Find & Inspect LP & Natural Gas Appliance Shutoff Valves

Find & Inspect LP & Natural Gas Appliance Shutoff Valves

Manual & automatic gas shutoffs

- POST a QUESTION or COMMENT about LP or natural gas shutoff valves: installation, location, leaks, testing & use

LP, Propane or Natural Gas Shutoff Controls & Valves:

This article describes the common locations of and inspection of LP or Natural Gas shutoff valves at heating appliances, stoves, and clothes dryers. A gas shutoff is a manual valve that can be closed to stop the supply of natural gas or LP gas to a heating appliance or to a building.

We distinguish between a gas shutoff valve and a gas regulator, which may also be called a gas valve but which has the job of controlling gas flow into a heating appliance automatically in response to a call for heat.

Our page top photo shows a gas shutoff located at an outdoor gas meter - the valve is on the leftmost of the two vertical gas pipes at the top of (this improperly installed) gas meter.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How & Where Locate & Inspect Natural Gas or LP Gas Fuel Shutoff Valves

Main Building gas shutoff valve located at the gas meter

Main Building gas shutoff valve located at the gas meter

A main building gas shutoff valve are normally located at the main gas meter.

An additional shutoff valve may be located in the street or sidewalk outside of the building - a device that cannot be readily seen nor used by a building owner.

[Click to enlarge any image]

We can see that the gas valve is in the "open" position because the movable lever is in the "down" position and parallel to the gas pipe.

Most gas companies advise their customers not to touch this valve.

They worry that you'll damage the valve and cause a more serious gas leak than ever.

Call your local gas company for assistance with the valve or the meter. Usually, because serious safety concerns apply, the gas company will respond immediately.

Watch out: General safety warning: improper installation and even improper inspection and testing methods involving natural or "LP" gas can involve dangerous conditions and risk fire or explosion.

If you smell gas you should leave the building immediately and should do so without doing anything that could create a spark such as operating a light switch or telephone.

From a safe location, call your gas company's

emergency line and/or your fire department.

From a safe location, call your gas company's

emergency line and/or your fire department.

The text provided here is a working draft and may be incomplete or inaccurate. Contact us to suggest text changes and additions and, if you wish, to receive online listing and credit for that contribution.

Also see OIL TANK PIPING & PIPING DEFECTS.

NOTICE: while example report language is provided here, reproduction of this or any of our web pages or their contents at other websites or in printed documents for sale is prohibited.

Our photo shows the shutoff valve on an outdoor LP gas tank.

The direction to turn the valve to "close" it is marked by an arrow on the valve.

You should find an document the location of the main shutoff gas valve (usually located at the gas meter or if the meter is outdoors, a main valve may be installed inside the building close to where the gas pipe enters the structure.

The LP gas tank shutoff control (photo at left) is the gray knob at the right side of the picture.

Gas shutoff valves at individual gas-fired appliances

Next you should find and document the location of individual gas shutoff valves at each appliance in the building that uses gas.

Building codes require that a gas shutoff be located at each appliance and outside of the jacket or cover of the appliance.

Our photos show a natural gas shutoff valve installed at a gas-fired water heater (above left) and a gas shutoff valve installed at a gas-fired warm air furnace (above right).

Typical gas fired appliances that would each have its own gas shutoff valve include gas fired boilers or furnaces, clothes dryers, water heaters, and gas fired cook stoves or range tops.

In some cases such as where a damaged or corroded flexible gas connector line joins the appliance to the building gas piping, moving the appliance could start a dangerous gas leak.

In these cases, such as a range top, gas stove or clothes dryer which may be pushed against a building wall, we like to see an additional gas shutoff valve for such appliances located in a more accessible location.

This permits the user or repair technician to turn off the gas supply without moving the appliance.

Our photo (left) shows a shutoff valve in an LP gas line that supplies a gas fired range top in a building where there was no other readily accessible location to provide a shutoff valve close to the appliance.

The range top was installed over an oven. An additional shutoff valve was installed inside the building but could not be readily accessed without lifting the range top or removing the oven below.

