Reducing The Fire Hazard in Aluminum-Wired Homes

Reducing The Fire Hazard in Aluminum-Wired Homes

- POST a QUESTION or COMMENT about the best methods to repair aluminum electrical wiring

Aluminum wiring repair guide:

How to reduce the risk of aluminum wiring by making the proper and safe repair - Dr. Jesee Aronstein, PhD, PE. This paper details the methods used to reduce the fire hazards of aluminum-wired homes.

This document answers most technical questions about the hazards and remedies of aluminum electrical wiring and includes a report on independent test results of alternative products and methods for repairing aluminum wiring.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Aluminum Wiring Repair Details: Recommendations for Reducing the Fire Hazard in Aluminum-Wired Homes

Aluminum wiring repairs: for a clear summary of the recommended & approved steps for repairing aluminum electrical wiring in homes see ALUMINUM WIRING REPAIR METHODS.

Aluminum wiring repairs: for a clear summary of the recommended & approved steps for repairing aluminum electrical wiring in homes see ALUMINUM WIRING REPAIR METHODS.

Alternative repair methods are described for cases where the special AMP TYCO COPLALUM method is not available. Extensive research, experience, and expert resources are cited by the leading expert on aluminum wiring, Dr. Jess Aronstein.

Updated aluminum wiring repair report: We recommend that you refer to the newest, updated version of this document,available online at ALUMINUM-WIRED HOMES, REDUCE THE HAZARD [.pdf document], Jess Aronstein, Ph.D., 25 November 2011 (Original: January 25, 1983).

The web version you are reading here is from 02/09/2006 This older version of the above document also answers most technical questions about the hazards and remedies of aluminum electrical wiring but lacks latest alternative repair product testing such as the ALUMINUM WIRE AlumiConn connector discussed above.

This report is based on more than twenty years of investigation and testing of aluminum wire branch circuit connections. Included are investigations of in-home performance, burnouts, and fires, laboratory testing, and extensive review of industry and public agency test results and documents. The laboratory testing and investigations have been performed primarily for the U.S. Consumer Product Safety Commission (CPSC), for litigants and insurance interests with respect to fires which may be aluminum wire related, and for Canadian consumer groups, among others.

J. ARONSTEIN -- CONSULTING ENGINEER, MECHANICAL AND MATERIALS ENGINEERING, BME, MSME, Ph.D., N.Y.S. P.E. LIC. NO. 39860

50 PASTURE LANE POUGHKEEPSIE, N.Y. 12603

Phone and FAX: (845) 462-6452 EMAIL protune@aol.com

Jesse Aronstein, PH.D., P.E. -

When this report was originally written: Vice President, Special Engineering Projects Wright-Malta Corp., Ballston Spa, NY -- This report was originally prepared for: Electrical Safety Conference - Electrical Fires University of Wisconsin-Extension Madison, Wisconsin 4/14/82

Original Report: January 25, 1982, Major Revision May 10, 1996, Updated September 12, 2000, Updated 3/5/03, Updated 05/22/07, Updated 11/25/2011, (this web article updated 3/10/2012 to link to newest .pdf version).

- Preface - Reducing the Fire Hazard in Aluminum-Wired Homes ...ii

- Introduction - Reducing the Fire Hazard in Aluminum-Wired Homes...1

- Electrical Safety Warning - regarding Reducing the Fire Hazard in Aluminum-Wired Homes ...3

- 1. Reducing the Possibility of Connection Overheating at Aluminum Wiring Repair-Connections ...4

- A. Use of Anti-Oxidant Compound and Abrasion - When making new connections to aluminum wire ...4

- B. Pigtailing using AMP "COPALUM" Connectors - Aluminum Wiring Repair ...5

- C. Pigtailing using "Scotchlok" Twist-on Connectors - Aluminum Wiring Repair ...6

- D. Pigtailing using Ideal #65 "Twister" Twist-on Connections - Aluminum Wiring Repair ...8

- E. Electrical Junction Box Fill Issues with Aluminum Wiring Repairs ...10

- F. Alternative Corrective Actions for Aluminum Wiring Repairs ...10

- 1) Service Panel Connections in Homes with Aluminum Electrical Wiring ...10

- 2) Receptacles and Switches for Aluminum Wiring Repairs ...10

- 3) Other Connections for Aluminum Wiring Repairs ...12

- G. New Circuits and Circuit Additions in Homes With Aluminum Wiring ...12

- H. Homes Wired With Alloy ("New Technology") Aluminum Wire ...12

- I. Homes Wired With Tin or Nickel Plated Aluminum Wire ...13

- J. Safety of Homes Wired With Copper-Clad Aluminum Wire ...13

- K. Misidentification of Plated Copper Wire as Aluminum ...13

- L. Circuit Usage in Homes With Aluminum Wiring ...13

- 2. Detection of Overheating Connections in Homes With Aluminum Wiring ...14

- A. Detection of overheating at Receptacles and Switches in Homes With Aluminum Wiring...14

- B. Detection of Overheating at Other Connections in Homes With Aluminum Wiring ...14

- 3. Reducing the Possibility of Fire if Overheating Occurs ...15

- A. Inside the Electrical Enclosures in Homes With Aluminum Wiring...15

- B. Cover Plates on Receptacles and Switches in Homes With Aluminum Wiring...15

- C. Adjacent to the Receptacles and Switches in Homes With Aluminum Wiring...15

- 4. If Fire Occurs (from any cause) - homes with Aluminum Electrical Wiring or in Any Home ...15

- 5. References - Aluminum Wiring Failure Research ...16

- 6. Bibliography - Technical Reports, Connector Performance With Aluminum Wire ...17

- More Information about aluminum wiring identification, hazards, repair methods, failure case reports

Also See: The Aluminum Wiring Information Website Aluminum Wiring Hazards and Repairs

PREFACE to Reducing the Fire Hazard in Aluminum-Wired Homes

[Original printed copy page numbers have been retained. New reference-links point directly to online documents such as US CPSC Publication 516 and photographs of repair procedures .--DF]

This report is based on twenty years of investigation and testing of aluminum wire branch circuit connections. Included are investigations of in-home performance, burnouts, and fires, laboratory testing, and extensive review of industry and public agency test results and documents. The laboratory testing and investigations have been performed primarily for the U.S. Consumer Product Safety Commission (CPSC), for litigants and insurance interests with respect to fires which may be aluminum wire related, and for Canadian consumer groups, among others.

