Outdoor Compressor Condenser Unit Diagnosis

Outdoor Compressor Condenser Unit Diagnosis

9 Steps to Diagnose / Fix an A/C or Heat Pump

Condenser Unit that's not running

- POST a QUESTION or COMMENT about air conditioner or heat pump outdoor compressor diagnosis & repair

This article summarizes common HVAC compressor condenser unit problems and their diagnosis.

For each diagnostic topic or step, we include links to more detailed HVAC compressor diagnostic and repair procedures.

Here we give troubleshooting tips for an air conditioning or heat pump compressor/condenser unit that:

- won't start

- is noisy

- cycles on and off too often

- won't stop running

- won't cool

- makes odd noises such as clicking or humming

Page top photo: the outdoor compressor/condenser unit for a split system air conditioner at a New York building.

This article forms part of our extensive series on how to diagnose an air conditioner or heat pump that is not cooling.

Also see our RECOMMENDED ARTICLES list at the bottom of this page.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Air Conditioner / Heat Pump Compressor Troubleshooting Steps

If your air conditioner or heat pump won't start, we suggest beginning diagnostics indoors at the room thermostat.

If the thermostat is not calling for cooling (or in heating mode, for a heat pump, if the thermostat is not calling for heat), then, of course, the compressor unit won't start because it's not being asked to do anything.

So if you haven't already checked your thermostat and the indoor air handler unit,

see AIR CONDITIONER WON'T START

Continuing below we give step by step diagnostics for non-starting compressor motors at the outdoor condenser unit.

Photo above: this 25 year old outdoor compressor condenser unit was so rusty that we were surprised to find it in perfect operating condition. Age alone is not a reason to condemn HVAC equipment.

Article Contents

- Step 1: RECOGNIZE & FIND THE OUTDOOR A/C COMPRESSOR/CONDENSER

- Step 2: IS THE COMPRESSOR/CONDENSER TURNED ON?

- Step 3: LISTEN: IS THE COMPRESSOR/CONDENSER MAKING ODD NOISES

- Step 4: THE COMPRESSOR/CONDENSER RUNS BUT DOESN'T PRODUCE COOL AIR (or HEAT in HEATING MODE)

- Step 5: THE COMPRESSOR/CONDENSER RUNS TOO LONG or NEVER SHUTS OFF

- Step 6: THE COMPRESSOR/CONDENSER TURNS ON & OFF TOO FREQUENTLY

- Step 7: BASIC ELECTRICAL CHECKS, VOLTS & AMPS

- Step 8: ABNORMAL REFRIGERANT PRESSURES

- Step 9: COMPRESSOR/CONDENSER MOTOR OVERHEATS

Step 1: Find the Outside Air Conditioning /Heat Pump Compressor-Condenser unit

While a trained HVAC technician is needed for most air conditioner or heat pump repairs, even an untrained building owner or occupant can easily make a first pass at troubleshooting this equipment.

Basic steps like checking your thermostat or making sure that electrical switches to the equipment are all ON can save you both the cost of a service call and a bit of embarrassment.

Other steps that we'll describe will need to be performed by an expert, but you might still want a basic understanding of what she or he is going to need to do, so we describe those procedures too.

But before we can look at the compressor/condenser for signs of trouble, of course we need to know what the equipment looks like and where it will be found. Then we can check its controls or listen to it for signs of trouble such as total silence, or odd noises.

Watch out: for tipping HVAC compressor/condenser units like that shown above whose support pad has settled over time, refrigerant leaks can lead to loss of cooling.

The indoor air handler fan/blower unit that distributes air through supply registers into the occupied rooms is described separately

at AIR HANDLER / BLOWER UNITS.

If you don't know what the outdoor compressor/condenser unit looks like, check the photos above and below on this page, and also

see details at COMPRESSOR & CONDENSING COIL.

If you're not sure where to find the compressor/condenser unit for your air conditioning or heat pump system, take a look at the photos just above (a conventional compressor/condenser unit) and at the top of this page (a split-system compressor/condenser unit).

Then walk around the building exterior to search for a similar piece of equipment outside your building. Most installers place the compressor/condenser unit close to a building side or back wall.

On multi-story buildings, the outdoor "condenser unit" might be mounted on a platform hung higher on a building wall like our photo (below) of A/C compressor-condenser units on a building in Buenos Aires, Argentina, or the unit may be found placed on a rooftop or balcony.

