Repairing Aluminum Wiring - US Consumer Product Safety Commission (CPSC) Publication #516

Repairing Aluminum Wiring - US Consumer Product Safety Commission (CPSC) Publication #516

- POST a QUESTION or COMMENT about the US CPSC recommendations for repairing aluminum electrical wiring in homes

Repairing Aluminum Wiring - US CPSC Publication 516:

US CPSC Publication No. 516 - CPSC #516 - How to repair aluminum electrical wiring in homes - advice from the U.S. Consumer Product Safety Commission. How to recognize unsafe aluminum electrical wiring; how to make pigtail connections to improve the safety of aluminum wire connections - what are the proper aluminum wire connectors to use?

This is an illustrated version of the original U.S. CPSC aluminum wiring repair document explaining the hazard of solid conductor aluminum electrical circuit wiring, and recommending the use of the AMP TYCO COPALUM special crimp connector to pigtail copper to the aluminum wires as an alternative to complete re-wiring of the building.

Also included here: a history of the aluminum electrical wiring fire hazard in North America.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Aluminum Wiring

[the history of aluminum electrical wiring and the aluminum branch circuit wire fire hazard]

[the history of aluminum electrical wiring and the aluminum branch circuit wire fire hazard]

US CPSC Publication No. 516 - CPSC #516 - How to repair aluminum electrical wiring in homes - advice from the U.S. Consumer Product Safety Commission. How to recognize unsafe aluminum electrical wiring; how to make pigtail connections to improve the safety of aluminum wire connections - what are the proper aluminum wire connectors to use?

This document was scanned from the original CPSC document explaining how to recognize the presence of an aluminum wiring hazard and how to repair aluminum wiring.

Article Contents

- ALUMINUM WIRING - the History and the Aluminum Wire Fire Hazard

- TROUBLE SIGNS of Overheating Aluminum Wiring

- WHAT THE HOMEOWNER CAN DO to Repair Unsafe Aluminum Electrical Wiring

- CAN THE ALUMINUM WIRING PROBLEM BE FIXED? - Yes

- THE CPSC RECOMMENDED ALUMINUM WIRING REPAIR METHOD: AMP TYCO COPALUM Crimp Connector Repair

- AlumiConn ALUMINUM WIRE CONNECTORS - recommended by the US CPSC for aluminum wiring repair

- ALUMINUM WIRING "REPAIR" METHODS NOT RECOMMENDED by the US CPSC

- WARNING ABOUT OTHER WIRE CONNECTORS, Crimp Connectors and Aluminum Wiring

- THE AMP TYCOCOPALUM CRIMP METHOD OF REPAIR for Aluminum Wiring in buildings

- HOW THE AMP TYCOCOPALUM CRIMP METHOD WORKS to Repair Aluminum to Copper Connections

- HOW TO USE THE AMP COPALUM CRIMPING PROCEDURE to Make an Aluminum to Copper Pigtail Connection

- CPSC RESIDENT POSTS - CPSC Contact Information

[Click to enlarge any image]

Edits or comments by Daniel Friedman, added for clarification, update, or to provide links to current sources of the AMP COPALUM Connector equipment and specifications are included in this document in [italicized brackets.]

For in-depth information about the aluminum wiring hazard and for description of alternative repair methods when the methods recommended here are not available, see More Information below.

Readers are welcome to make and freely distribute printed copies of this article.

For the latest US CPSC publication on aluminum electrical wiring in printable PDF format see Aluminum Wiring - CPSC Publication #516-PDF.

U.S. Consumer Product Safety Commission Aluminum Wiring Repair Recommendations

U.S. Consumer Product Safety Commission Washington DC 20207

On April, 28,1974, two persons died in a home fire in Hampton Bays, New York. Fire officials determined that the fire was caused by a faulty aluminum wire connection at an outlet.

Since that tragic accident, the U.S. Consumer Product Safety Commission staff and other government officials have investigated numerous complaints from homeowners throughout the nation who have had trouble with small gauge aluminum branch circuit wiring.

The Commission has also had research conducted that shows that homes wired with aluminum wire manufactured before 1972 ("old technology" aluminum wire) are 55 times more likely to have one or more connections reach "Fire Hazard Conditions" than is a home wired with copper.