This report was first issued by Wright-Malta Corporation, which at the time had one of the largest aluminum branch circuit connection testing operations in the world. In 1982, there were approximately 7,500 aluminum and aluminum-copper connections on long-term test, plus (for comparison purposes) a substantial number of copper-wired connections. The results of the tests performed at Wright-Malta Corp. have been documented in reports written for CPSC and in published articles and technical papers. A partial listing is provided in Section 7, Bibliography.

In initiating this report, Wright-Malta Corporation did not represent any commercial interests. The company did not (and still does not) manufacture or market any of the products or services involved or any competitive products or services. Wright-Malta Corporation's aluminum wire testing activity was completed in the late 1980's, and the company has not been involved in this matter (including the revisions of this report) since that time.

This report is made available by the original author for homeowner, inspector, and trade information. The report reflects best information and test results available through the revision date.

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 1

INTRODUCTION to Reducing the Fire Hazard in Aluminum-Wired Homes

A fundamental principle of electrical safety for wiring in buildings is that high temperatures are hazardous. While some protection is provided by electrical enclosures, the high temperature that can develop at failing branch circuit connections can lead to fire in many ways.[1]

Aluminum-wired connections in homes have been found to have a very high probability of overheating compared with copper-wired connections.[2][3][4] The aluminum-wired connections that fail tend to progressively deteriorate at a slow rate, and after many years can reach very high temperature while still remaining electrically functional in the circuits. A large number of connection burnouts have occurred in aluminum-wired homes. Many fires have resulted, some involving injury and death. Examples of overheating of two common types of aluminum wire connections are shown in Figures 1 and 2 (following page).

The probability of aluminum-wired connection overheating in a home varies considerably according to the types of connections, the installation methods used, and the circuit usage, along with many other factors. Without detailed knowledge of the installation in a particular home, it is not possible to provide specific advice on corrective measures.

The most certain corrective action for all cases would be to rewire the home with copper wire. This is expensive and impractical in most cases. A practical approximation to rewiring can be achieved by a method known as "pigtailing", using a specially-selected connector and installation method to splice a short length of solid copper wire to each aluminum wire end. The copper wire "pigtail" is then connected to the circuit breaker, light fixture, receptacle, dishwasher, or other termination. This method is only effective if the connections between the aluminum wires and the copper pigtails are extremely reliable. Pigtailing with some types of connectors, even though they might be presently listed by UL or certified by CSA for the application, can lead to increasing the hazard.[5][6] (See Figure 1.)

Other actions and partial repairs are less certain in effectiveness, but they still can substantially reduce the risk of fire due to aluminum wire connection overheating. Among the possibilities are replacing certain failure-prone types of devices and connections with others more compatible with the aluminum wire, and removing the ignitable materials from the vicinity of the connections. These actions can be accomplished at lower cost than rewiring or complete pigtailing, but with less Reduction of the hazard. The homeowner has choices to make. The objective of this report is to present the choices with a relative ranking of fire risk Reduction .

The corrective methods and fire preventative actions described in this report are based on the best information available at this time. The installation and repair information in this report is provided only for guidance in establishing specifications for contracted work, which must be done in accordance with applicable codes and regulations by qualified electricians.

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 2

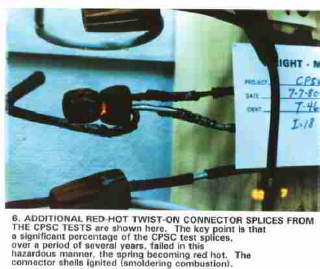

FIGURE 1 - The use of most types of twist-on connectors for pigtailing repairs can lead to hazardous results.

This twist-on pigtailing connection (two #10 aluminum wires with one #12 copper wire, in a 20-amp circuit) remains electrically functional in the circuit, but becomes extremely hot whenever a significant amount of current flows. The heat has deteriorated the insulation on both the connector and the wires.

A portion of the connector's spring (white overheated section of spring in photo) becomes red hot at current above 12 amps.

FIGURE 2 - An example of overheating of wire terminals on a receptacle. Enough heat was generated by current flowing through the aluminum wire connections to cause charring of the receptacle body and disintegration of the insulation that was on the wire. Note that the face of the receptacle, as the original homeowner would have seen it with the cover plate on, looks normal.

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 3

ELECTRICAL SAFETY WARNING - regarding Reducing the Fire Hazard in Aluminum-Wired Homes

There is risk of property damage, injury, and death associated with working on the electrical system of a home. Shock, electrocution, and fire hazards are present. All work involving electrical components in the home wiring system should be done by persons trained and qualified for the job, with the power turned off at the main disconnect (main breaker, switch, or fuse block). Refer to appropriate industry and trade publications for safety precautions that should be taken.

Since the practical application of the information contained in this report is totally in the homeowner's or contractor's control, and the report's information can reduce but not eliminate the associated hazards, the author and/or provider of this report disclaim any responsibility or liability of any sort related to the information that it contains.

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 4

1. REDUCING THE POSSIBILITY OF CONNECTION OVERHEATING at Aluminum Wiring Repair-Connections

A. USE OF ANTI-OXIDANT AND ABRASION - Aluminum Wiring Repair

To make the lowest resistance and most permanent connections to aluminum wire, the following procedure must be followed:

1) After stripping the insulation off the wire for the proper distance, using a stripping tool that does not nick the wire, coat the bare aluminum with Burndy "Penetrox A" compound. (Caution: some other "oxide inhibitor" compounds sold for the purpose are flammable. Penetrox A is not. Do not substitute.)