If you are troubleshooting a window mounted air conditioner, also called a "room air conditioner " like those shown in our photo below,

...

Step 2: Does The A/C or Heat Pump Turn ON?

Above: an example of the service switch mounted next to an A/C compressor/condenser unit that sits on the lower roof of a two-story building in New York. I've circled the switch in red.

This outdoor "service switch" is used to turn off the equipment when necessary such as during repair work. The service switch may be a fuse pull-out, lever, or a circuit breaker, must be readily accessible and line-of-sight visible from the equipment that it is protecting.

Assuming that your thermostat is calling for cooling (in hot weather) or heating (if you have a heat pump and are in the heating season), is the outdoor compressor-fan unit running at all?

If not, be sure that the outdoor compressor/condenser unit service switch (shown above) and the air conditioner indoor power switch, fuse, or circuit breaker are all in the "on" position.

Check the outside compressor condensing coil for damage or blockage.

A blocked condensing coil can cause the compressor to overheat, stop running, or become noisy and work poorly.

If you cannot find your air conditioner controls and switches

see A/C - HEAT PUMP CONTROLS & SWITCHES - list of controls and switches found on air conditioners and heat pumps

...

Step 3: Is the compressor motor or fan making a funny noise?

Is the condenser unit motor or fan motor humming, chattering, clicking, or making other strange noises?

If so, see COMPRESSOR CONDENSER NOISES which are part of our more complete

article HVAC SYSTEM NOISE DIAGNOSIS - home - where we describe every known type of A/C noise or sound and give possible causes for each.

Some of these noises are traced to the cooling fan or to a failing compressor motor or to a bad contactor or relay switch.

For condensing unit fan diagnostics

see FAN, COMPRESSOR / CONDENSER UNIT where we explain the diagnosis of problems with the compressor/condenser fan and fan motor. For example, a ticking or clicking noise might be traced to a loose fan blade or even something as simple as a twig that has fallen into the condenser unit, while humming might mean that a motor can't start or has failed.

Also see ELECTRIC MOTOR DIAGNOSTIC GUIDE where we provide diagnostic steps for electric motors that can be used to check a fan or compressor motor.

At BURNED-OUT COMPRESSOR we explain that if the condensing unit fan is not working, the compressor itself may shut down or even be ruined by overpressure or over temperature.

Also see these COMPRESSOR / CONDENSER UNIT NOISE FAQs

...

Step 4: A/C or Heat Pump Runs but Doesn't Cool or Heat

Do the compressor and fan run but cooling capacity is insufficient or supply air not cool enough?

What is the "Cooling Capacity" of the Air Conditioning Equipment?

The cooling capacity of the air conditioning equipment refers to the ability of the compressor/condenser (usually outside) and the air handler/evaporator (usually inside) to deliver cool air to the occupied space.

Briefly, the compressor/condenser draws refrigerant gas from the building air handler, compresses it and cools it back to a liquid refrigerant, and the air handler/evaporator coil permits liquid refrigerant to evaporate inside a cooling coil, across which the fan blows building air to cool and dehumidify it.

The particular

combination of this equipment has a cooling capacity, usually rated in BTUh or thousands of BTU's of cooling capacity per hour,

documented on equipment data tags discussed

at RATED COOLING CAPACITY.

Also see COOLING RULES OF THUMB to guesstimate how many tons or BTUs of cooling a building needs.

...

Step 5: Long A/C Condenser Unit On-Cycles

Air conditioner or heat pump long on-cycles, usually meaning that the system is providing insufficient cooling, are often caused by loose or worn compressors.

Problems such as an aging air conditioner compressor motor that is at or near the end of its life may be unable to properly compress the returning refrigerant gas to a sufficiently high pressure.

A service technician will need to evaluate and test the system and if needed, replace the compressor.

But here we outline, for both HVAC technicians and building owners or occupants, the basic questions to ask and steps to take to troubleshoot an air conditioner or heat pump compressor that is not working.

Since this is a costly repair, be sure to ask why the compressor failed and to correct any underlying cause (such as low voltage).

A Longer than Normal on A/C or Heat Pump Cycle May Be Due To:

- An inefficient or damaged air conditioning compressor

- Low voltage to the equipment

- Improper refrigerant charge (so cooling coil is not sufficiently cool)

- A compressor that has lost its ability to "compress" the refrigerant due to internal wear.

This condition can be diagnosed by an air conditioning service technician who will install air conditioning manifold gauges onto the system to check the compressor suction vacuum and discharge or "high side" output pressure.

