Air Conditioning & Heat Pump Compressor/Condenser Parts

Air Conditioning & Heat Pump Compressor/Condenser Parts

List of all major components of the HVAC compressor/condenser unit

- POST a QUESTION or COMMENT about HVAC compressors & condensers: the condensing unit

Air conditioner compressor / condenser unit component parts guide:

Here we describe each of the parts or components that make up the outdoor portion of an air conditioning or heat pump system: the compressor/condenser unit.

For each of the air conditioner or heat pump compressor/condenser unit parts we describe the part, its location, its function, and how it works.

This article series discusses the outdoor components of air conditioners and heat pumps, how they work & how to repair them: how the air conditioning compressor-condenser unit works; the detection of defects in air conditioning compressor and condensing units, including evaluation of air conditioner compressor noises, hard starting, lost cooling capacity, and detection of a burned out compressor or A/C compressors at or near end of their life.

Here we also include links to key articles discussing the indoor components of an air conditioner or heat pump system including the air handler and its controls and the ductwork system.

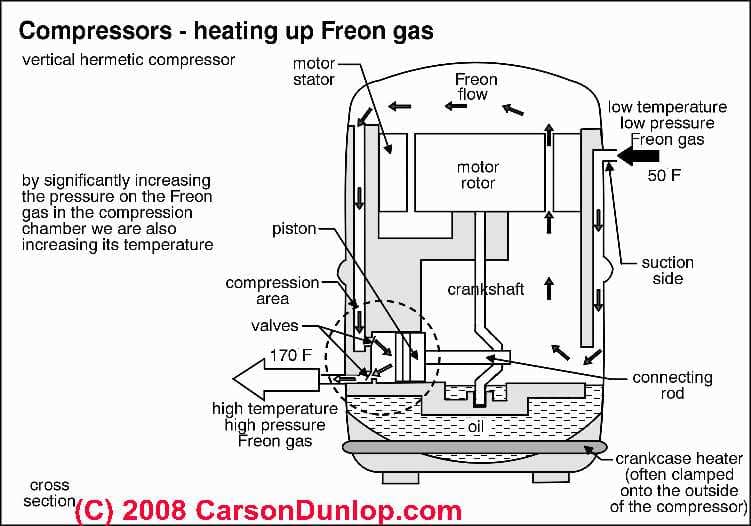

Page top sketch of the internal parts of an HVAC compressor motor is provided courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Compressor / Condenser Unit Parts & How They Work

What are the Components of the Outdoor Portion of a Central Air Conditioning System - the Air Conditioning Compressor Unit?

What are the Components of the Outdoor Portion of a Central Air Conditioning System - the Air Conditioning Compressor Unit?

The outdoor half of a typical air conditioning system (shown in our photo) is a unit containing the refrigerant compressor and condensing coil and a cooling fan.

The compressor motor itself (sketch at page top) is not visible unless the covers of this unit are removed.

Bottom line: The job of the air conditioning compressor is to reduce pressure on the low side (cooling side) of the system and to increase pressure on the high side (warming side) of the system.

These pressure differences move refrigerant through the system and enable it to change states from liquid to gas (at the TEV and in the evaporator coil) and from gas to liquid (in the condensing coil).

This process moves heat (absorbed by the evaporator coil inside the cooling or refrigerated area) through the condenser coil and into outside air (or water).

Article Contents

- A/C or HEAT PUMP COMPRESSOR MOTOR + refrigerant metering devices like capillary tube or thermostatic expansion valve

- REFRIGERANT LINES + filters, fittings

- CONDENSING COIL

- COOLING FAN

- ELECTRICAL CONTROLS & SWITCHES

1 - The Air Conditioning Compressor Itself, consisting of:

In residential A/C (or heat pump) units the A/C compressor motor is most often a hermetic motor-compressor combined inside a single sealed unit like the Carrier™ unit shown

at left.

You cannot actually see the individual A/C compressor parts because at least on residential air conditioners or heat pumps, the entire assembly is enclosed.

If a ductless split-system air conditioner

is installed an outside compressor unit is still required,

If a "portable" indoor air conditioner

is in use, all of these parts may be inside of a single portable cooling unit, usually mounted on wheels.

Portable air conditioner units use a duct and fan system to blow to outdoors the heat that has been extracted from indoor air.

Window air conditioners

also contain all of these parts in a single unit, but by hanging the window unit in a window or in a wall opening, the device has ready access to outdoor air into which it ultimately is transferring heat from indoors.

How does an air conditioning compressor motor work?

The job of the compressor/condenser unit is to recompress warm refrigerant gas (pulled from the indoor air handler cooling coil) back to a liquid refrigerant that can be returned to the indoor cooling coil once again.

When the room thermostat calls for cooling, both the indoor blower or air handler and the outdoor compressor/condenser begin to work. Control circuits and a contactor relay turn on the outside compressor/condenser motor and its outdoor cooling fan as well.