2) Abrade the surface of the aluminum wire, with the compound on it, with #240 grit "wet-or-dry" abrasive paper. Maintain the coating of compound while abrading.

3) Coat mating parts of the connector or terminal with the inhibitor compound.

4) After completing the connection, thoroughly clean off excess compound which is not inside the connection.

A detailed photo-illustrated description of this alternative repair procedure for pigtailing aluminum wiring, including careful use of non-flammable anti-oxidant is available

at Special Aluminum Wire Repair Method using for twist-on splice w/aluminum

*** CAUTION - THESE REPAIRS MUST BE DONE BY A QUALIFIED ELECTRICIAN ***

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 5

B. PIGTAILING USING AMP "COPALUM" CONNECTORS for Aluminum Wiring Repairs

The AMP "COPALUM" connector is applied using a special set of dies in a power-driven tool. After application of the connector, a heat-shrink insulator is applied. Solid copper wire "pigtails" spliced to the aluminum wire this way may be connected to receptacles, switches, circuit breakers, lamps, appliances, and all other terminations in the normal manner.

(Note: all aluminum branch circuit wire terminations in the home must be treated this way for a complete and permanent repair, as the overheating problem involves all types of aluminum-wired connections.)

Repair by pigtailing using COPALUM connectors installed by a qualified electrician is the only method considered by CPSC to be a permanent repair. Their recommendation is based on extensive testing.

The method is described in more detail, and sources for more information are provided in an article in Consumer Reports, January 1981.[7] While the application of COPALUM connectors is considered to be satisfactory without special preparation of the aluminum conductor, it is suggested that antioxidant compound and abrasion as per Section 1A (above) be used to provide an additional safety factor.

WARNING - Use of other types of crimp-on connections with aluminum branch circuit wire can be hazardous. Do not use commonly-available crimp connectors applied with a plier-like hand tool, even though they are often sold as applicable for "all wiring repairs", and in fact may be made by AMP (the same manufacturer that makes the "COPALUM" connector). If the AMP COPALUM connector (with its special tooling and qualified installer) is not locally available, see Section 1C, below.

Illustration of copper wire pigtails spliced to aluminum circuit wires using AMP Copalum connectors (Source: U.S. Consumer Product Safety Commission)

[Click to enlarge any image]

The US CPSC Publication 516 is available at Repairing Aluminum Wiring US Consumer Product Safety Commission Publication #516 where we have posted an on-line copy. This document is also available from the US CPSC and from the US Superintendent of Documents, Pueblo CO.

A photo-illustrated description of this procedure is available at The repair recommended by CPSC

*** CAUTION - THESE REPAIRS MUST BE DONE BY A QUALIFIED ELECTRICIAN ***

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 6

C. PIGTAILING USING "Scotchlok" TWIST-ON CONNECTORS for Aluminum Wiring Repairs - an alternative repair method for aluminum wiring [No Longer Recommended - June 2007]

Provided that special installation methods are used, 3M "Scotchlok" connectors were considered to be the best available alternative to the COPALUM crimp connector for pigtailing prior to availability of the ALUMINUM WIRE AlumiConn connector. The 3M Scotchlok connector had shown the best performance in this application compared to other types of twist-on connectors. The testing has not been as extensive as for the COPALUM crimp connector, however. [This Repair Method is No Longer Recommended - June 2007]

While this repair method is no longer recommended, in order to assist in recognition of its occurrence in the field, the text below discusses this "Scotchlok" method in detail. Readers of this section who intend to apply this method should be sure to review the step by step photo illustrations of this method located at Special Aluminum Wire Repair Method using for twist-on splice w/aluminum.

(Note: twist-on connectors are often called "wire nuts", which is actually the brand name of a specific type NOT recommended for use with aluminum wire.)

The 3M "Scotchlok" connectors [No Longer Recommended For Aluminum Wiring Repairs - June 2007] were generally available in four sizes, designated on the box (of 100) as product model "Y", "R", "G", or "B" (in increasing order of size). The model designation corresponds to the color of the insulating shell (yellow, red, green, or blue). The "R" and "G" are the most useful sizes for aluminum wire pigtailing of the #12 and #10 wire (15 and 20 amp circuits, respectively).

To achieve the successful performance demonstrated by independent testing, installation of solid copper wire pigtails to solid aluminum branch circuit wire with these Scotchlok twist-on connectors [No Longer Recommended For Aluminum Wiring Repairs - June 2007] must have been done as follows:

1) Select the appropriate size of connector for the wire combination to be joined (see listings on carton). Do not join more than four wires in one connector. Three is the recommended maximum. Where there is a choice of connector sizes for the combination to be spliced, use the largest connector that is rated for the particular combination of wires.

2) Strip the insulation off the wires, using a stripping tool that does not nick the wire, for a length approximately twice that normally required for the size of Scotchlok connector being used. (See manufacturer's instructions.)

3) Apply "Penetrox A" compound to the aluminum wire(s) and abrade as per Section 1.A.2 above.

4) Hold the stripped ends of the wires parallel, and then twist them tightly together in the clockwise direction using a pair of pliers.

5) Cut off the excess length of bare pre twisted wires.

6) Fill the spring inside the connector with Penetrox A.

7) Screw the Scotchlok connector onto the pre twisted wires as far as it will go.

8) Thoroughly wipe off all traces of Penetrox A from the wire insulation and plastic insulating shell of the connector.

WARNING: Always pigtail solid copper wire to the aluminum wire. Do not connect stranded copper wire directly to the solid aluminum wire.