If gauge ports are not installed on the air conditioner compressor unit, the technician cannot make this test without cutting the refrigerant lines to install gauge ports (adding to the cost of this diagnosis). - Blocked or lost air flow due to a variety of causes (dirty filter, damaged or leaky ductwork) that fails to deliver enough cool air to satisfy the thermostat

- Abnormal heat gain in the building (open windows, air leaks, unusual weather) so that the A/C or heat pump cannot satisfy the thermostat

- Very low thermostat settings: if the thermostat is set too low, the cooling system may not be able to bring the building down to that temperature

- More diagnostic help for long cooling system on-cycles is

at LOST COOLING CAPACITY

See our detailed diagnosis and repair steps given

at LONG-ON CYCLING AC COMPRESSOR.

A compressor which appears to have lost cooling capacity

can be diagnosed by a service technician who can connect the appropriate test gauges to the system. Lower than normal discharge pressure and higher than normal suction vacuum will indicate this problem.

But before assuming that something is wrong with the air conditioning compressor,

some basic investigation is in order.

Unless there is an obvious indication of a compressor problem (noise, hard starting, compressor won't start), the service technician, to be thorough and economical, will inspect the system in an order, checking the easy and least costly problems first, such as:

- presence of electrical power

- proper setting and operation of system controls

- condition of filters

- condition of duct work

- operation of blower fans

...

HVAC Compressor Won't Stop At All

If your A/C won't turn off at all, that may be the same problem as "long on cycles" we discussed at Step 5: THE COMPRESSOR/CONDENSER RUNS TOO LONG or NEVER SHUTS OFF

It could be that the room thermostat is set to a temperature that the system cannot reach - due to lost cooling or due to a setting below the capability of the system.

If your A/C won't turn off even if you set the thermostat to a temperature that is above the current room temp, then the thermostat or an A/C control board or switch is bad and needs replacement - in that case you need a service call from a trained HVAC Technician.

First check that the thermostat is not calling for cooling or turn it off completely. Also check for thermostat wires that are shorted together.

If the HVAC compressor motor will stop but the compressor / condenser fan is not working properly,

see

...

Step 6: Common Causes of Short HVAC Compressor On Cycles

What about the opposite problem: compressor on-cycles that are too short?

Just below is a brief summary of some diagnostic tips for short cycling HVAC compressors.

Complete details about rapid or too frequent compressor on-off cycling given

at SHORT CYCLING AC COMPRESSOR

Five most-common causes of a home air conditioner compressor short cycling on and off too rapidly - Short Cycling Air Conditioner Diagnosis & Repair

- Loss of air conditioner refrigerant -

a refrigerant leak in the system. You may be able to repair the short cycling problem temporarily by recharging the air conditioning system but the proper repair is to find and fix the leak.

Otherwise you will have to keep repeating the costly service call to just add refrigerant.

See REFRIGERANT LEAK DETECTION - A/C coil Icing -

the evaporator coil (cooling coil) is iced over (such as due to improper refrigerant charge or dirt or a reduced air flow due to a dirty filter) - take a look in the air handler to see if the coil is blocked by ice or dirt.

See FROST BUILD-UP on AIR CONDITIONER COILS - Oversized air conditioner -

if the short cycling has always been a problem since the day the system was installed, there is a good chance that the unit is too big (too many BTUS) for the space being cooled.

A more subtle version of this same problem is that you've done something like closing doors or adding a partition that had the effect of reducing the size of the space being cooled.

Sometimes we can mitigate this problem by running the blower fan at a lower speed or by opening interior doors to increase the size of the space being cooled or even by moving the thermostat.

See AIR CONDITIONER BTU CHART

and OPERATING TEMPERATURES HVAC - A/C control problem -

it's less likely, but a damaged control board or switch could also be causing rapid equipment on-off cycling. - Compressor damage or compressor start troubles -

Having serviced A/C systems in several climates, across all of them I've seen these other causes of air conditioner short cycling:

a) If someone manually turns the air conditioner thermostat up and down or on and off too frequently, or if someone does not wait long enough before turning the system ON after turning OFF the air conditioner, a hard-starting compressor may find that it has been shut down with high internal head pressure inside the compressor.

Normally that head pressure bleeds off over time, making it easier for the compressor to restart (against low head pressure) the next time it turns on.

