions in the system

- add the primary and secondary regulators and set-pressures

You want to make sure that your system piping and regs are designed for the flow required by your equipment - something I can't make out from our discussion so far.

A second stage regulator whose capacity is much higher than you need ought not be a problem as long as you're operating it within the supply range it's designed to deliver - both min and max.

Naturally I'd be stupid to rule out a gas pipe obstruction, as we've no idea of the age or condition of your system nor the possible sources of obstruction (rust debris, moisture, even insects or damage), but

The number one problem we've found with LP and natural gas supply capacity troubleshooting is under-sized piping.

On 2022-11-09 by CaptTPT

Yes. The supply line from the first stage regulator to the second stage regulator is 3/4” and about 40 ft. The line from the second stage regulator to the valve is 3/4” and about 30 ft. Another piece of data for today. Pressure gauge at first stage regulator shows 11 psi, and with the system running it remains 11 psi. Second stage regulator is outside but under cover with the vent facing down and a clean screen.

The second stage regulator is an Emerson-Fisher R622-DFF which is rated to a capacity of 1,400,000 BTU/hr. Is it possible the capacity is too hi? I recall reading if the capacity is too hi it can fluctuate pressure. Have not been able to confirm that.

Ok last piece of data on this. Pressure at the secondary regulator on the upstream side remains 11psi while running. Pressure at the downstream side is 14” wc static and 13” wc running.

I then put the manometer back at the valve and the input pressure is 14” wc static and drops to 8” wc when running. This suggests an obstruction to flow in the line from the regulator to the valve. Do you agree with this?

On 2022-11-07 by InspectApedia (Editor)

@CaptTPT,

Have you checked the total gas piping run length and diameter to be sure that it's large enough?

On 2022-11-06 by CaptTPT

New system startup. Old Modine 105K BTU heater w/LP conversion completely disassembled, cleaned, and reassembled with all new parts. New standing pilot Resideo valve and new pilot assembly, and Fisher R622 regulators. Three 100 lb tanks connected to 3/4” manifold and short 3/4” lines to regulators and valve. No other appliances.

Tank manifold pressure is 75 psi at 40 degrees F outside. Second stage set to 11”wc initially measured at regulator and valve input. Unit fires normally but input pressure drops to 6”wc. Valve shuts off burner and pilot in about 2 minutes. Second stage adjusted to 14” wc, per Resideo upper input pressure recommendation.

Unit fires normally but input pressure now drops to 8” wc and valve again shuts off system in 2 minutes. When unit shuts down there continues to be 24v at valve. Does this indicate a faulty first stage regulator? What other checks can be done to determine problem?

On 2022-08-30 by InspectApedia (Editor) - look at the INPUT PRESSURE permitted by the gas regulator

@Anonymous,

Not necessarily. You need to look at the INPUT PRESSURE permitted by the gas regulator that is mounted in or on the range itself to see what its input pressure rating is. If the range regulator's own input pressure is less than 11"WC then you'd need a secondary regulator ahead of the range.

On 2022-08-29 by Anonymous

I am connection a beach duel fuel range to a 40lb propane bottle. Can I use a 11" WC regulator in the first stage?

On 2021-05-03 by (mod) - What does the LP gas regulator do when gas pressures fall very low as an LP tank runs out of fuel?

@Scott Wilson,

Thanks Scott that's interesting question.

I have not come across specifications for an LP gas regulator that include an automagic shut-off feature in the presence of low gas pressure. (If you find such do let me know)

In a propane tank that still has a reserve of liquid propane the pressures in the tank will be between 100 psi and 200 psi under normal conditions.

(Hotter ambient temperatures produce higher pressures in the LP tank).

A typical residential propane appliance regulator drops the tank regulator's outlet pressure to 10.5" WC (about 0.38 psi or about 6 ounces of pressure) that is the pressure fed into the appliance itself. (High pressure regulators used, for example at some large gas appliances may require up to 60 psi).

If an installation uses the LP tank's fuel to the point at which there is no longer any liquid fuel supply in the LP tank, from that point, continued LPG use drops pressure in the tank rapidly. Once pressure in the whole system falls below the delivery pressure of the appliance regulator (e.g. below 6 oz) then your appliance burner will first be seen to burn with a very low flame that eventually peters out completely as the fuel is totally exhausted.

Watch out: the gas industry warns that allowing LP to run out can be dangerous: if an LP tank is exhausted, and IF the appliances it serves us a standing pilot (a lit gas flame that in turn is used to ignite burners), the pilots go out. When the tank is re-filled the result can be dangerous LP gas leaks in the building at any un-lit gas pilot orifices.

For this reason, some LP delivery companies won't deliver fuel if you've run out completely, unless a gas technician can be admitted to the building to be sure that any pilots have been re-lit. In the U.S., federal plumbing & gas code codes require that any out-of-gas calls will require a service call by a licensed plumber or gas appliance service technician who must test for gas leakage in the building - at the building owner's expense.