SAFETY WARNING: Do not use other types of twist-on connectors with aluminum wire, even though they may be listed (UL) or certified (CSA) for the application.[5][6][11][12] Even twist-on connectors qualified to newer, more rigorous standards have failed in ...

*** CAUTION - THESE REPAIRS MUST BE DONE BY A QUALIFIED ELECTRICIAN ***

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 7

...long-term tests with aluminum wires. For example, an Ontario Hydro report shows that connections made between aluminum wire and stranded copper wire, using CSA certified "special service" twist-on connectors especially made for that application, have only one-tenth (1/10) the life of similar connections made between solid copper and stranded copper.[8] As another example, the recently UL-listed Ideal #65 twist-on connector performed poorly in laboratory tests and burnouts of these connectors in residential "pigtailing" applications have been reported.[11] [12]

NOTE: The 3M Scotchlok twist-on connector was listed by UL as suitable for aluminum wire applications until about 1987, when UL's revised test standard was issued. According to the manufacturer, the connector was not submitted for listing under the new standard. Without the connector being listed for aluminum wire by UL, the manufacturer does not recommend that usage. Nevertheless, its performance in long-term tests in the pigtailing application, particularly when installed as described above, is superior to other twist-on connectors that may be UL listed or CSA certified for use with aluminum wire.

There are three design features that make the Scotchlok the best choice of twist-on connectors for the aluminum wiring pigtailing application as the next-best alternative to the COPALUM repair. First, the cross section of the internal spring on the Scotchlok is large relative to other twist-on connectors of comparable wire capacity. Second, inside the connector there is a metal sleeve around the spring that provides improved heat dissipation in case failure does occur. Third, the insulating shell of the connector is made of a flame-proof self-extinguishing material. (All of these features subject to change by the manufacturer.)

Local electrical inspectors have the responsibility under the National Electrical Code of determining whether or not the materials used in an installation are "suitable for the purpose". Most generally, the UL listing label is taken as sufficient evidence of suitability. The inspector has the authority to accept use of materials that are not UL listed for the specific application if there is sufficient reason to consider that they are safe and in fact suitable. Where inspection is required, if the inspector will accept pigtailing with the Scotchlok connectors, then the job is in conformance with the requirements of the National Electrical Code (or most local codes). It is always desirable to obtain the local inspector's approval for aluminum wire pigtailing with the Scotchlok connectors prior to starting the job.

Supporting information and test reports are available if required to help obtain approval.

*** CAUTION - THESE REPAIRS MUST BE DONE BY A QUALIFIED ELECTRICIAN ***

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 8

D. PIGTAILING USING IDEAL #65 "TWISTER" CONNECTOR for Aluminum Wiring Repairs

After about 1987, when UL adopted a revised standard (UL486C) applicable to twist-on connectors for aluminum wire, twist-on connectors were no longer being marked (in the USA) as UL listed for aluminum wire applications. In 1995, UL accepted a twist-on connector - the Ideal #65 "Twister" - for aluminum-to-copper wire combinations, including those commonly used in the "pigtailing" retrofit. The Ideal #65 has been heavily promoted for that application. The connector is essentially the same as twist-on connectors that had performed poorly in previous testing, the major difference being that it is pre filled with inhibitor compound. Based on its construction, there is good reason to question the long-term performance of the Ideal #65. Because of its UL listing, however, most electrical inspectors would accept this connector for pigtailing of aluminum wiring.

As soon as it appeared on the market, the Consumer Product Safety Commission (CPSC) questioned UL's listing of this connector for the aluminum wire pigtailing wire combinations. Although the manufacturer claims that the connector has been thoroughly tested for the application, neither the manufacturer or UL have released any substantive test data. The manufacturer states that the connector has received CSA certification for the same wire combinations. Information developed so far indicates the following:

- After its introduction, the manufacturer's manager of engineering stated (to CPSC) that the Ideal #65 is not intended for use in the pigtailing retrofit application, but only for such applications as connecting lighting fixtures and ceiling fans. Ideal committed to CPSC to change its advertising and instructional information accordingly, but did not follow through on that commitment.

- UL did not independently perform the "heat-cycle" life tests required by their standard. These tests were performed by the manufacturer, with UL accepting the manufacturer's results.

- The connector was not "heat-cycle" tested for the common pigtailing wire combinations with current passing through the aluminum-aluminum wire path (in an aluminum-aluminum-copper splice).

- The "heat-cycle" tests that were performed by the manufacturer on the Ideal #65 "Twister" connector were not done using aluminum wire of the type actually installed in homes built in the 1960's and early 1970's.

- The CSA certification was based on UL's acceptance for listing. CSA did not independently evaluate the Ideal #65 connector. In fact, the use of a zinc-plated steel spring in the connector violates a CSA general requirement for connectors for aluminum wiring.

- Both the plastic insulator of the connection and the inhibitor compound inside the connector ignite readily and burn freely. This increases the chance of fire ignition if connection failure occurs.

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 9

Independent testing of the Ideal #65 "Twister" has demonstrated the following:[11]

- Installed according to the manufacturer's instructions (without abrasion or pre twisting), the connector does not reliably establish low-resistance connections. (This finding contradicts the manufacturer's claim that particles in the inhibitor inside the connector serve to abrade the wire and eliminate the need for separate abrasion of the wires.)

- The Ideal #65 connector does not consistently pass the UL "heat-cycle" test requirement when tested with aluminum wire of the type actually installed in homes with current passing through the aluminum-aluminum path in a pigtailing (aluminum-aluminum-copper) splice.

- The performance of the Ideal #65 Twister is essentially the same as that of poorly-performing twist-on connectors previously evaluated for the aluminum wire pigtailing application.

Additionally, field burnouts have now been reported with the Ideal #65 connectors in their rated applications. With CPSC skeptical (and requesting that UL withdraw its listing), the manufacturer seeming to agree that the connector is not for the pigtailing retrofit application, independent tests clearly demonstrating poor performance, and field failures reported, the use of the Ideal #65 "Twister" connector for the pigtailing application is definitely not recommended.