Automatic Gas Shutoff Valves on Water Heaters, Temperature-Operated

Above is a Watts 210-5 automatic gas shutoff valve installed at the temperature-pressure relief valve on a gas fired residential water heater.

The gas piping has not been connected. Gas supply piping is passed to the Watts 201-5 and from it outlet onwards to the water heater's own gas controls and burner.

The Watts 201-5 valve shown will shut off the gas supply if water temperature exceeds 210°F.

Details about this gas fired water heater automatic gas shutoff valve are

at GAS WATER HEATER AUTOMATIC SHUTOFF - temperature operated gas supply shutoff for water heaters, Watts 210-5 series.

Automatic Gas Safety Valves on Heating Boilers

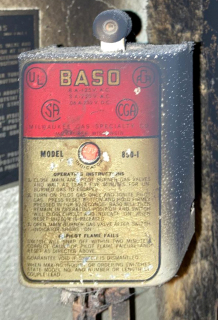

Above: a contemporary BASO pilot switch, the L62 Series No. L62AA described by BASO:

The L62 Series safety pilot switch is for use on standing pilot burner equipment requiring main burner shutoff when the pilot flame heating the thermocouple becomes extinguished.

The L62AA replaces BASO® 850-1 through 8. The L62GB replaces BASO® 853-1 through 6 and L62EA models. A universal mounting bracket is included with the L62GB to permit replacing other competitive models. - BASO cited below.

This control could replace the antique BASO gas pilot safety switch shown just below.

Shown above is an antique BASO Model 850-1 automatic gas shutoff valve, courtesy of InspectApedia reader Betsy. This automatic gas control was found on a 1950s Hydrotherm boiler described at

As we see Milwaukee Gas Specialty on the control label we know that this BASO automatic gas shutoff switch gives an earliest-possible date for this control of 1934. The last probable year for this control would be 1957 when the company changed its name.

The Milwaukee Gas Specialty Company introduced the Baltimore-Automatic Shut-Off (BASO) switch in 1934.

In 1957 the Milwaukee Gas Specialty Company changed its name to BASO - the company is still in business today.

Gas Pilot Safety Switch Manuals

Above: the BASO L61 Gas Safety Shutoff control described below.

- Contact: Baso Gas Products LLC, 450 E Horseshoe Rd, Watertown, WI 53094 USA, Tel: 1-877-227-6427, Web: baso.com, offices in Australia Canada China Europe India and Mexico as well as the U.S.

- BASO L61 L62 GAS SAFETY SHUTOFF DEVICES DESCRIPTION [PDF] (2015)

- Excerpt from product description:

The L61 and L62 Series BASO® Safety Shutoff Devices are for use on all gas-fired, standing pilot equipment that requires main burner shutoff when the pilot is extinguished.

Typical applications include domestic central heating and commercial space heating appliances, as well as industrial processing equipment (for example, die-casting machines and degreasers).

The L61 and L62 monitor the pilot flame through the use of a thermocouple In 100% shutoff model L62GB applications, if the pilot flame is extinguished, the switch will interrupt gas flow to the main burner and pilot burner, shutting down the appliance.

In Non-100% shutoff models L61LL and L62AA applications, if the pilot flame is extinguished, the switch will interrupt gas flow to the main burner only, shutting down the appliance.

Pilot gas will continue to flow until the pilot gas is manually shut off. - BASO L72GB SAFETY SHUTOFF DEVICE INSTRUCTIONS [PDF] (2017)

- BASO L72AA INSTALLATION INSTRUCTIONS [PDF] (2017)

Visual Signs of LP Gas Leakage at an Appliance Gas Valve

Even if the natural gas or LP Gas is shut off or no longer supplying an appliance, stains at the gas piping such as we show below this little LP gas shutoff at a water heater (in a city in Mexico) may indicate a history of leaks at the gas pipe connections.

In this case we found that a damaged, grooved mating face on a flare fitting had caused many years of slow gas leakage at this valve. T

he black stains at the flare fitting and copper tubing at the left side of the valve (photo at left) were pointed-to by the gas delivery driver as evidence of a history of gas leaks.

The repair required replacement of a flare fitting and re-making the joint.