The hazard investigated by the Commission staff occurs at connections to old technology aluminum wire, such as at outlets or switches or at major appliances such as dishwashers, furnaces, etc. Corrosion of the metals in the connection, particularly the aluminum wire itself, causes increased resistance to the flow of electric current and that resistance causes overheating.

Homes built before 1965 are unlikely to have aluminum branch circuit wiring. Homes built, rooms added, and circuits rewired or added between 1965 and 1973 may contain aluminum wiring.

In 1972, manufacturers modified both aluminum wire and switches and outlets to improve the performance of aluminum wired connections. Sale of the old style wire, switches and outlets still on dealers' shelves however, continued after 1972.

TROUBLE SIGNS [of overheating aluminum wiring]

Signs of trouble in aluminum wire systems include warm-to-the- touch face plates on outlets or switches, flickering lights, circuits that don't work, or the smell of burning plastic at outlets or switches.

Unfortunately, not all failing aluminum wired connections provide such easily detected warning signs; aluminum wired connections have been reported to fail without any prior indications or problems.

1 The survey conducted by the Franklin Research Institute defined "Fire Hazard Conditions" to occur when receptacle cover plate mounting screws reached 149~C (3O0~F), or sparks were emitted from the receptacle, or materials around the receptacle were charred.

WHAT THE HOMEOWNER CAN DO [to repair unsafe aluminum electrical wiring ]

If you have noticed any of the trouble signs, have a qualified electrician determine whether the problem is caused by deteriorating connections to aluminum wiring. DO NOT TRY TO DO IT YOURSELF. You could be electrocuted or you could make the connections worse by disturbing them. If you are not certain whether your home has aluminum branch circuit wiring, you may be able to tell by looking at the markings on the surface of The electric cables which are visible in unfinished basements, attics or garages.

Aluminum wiring will have "Al" or "Aluminum" marked every few feet along the length of the cable. (Note - The marking "CU-clad" or "Copper-clad" in addition to the "Al" or "Aluminum" means that the cable uses copper-coated aluminum wire and is not covered by this message.)

If you do have aluminum branch circuit wiring, the Commission suggests that you have a qualified electrician check the system for impending trouble. Remember, you may not have noticed any of the warning signs, but research shows that trouble may develop over time and an electrician may spot potential problems before you notice them.

CAN THE [aluminum wiring] PROBLEM BE FIXED?

One method of eliminating the risks associated with old technology aluminum wiring terminations is to eliminate the primary cause: the aluminum wire itself. Depending upon the architectural style of your home and the number and locations of unfinished spaces (e.g., basements and attics), it may be relatively easy to rewire your home.

A new copper wire branch circuit system would be installed, and the existing aluminum wire would be abandoned inside the walls. This is the most expensive method of repairing an aluminum wired home; but if you can afford the cost, it is also the best method available.

Since it may be impractical to rewire some types of aluminum wired homes (e.g., condominium units), or since rewiring may be prohibitively expensive for some homes (e.g., split-levels with no unfinished areas), the Commission staff attempted to find a repair method which would permit the continued use of existing old technology aluminum wire. The main criteria to be met by such a repair method are:

- It must permit the repair of every connection to, or splice between, aluminum wire in the home;

- The repaired connections must be permanent but must result in a system that can be maintained without the need for special switches, wall outlets or other connectors;

- The repair technique must be practical for use in an occupied and furnished home.

- The CPSC-sponsored research, laboratory tests, and demonstration projects identified only one method of repairing existing aluminum wire circuits which meet these criteria. That repair is known as the crimp connector repair.

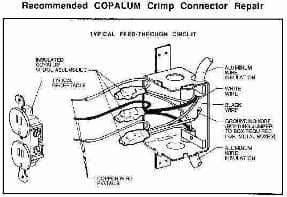

- The crimp connector repair consists of attaching a piece of copper wire to the existing aluminum wire branch circuit with a specially designed metal sleeve and powered crimping tool. The metal sleeve is called a COPALUM parallel splice connector and is manufactured only by AMP Incorporated. This special connector can be properly installed only with the matching AMP tool. This tool makes a permanent connection that is, in effect, a cold weld. An insulating sleeve is placed around the crimp connector to complete the repair.

