Fix Inadequate LP Propane & Natural Gas Pressure / FlowInadequate fuel as cause of gas appliance malfunction

Fix Inadequate LP Propane & Natural Gas Pressure / FlowInadequate fuel as cause of gas appliance malfunction

- POST a QUESTION or COMMENT about LP gas pressure, propane gas pressure, and natural gas pressure in piping, at regulators, at appliances

LP or Propane Gas Pressures & Natural Gas fuel supply problems & solutions.

Here we describe the common causes of inadequate LP or natural gas flow or pressure to appliances and generators. Inadequate gas flow can cause appliance malfunction such as backup generator surging and may be unsafe as well.

This article series gives the standard pressure ranges and pressure settings for LP gas, propane gas, and natural gas fuels, including pressures found in the distribution service piping, in the in-building gas piping, and at gas fired appliances such as gas stoves, clothes dryers, furnaces, boilers, and LP gas or natural gas fired water heaters.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

LP or Natural Gas Set Pressure & Flow Problems, Q&A & Fixes

On 2023-06-20 by InspectApedia Publisher - traced the issue to a fuel flow problem

@Kenneth A Myers,

I had a lawnmower that would start, run fine for about 30 seconds, then die. Ultimately I traced the issue to a fuel flow problem.

The carb would fill with gasoline but only slowly - there was a debris clogged float needle. So when the machine was off for a time the carb float bowl got refilled but when I started the motor it'd use up what fuel was in the float bowl then the motor would die.

I understand your generator is fueled by propane, but still you could have a similar problem such as a too-long line run at a too-small diameter or a bad regulator.

On 2023-06-20 by Kenneth A Myers

As I continue to try to successfully reactivate my standby generator, it seems more likely that it is not a fuel issue as I had suspected it was. I had replaced the spark plugs with a "High performance" equivalent, so I bought a new set of the original OEM Champion plugs and put those in.

The generator starts and runs for just about 40 seconds before stopping and revealing the error code 1501 loss of RPM sense. Thing is that the run time is not varying regardless of how long it sits between tries.

It will start each time I try it as long as I reset the error code, but runs the same length of time before stopping.

On 2023-06-13 by InspectApedia-911 (mod) - generator difficulty sounds more and more like a fuel flow problem or a clogged or dirty air filter

@Kenneth A Myers,

That does sound more and more like a fuel flow problem or a clogged or dirty air filter.

You might try following all of the fuel line from the propane tank through the engine.

On 2023-06-13 by Kenneth A Myers

@InspectApedia DF, The generator has been in service as it is for a few years now, in its present location. It cycled regularly without problems. It has been well maintained. Oil level is good, and oil looks very good. Once I had replaced the relay, the generator would turn over, but sputtered and did not start.

I tried using some starter fluid, but it still did not start. Eventually, after about a week of trying every day, I got it to start by manually opening the butterfly on the carb. It turns over freely, but when it starts, it runs for about 45 seconds and then dies.

Manually working the carb linkage is not having any effect. It dies, and I get the rpm sense loss error 1501. 80% propane in a 500 gal. tank. It has not been disconnected and the inline shutoff valve is fully open. There is a regulator at the tank, and another at the generator. Neither shows any signs of corrosion or degradation.

Thank you so much for helping. I am a low income veteran and was lucky to have been able to get this generator installed while I still had a decent income.

The failed relay showed no signs of heat damage

On 2023-06-12 by InspectApedia DF (mod)

- LP powered generator problems that were traced to other causes including inadequate gas piping size for long runs

@Kenneth A Myers,

We have had readers report LP powered generator problems that were traced to other causes including inadequate gas piping size for long runs.