Nevertheless, the Ideal #65 "Twister" is in fact the only readily available pigtailing connector at this time that is UL listed for the application. This carries considerable weight with inspectors and electricians. If it becomes necessary to have a UL listed twist-on connector (for the aluminum wire pigtailing combinations), this is the only choice. To help assure a safe long-lived connection, the installation should be done as follows:

1) Strip the insulation off the wires, using a stripping tool that does not nick the wire, for a length approximately twice that required by the manufacturer's instructions.

2) Apply "Penetrox A" compound to the aluminum wire(s) and abrade as per Section 1.A.2 above.

3) Holding the stripped ends of the wires parallel, twist them tightly together in the clockwise direction using a pair of pliers.

4) Cut off the excess length of bare pre twisted wires.

5) Screw the connector onto the pre twisted wires as far as it will go.

SAFETY WARNING: Always pigtail solid copper wire to the aluminum wire. Do not connect stranded copper wire directly to the solid aluminum wire.

Because of its smaller spring cross section, lack of a surrounding metal sleeve, and because its insulating shell and corrosion inhibitor are easily ignited and relatively free-burning, the Ideal #65 twist-on connector is considered to have a lower certainty of permanent, safe, and complete correction than pigtailing with the Scotchlok twist-on connectors (which in turn ranks below the Amp COPALUM repair).

*** CAUTION - THESE REPAIRS MUST BE DONE BY A QUALIFIED ELECTRICIAN ***

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 10

E. Electrical Junction BOX FILL Issues with Aluminum Wiring Repairs

Most aluminum wire splices and terminations that are to be pigtailed are in metal or plastic electrical enclosures ("boxes"). Some are too small to accept the pigtailing connectors in addition to the items originally in the box. When this happens, the available volume can be increased by changing the box, extending it, or adding an adjacent box. Some cutting and subsequent touch up of finished surfaces may have to be done when boxes are changed or added.

F. ALTERNATIVE CORRECTIVE ACTIONS for Aluminum Wiring Repairs

With less certainty of safe, permanent, and complete correction relative to pigtailing of all connections, the following actions can reduce the probability of aluminum-wired connection overheating, thereby reducing the hazard. Note that ground connections should be addressed as well as the neutral and line connections.

1) Service Panel Connections: Remake all branch circuit aluminum wire connections using "Penetrox A" compound and abrasion of the aluminum wire, as described above in Section 1A. Make sure all connections are tight. Recheck tightness after one year, and thereafter at intervals determined by the amount of loosening detected, if any.

Visually inspect the service entrance cable connections. If there is any abnormality or signs of corrosion or overheating then servicing is required.

*** CAUTION - SUBSTANTIAL HAZARD: THE SERVICE ENTRANCE CONDUCTORS AND CONNECTORS ARE LIVE (ELECTRICALLY ENERGIZED) EVEN WHEN THE MAIN BREAKER OR SWITCH IS "OFF" OR THE MAIN FUSES PULLED. SERVICING OF THE SERVICE ENTRANCE CONNECTIONS CAN ONLY BE DONE SAFELY WITH POWER COMPLETELY DISCONNECTED AT THE UTILITY POLE OR METER.

2. Receptacles and Switches ("wiring devices"): Replace with CO/ALR devices installed per industry recommendations.[9]

NOTE: Some CO/ALR wiring devices that are available are old stock and should not be used. The indium plating used on the screw terminals of some brands degrades with time, so the devices have a limited shelf life. Inspect the screw terminals and the terminal plate. If the terminals have a fresh metal look, they are probably OK. If the screws and/or terminal plate look tarnished or off-color, do not use them with aluminum wire, as the long-term performance and safety would be questionable.

*** CAUTION - THESE REPAIRS MUST BE DONE BY A QUALIFIED ELECTRICIAN ***

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 11

If full replacement cannot be done due to economic factors or limited availability of fresh CO/ALR rated devices, then the following actions are suggested:

- Replace all devices which have "push-in" wire terminations where there is no provision for reconnection to a binding-head screw terminal.

- Replace all devices which have 6-32 size terminal screws. (Outside diameter is 0.138", the same as the screws which hold the device to the box: 8-32 screw threads are 0.164".)

- Replace all devices which have steel terminal screws. (Check with magnet after turning the MAIN POWER OFF!)

- Priority should be given to the replacement of unsuitable devices in the more heavily loaded circuits, in which portable heaters, cooking appliances, air conditioners, and similar loads are used. All unsuitable receptacles and switches on these circuits should be replaced, not just those into which the loads are plugged. (Since the wiring devices are most often "daisy-chained" in the circuit, full current flows through the wiring terminals on all of the devices "upstream" of the device into which a load is plugged.

Receptacles and switches which are not being considered for replacement should be inspected for heat damage. (Replace all damaged receptacles.) Reconnect the aluminum wire at the screw terminals by preparing the aluminum wire per Section 1A, above, and connect to the screw terminal per the industry recommendations.[9]

Re-tightening existing screw terminal connections, without remaking them, is simpler but less effective.

If CO/ALR devices are not available for replacement, the next best alternative, besides pigtailing, would be the use of devices with brass (nonmagnetic) 8-32 terminal screws. Connect per the industry recommendations after preparing the wire as described above in Section 1A.

NOTE: In all cases, when installing the connected device into the box in the wall, push it into place while folding the wires behind it. then pull the device out slightly and check the tightness of the terminal screws prior to screwing the device to the box.

