Aluminum Wire: Failure to make adequate wire-to-wire metallic contact leads to overheating aluminum wire connections

Aluminum Wire: Failure to make adequate wire-to-wire metallic contact leads to overheating aluminum wire connections

- POST a QUESTION or COMMENT about the failure of connectors used in aluminum wiring repairs

This article explains the reasons for and effects of inadequate contact between aluminum conductor wires inside of a twist-on connector.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Inadequate Contact Between Aluminum Conductors in Twist-On Connectors

Color photos and descriptive captions from CPSC Meeting 9/28/95. In this document aluminum wire twist-on connector failures and repair procedures are described, including aluminum wire repair methods which work and methods which do not work and are unsafe. This document series describes hazards with existing aluminum wiring repair products, explains the aluminum wiring failure mechanism, and reviews recommended retrofit procedures including use of readily-available materials.

This information was presented to the US Consumer Product Safety Commission by Dr. J. Aronstein, 9/28/95. The minutes of that meeting were obtained under the Freedom of Information Act and posted by Daniel Friedman January 1996.

Click any image to see an enlarged version.

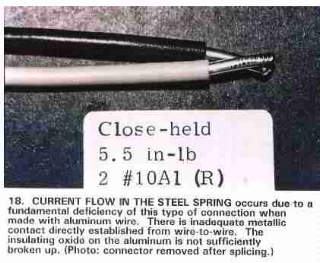

17. The characteristic heating in a band around the connector shows us where the heat is being generated. In all of those failures shown, from both lab and homes, the heat is generated by current

flowing in the connector spring. Here, all of the current is passing from wire-to-wire through sections of the steel spring.

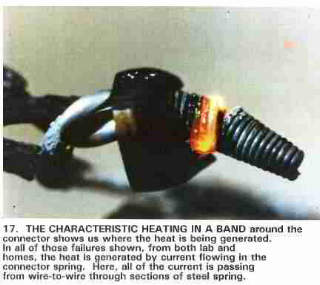

18. Current flow in the steel spring occurs due to a fundamental deficiency in this type of connection when made with aluminum wire. There is inadequate metallic contact directly established from

wire-to-wire. The insulating oxide on the aluminum is not sufficiently broken up. (Photo: connector removed after splicing.)

19. The amount of twisting together of the wires varies substantially with the hardness, size(s), and number of wires installed. Inadequate mechanical disturbance results in poor electrical contact at

the wire-to-wire interface. This is a fundamental deficiency of twist-on connections with aluminum wire.

...

Continue reading at ALUMINUM WIRING EQUIVALENT CIRCUITS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ALUMINUM WIRING IDENTIFICATION

- ALUMINUM WIRING REPAIR METHODS

- ALUMINUM WIRING REPAIR ELECTRICIANS

- ALUMINUM WIRING REPAIR METHODS - CPSC Meeting 9/28/95

- COPPER PIGTAILING for ALUMINUM WIRE

- COPPER PIGTAILING FAILURES in ALUMINUM WIRING

- ALUMINUM WIRING FIELD FAILURES

- ALUMINUM WIRE to WIRE CONTACT

- ALUMINUM WIRING EQUIVALENT CIRCUITS

- ALUMINUM WIRING CONNECTOR CURRENT FLOW

- ALUMINUM WIRING CONNECTOR DETERIORATION

- ALUMINUM WIRING CONNECTOR UL TEST INADEQUATE

- ALUMINUM WIRING SPECIAL CONNECTOR FAILURES

- AMP TYCO COPALUM CONECTORS

- SCOTCHLOK 3M REPAIR CONNECTORS

- ALUMINUM WIRING REPAIR SPECIAL CONCERNS

- ALUMINUM WIRING REPAIRS NOT-RECOMMENDED

- REDUCE THE AL WIRE RISK: DETAILS

Suggested citation for this web page

ALUMINUM WIRE to WIRE CONTACT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about the failure of connectors used in aluminum wiring repairs.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1]AlumiConn [Website: AlCopStore.com ] ™ AlCopStore.com

223 Salt Lick Road, #279,

St. Peters, MO 63376

Tel: 866-826-2256, Fax: 636-754-0500, Email Sales: pking@AlCopStore.com, Email General Inquiry: info@AlCopStore.com - [2] "Repairing Aluminum Wiring," [As updated 2011] U.S. Consumer Product Safety Commission Publication available online

- [3] "Record of Commission Action, Commissioners Voting by Ballot", CPSC Publication No. 516, Repairing Aluminum Wiring (original version op.cit.), (Briefing package dated March 15, 2011), Quoting:

The Commission voted unanimously (5-0)·to approve republication of CPSC Publication No. 516, Repairing Aluminum Wiring, with the explicit recognition that the COPALUM and AlumiConn connectors currently are the only products that meet the agency's standards to prevent aluminum wire fire hazards

Copy on file as /aluminum/Pub516_Alumi_Conn.pdf - [4] Dr. Jess Aronstein, protune@aol.com is a research consultant and an electrical engineer in Schenectady, NY. Dr. Aronstein provides forensic engineering services and independent laboratory testing for various agencies. Dr. Aronstein has published widely on and has designed and conducted tests on aluminum wiring failures, Federal Pacific Stab-Lok electrical equipment, and numerous electrical products and hazards. See ALUMINUM WIRING BIBLIOGRAPHY and see FPE HAZARD ARTICLES, STUDIES for examples.

- [5] "The Influence of Corrosion Inhibitor and Surface Abrasion on the Failure of Aluminum-Wired Twist-on Connections", Aronstein, J.; Campbell, W., Components, Hybrids, and Manufacturing Technology, IEEE Transactions on Volume 7, Issue 1, Mar 1984 Page(s): 20 - 24

- [6] Thanks to reader Thomas Kremer for suggesting clarification to this topic 08/09

- [7] Personal communication, Email, P. King to D Friedman, 3/10/2012 [copy on file AlumiConn_PK120310.pdf].

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- ALUMINUM WIRE REPAIR METHODS to reduce risk in buildings with Aluminum Electrical Wiring - Overview of Acceptable Repair Practices (in the document you are presently viewing)

- Reducing the Fire Hazards in Aluminum-Wired Homes, Jess Aronstein, Ph.D., This document answers most technical questions about the hazards and remedies of aluminum electrical wiring. Some of the sections of this very thorough document are listed below:

- Fire Hazards With Aluminum to Copper Twist-on Connectors & Acceptable Aluminum Wiring Repair Practices Color Photos, Current Issues. 9/28/95 CPSC Meeting Minutes

- REPAIRING ALUMINUM WIRING, US CPSC Pub. No. 516 U.S. Consumer Product Safety Commission Publication available online

- Directory of Home Inspectors accessible via Internet

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.