See GAS SUPPLY for ELECTRIC GENERATORS at https://inspectapedia.com/electric/Backup-Electrical-Generator-Gas-Piping.php

Also there are usually good diagnostic steps for hard starting LP gas fueled generators right in the manual for the specific unit. If you don't have the manual for your backup generator, please see

MANUALS for BACKUP GENERATORS

https://inspectapedia.com/electric/Backup_Electrical_Generators.php#Manuals

Other causes for hard-starting LP fueled backup generators:

- Inadequate oil supply in the motor crankcase -I mentioned this before and cite it again in hope we can help some readers avoid destroying their generator. Some generators, the sophisticated models, include an oil level sensor. If the oil level is too low the sensor may prevent starting the engine.

- Weak or under-charged starter battery

- Starter wiring loose or corroded

- Electrical connections to generator not removed - don't try to start the generator "under load" - unplug anything connected to it until the motor is running normally

- More electrical: you've installed a new spark plug; be sure it's gap was correctly set and that the ceramic insulator isn't cracked, then that its connected wire and cap are clean, snug, and that the spark plug wire itself isn't cracked or damaged. A leaky plug wire can short to the engine or frame making spark weak.

- Improper use of the CHOKE - vs - RUN settings during starting (check the manual for your unit, but in general, use full choke only when the engine is cold, use half choke if the engine is already warm.

- More on fuel supply: on older generators or units left unused for a long time and that are using gasoline as fuel, check for a dirty carburetor or a stuck or bad carb float or dirt in the needle valve operated by the carb float. Check that there is good fuel flow into the carb too.

- Dirty air filter: I've sometimes found that the air filter on older motors was nearly totally clogged with dirt and crud. Check and then clean or replace the air filter if it's dirty.

On 2023-06-12 by InspectApedia DF (mod) - generator is hard to re-start

@Kenneth A Myers,

If this has always been a problem, since new, then there could be a fuel flow or supply problem.

If you tested your fuel lines and confirmed that there are no gas leaks, then air in the fuel line sounds like an unlikely problem; after-all, once we've purged the fuel line from tank to generator, any initial air problem ought to have been addressed and closed out.

When a relay fails it can be diagnostic to examine it closely. For example, if the points are badly burned we might ask if the relay was forced to short-cycle until it burned-up. In turn that short cycling could be caused by another problem.

When the generator is hard to re-start, could the cause be something other than fuel delivery, such as a binding gear or crank?

Are you able to manually turn over the motor's crank ? (I realize there may be no obvious access on some generators)

Have you checked for an oil or lubricant problem?

On 2023-06-12 by Kenneth A Myers

Had a relay fail on my propane powered generac standby unit which resulted in a failure to start. I ordered a new relay, but recieved a faulty relay, which delayed repairs. Then it was difficult to restart.

I got it started, but after running a few minutes, it shuts down with 1501 loss of rpm sense error. No problem restarting with the same result each time. New spark plugs and air filter, plenty of fuel in the 500 gal tank, no history of issues prior to this. I suspect air in the fuel line. How should I proceed?

On 2022-12-26 by InspectApedia Publisher - why won't double oven temperature get up to where I want when both top and bottom run at once

@Cal if,

There are several possible explanations for why your oven temperature won't get up to where you want when both run at once, but since you say that each individual oven reaches the desired temperature when just one runs at a time, my first diagnostic-guess would be that the total fuel flow is too limited to run both ovens at once.

That could be due to a too-long gas line at too-small diameter,

or it could be that the gas regulator at the LP tank is not quite properly adjusted.

It would be helpful to know the total distance: LP tank (Propane tank) to the oven and the pipe or copper tubing diameter.

Watch out: don't try adjusting the gas regulator yourself - if you think that's needed get help from a trained gas service technician. Making a mistake could result in a fatal fire or explosion .

On 2022-12-26 by Cal if

I have a double using propane. When i uses the top oven or the bottom oven with out using both ovens at the same time i have no problems with temperature. When using both ovens simultaneously. The top oven fails to get up to temperature. Why?

On 2022-12-03 by InspectApedia (Editor)

@john f,

Thanks for the follow-up.