*** CAUTION - THESE REPAIRS MUST BE DONE BY A QUALIFIED ELECTRICIAN ***

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 12

3) Other Connections: Pigtailing to solid copper wire, as described in previous sections, should be used for connections between branch circuit aluminum wire and screw terminals or stranded leads of built-in appliances, heaters, furnaces, fixtures, and controls. Do not connect aluminum wire directly to stranded copper wire leads. Use an intermediate solid copper pigtail. The solid copper is then spliced to the stranded copper lead in the conventional manner. In some instances, such as connections to motors, there is often not enough space in the junction box for the pigtailing connectors, and an external junction box must be added.

Splices involving only the branch circuit aluminum wire (ie: aluminum-to- aluminum wire connections) should be made using the Scotchlok twist-on connector with the same installation procedure as described for pigtailing (abrasion of aluminum wire under a coating of inhibitor compound, pre-twist the wires tightly together, etc.).

G. NEW CIRCUITS AND CIRCUIT ADDITIONS in Aluminum Wired Homes

Use copper or copper-clad wire for all circuit additions and for the installation of new circuits.

H. HOMES WIRED WITH ALLOY ("NEW TECHNOLOGY") ALUMINUM WIRE

The Corrective actions described in the sections above are required for homes wired with "new technology" wire just as they are for the "old technology" wire.

Homes wired with the alloy aluminum wire may have lower probability of overheating at the binding head screw connections. There is little improvement in the probability of overheating in other types of terminations, however. In particular, the alloy aluminum conductors show high failure rates in tests with twist-on connectors.[6][8] The alloy wires have improved mechanical properties but may have essentially the same electrically-insulating oxide surface film. As with the "old technology" ("EC" grade) aluminum wire, the oxide must be removed to reliably make a low resistance connection.

*** CAUTION - THESE REPAIRS MUST BE DONE BY A QUALIFIED ELECTRICIAN ***

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 13

I. HOMES WIRED WITH tin or nickel PLATED ALUMINUM WIRE

Aluminum wire plated with tin or nickel was listed by UL in the early 1970's. The actual amount that was ever installed in homes in that time frame, if any, is very small. The only known brand name (on the cable jacket) that would indicate plated aluminum wire is "SINIPAL". In general, it can be assumed that the aluminum wire in a home is not plated.

Tests of plated aluminum wires with twist-on connectors showed that the plating did not solve the connection deterioration and overheating problem.[10] If it is known with certainty that the aluminum wire is plated, omit the abrasion step in the connection procedures described above. The corrosion inhibitor compound is still required, however. (Note: abrasion of the plated aluminum wire is not harmful provided that the inhibitor compound is used.)

J. Safety of HOMES Wired WITH COPPER-CLAD ALUMINUM WIRE

Copper-clad aluminum wire has a thin copper outer skin and a core of aluminum. Therefore it looks like copper, except on close examination of a cut end. Markings on the cable jacket would include "Al" or "Aluminum". There is no known history of connection overheating problems associated with copper-clad aluminum wire. No corrective actions are required for copper-clad aluminum wire.

K. MIS-IDENTIFICATION - PLATED COPPER WIRE as "Aluminum"

Plated copper wire is relatively common in older homes, and it looks like aluminum wire. It was commonly used with rubber-based insulation. Identification can be made by careful inspection of a cut end of the wire. In general, plated copper wire would not be present in nonmetallic sheathed cable ("Romex"), it is most generally found in metallic sheathed cable ("BX"). Cable of the "BX" type is not likely to contain aluminum wire.

L. CIRCUIT USAGE vs. Risk in Aluminum Wired Homes

Keeping the circuit current low will minimize the possibility of fire hazard due to overheating aluminum wire connections. Heat generation at a connection is related to current flow. The lower the current, the less heat produced at a given failing connection. Where no corrective actions have been taken, occupants of aluminum-wired homes should minimize the use of plug-in appliances that draw current approaching the circuit rating, such as portable heaters, cooking appliances, and air conditioners. Additionally, the total of all loads active at any time on a given circuit, due to TV's, computers, lighting, etc., should be minimized.

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 14

2. DETECTION OF OVERHEATING CONNECTIONS in Aluminum-Wired Homes

Detecting an overheating Connection in the early stages, and taking corrective action, can be an effective fire-prevention procedure. This is an inexpensive way of reducing the fire hazard where complete corrective actions have not yet been taken. The effectiveness is limited, however, and strongly depends on the thoroughness and frequency of inspection.

A. DETECTION OF OVERHEATING AT RECEPTACLES AND SWITCHES in Aluminum Wired Homes

With main power off, remove the cover plates of the receptacles and switches ("wiring devices"). Using a bright flashlight, carefully inspect the area of each wire terminal. The wires should be connected at the screw terminals (not inserted into "push-in" wiring holes in the back of the device). Look for the following signs of overheating: 1) charring or discoloration of the plastic wiring device body around the screw terminals, 2) abnormal tarnishing or corrosion of wire and screw terminal, and 3) melting, bubbling, burnback, or discoloration of the wire insulation. If any of these signs of overheating exist, or if the device is push-in backwired, replace or reconnect the device as previously described. Each and every wiring device should be inspected (not just a random sample). Replace all cover plates before restoring main power.

WARNING: The often-quoted advice to "feel the outlet faces" to detect overheating is ineffective and, potentially, dangerously misleading. The homeowner cannot be expected to know how much current, if any, a receptacle's connections have been carrying, and for how long, prior to being tested in that manner.

B. DETECTION OF OVERHEATING AT OTHER CONNECTIONS with Aluminum Wiring

Periodic visual inspection, looking for signs of discoloration, insulation deterioration, or other abnormalities, is the only readily available method for detecting overheating of the various wire splices and terminations in the home. Inspection of electrical boxes and panels other than at wiring devices should be done by a qualified electrician or inspector, and must include all connections, not just a random sample.

WARNING: So-called "warning signs", such as flickering lights, inoperative circuits, strange odors, smoke, sparks, and arcing, occur at advanced - and hazardous- stages of connection failure. Additionally, they cannot be counted on to occur in all instances.

