Electric Motor Diagnostic FAQs-3

Electric Motor Diagnostic FAQs-3

Fix or Select Electric Motors - Q&A Set #3

- POST a QUESTION or COMMENT about how to troubleshoot electric motors such as air conditioning compressor motors, heating equipment burner or fan motors, swimming pool motors, water well pump motors

Electric motor diagnostic FAQs set #3:

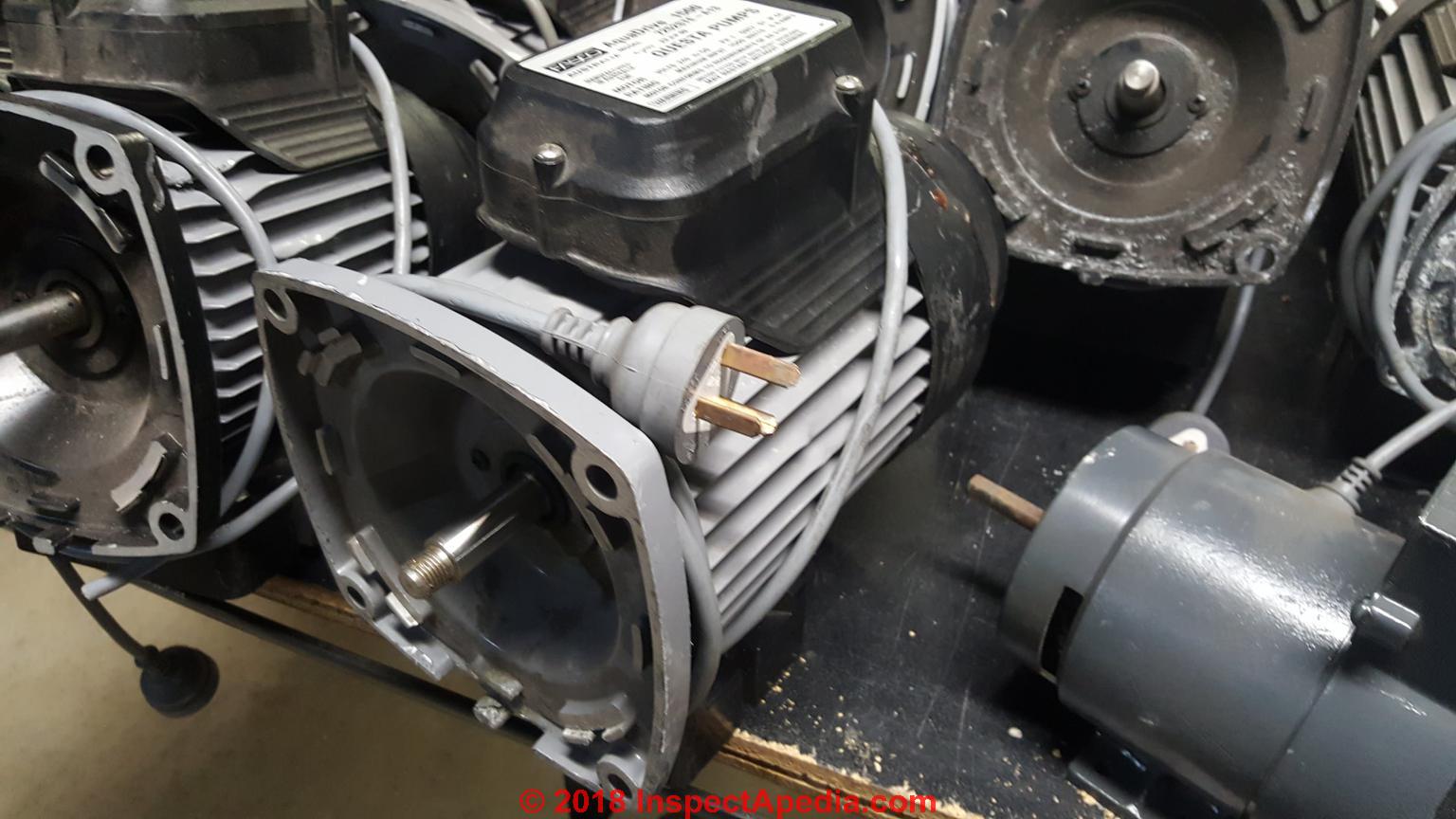

These questions and answers help in diagnosing or repairing electric motors. The page top of an oil burner electric motor points out that many electric motors used on building mechanical systems and appliances look a lot alike.