See HARD STARTING COMPRESSOR MOTORS

But if someone is turning the system on and off quickly, the compressor may have a hard time re-starting against the pressure on its outlet side. A starter capacitor addition or replacement might fix the problem. If your A/C compressor is showing this symptom but works OK if you leave it shut off for 30 minutes or longer, that may be the trouble.

b) We have also see or a damaged compressor internal refrigerant valve causing high head pressures.

In sum, you need a service call from a professional to correctly diagnose and repair the problem. Ask the service tech what she/he found and let us know - what you find will help other readers.

...

Step 7: Voltage & Current Checks at the Compressor

Bad Supply Voltage to the Compressor/Condenser Unit

An example of an "underlying cause" of A/C compressor failure includes variations in supply voltage to the unit. That leads to improper compressor operation and loss of cooling output and eventually motor failure.

Low amperage draw by the Compressor Motor

An Amps Test - performed by a trained service technician or electrician - checks the current drawn by the compressor motor.

Unlike a high-amp current draw which indicates that the compressor is damaged internally in a way that its piston(s) is (are) tight in the cylinder, a low-amp current draw, if below normal, may confirm internal wear on the compressor parts, and would support the diagnosis that the compressor is worn and inefficient.

Where there are no gauge ports to actually measure compressor low side and high side vacuum and pressure, this simple electrical test is a useful first step.

See ELECTRIC MOTOR DIAGNOSTIC GUIDE for how-to details.