WARNING: Inspections can reveal what has happened in the past, but cannot assure future safe performance. A high resistance connection may not have overheated simply because no significant current was ever flowing in its part of the circuit. It will look "like new". The same connection may then overheat to hazardous levels when a new load (TV, portable heater, cooking appliance, or other) is plugged into the circuit.

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 15

3. REDUCING THE POSSIBILITY OF FIRE IF CONNECTION OVERHEATING OCCURS in aluminum Wired Homes

Overheating connections can get hot enough to ignite fire, if there is an ignitable material nearby. Whether one has a "burned out connection" or a serious fire loss is determined to a great extent by the materials that are near the overheating connection. Removing the easily ignited materials from the vicinity of the aluminum wire connections can substantially reduce the possibility of fire ignition if a connection overheats. This activity is most efficiently done as part of a general inspection for overheating connections (Section 2, above), and should be done with the main power off.

A. INSIDE THE ELECTRICAL ENCLOSURES - homes with Aluminum Electrical Wiring

Wallpaper and wood paneling material are often installed so that they intrude into the wiring device boxes, sometimes in actual contact with the wire terminals. These materials should be cut back beyond the border of the box. Remove all dust, wood chips and splinters, paper material, and other extraneous combustible materials from the receptacle and switch boxes and all other electrical enclosures.

B. COVER PLATES ON RECEPTACLES AND SWITCHES - homes with Aluminum Electrical Wiring

Use metal cover plates on receptacles and switches. Most "decorator" type plastic and wood cover plates ignite relatively easily. Metal cover plates provide better protection and also serve to dissipate the abnormal amount of heat generated by a failing connection inside the box.

C. ADJACENT TO THE RECEPTACLES AND SWITCHES - homes with Aluminum Electrical Wiring

Bedding, furniture, drapes, books, newspapers, and other potential fuels are often found in direct contact with the wiring devices. Remove all combustible materials that are in contact at the face of receptacles and switches, so that there is at least 2" of clearance.

4. IF FIRE OCCURS (from any cause) - homes with Aluminum Electrical Wiring or in Any Home

KNOW WHAT TO DO IF FIRE OCCURS. HAVE A PLAN. DISCUSS IT WITH THE WHOLE FAMILY. SEE YOUR LOCAL FIRE DEPARTMENT FOR GUIDANCE.

INSTALL SMOKE and CO DETECTORS in your home. EARLY WARNING IS VERY IMPORTANT.

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 16 of original document

Aluminum Wiring Repair Articles

- ALUMINUM WIRING IDENTIFICATION

- ALUMINUM WIRING REPAIR METHODS

- ALUMINUM WIRING REPAIR ELECTRICIANS

- ALUMINUM WIRING REPAIRS NOT-RECOMMENDED

- REDUCE THE AL WIRE RISK: DETAILS

...

Continue reading at ALUMINUM WIRING IDENTIFICATION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Suggested citation for this web page

REDUCE THE AL WIRE RISK: DETAILS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] J. Aronstein, "Fire Due to Overheating Aluminum Wired Branch Circuit Connections", Electrical Safety Conference: Electrical Fires; Cause, Prevention, Investigation. University of Wisconsin, Extension, Madison WI, April 7, 1981.

- [2] "National Controlled Study of Relative Risk of Overheating of Aluminum Compared With Copper Wired Electrical Receptacles in Home and Laboratory", Executive Summary. Prepared for U.S. Consumer Product Safety Commission. Report #F-C4812-01, Franklin Research Center, Philadelphia, PA, April 20, 1979.

- [3] R. Newman and W.H. King, Jr., "Pilot Study of Branch Wiring Systems in Montgomery County, Maryland", U.S. Consumer Product Safety Commission, Sept., 1977.

- [4] J. Aronstein, "Summary Report, Study of Overheating of Aluminum-Wired Electrical Receptacles in Scarborough, Toronto, Homes", Wright-Malta Corp., Ballston Spa, NY, January 11, 1982.

- [5] J. Aronstein, "Test of 'Old Technology' Aluminum Wire With Twist-On Connectors", Project Report CPSC-C-79-0079, Task II, For U.S. Consumer Product Safety Commission, Wright-Malta Corp., Ballston Spa, NY, Feb. 24, 1981.

- [6] J. Aronstein, "Overheating Failures of Presently-Listed Aluminum-Wired Connection Combinations Within Rated Service Conditions", Wright-Malta Corp., Ballston Spa, NY, November 23, 1981.

- [7] "The Trouble With Aluminum Wiring", Consumer Reports, January, 1981, p. 42.

- [8] R.L. Hicks, "Pigtail Splicing Connections for Baseboard Heaters and Similar Cyclic Loads", Ontario Hydro Research Division, Report #78-235-K, May 17, 1978, p. 3, (Table 1).

- [9] "Aluminum Building Wire Installation Manual and Design Guide", The Aluminum Association, Inc., Washington, DC. (p. 12 in 1978 Edition).

- [10] J. Aronstein and T.K. Hare, "Evaluation and Analytical Electron Microscopy Investigation of a Plated Aluminum Wire for Branch Circuit Applications", IEEE Transactions: Components, Hybrids, and Mfg. Tech., V. CHMT-11 No. 2, June 1988.