Watch out: LP suppliers and equipment and tank manufacturers also warn that it's a bad idea to allow an LP tank to run out completely because of the risk of condensation in the tank, causing corrosion that damages the tank or regulator or that can ultimately make them unsafe.

On 2021-05-02 by Scott Wilson

An LPG gas regulator is connected to a LPG tank. Regulated LPG therefore feeds to a stove/oven at a typical pressure of 11" WC. What happens as the LPG tank is almost empty? At some point the regulator will be unable to supply the propane at the rated 11" WC. I suspect at this point the regulator would fully close.

To avoid "chatter" it might make sense to do the cutoff at say 9" WC and not reopen again until it could deliver the full 11" WC. I am not a gas expert. So what really happens at the regulator at this point when the gas is almost exhausted? Thanks... your pages are filled with interesting info.

On 2021-04-07 - by (mod) -

@Rudolf Henriquez,

Quite so Rudolf;

I suspect the case is that the regulator used on an LP gas tank is not concerned with the tank size; instead it's designed to work in the proper pressure range for delivering LP gas out of that tank; In normal operation there is LP gas above the liquid in the tank, at a pressure that varies by ambient temperatures (around the tank) but not by tank size.

So instead the plumber chooses to use a 1 or two stage regulator system based not on LP tank size but on the building's distribution system: pipe diameters and lengths.

On 2021-04-06 by Rudolf Henriquez

There are only a few options regarding lpg gas tanks, but yet so many types of gas regulators.

It should not be difficult to install a home or residential regulator. But no provider of regulators does tell which is suitable for 20lbs tank, for 100 lbs tank. All you find is first stage, second stage, dual stage or a bunch of other terms that are useless for a handyman. Why not make it easy.

Installing a gas regulator is not rocket science. Nobody is born a specialist! We all learned it from someone.

Bottom line of concern. This regulator is for this application, go do your thing, test it for leakage with soapy water, voila!

On 2020-12-03 - by (mod) -

Bo

I'm so sorry that your question appears to be lost. It's possible that you included an email or an image - in which case you'd have seen a notice from the Comment Box software that allows us to accept your comments, stating that your comment will wait for moderator approval.

I searched our site too, for your name Bo McElya and found no comment posted nor waiting for approval, which says maybe there was some external problem as all of our readers' comments are saved by the Comments Box software.

On the other hand, I'm disappointed in seeing rage and profanity from a reader. Please consider that this website is a labor of love, worked-on full time for decades, providing researched, unbiased information to readers. But we have literally millions of readers and so thousands of questions; sometimes it is difficult or impossible to give everyone an instant researched authoritative detailed free answer. Sometimes we need a bit more time.

In any event I'm sorry you didn't get the help you needed, and I hope you can find a comfortable home elsewhere.

On 2020-12-02 by Bo McElya

I entered a question in one of your articles about LP gas regulators a few days ago and submitted it. I have came back seeking the answer and I cannot find any evidence of the question ever being posted. I would like to have been informed if my question violated any standards of yours or whether it was lost in the system or anything regarding it.

I searched for my name in your search box and found nothing. I evidently wasted a few hours of my time dealing with your site and am pissed off because I wanted your "expert" advice before continuing with the project I was working on but finally said the hell with it and continued. I will not be coming back to this site and would give it a negative zero rating if that's possible. Thank you for wasting my time.

On 2020-11-06 - by (mod) -

When troubleshooting, yes. But four basic operation you are relying on the proper functioning of the correctly selected and installed pressure regulators rather than monitoring pressure in the gas delivery system

On 2020-11-03 by Larry

Do gas valve pressures need to be checked when using natural gas

On 2020-03-29 - by (mod) -

Forgive that this answer may sound a little simplistic, but from what you have described, in considering the safety hazards involved, in my opinion you should replace the regulator.

Time and labor to disassemble and full with a regulator combined with the risk of making a mistake that leaves it unsafe Compares poorly with the Simplicity of Simply replacing it. The cost is about the same or less to replace.

On 2020-03-29 by Ryan

I have a dual propane regulator, the drop down red/green lever sometimes drops and sometimes takes forever to drop after I turn the propane tank on. Any ideas why and how i could fix it? Also it has started to visibly slowly leak propane out of regulator, any ideas how to fix?thanks

On 2020-02-18 - by (mod) - does a gas regulator problem cause "high" indoor carbon monoxide gas levels?

Bob

Thanks for asking an important life-safety question: does a gas regulator problem cause "high" indoor carbon monoxide gas levels?

(Normally there should be zero or close to zero CO indoors)

Help me understand the question. I am very afraid that we're barking up the wrong tree and risking a carbon monoxide poisoning fatality.