Gas shutoff valves located inside of heating appliance covers and jackets

Safety Recommendation: a gas shutoff valve

should be installed in the gas line close to (but outside the cabinet of) each gas-fired appliance/device. [There are a few exceptions that permit the valve to be inside the appliance - ed.]

If your building has gas fired appliances that lack an accessible gas shutoff valve you should ask a licensed professional plumber or heating technician to install one.

Safety Recommendation:

If you see that the local manual gas line shutoff valve at a gas-fired appliance has been installed only inside the jacket or cover, this is an unsafe condition: the valve could be difficult to reach in an emergency.

Check with your local building code inspectors. Relocation of such valves is usually a minor expense and can be handled by most licensed plumbers or heating service technicians.

Abandoned gas shutoff valves may be very dangerous

Gas valves might be found be left in place when an appliance has been removed.

Watch out: If the gas valve does not include a lock to prevent it from being opened, the gas pipe should be capped so that the valve cannot be opened to let explosive gas into the building.

Watch out: If the gas valve does not include a lock to prevent it from being opened, the gas pipe should be capped so that the valve cannot be opened to let explosive gas into the building.

Our photo (left) shows a "live" natural gas line in an old house in Newburgh, New York.

Someone who doesn't know better might open this valve, causing a serious or potentially fatal explosion in the building.

Gas surprises:

Gas light and gas fireplace lines and valves may be "live" in older homes which used natural gas to supply energy to gas fireplaces or even to gas lights.

Never assume that an old gaslight fixture (photo at left) is safe and that the piping does not contain gas.

Often these fixtures were converted to electricity, having wires run conveniently through existing gas piping.

But an old gas fixture that has not been electrified may still release dangerously explosive gas into a building.

Types of Gas Shutoff Valves

For safety be sure that the shutoff valve you select for installation on gas piping is rated and approved for that application.

For safety be sure that the shutoff valve you select for installation on gas piping is rated and approved for that application.

Do not use a water shutoff valve on gas piping.

Furthermore at least some gas shutoff valves include in the product description a warning not to use the valve on water piping.

Shown above: a NIBCO gas rated ball valve with a red handle.

This is a low-pressure gas line shutoff described by NIBCO as

5 psi for indoor shutoff per CGA 91-002 and ASME B16.44, 1/2 psi for indoor appliance connections per ANSI Z21.15 and CSA 9.1, Not for water service. - Source cited at the end of this section.

Question: OK to use an "LP"-marked shutoff valve on natural gas piping?

2018/11/22 Sparky said:

Can a shut off valve that is marked “LP” on the handle be used as a natural gas shut off valve? The color of the handle is red and I have seen yellow colored handles before and wanted to know the difference.

Reply: Yes but check the valve markings or labeling for use with gas piping - do NOT rely on the color of the valve handle

Sparky

Gas valves intended for use as shutoff controls for either LP or Natural Gas are marked with specific stampings that identify them as gas shutoffs. In North America look for an AGA stamp on the gas shutoff valve body or in Canada, a CSA stamping along with additional stamps and marks we will discuss here.

Do not rely on the color of the valve handle as an indicator of its intended use.

While a gas valve handle color is often yellow or red you will also find gas-rated shutoffs with valve handles in other colors such as green or blue.

Plumbers don't rely on the gas valve handle color. More-often the valve handle color is simply part of the manufacturer's brand identification.

Not to mention confusion that could arise from the fact that that valve handles can be replaced or swapped on and off on the same valve.

Shown here are two gas ball-type valves produced by Eastman. One valve has a red handle (above) and the other Eastman valve has a yellow handle (below).

Both of these in-line flare type (internal ball type) gas valves are permitted for use on on either LP (propane) and NG (natural gas) piping.

Both of these valves are rated for use on either LP gas piping or natural gas piping.

The red-handled gas shutoff above is described as:

- For use with liquefied petroleum, LP gas & air mixtures up to 175 psi? Brass body? 1/2" OD flare x 1/2" FIP

The yellow handled gas shutoff valve shown below is described by the company as:

- The Eastman Straight Flare Brass Gas Ball Valve is for safe use with liquefied petroleum gas, LP gas, and air mixtures up to 175 PSI.