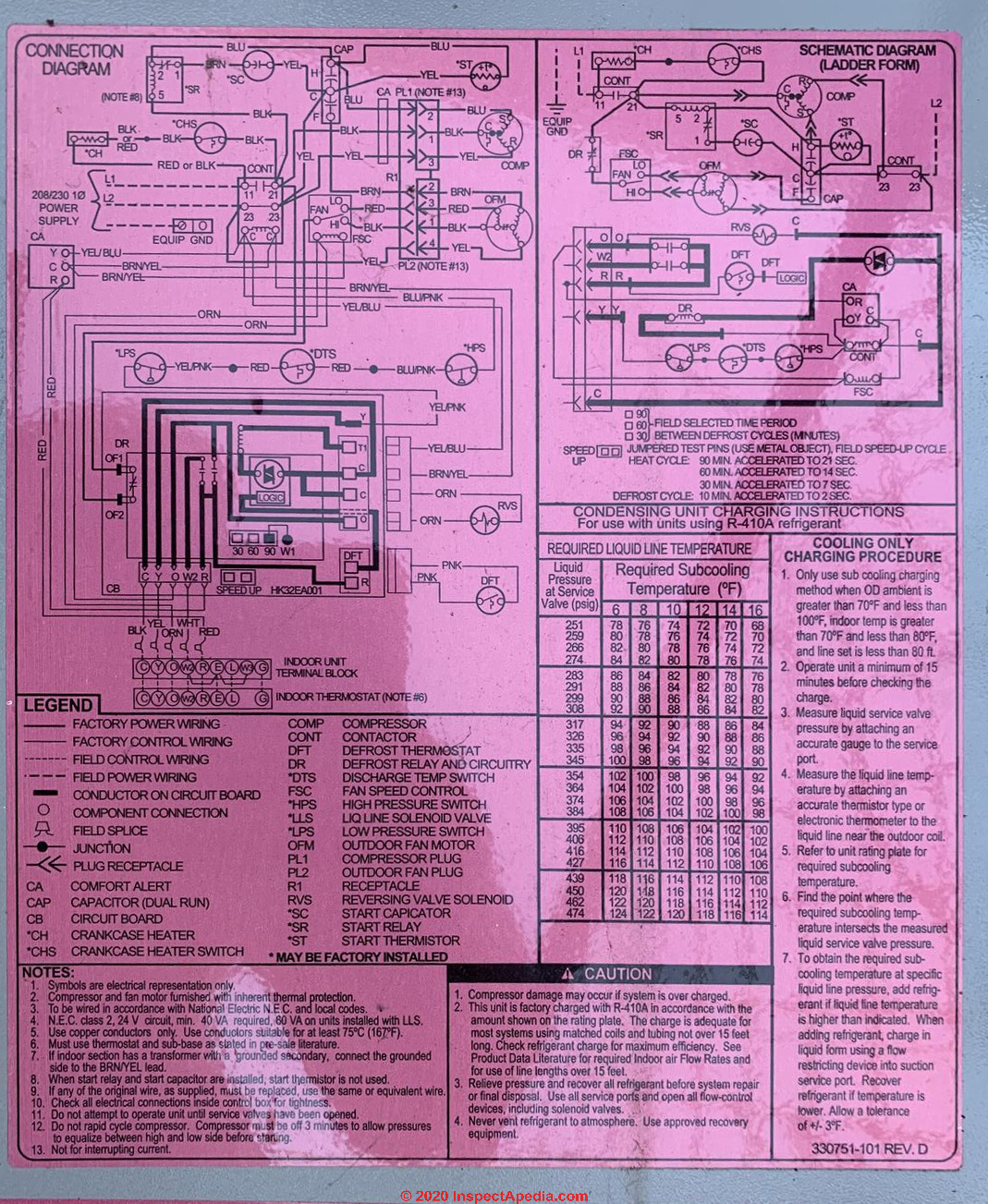

The service technician can make these basic electrical tests right at the outdoor compressor/condenser unit, referring, if necessary, to its wiring diagram. We give an example of these basic connections and wiring just below.

Basic Compressor Condenser Unit Wiring Connections

Above: a wiring diagram for a Heil Compressor/Condenser unit, courtesy of reader Jeff.

[Click to enlarge any image]

Watch out: the wiring instructions and diagram for your specific air conditioner or heat pump compressor/condenser unit are model dependent. This wiring diagram may not apply.

General HVAC Compressor/Condenser wiring connections.

Contactor relay T1

Red wire to dual start/run capacitor C or COM terminal

Red wire to Compressor’s R run terminal

Red wire to Fan motor’s R run terminal

Contactor Relay T2

Black wire to Compressor’s C or COM terminal

Black wire to Fan motor’s C or COM terminal

Contactor Relay L1 - black line voltage in

Contactor Relay L2 - red line voltage in

Contactor Green wire connects grounds contactor & other components to system ground

Contactor Relay low voltage wires (24VAC) to the magnet that operates the relay

Start-Run Capacitor FAN terminal yellow or brown wire to Fan motor’s S terminal

Start-Run Capacitor C or COM terminal red wire to Compressor/Condenser Contactor Relay T1

Start-Run Capacitor H or HERM terminal purple wire to Compressor’s S or Start Terminal

Wiring for the compressor/condenser unit fan and for replacement fan motors is discussed

at FAN REPLACEMENT WIRING, COMPRESSOR/CONDENSER

Watch out : At REFRIGERANT FLOODBACK, LIQUID SLUGGING we explain how liquid refrigerant entering a heat pump or air conditioner compressor motor can destroy it and we discuss the recommended time that the system should be LEFT OFF if was switched off while it was running

...

Step 8: Abnormal HVAC Compressor Refrigerant Pressure

Abnormal refrigerant pressures - checked by a trained service technician

Refrigerant line pressure readings which are abnormal (probably too low) on the high pressure side (compressor output) or on the low pressure side (compressor input or suction line) can indicate a problem with the compressor's ability to develop normal operating pressure ranges and thus will affect the cooling capacity of the air conditioning system.

An inspection and test might discover that there has been a refrigerant leak and the system needs both leak repair and then refrigerant recharging. These are not tasks that a homeowner can perform.

For more details on air conditioner refrigerant line pressures and how they are examined

see COMPRESSOR PRESSURE READINGS

Details about air conditioning compressor functions, how air conditioner compressors work, what goes wrong with air conditioner compressors, and how to measure and diagnose air conditioner compressors are provided

...

Step 9: Overheating Condenser Unit Motor

Compressor-Cooling Water Test?

Compressor/Condenser Cooling: Can Cooling Down the Air Conditioner Compressor Motor with Water Keep the A/C Working?

Several readers have described a step of cooling down an overheated air conditioning or heat pump compressor motor to get it running again producing cool air indoors. One reader used a garden hose to spray the outdoor unit (after all it's intended to tolerate being rained-on). Another used a watering can. A third, buckets of water.

All three reported that this step got their cooling system cooling again when before either the compressor had stopped running entirely or it was running but the system was not producing cool air. But for several reasons this is not an effective durable repair:

- The "repair" achieved by pouring water over a hot compressor is not lasting and if you wet electrical components it could cause damage or be dangerous

- It's hot standing outside dumping water on your A/C unit and you're not supposed to have to do that

- The loss of cooling means there is some problem to be found and fixed

While we wait for more comments from air conditioning service technicians and experts (CONTACT us), here are some interpretations of what may be going on:

- The A/C compressor motor may be at or near end of life,

and running hot. An air conditioner motor that is overheating may turn itself off on thermal reset. In this case when the motor cools down ,it may automatically reset itself and start up again - for a while. Sometimes you can get a compressor motor starting again on its own by adding or replacing a starting capacitor -

see CAPACITORS for HARD STARTING MOTORS.