On 2022-12-03 by john f

@InspectApedia (Editor), yes, all seems fine. thanks so much for your advice.

On 2022-12-03 by InspectApedia (Editor) - is the LP gas pressure to my propane furnace adequate?

@john f,

Good question: is the LP gas pressure to my propane furnace adequate?

I don't know - from just your text. The underlying question is of adequate total flow or provision of fuel at the necessary rate for the furnace to work properly. If flow is inadequate your furnace may fail to burn reliably, could burn with a too-low flame, and might not provide consistent and reliable heat.

Inadequate flow could happen not just from low LP pressure but also from a combination of too-small diameter LP gas supply piping between the LP tank and the furnace, over a "too-long" run for that pipe size.

Bottom line: if your gas furnace ignites and heats the home adequately, then running it with LPG pressure at 10", the bottom of the recommended range, is just fine. I wouldn't worry unless or until you see some sign of an operating problem.

On 2022-12-03 by john f

My propane gas furnace failed after 7 years. After installing new one, the technician noted that the pressure of the house propane lines is 10". The furnace calls for 10-12". Should I have the pressure adjusted or just not worry; thanks!!

On 2022-10-29 by InspectApedia-911 (mod)

@Sarpeo,

That's an interesting question. Since there's more information that your paid on site technician will see that is revealed in your question my answer is only a guess. It's possible that when you have more Supply available of the input end of a system, the piping system can support a greater flow rate.

On 2022-10-29 by Sarpeo

4*48kg tanks installed.

2 open the same time.

Appliance needs 1.5kg/h.

4-5 meters pipes.

3 stage of pressure regulators

Tank pressure to 1 bar, then to 100mbar, then FRS to 20mbar working pressure.

My question is, why, when openning the 4 tanks together, I get more gas flow for the same end working pressure ( i only measure after the last regulator )

Would measuring before the last regulator (and after 100mbar) show me the reason ?

Trying to find reason before paying for a technician

Thank you!

On 2022-10-23 by InspectApedia (mod) - Is it possible to have a volume delivery issue that has nothing to do with pressure, such as gas pipe size?

@Rick,

Yes, I think you're on the right track. Inadequate gas pipe size is one of the more common problem we've encountered with people having an installation with high btu input demand.

On 2022-10-23 by Rick

In the interest of full disclosure, I am a total laymen when it comes to this topic. Please do not swear too much as you try to make sense of my questions!

I am running 28 stoves in a barn and each is designed with an input BTU of 80,000. The fuel source is LP - NOT Natural Gas. The delivery lines total about 500 yards both in and out of the building. The storage bulk tank is a 30,000 gallon tank. The stoves all light as they should but many go out and continue a re-light cycle for about 2 minutes before sitting idle.

Our maintenance personnel have instructed me to clean the orifice bar as well as replace the spark ignitor and flame sensor (a single electrode) but it has not helped any...the problem persists. The pipe diameter from the tank to the building is approximately 3" and the diameter in the building is 1".

There is a piece of copper tubing (3/8"-1/2" Diameter) that the installer left in place that makes the transition from the exterior pipe to the interior pipe. it is approximately 48" in length.

While I am not expecting a solution to the problem, my question is this: Is it possible there is a volume delivery issue that has nothing to do with pressure? Is it possible the pipe diameters need to be larger - or at least consistent in order to maintain sufficient LP delivery to each regulator?

On 2021-01-11 by danjoefriedman (mod) - my generator will not stay running

You may need larger diameter gas piping

On 2021-01-11 by Robert

I have a 11000 watt portable generator ,propane, hooked up to a home 250 gal tank, on same tank ,I have gas logs,problem is my generator will not stay running,

I have them both on 1/2 inch line generator is about 30ft,gaslogs about 40ft from tank logs work fine generator acts like it is running out of fuel. What do I need to fix problem

On 2020-11-24 by (mod) - check LPG piping, elbows, valves

Chuck:

If you have the proper regulators installed (at the tank and at the appliance) but gas flow is still too weak, AND provided there is LPG in the fuel tank,

AND if you're sure the appliance itself is not damaged and is properly installed

THEN

I suspect either piping that's too-small in diameter for length of run, or a clog or blockage in the piping or at an elbow or fitting.