This article series describes A/C electrical motor troubleshooting: here we provide an electric motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor problems for motors found on HVAC equipment in buildings such as air conditioners, furnace or air handler blower fans, oil burner motors, well pumps, and condensate return pumps.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

A/C Electric Motor Selection, Installation, Repair FAQs

These questions & answers were posted originally

These questions & answers were posted originally

at ELECTRIC MOTOR DIAGNOSTIC GUIDE - home.

On 2018-05-09 by Iain - can I use a pool pump motor for woodworking equipment or in a woodworking shop table saw, drill, sander etc.

I've come into possession of a few used single phase motors (1 to 3HP) designed for pool pumps

I want to use them in my workshop to run a sander or two. Nothing high speed.

Made by Fasco.

Duty S1 IP 44. Do you have any information that tells me the difference in performance between a motor designed for pumps and one designed for "general purpose"?

[Click to enlarge any image.]

On 2018-05-09 by (mod)

What first occurs to me is that pool pumps typically have a duty cycle that anticipates long on-times, but at least some pool pump motors may also be relatively low torque and may not perform well under some woodworking loads such as sawing or planing

Things to Check when Re-Purposing an Electric Motor

Look at the data tags on your motors and on the data specification of typical woodworking motors. You want to identify:

1. Service factor: a multiplier x motor horsepower to give a maximum horsepower that the pump can deliver for short periods of time.

This may be more important for a motor used on a table saw (biting into wood at the start of a cut, without stalling) than for a pump motor moving water that never encounters much initial resistance)

EG: A 1 hp electric motor with a service factor of 1.5 can deliver 1.5 hp for a brief time without damage. But you will overheat and perhaps damage the motor if you load it such that it must deliver more than its rated hp for very long - such as making a long rip saw cut in thick wood.

2. Horsepower - Woodworking motors are sold in both 1725 and 3450 rpm versions, typically in the 3/4 to 4 hp. range. (See Leeson's woodworking motors for some examples).

These motors will use a start/run capacitor and are designed for high torque that's needed when the motor encounters the resistance of turning a saw blade or drill into wood or other materials.

The motor shaft will also be designed to carry a pulley or blade and extends for a greater distance outside of the motor casing than a that of a pool pump.

Pool pump motors are most-commonly sold in the 3/4 to 2HP range (tell me the specs and show me the data tags on some of your motors).

3. Torque - I would look closely at the torque capacity of your pump motors when considering a woodworking application. Pump motors may be of lower torque capacity.

4. Speed - 1725 /3450 rpm, multi-speed or variable speed - Both types of motors are sometimes sold in two-speed or occasionally variable-speed versions that can be handy for woodworking purposes but not essential.

5. Voltage - 120/240 VAC and phase (all of your pumps and all light-duty woodworking motors are likely to be single phase 120 VAC)

6. Motor shaft design and end - (usually threaded on pool pumps) and ease of connecting the motor to a woodworking machine (don't try welding or modifying a shaft)

Pool pump motors will have a short drive shaft that was intended to operate an impeller inside a pumping chamber. That may be less easy to connect to your woodworking equipment.

Bottom line: for light duty woodworking low-torque applications such as driving a small belt sander or a drill, you can be successful using a pool pump motor.

This motor catalog from AO Smith / Emerson has helpful details that describe the selection of replacement motors for pool pumps and other applications:

- AO SMITH EMERSON MOTOR CATALOG [PDF] (2011) AO Smith Electrical Products, 531 North Fourth St., Tipp City OH 45371 USA, www.pool-motors.com

Question: are there different test procedures for DC electric motors?

This article describes a lot of diagnostic test procedures for A/C electric motors such as those found in air conditioners, heat pumps, washing machines, clothes dryers, condensate pumps, well pumps, even garage door openers. But what about direct current motors such as used by hobbyists and in some automotive or boat applications?

Reply:

Hobbyist LB Miller has described the design and function of a simple test fixture useful for determining the electrical resistance of DC motors by providing a 1A current to the motor and measuring the voltage drop across the motor, thus giving motor resistance in milli-ohms. Note that his approach is for DC motors. [33]

Question: table saw motor hums, doesn't run

(Feb 18, 2014) Anonymous said:

I have a Bosche table saw and the motor has malfunctioned. It is a 120volt motor. When switched on it "hums" but does not spin. What could be the cause of this? Is it repairable?