The air conditioning or heat pump compressor compresses the incoming refrigerant to a high pressure gas and moves that gas into the condensing coil described just below.

Typically a piston moves up and down inside of a cylinder inside the compressor motor, drawing in refrigerant gas on the down stroke of the piston, and compressing the refrigerant gas on the up stroke of the piston.

(Some refrigeration compressors such as those made by Frigidaire™ used a rotary compressor design that we found durable and powerful enough to lead us to salvage and re-use these motors for other purposes.

The refrigerant gas leaves the compressor at high pressure and at high temperature (since compressing a gas will raise its temperature).

In most air conditioning or heat pump compressors, a piston moves up and down to draw in and then compress refrigerant gas, moving refrigerant vapor from the incoming low side to the outgoing high side of the compressor.

The refrigerant gas leaving the compressor (and entering the condensing coil) will contain both heat that the refrigerant absorbed at the evaporator coil (heat from air in living space of the building), and additional heat produced at the compressor by the process of compressing the gas.

The refrigerant gas is thus heat laden with SENSIBLE HEAT (web article explaining sensible heat is heat that we can measure) from the living area and compressor heat from the compressor motor.

Low side and high side refer to the low-pressure and high-pressure areas of the air conditioning equipment and are defined in more detail

at SEER RATINGS & OTHER DEFINITIONS where we also explain sensible heat and other air conditioning terms.

Refrigeration and Air Conditioning Theory

In an air conditioning system, pressure is used to change (increase) the vaporization point (state change from liquid to gas) or condensation point (state change from gas to liquid) of the refrigerant.

On the A/C system's high side (high refrigerant gas pressure side of the system), the condensation point must be some temperature above ambient outdoor air temperature (if air is being used to cool the condensing coil) or condensation of the refrigerant gas back to a liquid will not occur.

Creation of high side & low side in a refrigeration system: refrigerant metering devices

The restriction in refrigerant flow created by

an adjustable THERMOSTATIC EXPANSION VALVE (TEV article)

[or on many systems

simpler CAPILLARY TUBES] located close to the evaporator coil (cooling coil) allows the compressor to raise the pressure and increase the temperature at which the refrigerant (coolant) will change state (from liquid to gas in the cooling coil, and from gas back to liquid in the condensing coil).

This restriction in refrigerant flow at the TEV is what allows the compressor a pressure difference between the high side and low sides of the system.

The evaporator coil is defined in detail

at A/C or HEAT PUMP COMPONENTS

and discussed further

at AIR HANDLER / BLOWER UNITS

TEVs, AEVs, thermostatic expansion valves, manual and adjustable expansion valves, and float valves are discussed

at THERMOSTATIC EXPANSION VALVES.

Capillary tubes for metering refrigerant are discussed separately

at CAPILLARY TUBES.

Room air conditioners such as window or through wall mounted units, and some other refrigeration equipment such as a home refrigerator, use a capillary tube (cap tube) instead of a thermostatic expansion valve.

A cap tube is simply a small diameter tube used to meter liquid refrigerant from the "high" side of the system into the cooling coil (the start of the low side of the system). Unlike a TEV, a cap tube is fixed in output and cannot be adjusted.

State changes of refrigerant are what remove heat:

Refrigeration systems rely on two state changes of the refrigerant: gas to liquid, and liquid back to a gas.

It is these state changes of the refrigerant that move sensible heat from one side of the air conditioning system to the other: by absorbing BTUs of heat during evaporation (in the evaporator coil) and by releasing BTUs of heat during condensation (in the condenser coil).

R12 refrigerant has a boiling point of -21 degF (change of state from liquid to gas vapor) and R22 has a boiling point of -41 degF.

State change of refrigerant gas to liquid:

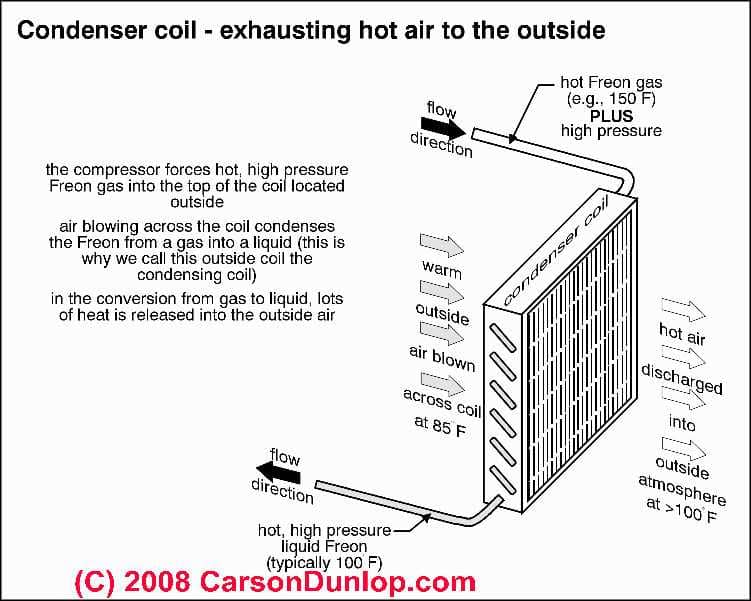

The state change of the air conditioning refrigerant from a high pressure high temperature gas back to a liquid occurs inside the outdoor condensing coil. This state change (gas to liquid) releases energy in the form of heat which is blown into outdoor air (or transferred into water)