These valves do differ: the red-handled gas valve is a right-angle or 90 degree valve connecting NPT to flare piping

while the yellow handled gas valve is a straight or in-line gas valve connecting NPT to a flare fitting (copper tubing).

A final comment on LP / Natural Gas shutoff valve interchangeability:

Watch out: do NOT use a control valve rated just for water on gas piping, even if it's a ball-type valve.

Shutoff valves rated for use on gas piping will generally be stamped "G" (for gas) or "WOG" for (OK to use on Water, Oil or liquid Gas piping).

A valve intended for use on gas piping will have an AGA stamp on it (American Gas Association) for valves sold in the U.S.

If you see a valve that is stamped "W" (water only) its internal seal is not as reliable as a valve rated for use on gas piping: such valves should not be used on gas pipes.

Look at the valve's body or rating for an AGA stamp, or look at the information provided by the manufacturer on a data tag attached to the valve.

Also in some communities the gas piping materials that are permitted for LP may not be permitted for natural gas & vice versa.

For example you may be required to use black iron piping rather than flexible copper tubing in some piping installations (such as running gas lines through concealed spaces).

Gas Control Valve for Appliances

Watch out: however SOME gas control valves used at, on, or within appliances like gas grills and ranges may be sold with a metering orifice for use with a specific gas (LP or natural gas) and for a specific appliances. THOSE gas valves are NOT interchangeable.

Watch out: however SOME gas control valves used at, on, or within appliances like gas grills and ranges may be sold with a metering orifice for use with a specific gas (LP or natural gas) and for a specific appliances. THOSE gas valves are NOT interchangeable.

For example a gas range top or cooktop gas control valve may be specifically set up for LP or NG and can't be swapped without conversion of an internal orifice.

Here I show as illustration a gas control valve sold by Fire Magic Grill Parts. This brass gas control valve is rated for use on both LP (propane) AND Natural Gas.

Watch out: this valve is not intended as a general-purpose gas line shutoff valve. It is sold as a gas control for use on certain models of FireMagic's gas grills.

In GENERAL (but not in every case), a gas control valve that is rated for LP ought also to be fine for natural gas - there is not such difference in delivery pressure as to require a different design. Here I am referring to a gas piping or gas supply line shutoff valve that might be installed close to the gas appliance.

Below is what the vendor says about this valve:

FireMagic main burner brass control valve. Features an adjustment screw, located at the bottom inside of the valve stem, that enables the valve to be used with either propane or natural gas. This valve does not come with an orifice.

Fits FireMagic Regal 1 and 2, Custom 1 and 2, Deluxe, Elite and Monarch models. IMPORTANT: Orifice "Not" Included. Replaces FireMagic OEM Part 3004. - retrieved 2018/11/25 cited in detail below.

Changing From LP to Natural Gas or Natural Gas to LP?

Watch out: you cannot simply switch fuels from LP to natural gas and expect the same, unmodified appliance to work correctly. Doing so would be unsafe, risking a gas fire or explosion as well as improper device operation.

In the ARTICLE INDEX found near the end of this article you'll find articles on

- GAS APPLIANCE CONVERT LP-to-NATURAL GAS

- GAS APPLIANCE CONVERT NG-to-LP

- GAS REGULATOR CONVERSION NG-LP

In those articles you'll see that both the gas regulators and orifices and other controls must be changed or modified.

Gas Line & Appliance Valve Suppliers

- Eastman supply valves, sold through Home Depot and other plumbing and heating suppliers;

- FireMagic Grill Repair Parts www.grillparts.com, Barbecue Renew Inc. 24 Commercial Pkwy, Santa Rosa Beach, FL 32459 USA, Tel : 850 622-9146 Website: Grillparts.com - retrieved 2018/11/25 original source: www.grillparts.com/firemagic/grillparts.asp

- NIBCO INC. World Headquarters 1516 Middlebury Street Elkhart, IN 46516-4740 USA Website: http://www.nibco.com Tel: 1.574.295.3000 or 1.888.446.4226, Retrieved 2018/11/25 original source http://www.nibco.com/Valves/Ball-Valves/Gas-Ball-Valves/GB1A-Gas-Ball-Valve-Female-x-Female-Lever-Handle/