The CPSC Recommended Aluminum Wiring Repair Method: [AMP TYCO] COPALUM Crimp Connector Repair

[Aluminum Wiring "Repair" Methods NOT Recommended by the US CPSC]

Two other repair methods are often recommended by electricians. While these repair methods are substantially less expensive than COPALUM crimp connectors, neither of these repairs is considered acceptable by the Commission staff.

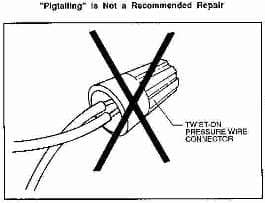

- The first repair ("pigtailing") involves attaching a short piece of

copper wire to the aluminum wire with a twist-on connector sometimes

called a wire nut; the copper wire is connected to the switch, wall outlet

or other termination device.

The Commission staff has evaluated the effectiveness of "pigtailing" as a repair. In OPSO-sponsored laboratory testing some brands of twist-on connectors have performed very poorly.

Over time, substantial numbers of these connectors have overheated in laboratory tests. Surveys of and statements made by electricians and electrical inspectors confirm the highly variable and often poor performance of these connectors when used with old technology aluminum wire. It is possible that some pigtailing "repairs" made with twist-on connectors may be even more prone to failure than the original aluminum wire connections.

Accordingly, the Commission staff believes that this method of repair does not solve the problem of overheating present in aluminum branch circuits."Pigtailing' Is Not a Recommended Repair

- The other repair recommended by the industry uses switches and

outlets labeled "COALR".

Underwriters Laboratories Inc. (UL) lists these devices especially for use with aluminum wire, although they can be used with copper or copper-clad wire. CO/ALR devices perform better with aluminum wire when installed carefully and according to best electrical practices than do the types of switches and outlets usually used in the original installations of old technology aluminum branch circuit wiring.

However, CO/ALP connectors are not available for all pat of the wiring system (for example, for permanently-wired appliances and ceiling mounted light fixtures). In the opinion of the Commission staff CO/ALR devices must be considered to be, at best, an incomplete repair. Further, CO/ALP wiring devices have failed in laboratory tests when connected to aluminum wire typical of that installed in existing homes. The test conditions simulated actual use conditions; no "overstress" type of testing was used.Exception: If you have an aluminum wire termination in your home which exhibits symptoms of failure, twist-on connector pigtails or CO/ALR devices may be used as an emergency temporary repair for a failed aluminum termination.

Should such a repair be performed, the Commission staff recommends that you arrange to have your home rewired or the COPALUM crimp connector repair performed as soon as possible.It is important to note that there is only one manufacturer of the special connectors and the tools required to make the repairs as recommended by the CPSC staff.

WARNING [about other wire connectors and crimp connectors and aluminum wiring ]

There are many other brands and types of crimp connectors - including those intended to be installed with a pliers type of hand tool - which are readily available to consumers at hardware stores, lumber yards, hobby supply stores, automotive supply stores, and so forth.

THE COMMISSION STAFF DOES NOT BELIEVE THAT THESE COMMON VARIETIES OF CRIMP CONNECTORS CAN BE USED TO RELIABLY REPAIR ALUMINUM WIRING.

THE [AMP TYCO]COPALUM CRIMP METHOD OF REPAIR [for aluminum wiring in buildings]

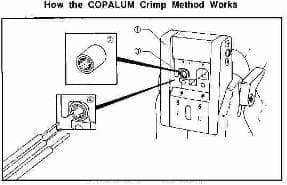

The precision dies in the COPALUM tool squeeze the connector and wires into a particular shape which was determined during the design of the COPALUM wire connector. Both the final shape of the connection and the amount that it is squeezed (deformed during crimping) are critical in making a reliable crimp connection. Upwards of 10,000 pounds of force is necessary to obtain the amount of deformation for which the connector is designed.

In addition, electricians who are authorized to install COPALUM connectors are thoroughly trained by the manufacturer to use the tool properly. The Commission staff emphasizes that this training is necessary to assure that the electrician uses the careful, professional workmanship required to make the crimp connector repair safe and reliable.

How the [AMP TYCO]COPALUM Crimp Method Works

[How to Use The AMP COPALUM] CRIMPING PROCEDURE

Follow the procedure below with attention given to steps 1 thru 4.