Reply:

Anon,

I would remove the motor from the saw completely - for safer testing.

With the motor out of the saw, see if you can rotate the shaft by hand.

If you can then the shaft is (probably) not bound and the problem may be a bad start capacitor (if there is one). There are also some simple tests in the article above that you might want to try when the motor is out of the saw.

Question: blower motor buzzes and won't start if it's hot

(Apr 7, 2014) Jan said:

My furnace 1/2 hp blower motor starts and runs quietly from cold but will not start and makes a loud buzzing sound when hot until the thermal breaker kicks in. The motor is hot to the touch when this happens. It will go through one heating cycle, turn off and not restart. BTW the motor is only 1 yr old.

Reply:

Jan,

Buzzing is often a bad relay, switch, or control board. Hot to touch motor sounds like a failing motor or motor start capacitor, possibly showing up when the system is hot. It's time for a call to your heating service tech. Let us know what s/he finds as it will surely help others.

Sometimes a hot electric motor won't start because the motor shaft is binding in the bearing.

Sometimes a hot electric motor won't start because at the higher temperature a winding or electrical connection has opened.

Question: AC not working to cool the home - change the blower motor?

(May 14, 2014) Jaime (from Huntington WV) said:

Hi! In 2010 we replaced our outside central air unit, without replacing the furnace inside. The forced gas heating inside works great for heat in the winter, but in the summer when it gets humid, or newer AC in combination with our older fan/motor inside the house do not work well together. I have very cold air coming out, but by the end of the day when the thermostat is set on 69, it just keeps going up and up to about 71.

From what I have been told, the humidity makes the air thicker which in turn the old fan/motor in the furnace part can't handle the cool air from the new AC, which in turn my duct work under the house sweats terrible. Can I replace the motor in the house with a newer/more powerful motor without replacing the entire furnace inside? I hope you understand what I meaning. =) Thank you! Email me or comment back BillandJaime2004@gmail.com

Reply:

would look for an operating problem, possibly improper refrigerant charge, or dirty filter, that is causing the coil to freeze - that could explain the reduction in cooling capacity as the day wears on. Look for frost or ice on the cooling coil.

Another direction of diagnosis: if the system is oversized then it will cool the home too quickly, failing to adequately dehumidify.

Question: cooker hood motor hums but runs if I give the fan a spin

(June 16, 2014) Robert holt said:

Hi. I have a cooker hood motor that hums when fan speed is selected but does not turn. I have taken it out from the impeller casing, and if I give ithe shaft a quick turn whilst power is on, the motor spins, but as soon as turned off, does not restart on button. Any help please

Thanks Rob

Reply:

Robert,

It sounds as if the fan motor needs a new start or start-run capacitor.

Question: Carrier air haandler blower motor repairs - noisy, intermittent run

(July 23, 2014) B said:

Hey guys - I'm having a problem with the blower motor in my carrier air handler. I keep it oiled regularly every yr to 2 yrs as equipment suggests. Started squeaking on me when we turned our ac on this summer.

After cleaning / lubricating the motor, restarted ac and it ran fine for 4-6 hours then wouldn't not kick on when tstat showed a higher inside temp then set at. I check ed the motor and all was clear and well lubed and restarted.

Ran OK for a period then same issue. Motor became noisy again and will only run intermittently and then get noisy and shut itself down. Is this a case of bad bearings / windings in the motor or could it be a wiring issue? Any helps would be great. Thanks in advance.

Reply:

B

Check first that the blower assembly itself is spinning freely, not binding, and doesn't have worn bearings.

Then consider that the motor may be failing internally, possibly a bad bushing or bearing.

You might extend its life with a hard start capacitor kit.

Question: how to oil an Emerson K55hxkwa-9803

(July 23, 2014) Jeff Wilmsmeier said:

Can you oil a Emerson K55hxkwa-9803

Reply:

Jeff I had trouble finding a manual for this fan motor online too - so I don't know the answer.

Look closely at the motor assembly. Oil ports will be obvious, often capped with a hinged cap or a hole facing up marked "OIL" on the steel body of the motor.

Or send us some sharp photos of all sides of the motor and we'll comment further.