Also see MOTOR OVERLOAD RESET SWITCH.

Also see HARD STARTING COMPRESSOR MOTORS. - The A/C compressor motor may be overheating

due to its location: for example in hot sun. Most equipment will tolerate this condition but an older unit or very hot sunny conditions may lead to thermal overheating and an overload circuit trip-off. - The A/C system compressor/condenser fan may not be running

or may be damaged, failing to adequately cool the refrigerant gas in the condensing coils. Watch the fan to see that it is running while the compressor motor is on, and perhaps even before and after the compressor motor starts or stops. [But not indefinitely.] - The A/C condenser unit coils may be blocked,

bent, dirty, damaged. It may be possible to clean the coils of leaves, dirt, grass kicked up by nearby mowing, etc. and thus improve the condenser operation and start making cool air again.

COMPRESSOR & CONDENSING COIL - The air conditioning or heat pump system may be very low on refrigerant

You'll need a service technician to check and repair this condition.

REFRIGERANT LEAK DETECTION

...

...

Continue reading at COMPRESSOR / CONDENSER REPAIR - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see COMPRESSOR / CONDENSER DIAGNOSTIC FAQs questions and answers posted originally at this page

Or see these

Recommended Articles

- COMPRESSOR / CONDENSER REPAIR - home

- BURNED-OUT COMPRESSOR

- CAPACITORS for HARD STARTING MOTORS

- COMPRESSOR / CONDENSER DIAGNOSTICS

- COMPRESSOR / CONDENSER INSPECTION CHECKLIST

- COMPRESSOR / CONDENSER INSTALLATION ERRORS

- COMPRESSOR / CONDENSER LEVELING REQUIREMENTS

- COMPRESSOR CONDENSER NOISES

- COMPRESSOR MOTOR INSULATION

- COMPRESSOR MOTOR REPLACEMENT

- CONTACTOR RELAY DIAGNOSIS & REPAIR

- CONTROL CIRCUIT BOARD, A/C

- CRANKCASE HEATERS

- ELECTRIC MOTOR DIAGNOSTIC GUIDE

- FAN, COMPRESSOR / CONDENSER UNIT

- FAN NOISES HVAC

- HARD STARTING COMPRESSOR MOTORS

- LONG-ON CYCLING AC COMPRESSOR

- MOTOR OVERLOAD RESET SWITCH

- NOISES, HVAC SYSTEM DIAGNOSIS - home

- REFRIGERANT PRESSURE CONTROLS & SWITCHES

- REFRIGERANT PRESSURE READINGS & CHARTS

- SHORT CYCLING AC COMPRESSOR

- TIGHT or SEIZED AC COMPRESSORS

Suggested citation for this web page

COMPRESSOR / CONDENSER DIAGNOSTICS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

...

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Comments

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Bychkov, Igor, Common Causes of [A/C or Heat Pump] Compressor Failure, Replacement Components Co, Carrier, Website: https://www.rchvacparts.com/

- Timothy Hemm, Yucala, CA, contributed photographs of electrical wiring and equipment installed in California buildings. Mr. Hemm can be contacted at TimHemm@yahoo.com

- Thanks to reader and research scientist Cyril Roberts, Barbados, for technical discussion and investigation of air conditioning system dehumidification problems (April 2009).

- Thanks to readers Beth & Dennis for asking about how to improve an inadequate air conditioning system supplying cool air through crawl space ducts and floor registers. (May 2010).

- Thanks to reader William Smith for discussing cooling coil leaks and lost cooling capacity diagnosis - June 2010

- Thanks to reader Jacob Behrends, FL for discussing how a clogged condensate drain line can overflow condensate into a condensate pan that in turn may contain a safety switch that shuts down the whole air conditioning system. August 2010.

- US DOE, DETERMINING ELECTRIC MOTOR LOAD AND EFFICIENCY [PDF] U.S. Department of Energy, - retrieved 2025/01/11 - local copy on file as Determining-electric-motor-load-and-efficiency-DOE.pdf

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.