Gas Line Fire Safety Valves

Fire safety valves for gas fuel lines that can shut off fuel supply in the event of a fire are also available, such as the Model 110-G Fire Safety Gas Shut-off Valve used in fuel gas piping systems and provided by Preferred Utilities (http://www.preferredutilities.com) in Danbury CT in the U.S. As Preferred explains:

Fire safety valves for gas fuel lines that can shut off fuel supply in the event of a fire are also available, such as the Model 110-G Fire Safety Gas Shut-off Valve used in fuel gas piping systems and provided by Preferred Utilities (http://www.preferredutilities.com) in Danbury CT in the U.S. As Preferred explains:

The valve is held open by a stretched wire containing a fusible link.

When the temperature rises above 165° F, the link will melt and the tension of the internal spring closes the valve.

The gas line safety valve installation instructions from Preferred include:

Locate the valve in a horizontal pipe run where the supply enters the boiler room, and/or each device or where dictated by code. Install the hold-open wire with the link(s) located in the area(s) to be temperature monitored.

Enough tension should be placed on the stretched wire to keep the valve in an open position.

Gas Line Safety Valve Sources

- Preferred Utilities Manufacturing Corp., 1-35 South St, Danbury, CT 06810, United States Tel: 203.743.6741, website: www.preferred-mfg.com, Danbury CT.

- Emerson Process Management, Website: http://www2.emersonprocess.com, Email: InfoCentral@EmersonProcess.com, provides Fisher Liquid Propane / LP-Gas valves provide shutoff, excess flow and back check functions and are used in bulk plants, bulk transports, bobtails, and in in-line installations.

- RegO® Products, USA, 100 RegO Drive

Elon, NC 27244 USA

Email: ecii@regoproducts.com,

Rego Europe Industriestrasse 9 35075 Gladenbach, Germany Email: info@rego-europe.de, Phone: 0049 6462 9147 10

Latin America, RegO S. DE R.L. DE C.V. Ave Apolo #504 Parque Industrial Kalos Del Poniente Santa Catarina, N.L. C.P 66370 Email: pechever@regoproducts.com.mx, Tel: 52 (81) 8032-5250

Rego Asia, SectionD, Floor 4, Building #15, 69 Xiya Rd, Shanghai Waigaoqiao Free Trade Zone Shanghai, China 200131 Email: Ming Jin ming@rego-asia.com, Tel: +21 504 62-183, 504 62-012 - Robertshaw Gas Valves, Robertshaw Controls Co, Invensys Controls, 191 E. North Avenue Carol Stream Illinois 60188 USA Customer Service Telephone 1.800.304.6563 Email: HVACCustomerService@Invensys.com

Similar fuel supply fire safety valves for oil fired heating equipment are described

at OIL SUPPLY LINE SAFETY VALVES, OSVs.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2019-10-30 - by (mod) -

You will understand the vagaries of trying to be helpful with any advice from a remote location. Over the last 50+ years of forensic and field work, in 100% of the cases in which I went to the site of a problem previously described by phone, email, photos, I always found important additional conditions, sometimes dominant ones. It's not that any individual (especially me) is smarter it's a matter of who has what experience.

Just to be safe I suspect your gas company, plumbing inspector, and building inspector will want your gas piping not just turned off but completely disconnected from the gas supply source before doing any such testing.

Just consider that you are testing at significantly-higher pressures than the gas supply system provided. Nobody wants the slightest chance of pushing contaminants or air or high pressure backwards through piping, regulators, tanks that could be damaged.

After considering safety, let's be sure you've got me to understand what problem we're chasing here.

A very common complaint we field here about poor performance of gas appliances is traced to under-sized gas piping, so that the flow rate to the fixture is inadequate. That's more likely to be true when there are long runs and multiple gas-burning appliances.

While the mercaptan (odorant) added to LPG usually means that if there's a gas leak the occupants will smell it even at very low concentrations, I agree that proper leak testing of new gas piping is a critical safety step and one that I'd be stunned to hear was actually skipped by an installer.