See ELECTRIC MOTOR LUBRICATION for detailed advice

Question: free AC inspection, said working perfectly, added refrigerant, recommends zero resistance filter

(Aug 22, 2014) Blower fan internal heat switch cuts motor after 30 min. said:

Had an HVAC CO provide a free inspection. A/C was working fine for prior 1 yr. Tech added refridg. and change dirty filter in attic. Now Blower Fan only runs 30 min and cuts off. Back on in 20 min. After 4-5 more visits, Tech wanted to sell me a new A/c at $8-$10,000. Found bent blower door and improper/wrong filter. Also, refridg. was 2 lbs low so none had been added by Tech.

What type of Blower Fan filter provides "0" airflow resistance...?

Thank very much,

New motor, cage bearings oiled and spinning freely. New fan belt. I removed the "new" filter and motor is now running cool enough that it is not cutting off from overheating. So I guess I am looking for a filter with no resistance.. any thoughts?

Reply:

Blower

I'm surprised that a tech would add refrigerant if the system was working properly - though we should keep in mind that a skilled HVACR tech may still not be an English major - so may not have explained what s/he was doing or why. Now I'm not sure what's wrong, but that offer of a costly new system is disturbing.

Ask to be shown and told what expensive parts are shot and how that diagnosis was made.

Then call a second HVAC company and ask for a second opinion before we accuse anyone of something further. If your system is an old one it might be at end of life, but working up until the time the tech touched the system is indeed worrisome.

A filter that gave zero air resistance would probably also not filter air passing through it.

A very very low air flow resistance air cleaner that is widely used is an electrostatic air cleaner. However usually we see these used in combination with a more conventional particle filter.

Kudos on getting the new motor going.

There are no zero-resistance air filters - since filtering will always create some resistance. But filters are rated for flow resistance. About the lowest flow resistance type is an electrostatic air cleaner. Typically those are preceded by a washable filter and some by a low-resistance fiberglass or other paper filter.

Take a look at inspectapedia.com/aircond/Best_Air_Filter.php

Question: Nordyne heat pump blower motor voltage checks

(Aug 30, 2014) Mike said:

Blower motor in Nordyne heat pump will not turn on. I have tried overriding thermostat but still won't kick on. I checked for voltage at transformer (240v-28vac) and looked good. I wanted to know how to test the blower motor relay. I thought I should see ~240vac across black and white wires of motor.

Reply:

Mike

Check the motor data plate - it more likely is a 120V unit.

A 28VAC transformer output is more likely being used to operate the blower's controls.

Well Pump Motor Diagnosis: grounded pump motor vs. air leaks in well piping

(July 18, 2015) Allen said:

Thanks for your prompt reply. After checking the voltage, the main and start windings are within specs. I did however receive a reading suggesting the motor is grounded. Could a damaged wire in the well casing be causing the symptoms?

Reply:

David:

Double-faults can occur but Occam's razor says we should look first for the simplest explanation as it's most likely.

Is it possible that during the repair a pipe connection simply was not perfectly tightened. For example I've found air leaks into piping (and thus potentially loss of prime) when a hose clamp on plastic piping at joints was not quite tight.

A problem is that air leaking in to the lines may not be so easy to detect unless your system has a clear plastic water filter in which you'd see bubbling and frothing. But you might start by tightening or double-hose-clamping every accessible connection.

On 2018-04-10 by (mod) -

Richard

I can't guess from your note where the problem lies: a compressor control not working, forcing the motor to try to start against a too-high head pressure, or an electrical short in wiring, control, or motor.

You might look through the motor diagnostic steps in the article above

On 2018-04-10 by richard

hi, i have a 2hp century motor 115v on a 29 gal. when i started it up it turned on for a couple of seconds and then trips breaker in the house. and keeps doing it over and over. its on a breaker by it self. the breaker is good 20amp. compressor was new never used. but i let the warranty time run out before i figured out that it wasn't the outlet or the breaker. so now I'm trying to get it working.

On 2018-04-03 by (mod) -

Bill I think your 2.3-2.4 A is within normal range for a 2.5A rated motor with no load. There will be some variation in motors, motor condition, and measurement devices. Look at LRA and RLA ratings for more detail.

See details at ELECTRIC MOTOR HORSEPOWER https://inspectapedia.com/electric/Electric_Motor_Horsepower.php

On 2018-04-03 by Bill

does a 1/8 hp 120vac motor pull the name plate amps when their is nothing hooked to it. My motor is rated for 2.5 amps, with nothing hooked to it the amps are 2.3,2.4 amps.

On 2018-03-16 by (mod) -

If the motor is hard to turn you'd probably just replace it. If it's a costly commercial unit then I'd change my mind and suggest taking the motor to an electric motor repair shop who will disassemble the motor, discover the nature of the damage, perhaps replace shaft bearings and then test for open windings.