- [11] J. Aronstein, "Evaluation of a Twist-On Connector for Aluminum Wire", Transactions, 43rd IEEE Holm Conference on Electrical Contacts, Philadelphia, 1997

- [12] J. Aronstein, "Analysis of Field Failures of Aluminum-Copper Pigtail Splices Made With Twist-on Connectors", Transactions, 45th IEEE Holm Conference on Electrical Contacts, Pittsburgh, PA, 1999

Reducing the Fire Hazard in Aluminum-Wired Homes Sept. 12, 2000 p. 17

6. BIBLIOGRAPHY: TECHNICAL REPORTS, CONNECTOR PERFORMANCE WITH ALUMINUM WIRE

R. Newman, "Hazard Analysis of Aluminum Wiring", April, 1975, U.S. CPSC, NIIC-0600-75-H006

M. Leger, "Metallurgical Analysis of Failed CO/ALR Devices", Ontario Hydro, #78-54-K, Ontario, Canada, February, 1978

J. Aronstein and W.E. Campbell, "Failure and Overheating of Aluminum-Wired Twist-on Connections", IEEE Trans. Components, Hybrids, and Mfg. Tech., V. CHMT-5 No.1, March 1982

J. Aronstein, "Tests of 'Old Technology' Aluminum Wire at Special Crimp Type Compression Connectors" (Amp COPALUM), Wright-Malta Corp. Project Report CPSC-C-79-0079 Task III, U.S. Consumer Product Safety Commission, Washington, DC, Feb. 5, 1983

J. Aronstein, "Tests of 'Old Technology' Aluminum Wire", Wright-Malta Corp. Project Report CPSC-C-81-1418, U.S. Consumer Product Safety Commission, Washington, DC, Feb. 10, 1983

J. Aronstein and W.E. Campbell, "Overheating Failures of Aluminum-Wired Special Service Connectors", IEEE Trans. Components, Hybrids, and Mfg. Tech., V. CHMT-6 No. 1, Mar. 1983

J. Aronstein and W.E. Campbell, "The Influence of Corrosion Inhibitor and Surface Abrasion on the Failure of Aluminum-Wired Twist-On Connections", IEEE Trans. Components, Hybrids, and Mfg. Tech., V. CHMT-7 No. 1, Mar. 1984

J. Aronstein and W.E. Campbell, "Evaluation of an Aluminum Conductor Material for Branch Circuit Applications", IEEE Trans. Components, Hybrids, and Mfg. Tech., V. CHMT-8 No. 1, Mar. 1985

R. Schubert, "Erratic Behavior of Al/Al Wire Junctions", Electrical Contacts - 1986, Proceedings of the 32nd IEEE Holm Conference on Electrical Contacts, Boston, 1986.

[Following added 3/5/2003 at Dr. Aronstein's suggestion, not part of original article -- DJF]

J. Aronstein, "Evaluation of a Twist-on Connector for Aluminum Wire", Forty-Third IEEE Holm Conference on Electrical Contacts, Jan 1997, 0-7803-3968-1/97. [This article describes the Ideal Industries Ideal#65 purple "Twister" twist-on connector marketed as a repair/retrofit for residential aluminum wiring .--DJF]

Abstract: A new type of twist-on splicing component for use with aluminum and copper wire combinations is tested to determine initial resistance, performance in a zero-current environment test, performance in a heat-cycle test, and portion of current carried by the connector's steel spring.

The splices tested consist of two aluminum wires and one copper wire. The aluminum wire samples used for the test are of the types actually installed in aluminum-wired homes. Initial resistance is found to be relatively high, and there is a significant sample-to-sample variation.

This reflects failure to consistently establish low-resistance wire-to-wire contact Through the insulating oxide film on the wire. Results of the environmental and heat-cycle tests show deterioration of a significant portion of the samples. The splices made with this connector are also found to be sensitive to mechanical disturbance, such as applied in normal installation when the completed splice is pushed back in to the junction box.

Based on the test results, it is concluded that this connector has not overcome the fundamental deficiency of twist-on connectors for use with aluminum wire applications. Keywords: aluminum wire, connectors, twist-on connectors, environmental test, heat-cycle test.

The Aluminum Wiring Information Website Aluminum Wiring Hazards and Repairs: in-depth info, photos, documents. Main Page.

The Aluminum Wiring Information Website Aluminum Wiring Hazards and Repairs: in-depth info, photos, documents. Main Page.- The Aluminum Electrical Wiring Hazard Explained (in the document you are presently viewing)ALUMINUM WIRE REPAIR METHODS to reduce risk in buildings with Aluminum Electrical Wiring - Overview of Acceptable Repair Practices (in the document you are presently viewing)Aluminum Wire Repair Method Details - "How to" details, how to identify, COPALUM repair, alternative repairs, history, products, research, source of special AMP TYCO COPALUM connectors & COPALUM Electricians (in the document you are presently viewing)COPALUM Electricians: Sources of TYCO COPALUM -Certified/Trained Aluminum Wire Repair Services (in the document you are presently viewing)

- ALUMINUM WIRING REPAIR, Other Products, Ideal 65 Purple Twister (not recommended), & other Aluminum Wire Products/Articles (in the document you are presently viewing)

- The Aluminum Wiring Bibliography: extensive resources on Aluminum Wiring

- Aluminum Wire Failure Reports & Photos: Real life aluminum wiring field failure reports can be seen at InspectAPedia.com/aluminum/Aluminum_Wiring_Failure_Reports.php

- Reducing the Fire Hazards in Aluminum-Wired Homes, Jess Aronstein, Ph.D., This document answers most technical questions about the hazards and remedies of aluminum electrical wiring. Some of the sections of this very thorough document are listed below:

- Fire Hazards With Aluminum to Copper Twist-on Connectors & Acceptable Aluminum Wiring Repair Practices Color Photos, Current Issues. 9/28/95 CPSC Meeting Minutes

- "Is YOUR Aluminum Wiring Safe?" article discussing safety claims made by some people without looking at the wiring, J. Aronstein, 11/21/95

- REPAIRING ALUMINUM WIRING, US CPSC Pub. No. 516 U.S. Consumer Product Safety Commission Publication available online

- FAQs on author/website credibility

- 12/1995 - PC Computing Magazine: Names this website as among the "Best 1001 Internet Sites." See the Engineering category, p. 146.

- Starting Point: named this website as a key Internet resource page as a Starting Point Hot Site

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.