Details at GAS PRESSURE DROP in PIPING may help your diagnosis.

On 2020-11-24 by Chuck

I just bought a new L.P. regulator from a local retailer it appeared to be the problem, but I still have a lack of propane to my appliance's older model rv trailer does anyone have an idea?

On 2020-11-22 - by (mod) -

I tend to believe the tech who was on-site, and certainly it is not likely to be correct to have the regulator for the wrong fuel. Was Amerigas actually on-site?

The only reason I said "not likely" is that some regulators are convertible between LPG and Natural Gas fuels - so your 2nd regulator might have been converted to propane.

An appliance regulator is usually in the $20. range for the part alone.

Watch out: operating any gas appliance with the wrong regulator in place delivers the wrong pressure and could make the appliances unsafe, risking fatal carbon monoxide poisoning.

On 2020-11-19 by Graves

Have 320 gal propane tank to run 4 year old 17KW Briggs & Stratton Standby Generator. Sometimes the generator starts after grinding for a few seconds, other times it won't start. A tech told me I have the wrong size 1st Stage Regulator (2 lbs) and the wrong size 2nd Regulator (2 lbs) and that I am not getting enough gas to the generator.

My propane company (Amerigas) says both Regulators are right.

The tech says the 1st Reg. should be 10 lbs and that my 2nd Reg. is for natural gas, not propane.

Amerigas refuses to replace them. I rent the tank from them. The tech wants $420 to replace both. WTF?

On 2020-04-06 - by (mod) - match gas connector BTUH rates with appliance - larger is OK

Chris

Have I misunderstood?

The gas line you installed bore a tag saying it could supply propane gas at a rate up to 60,500 BTUH while your dryer only uses 22,000 BTUH ?

If so then the dryer's gas requirement is much less than the gas line capacity - so we would not think that the gas connector line BTU rating was inadequate.

On 2020-04-06 by Chris O. - wrong size flexible gas connector

Also, the regulator that was required for the proper wc on my appliance has a 3/8” outlet. I’m also wondering if it would make a difference that I used a 1/2” flex hose from there to appliance considering that the pressure is already regulated but it does make sense that the larger 1/2” hose would still have higher volume than the 3/8” flex hose.

I want to get the right one before I use it again so I don’t have to worry about personal injury or damage to my home and dryer. Thanks for your time

I converted my gas dryer to propane and Im trying to confirm the correct sized flex hose to use from appliance to supply line.

I already installed a regulator at the supply connection with 14” wc. I had picked up a flex hose from Home Depot that was labeled for gas dryers, however upon installation I saw the BTUH rating table on the packaging.

I had 1/2 flex hose 4’ long rated at 60,500 btuh. My dryer is rated at 22,000 btuh. I needed cloths dried so I installed anyway and closely monitored it while operating and it was fine although they got done faster than expected.

Based off the btuh table tho I would think that I should be running a 5’ 3/8” flex hose putting the rating at 24,900.

There is a 6’ 3/8” flex hose with a 23,100 rating as well but that will leave me with a lot of extra hose and I’m concerned about it getting kinks and unnecessary bends.

The only thing specified in the installation instructions from the appliance manufacture is to use 1/2” straight pipe for the supply line. Any recommendations?

On 2019-11-05 - by (mod) - gas connector & connector for coffee roaster

Start by checking the input pressure range accepted by the pressure regulators that I would expect you will find installed at each of your gas appliances.

If those accept the boosted pressure range then you're fine. Very often the root problem in case of such as the one you described is that the supply piping diameter is too small.

Each gas appliance has its own local gas pressure and flow rate regulator; each of those will have stamped right on the regulator the range of input gas pressures that the regulator can accept.