On 2018-03-16 by Anonymous

how to repair DC motor for aircon fan 300VDC, hard to turn

On 2018-02-18 by Namis

Can I use a well pump motor for table saw

On 2018-01-19 by (mod) -

Sorry Custom, I'm not at all familiar with your equipment. I suspect the problem is a control or switch, not a motor.

On 2018-01-19 by Custom

16 foot 1974 built Cincinnati 750 ton hyd press brake. Both operator foot peddles, and hand control, motor cuts off at top limit switch. Ram will not go down. Ram will only go up. Help!!!! Gone through control panel, all relays, replaced wiring harness between limit switch box and control panel. What am I missing? Thanks in advance! Jordan

On 2018-01-06 by Brian Blakey

email signup

On 2017-12-30 by (mod) -

Try replacing the switch

On 2017-12-28 by Neil

I have a 2 Ryobi saw benches that have been giving , both seem to have the same problem , the motor starts fine but when turned off both seem to stop and then start a rocking motion for around 10 seconds.

If I turn off from the 13amp plug it’s fine, but as soon as you turn on again it’s rocks ,told it maybe the compacitor , so this was changed , but no change to rocking motion , so any ideas what is causing it to rock

On 2017-12-25 1 by (mod) -

Perhaps the winding opens when the motor is spinning.

On 2017-12-24 by m.Iqbal

when I check my cooler winding by a test lamp/metter.winding is ok but when I give line body showing curent ,what is reason .please reply me .

On 2017-11-29 by (mod) -

Sounds like the motor is overheating just as you say. Often the rotating shaft or shaft bearing overheats and binds. Or internal windings become worn and damaged.

The table above gives some motor diagnostics that in turn would direct the repair.

You might undertake a repair as a fun project (do not get electrocuted, right?) though often it is economical to just buy and install a replacement motor.

On 2017-11-28 by Danny

I have a Dewalt chop saw that I bought used for a very low price. It runs but as I suspected, after one or two cuts the motor loses power, over heats, and emits that all too familiar, burned out electric motor smell.

I am not greatly experienced in electric motor diagnostics but would like to know what exactly has happened to this unit, and how to go about repairing it.

...

Continue reading at ELECTRIC MOTOR DIAGNOSTIC GUIDE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see ELECTRIC MOTOR DIAGNOSTIC FAQs-4 - more-recent questions and answers about fixing electric motors

Or see these

Electric Motor Diagnosis & Repair Articles

- ELECTRIC MOTOR DIAGNOSTIC GUIDE - home

- A/C ELECTRIC MOTOR COMPONENTS

- BURNED-OUT COMPRESSOR

- CAPACITOR TYPES, for MOTORS

- CAPACITORS for HARD STARTING MOTORS

- CHATTERING RELAY CONTROL SWITCHES

- COPELAND ELECTRICAL HANDBOOK [PDF]

- ELECTRIC MOTOR 3-PHASE MOTOR SELECTION

- ELECTRIC MOTOR 3-PHASE TROUBLESHOOTING

- ELECTRIC MOTOR CENTRIFUGAL SWITCH or PTC PRD

- ELECTRIC MOTOR DATA TAG

- ELECTRIC MOTOR HORSEPOWER & CIRCUIT WIRE SIZE

- ELECTRIC MOTOR LUBRICATION

- ELECTRIC MOTOR NOISE DIAGNOSIS

- ELECTRIC MOTOR OFF on RESET

- ELECTRIC MOTOR OVERHEATS

- ELECTRIC MOTOR OVERLOAD RESET SWITCH

- ELECTRIC MOTOR RUN DIRECTION

- ELECTRIC MOTOR START SWITCH

- ELECTRIC MOTOR TESTS

- ELECTRIC MOTOR WIRING DIAGRAMS & GUIDES

- ELECTRIC MOTOR WON'T START / RUN

- HARD STARTING COMPRESSOR MOTORS

- HARD STARTING ELECTRIC MOTOR CAUSES

- OIL BURNER NOISE DIAGNOSTIC INDEX

- RESET BUTTON, ELECTRIC MOTOR

- TIGHT or SEIZED AC COMPRESSORS

- WATER PUMP PROTECTION SWITCH

Suggested citation for this web page

ELECTRIC MOTOR DIAGNOSTIC FAQs-3 at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.