(1) Use the correct tool and dies (recommended by the AMP field representative) for the splice being crimped. Ensure that the color coding and marking designation on the splice correspond to the color coding and marking designation on the tool.

(2) Be sure the perforated liner is inside the splice. The ends of the liner are flared to prevent removal.

(3) Load the splice into the dies of the tool.

(4) Insert stripped wires into the splice until the ends of wires extend beyond end of the splice. Wires should be parallel in the splice. Insulation of the wire MUST NOT ENTER the splice.

You should request a copy of AMP literature from your electrician prior to his beginning work. Discuss with your electrician any information in the literature which you do not understand. Remember, every connection of aluminum-to-aluminum or aluminum-to-copper wire in your home should be repaired in order to obtain the maximum benefit from such repair work.

All appliances connected directly to #12 or #10 AWG aluminum branch circuit wiring (for example, dishwashers, cooking equipment, heaters, air conditioners and light fixtures) must be repaired in addition to wall outlets, switches, junction boxes and panel boxes.

To determine whether the COPALUM crimp connection method of repair is available in your area, you may wish to write or call the manufacturer of the COPALUM connector for a list of authorized electricians who are doing aluminum branch circuit repair work in your area. You may write to:

[DJF NOTE: the following address which appears in CPSC #516 is OBSOLETE]

AMP Incorporated

Att: Aluminum Wire Repair Program

Mail Stop 140-13

P.O. Box 3608

Harrisburg, PA 17105-3608

PHONE: 1-800-522-6752

[15 January 2008 DJF note: We add the following update and detail to this US CPSC document: Consumers and electricians may have difficulty obtaining further information, advice, or equipment from AMP or the successor distributor, TYCO, for the COPALUM connector and aluminum wiring repair.

Consumers and electricians needing to evaluate or repair aluminum wiring should see

REDUCING THE FIRE HAZARDS IN ALUMINUM-WIRED HOMES,

details of the hazard of and what to do about aluminum wiring, aluminum wiring repair methods, aluminum wiring failures research, field and lab experience, expert sources.

This document answers most technical questions about the hazards and remedies of aluminum electrical wiring.

[DJF NOTE: ] Consumers or electricians looking for access to the "AMP" COPALUM connectors and special crimping tool should contact Tyco Electronics:

See Tyco Electronics for access to the

COPALUM Connectors and Heat Shrink Tubing System or

General Information about the AMP COPALUM [DJF NOTE 01/15/2008: now TYCO COPALUM] Connectors and Tooling

The reconnection of old technology aluminum wire is fast and efficient with AMP COPALUM connectors and tooling.]

The Commission staff wishes to remind you that all modifications and additions to your wiring system should be done in accordance with local regulations and inspected by municipal authorities. You should insist that repairs to your aluminum wiring be inspected.

[DJF note: Consumers should make certain that their electrical inspector or electrician is fully familiar with the hazards of aluminum electrical wiring, and fully trained in proper repair methods for aluminum wiring. Improper repairs using improper devices or equipment, or incomplete repairs, such as failure to address every connection in the building, or using non-recommended parts and devices, may actually increase the risk of a fire or loss.]

7 Elements of Key Aluminum Wiring Repair Advice Home Inspectors Should Give to their Clients

The following advice is excerpted from ALUMINUM WIRING GUIDE for HOME INSPECTORS and was not part of the original US CPSC document.

- Watch out: Aluminum Electrical Wiring is a Fire Hazard in Homes -

see ALUMINUM WIRING SAFETY ASSESSMENT - CPSC.

For help in recognizing aluminum electrical wiring in homes

see ALUMINUM WIRING IDENTIFICATION. - Aluminum Electrical Wiring repairs in a home where that work has not been performed will be a significant expense

- Aluminum wiring repairs should not be deferred, as the risk increases with age and use of the electrical system; meanwhile be sure that the home has working smoke detectors, and turn off any circuits behaving oddly.

- Aluminum wiring repairs should be performed only by a licensed electrician who is well informed about the correct repair methods. Using an improper repair method may actually increase the risk of a fire.