If your gas system pressure at those regulators is higher than the regulator can safely accept then you'll need to install an additional step-down pressure regulator.

On 2019-11-03 by Randy T

Greetings, I recently installed a separate natural gas line for a coffee roaster in my home that needs 30-40 Mbar (< 0.5 psi) pressure to be able to roast at its capacity. i only have ~15 mbar (.25 psi) service and have to reduce the roaster’s capacity to less than half per batch

because the incoming service pressure is not adequate to roast larger batches. the gas company will increase line pressure from .25 psi to 2 psi, but then i think i’ll have to step down all my other gas appliances (stove, furnace, fireplace, water heater, etc) and am afraid this will introduce unintended problems with those units.

Is there a way to just increase pressure to my coffee roaster (i.e., small pump) without increasing service pressure to the whole house? >

On 2019-02-09 - by (mod) -

John I apologize but I'm confused by the question.

IF you mean that there is gas supply to the heater but its regulator isn't opening to let gas flow to the pilot, I suspect you've got the control knob set wrong.

Watch out: making a mistake can cause fire, explosion, death. So if you're not sure about what you're doing get help from a trained service tech.

That warning said, typically a gas heater that uses a pilot will have a knob that's set to PILOT then held in or a button is pressed in or down, to permit lighting the pilot.

If the pilot will not stay lit then there may be a bad thermocouple or improper pilot adjustment.

On 2019-02-09 by John

Gas coming inside to wall heater through outside regulater but not going through regulater in wall heater not leating pilot to get any gas to light

On 2018-11-22 - by (mod) -

You probably need either a larger-diameter lion or a higher pressure delivery and a step down pressure regulator at the barn end.

On 2018-11-22 by Al

I ran a 2 inch gas line from my house to my barn about 200 feet then I took a half inch line to buy 250,000 BTU heater and it will not run is it because of gas pressure

On 2018-10-09 by Travis

As more and more propane powered generators, or dual fuel as they're called, become available, there should be an explanation of how much pressure is required to power one.

For instance, would it be possible to run a portable one off a household propane or natural gas line? I have found very little explanation of this.

If a manufacturer produces a generator that can run off of household pressure, they'd have a big seller. In a hurricane it would last a long time powering necessary home appliances, such as refrigerators.

On 2018-10-10 by (mod) - special LPG pressure requirements for dual-fuel generators?

Travis

Thank you for asking interesting and important question. We have fielded questions about this from a number of readers.

I'm what I have learned so far, pressure isn't the issue because the pressures are pretty standard and are the same as for other typical Propane fuel appliances.

The problem arises when people run fuel lines over a greater distance. All of these generators come with a table that will show that for a given piping distance you may need to increase the diameter of the fuel piping.

The most Troublesome example of this came up in discussion with a reader who couldn't get his generator to work properly because it never had enough fuel flow.

The static pressure was correct but as soon as the generator started using fuel the pressure in the system dropped because his piping was considerably under sized for the length or which it had been run.

That said, I'll see what else I can find and we'll add it here. Thanks again

Also see BACKUP ELECTRICAL GENERATORS

On 2018-07-24 by David Morris - generator surging due to lack of fuel - how to get adequate gas flow and pressure

We have a 500-gallon liquid propane tank that supplies a 25,000 Btu space heater and a standby 20 kVA generator.

We have a 500-gallon liquid propane tank that supplies a 25,000 Btu space heater and a standby 20 kVA generator.

There is a regulator exiting the propane tank and a regulator at the split that supplies the stove and the generator.

Frequently, when the generator is running in case of a power outage, the generator will "surge", causing the lights to flicker and this is not good for motors or electronics.

I have on several occasions noticed the two regulators "fighting each other" and I learned in school that you can't put two pressure controllers back-to-back and expect either of them to work.

Is there some method using orifice plates to regulate the pressure between the tank and the second (house) regulator to maintain the requisite pressure at the upstream side of the house regulator with a "control action"?