Nevertheless, pressure tests of a static system test for leaks, not flow rate. As an engineer you'll appreciate the difference. So finding that there are no leaks does not speak to a gas appliance performance problem.

Similarly, measuring static pressure in a piping system also does not speak to flow rate when the system is live and in use.

On 2019-10-30 by Anonymous

Thanks Dan,

Some additional info:

1) the sensor is a small solid stainless device with a pair of wires coming out the sealed end. They make several device ranges with the same body that go up to several hundred pounds.

I understand what you are saying about the pressure test, but you are missing some details;

a) when doing the "pressure test", the gas valve will be turned off

b) the sensor will be removed and replaced by a nipple, tee, air compressor fitting and gauge

The point is mainly this:

1) I had a gas company come out and install piping for me. This is a new house. They were never happy about doing it because I have a basement (In TX there are almost no basements).

When it came time to install branch lines to where appliances would be (on demand water heater, oven/range, grill... also to gas log fire places already installed and working), they balked and didn't want to finish the job.

I later learned they had put in a hi pressure system. I subsequently called another gas company and they had no problem with anything, but said that I should increase the pipe sizes appropriately (I know what to use here - they agreed with it) to make it a std pressure system (~ 1/2 #).

the existing piping was tested but I want to test the modifications I make. Then I will test the entire thing. (The existing piping goes up into the exterior wall next to the fire places so if a leak is ultimately there I want to be able to make sure that there is none in my work, and isolate the fault.

The sensor is just to continuously monitor the pressure. I am also installing a gas detection and removal system which consists of a PLC, propane sensors and brushless duct fans, and sidewall supply and exhaust. (OK, I'm and engineer, with years of factory experience in this type of thing)

Anyhow, thanks for the pointers, I'll checkout the docs you pointed to. I have had to become somewhat of an expert myself, although it's really impossible to find out about every nuance possible.

One other question as I am getting ready to make the mod's, I know - no unions or swing joints, but on a branch line coming of the main can I make an offset to the riser instead of just a straight line to the riser? I also understand that the fewer joints the better, but it can be hard to get pipes good and tight and hit a floor hole without having a smaller nipple to trim to fit.

On 2019-10-29 by (mod) - install a gas cut off valve in the crawl space right after the main supply ?

You can install additional shutoff valves in a gas line, PM but

Watch out: I'd be careful about installing a monitoring device of any sort that is under permanent pressure - as if the device leaks or blows you have a dangerous gas leak in your crawl space.

There are gas pressure loggers and transducers or devices used to monitor commercial gas distribution systems but I've not seen such products installed in a residential setting.

Check with your local plumbing inspector about installing a tee in the line that leads to a normally-off shutoff valve that you an open to allow a downstream (from the valve) pressure gauge or sensor.

See this gas test inspection guideline from NY State https://app.mygov.us/includes/file_upload_functions.php?download_document=17128&city_id=261

also available as a download right here as GAS TEST INSPECTION GUIDELINES [PDF] Farmers Branch,

You might also want to check with the manufacturer of the specific gas pressure monitoring device you are purchasing to see what installation details they recommend.

Finally: what you are describing is NOT a "pressure test" as you phrased it in the end of your question.

A pressure test of gas piping is usually performed with NO COMBUSTIBLE GAS in the system whatsoever; rather the piping is capped and then air is pumped or inserted into the piping system and a gauge is monitored for pressure drop.

That's because a residential gas delivery system whether LP or Natural Gas operates at very low pressures - leaks can be slow and hard to detect, so the system is tested at a higher pressure using air - which of course also avoids a fatal fire or gas explosion.

We discuss gas pressures at GAS PRESSURES LP vs NATURAL GAS

On 2019-10-29 by pm

For maintenance and monitoring I would like to install a gas cut off valve in the crawl space right after the main supply come thru the exterior wall. I would also like to install a TEE with an electronic pressure sensor in its outlet. Is this permissible?

Note there is an outside cutoff valve right before the regulator. This is LP.

The main purpose id to be able to pressure test the under house pipe easily without messing with the regulator.

On 2018-11-25 - by (mod) -

Sparky

As long as your gas line shutoff valve is being used on gas piping (that is it's not an appliance control valve) AND as long as the valve is rated for use on gas piping (that is, it's not a water shutoff valve) you can use it on either Natural Gas (NG) or on propane (LP).