See ALUMINUM WIRING REPAIR ELECTRICIANS - Do use one of the following aluminum wiring repair methods:

- Do not use any of these aluminum wiring repair methods

- COALR or CU-AL devices -

See ALUMINUM WIRING REPAIR COALR & CU-AL - Twist-on connectors such as the Ideal-65 purple "twister" -

See ALUMINUM WIRING REPAIRS NOT-RECOMMENDED

- COALR or CU-AL devices -

- Feel free to copy and place this ALUMINUM WIRIING SUMMARY free to copy page at your website or to make printed copies to give to consumers at no charge

...

Continue reading at ALUMINUM WIRING REPAIR METHODS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ALUMINUM-WIRED HOMES, REDUCE THE HAZARD - PDF

- ALUMINUM WIRING GUIDE for HOME INSPECTORS

- ALUMINUM WIRING IDENTIFICATION

- ALUMINUM WIRING REPAIR METHODS - home

- ALUMINUM WIRING REPAIR ELECTRICIANS

- ALUMINUM WIRING REPAIR METHODS - CPSC Meeting 9/28/95

- ALUMINUM WIRING REPAIRS NOT-RECOMMENDED

- REDUCE THE AL WIRE RISK: DETAILS

Suggested citation for this web page

REPAIRING ALUMINUM WIRING, US CPSC Pub. No. 516 at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- U.S. Consumer Product Safety Commission

Washington, D.C. 20207

TOLL FREE HOTLINE: 800-638-CPSC OR 800-638-2772

TTY (INCLUDING ALASKA AND HAWAII) 800-638-8270

TTY MARYLAND ONLY 8O0-492-8104

US CPSC REGIONAL OFFICE ADDRESSES

CENTRAL REGIONAL CENTEr

230 SOUTH DEARBORN ST.

ROOM 2944

CHICAGO, IL 60604

(312) 353-8260

EASTERN REGIONAL CENTER 6 WORLD TRADE CENTEr

VESEY STREET, 3RD FLOOr

NEW YORK, NY 10048

(212) 264-1125

[DJF NOTE: this address is OBSOLETE]

WESTERN REGiONAL CENTEr

555 BATTERY STREET

ROOM 415

SAN FRANCISCO, CA 94111

(415) 556-1816 - [1]AlumiConn [Website: AlCopStore.com ] ™ AlCopStore.com

223 Salt Lick Road, #279,

St. Peters, MO 63376

Tel: 866-826-2256, Fax: 636-754-0500, Email Sales: pking@AlCopStore.com, Email General Inquiry: info@AlCopStore.com - [2] "Repairing Aluminum Wiring," [As updated 2011] U.S. Consumer Product Safety Commission Publication available online

- [3] "Record of Commission Action, Commissioners Voting by Ballot", CPSC Publication No. 516, Repairing Aluminum Wiring (original version op.cit.), (Briefing package dated March 15, 2011), Quoting:

The Commission voted unanimously (5-0)·to approve republication of CPSC Publication No. 516, Repairing Aluminum Wiring, with the explicit recognition that the COPALUM and AlumiConn connectors currently are the only products that meet the agency's standards to prevent aluminum wire fire hazards

Copy on file as /aluminum/Pub516_Alumi_Conn.pdf - [4] Dr. Jess Aronstein, protune@aol.com is a research consultant and an electrical engineer in Schenectady, NY. Dr. Aronstein provides forensic engineering services and independent laboratory testing for various agencies. Dr. Aronstein has published widely on and has designed and conducted tests on aluminum wiring failures, Federal Pacific Stab-Lok electrical equipment, and numerous electrical products and hazards. See ALUMINUM WIRING BIBLIOGRAPHY and see FPE HAZARD ARTICLES, STUDIES for examples.

- [5] "The Influence of Corrosion Inhibitor and Surface Abrasion on the Failure of Aluminum-Wired Twist-on Connections", Aronstein, J.; Campbell, W., Components, Hybrids, and Manufacturing Technology, IEEE Transactions on Volume 7, Issue 1, Mar 1984 Page(s): 20 - 24

- Reducing the Fire Hazards in Aluminum-Wired Homes, [.PDF document], Jess Aronstein, Ph.D., 21 May 2007. This document answers most technical questions about the hazards and remedies of aluminum electrical wiring and includes a report on independent test results of alternative products and methods for repairing aluminum wiring. Some of the sections of this very thorough document are listed below:

- HOW TO REDUCE THE RISK of aluminum electrical wiring in buildings

- ALUMINUM WIRING REPAIR ELECTRICIANS specializing in aluminum wiring repairs

- ALUMINUM WIRING REPAIR, Other Products for aluminum wiring, ones that work, or don't

- DETAILED EXPLANATION of the aluminum electrical wiring hazard

The Aluminum Wiring Information WebsiteAluminum Wiring Hazards and Repairs: in-depth info, photos, documents.