These questions were posted at at GAS PRESSURES LP vs NATURAL GAS or as comments and replies at the bottom of this page.

On 2018-07-24 by (mod) - How to Fix Inadequate LP Gas Supply to an Electrical Generator

David

David

Fixing Inadequate LP Gas Supply to an Electrical Generator

An authoritative answer should come from your gas supplier as I'm uncertain myself of the right solution. But I suspect that the regulators are not properly placed, pressures are set wrong, or the gas piping is too small.

Less common is an under-sized LPG tank itself. (250 gallon is a common minimum size).

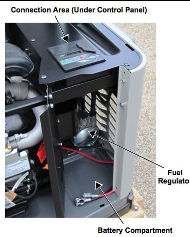

The photo, adapted from Generac cited below, shows a typical LPG regulator on a Generac LP gas fueled generator

Details of how to fix this problem are

at GAS SUPPLY for ELECTRIC GENERATORS where we give a list of things to check and fix.

Also see BACKUP ELECTRICAL GENERATORS

More information: LPG PROPANE TANK PRESSURES is a separate article on propane pressures at the tank and meter.

On 2018-07-26 by David Morris

After some more research on the regulators in my system, they appear to be sized properly. The "primary" or "first stage" regulator at the tank is rated for 2.5MM Btu/hr and is adjustable from 5 - 10" psig.

The "secondary" or "house" regulator is sized rated for 935,000 Btu/hr and will deliver up to 11" wc with a 10 psig inlet pressure.

My maximum, "full load" use is 372,000 Btu/hr or about 149 cfh @ 2500 Btu/scf for propane which is between the "gross" and "net" heating values and closer to the "gross".

The generator at full load consumes 136 cfh and my small space heater uses 13 cfh. So now my focus shifts, first to the supply tubing size.

From the tank regulator to the house regulator is right at 50 feet and it's 1/2" Type-L copper. However, the installer used 3/8" tubing from the house regulator to the generator inlet and that distance is about 3 feet. So my real question is this:

Are the minimum line size requirements for the distance from the tank to the generator or from the house regulator to the generator?

In any event, I realize that the 3/8" is likely too small even given the short length of run. With my pressure gage (a good Dwyer gage calibrated from 0 - 15" wc) attached at the debris leg right at the generator inlet, I tested the system. The static pressure with the generator down was 11" wc.

I started the generator manually (no load, just in "exercise" mode) and the pressure dropped to 9". That's an 18% pressure loss at no load. I've got a Kohler technician coming out next week to take a look at it and when he gets here I'll shut the utility power off and let the generator load and do some more fuel system hydraulics investigation.

Comments, especially on the "minimum piping size" portion of my issue?

On 2018-07-26 by (mod) - under-sized gas piping causes inadequate supply to larger generators

While I am reluctant to rule out a problem with the regulator first stage, nevertheless at sounds from your notes as if from my reading of the table your pipe diameters are all too small. You need 1 inch.

see if I'm right, check the tables in the reference that I gave you

EXAMPLE: 20kW Generac LPG-fueled generator using a 3/4” diameter gas line can run just 15 feet of pipe. To go to longer distances (up to 115 ft or 35meters) you’d need to use a 1” diameter gas line.

Also see BACKUP ELECTRICAL GENERATORS

On 2017-08-12 by (mod) - normal pressure for natural gas within a household piping system

Thank you Jack for the question, as I am always really grateful when a reader helps us make our information more clear or helps correct a mistake.

I think both statements are correct and reasonable.

Natural gas pressures arriving at a building's gas meter from the gas company's piping vary considerably depending on the location and supplier.

And in fact the service gas pressure may also vary during the day or from season to season, but it must always be at or above the required minimum pressure for gas appliances in the building to work properly.