The gas regulator would not explain high CO readings in a home.

The typical causes of the presence of ANY carbon monoxide in a home include

- improperly-vented gas-fired appliances or heaters

- inadequate combustion air supply to gas-fired heaters or appliances

- improper burner adjustment or maintenance in gas fired heaters or appliances

See details at https://inspectapedia.com/hazmat/Carbon_Monoxide_Alarms.php CO ALARM CAUSES

On 2020-02-18 by bob

I have had gas company come out and test regulator 3 times and it has tested fine but I continue to get high carbon monoxide readings in house. Is it possible that the regulator could still be faulty even though it tests ok when gas company comes out?

On 2019-08-06 - by (mod) - What is the typical pressure in a 2 stage regulator system

Paul all of those pressures are detailed at

GAS PRESSURES LP vs NATURAL GAS

Please take a look and if any of that's unclear don't hesitate to ask.

On 2019-08-05 by Paul Boseley

Hi What is the typical pressure in a 2 stage regulator system between the high pressure regulator at the tank and the 2nd stage regulator at the appliance please

On 2019-05-13 by (mod) -

I would expect your plumber to be looking for a defective first stage or primary gas regulator, or perhaps pressure lines being rerouted too close to a heat source.

On 2019-05-12 by Mike

LP delivery company has set first and second stage regulators at the tank. Over several attempts to regulate the pressure for my furnace (spec'ed for 11 - 13.x inH20) I have had failed gas valves. The pressure starts out fine at 11/12 inH20 but over time goes up and up. 20, 25 inH20.

New furnace.

New tanks.

New regulators.

No other appliances using LP / on the line.

Pipe from tanks to furnace is on the same level. Run is < 100ft.

1/2 of the line that wasn't black iron (it was yellow covered thin conduit) has been replaced with black iron.

the entire line has been insulated.

what is going on?>

On 2019-01-29 - by (mod) -

Is this a change or has the problem always been there?

See GAS REGULATOR TEST PROCEDURES

On 2019-01-29 by Anonymous

Have 2 propane tanks outside. 200 gallon and 100 gallon connected together. Problem is low gas flow to furnace. Have checked both regulators at tanks and have 11" water column on both. Disconnected gas line at tanks and furnace and blew air from compressor through both at 100 psi.

No restrictions in gas line. When I reconnect gas lines and open valves at tanks. Gas is leaving regulators at 11-12 " water column but when I check at furnace pressure is too low to even start furnace. Around 2-3 " pressure.

On 2019-01-02 - by (mod) - leak coming from my lp regulator for a generator.

Mike in that case the regulator needs replacement -

Watch out: turn the gas OFF.

On 2019-01-02 by Mike

Smell and sound coming from screen on regulator.

I have a leak coming from my lp regulator for a generator. All connections are tight.

...

Continue reading at GAS REGULATORS, TWO STAGE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see GAS REGULATORS for LP TANKS FAQs - questions and answer about LP gas tank or cylinder regulators posted originally on this page

Or see these

Recommended Articles

- GAS APPLIANCE CONVERT LP-to-NATURAL GAS

- GAS APPLIANCE CONVERT REGULATOR NATURAL GAS-to-LP

- GAS APPLIANCE OPERATION at HIGH ALTITUDE

- GAS BTUH, CUBIC FEET & ENERGY - how to calculate or convert between cubic feet of gas, liquid gallons of LP gas, and BTUs per cubic foot or gallon of gas fuels.

- GAS LEAK DETECTION, LP / NG

- GAS LP & NATURAL GAS SAFETY HAZARDS

- GAS METERS - home

- GAS PIPING, VALVES, CONTROLS - home

- GAS PIPING CLEARANCES, CODES & DEFECTS

- GAS PRESSURE FLOW INADEQUATE

- GAS PRESSURES LP vs NATURAL GAS

- GAS REGULATORS & APPLIANCE / HEATER CONTROLS - home, Natural Gas regulators & appliance regulators, NG & LP

- GAS REGULATOR ADJUSTMENT PROCEDURE

- GAS REGULATORS for LP TANKS - home, LPG / Propane systems

- GAS REGULATOR TEST PROCEDURES

- GAS REGULATORS, TWO STAGE

- GAS TANKS LP / PROPANE

Suggested citation for this web page

GAS REGULATORS for LP TANKS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to GAS APPLIANCES, PIPING, CONTROLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about LP gas tank or cylinder regulators & controls .

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Comments

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- National Fuel Gas Code, ANSI Z223.1-yyyy - American Gas Association / National Fire Protection Association

- LP-Gas Serviceman's Handbook,Fisher-Rosemount, Fisher Controls

- National Fire Protection Association (NFPA) Pamphlets No. 54 and 58.

- Specifications for Gas Installations, Central Hudson Gas and Electric Corporation

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.