The Aluminum Wiring Information WebsiteAluminum Wiring Hazards and Repairs: in-depth info, photos, documents.- Recognizing Aluminum Wiring photos and tips

- Reducing the Fire Hazards in Aluminum-Wired Homes, details of the hazard of and what to do about aluminum wiring, aluminum wiring repair methods, aluminum wiring failures research, field and lab experience, expert sources. This document answers most technical questions about the hazards and remedies of aluminum electrical wiring. UPDATED 3/5/2003, Edits-df 12/05/2005

- Aluminum wiring failure reports from existing installations. 7/14/2004

- Fire Hazards With Aluminum to Copper Twist-on Connectors & Acceptable Aluminum Wiring Repair Practices Color Photos, Alternative Retrofit/Repair Procedures, Current Issues. 9/28/95 CPSC Meeting Minutes

- "Is YOUR Aluminum Wiring Safe?" article discussing safety claims made without looking at the wiring, J. Aronstein, 11/21/95

- REPAIRING ALUMINUM WIRING, US CPSC Pub. No. 516 U.S. Consumer Product Safety Commission Publication CPSC#516

- AMP COPALUM CONNECTOR - this one works and is US CPSC-recommended for Aluminum Wiring Pigtailing Repairs

- Jan 2005 - Tyco Electronics website provides information about the AMP COPALUM connector program

- 1 May 2003 - U.S. CPSC announced that Tyco Electronics Corp. will continue offering the COPALUM connector repair system until at least 2005 - for details see the Tyco Press Release.

- AMP Corporation, Harrisburg PA 17105 800-522-6752 - CPSC's recommended COPALUM aluminum-copper retrofit - US Customer Support 800-522-6752 [See the TYCO announcement above]

- AMP Canada Product Information Department, 905-470-4425 the COPALUM connector line is available in Canada; they do not appear to have a contractor training/certification program such as is (at least in a few places) available in the USA.

- Jan 2005 - AMP COPALUM Connectors & Equipment Source for at Tyco Electronics

- CPSC RESIDENT POSTS [CPSC Contact Information]

BOSTON, MASSACHUSETTS, BRIDGEPORT, CONNECTICUT, BUFFALO, NEW YORK, CHARLOTTE, NORTH CAROLINA, CINCINNATI, OHIO, CLEVELAND, OHIO, DENVER. COLORADO, DETROIT, MICHIGAN, HONOLULU, HAWAII, HOUSTON, TEXAS, INDIANAPOLIS, INDIANA, KANSAS CITY, MISSOURI, LOS ANGELES, CALIFORNIA, FT. LAUDERDALE, FLORIDA, MILWAUKEE, WISCONSIN, NEW ORLEANS, LOUISIANA, ORLANDO, FLORIDA, PHILADELPHIA, PENNSYLVANIA, PHOENIX, ARIZONA, PITTSBURGH, PENNSYLVANIA, PORTLAND, OREGON, ROCKVILLE, MARYLAND, SAN JUAN, PUERTO RICO, SEATTLE, WASHINGTON, ST. LOUIS, MISSOURI, ST. PAUL, MINNESOTA, TULSA, OKLAHOMA

THE U.S. CONSUMER PRODUCT SAFETY COMMISSION (CPSC) IS AN INDEPENDENT REGULATORY AGENCY CHARGED WITH REDUCING UNREASONABLE RISKS OF INUURY ASSOCIATED WITH CONSUMER PRODUCTS. THE U.S. CONSUMER PRODUCT SAFETY COMMISSION IS HEADED BY FIVE COMMISSIONERS APPOINTED BY ThE PRESIDENT WITH THE ADVICE AND CONSENT OF THE SENATE - Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.