You'll see a gas pressure regulator at the gas meter, providing a regular supply in the pressure range we cited in this article:

A typical gas pressure on the house side of the gas meter and its incoming gas pressure regulator will be 0.27-0.29 psi and in any case should not be less than 0.25 psi - that's in order to deliver a standardized gas pressure to building gas burning heaters or other appliances.

Virtually every gas appliance or heater ALSO has its own local gas pressure regulator feeding gas smoothly into the appliance, recognizing that the line pressure might be a bit higher than the specific appliance wants.

Furthermore **IF** a specific gas appliance actually requires a lower gas pressure than 0.25, the regulator will handle that pressure step-down.

Notice that the AGA's text that you quoted says ... to under 1/4 psi IF THIS IS NECESSARY.

Examples of local appliance gas regulators are at GAS REGULATORS for APPLIANCES - https://inspectapedia.com/plumbing/Gas_Regulators.php

There we point out that the reason for local gas pressure regulators at the appliance is to assure not just appropriate static gas pressure, but to be sure that the gas FLOW is adequate - and is maintained at the necessary pressure.

For example the total incoming gas flow rate on a gas cooktop will be much greater when all four or five burners are on than when just one burner is on. It's the appliance regulator that handles that.

If things still look wrong to you, help me out by pointing out what specifically seems odd to you and I'll be glad to work on this topic further.

On 2018-08-01 by purushottam - do I need 3 regulators in parallel?

The capacity of lpg regulators at the outlet of lpg vapourisers is 230kg/hr.the demand is 630kg/hr.the set pressure is 1.4bar and inlet pressure is 270 psig.

do we have to go in for 3 regulators of 230kg/hr or increase the set pressure to about 2bar to get required capacity of 630kg/hr using only two regualtors in parallel?

On 2018-08-01 v by (mod) - how do I get the right pressure? 3 gas regulators?

I think you'll need a larger LP gas regulator - running 3 in parallel seems a bit of a kludge.

I'd be reluctant to go too high on outlet pressure as you may overpower the second-stage at-appliance regulator that's using the gas.

Usually high capacity high-demand systems use a two-stage regulator design.

That would be perhaps the best alternative. Check with your gas supplier to be sure they agree as if they don't they will probably stop gas delivery (and your system could be unsafe)

On 2017-08-12 by Jack From Michigan

Under Typical Natural Gas Pressures at GAS PRESSURES LP vs NATURAL GAS

"Natural gas pressures in the building gas piping between the gas meter and the appliance regulator is typically about 7.5 to 8" wc (about 0.27-0.29 psi) and needs to be at least 0.25 psi to meet the appliance regulator's output requirements."

Under The American Gas Association offers this explanation...

"At the customer's gas meter the incoming natural gas passes through another regulator to reduce its pressure to under ¼ pound (0.25 psi) if this is necessary.

(Some services lines carry gas that is already at very low pressure.)

This is the normal pressure for natural gas within a household piping system."

They cannot both be true, so which is it?

...

Continue reading at GAS SUPPLY for ELECTRIC GENERATORS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- GAS APPLIANCE CONVERT LP-to-NATURAL GAS

- GAS PIPING, VALVES, CONTROLS - home

- GAS PRESSURES LP vs NATURAL GAS

- GAS PRESSURE vs BUILDING HEIGHT

- GAS PRESSURE FLOW INADEQUATE

- GAS COOKTOP INSTALLATION

- GAS REGULATORS & APPLIANCE / HEATER CONTROLS

- GAS REGULATORS for LP TANKS

- GAS SUPPLY for ELECTRIC GENERATORS

Suggested citation for this web page

GAS PRESSURE FLOW INADEQUATE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to GAS APPLIANCES, PIPING, CONTROLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Bosch, "Gas Cooktops Installation Manual, NGM Gas Cooktops (NGM30, NGM50, NGM 56, NGM80, NGM86, NGMP65)", (2013), Bosch, 1901 Main St., Suite 600, Irvine CA 92614, Tel: 800-944-2904, Website: www.bosch-home.com

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.