Please see your question along with a more detailed reply and some illustrations that I've added to the article above.

You may have to clear your browser cache to see the updated page.

On 2018-11-22 by Sparky

Can a shut off valve that is marked “LP” on the handle be used as a natural gas shut off valve? The color of the handle is red and I have seen yellow colored handles before and wanted to know the difference.

On 2016-01-24 - by (mod) -

Jim I can't picture enough of the situation to have an opinion; the valve must be accessible; ask your local building department what they will accept.

On 2016-01-18 by Jim

I want to replace a gas stove on a kitchen island. There are no accessible cabinets next to it to put a cutoff valve. Could I instead use a in-wall "Key valve" like those used for for for fireplaces and connect it through the wall directly behind the stove to the valve under the stove?

On 2015-05-18 - by (mod) -

Anon:

No if you are leaving a home in a cold weather / freeze-risk area where gas fuel is needed for heat.

OK but not typical if you are leaving a home unattended for a long period - weeks - months - and the fuel is not needed.

On 2015-05-18 by Anonymous

is it advisable to shut off a manual gas shut-off valve before going on holidays

...

Continue reading at GAS REGULATORS & APPLIANCE / HEATER CONTROLS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- GAS APPLIANCE CONVERT LP-to-NATURAL GAS

- GAS PRESSURES LP vs NATURAL GAS

- GAS WATER HEATER AUTOMATIC SHUTOFF

- OIL or GAS FUELED HEATING EQUIPMENT SHUTOFFS

Suggested citation for this web page

GAS SHUTOFF VALVES, LP or NATURAL at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to GAS APPLIANCES, PIPING, CONTROLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Preferred Utilities Manufacturing Corp., 1-35 South St, Danbury, CT 06810, United States Tel: 203.743.6741, website: www.preferred-mfg.com, Danbury CT.

- Emerson Process Management, Website: http://www2.emersonprocess.com, Email: InfoCentral@EmersonProcess.com, provides Fisher Liquid Propane / LP-Gas valves provide shutoff, excess flow and back check functions and are used in bulk plants, bulk transports, bobtails, and in in-line installations.

- RegO® Products, USA, 100 RegO Drive

Elon, NC 27244 USA

Email: ecii@regoproducts.com,

Rego Europe Industriestrasse 9 35075 Gladenbach, Germany Email: info@rego-europe.de, Phone: 0049 6462 9147 10

Latin America, RegO S. DE R.L. DE C.V. Ave Apolo #504 Parque Industrial Kalos Del Poniente Santa Catarina, N.L. C.P 66370 Email: pechever@regoproducts.com.mx, Tel: 52 (81) 8032-5250

Rego Asia, SectionD, Floor 4, Building #15, 69 Xiya Rd, Shanghai Waigaoqiao Free Trade Zone Shanghai, China 200131 Email: Ming Jin ming@rego-asia.com, Tel: +21 504 62-183, 504 62-012 - Robertshaw Gas Valves, Robertshaw Controls Co, Invensys Controls, 191 E. North Avenue Carol Stream Illinois 60188 USA Customer Service Telephone 1.800.304.6563 Email: HVACCustomerService@Invensys.com

- National Fuel Gas Code, ANSI Z223.1-yyyy - American Gas Association / National Fire Protection Association

- LP-Gas Serviceman's Handbook,Fisher-Rosemount, Fisher Controls

- National Fire Protection Association (NFPA) Pamphlets No. 54 and 58.

- Specifications for Gas Installations, Central Hudson Gas and Electric Corporation

- "Gaslight", Gary Quilliam, The Old House Journal, March/April 1989 article describes fixtures, modern fixtures, and sources of supply.

- Residential Gas Hot Water Heater Pocket Partner - Testing and Trouble Shooting, 19. State Corp., Ashland City, TN 37015

- Carbon Monoxide Gas Toxicity, exposure limits, poisoning symptoms, and inspecting buildings for CO hazards

- HOT WATER HEATERS - a detailed guide to all types of hot water sources, problems, inspection, repair

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.