Note: the compressor has to produce high enough output pressure that the gas moving through the condensing coil moves at a good velocity in order to scrub the entire condensing coil tubing surface and thus transfer its heat out through the condensing coil tubing into ambient air (or water).

State change of refrigerant liquid to gas:

the state change from a liquid refrigerant to a low pressure gas occurs in the indoor evaporator or cooling coil, absorbing energy in the form of heat (the heat in indoor air being blow across the evaporator coil), thus moving heat from the indoor air into the refrigerant gas in the system. For example, R12 changes state at -21 degF; R22 changes state at -41 degF.

Watch out: use safety glasses when handling refrigerant gases. Getting a liquid refrigerant in your eye can cause serious permanent eye damage.

Special oil used in air conditioning & refrigeration compressor motors

Air conditioning and refrigeration compressors use a special oil which does not react with the refrigerant liquid or gas in the system. The oil may mix and travel with the refrigerant however, and some cooling systems are designed for deliberate movement of the compressor oil in order to lubricate some parts such as refrigerant metering valves or compressor valves.

All of the above-listed air conditioner or heat pump components are discussed in detail throughout this website using the links at the left of these pages.

2 - Refrigerant lines

The larger diameter refrigerant suction line

connects the indoor evaporator coil outlet to the compressor inlet.

The larger refrigerant line (located on the low side of the system) reduces system pressure and causes vaporization of the refrigerant (so that sensible heat is absorbed and the suction line feels cool to the touch).

Refrigerant returning to the compressor from the evaporator coil and through the refrigerant low pressure suction line, is in the form of a low pressure, low temperature gas.

Most air conditioning compressors are designed only to pump gas vapors, not liquid refrigerant (which could damage compressor internal parts).

The refrigerant gas entering the compressor at its inlet port is said to be heat laden, that is, it was at a low-enough temperature to have absorbed heat from the evaporator coil in the living area.

The smaller-diameter high pressure refrigerant lines

connect the compressor outlet and the condensing coil inlet and also

move refrigerant liquid in it's cooled, condensed and now liquid state from the outlet of the condensing coil to the thermal expansion valve (basically a refrigerant metering device) and the evaporator coil inlet in the air handler unit in the building.

This smaller (in diameter) refrigerant piping or tubing (located on the high side of the air conditioning system) reduces volume and thus increases pressure and temperature in the lines (so that sensible heat can be transferred to ambient outdoor air or water if a water-cooled air conditioner system is in use).

Service valves or ports

are usually present on the refrigeration lines near the compressor. to permit testing the condition of the air conditioning system and permit removal, replacement, or additions to the refrigerant in the system.

3 - Condensing coil

Shown in the sketch above, the cooling coil receives high pressure refrigerant gas from the compressor and cools (condenses) this refrigerant gas back to a liquid state.

Sketch from Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

Typically refrigerant leaves the compressor and enters the outdoor condensing coil at about 100 psi and about 95 degF. These pressures vary of course by type of refrigerant, ambient temperatures, compressor details, etc.

4 - Outdoor cooling fan

The cooling fan moves outdoor air across the condensing coil to cool it and assist in condensing the high pressure, high temperature refrigerant gas back into a liquid.

It is this process

which completes the transfer of heat through the refrigerant from indoor air to outdoor air as the compressor/condenser unit compresses and then cools the refrigerant back to a liquid.

See FAN, COMPRESSOR / CONDENSER UNIT for help in diagnosing and fixing problems with the outdoor compressor/condenser fan and fan motor.

Watch out: as we explain

at BURNED-OUT COMPRESSOR, if the condensing unit fan is not working the compressor itself may shut down or even be ruined by overpressure or over temperature.

Also see NOISES, COMPRESSOR CONDENSER where some noise problems are traced to the cooling fan .Electrical shut-off switch(es)

For service at the unit are provided to permit maintenance and repair of the equipment. Below we describe the basic electrical switches and controls on air conditioners and heat pumps.

See A/C - HEAT PUMP CONTROLS & SWITCHES for details.

5 - Electrical Controls & Parts for the A/C or Heat Pump include:

Circuit breakers or fuses

at the electrical panel

protect the circuit supplying power to the air conditioning system. Typically separate circuit breakers (or fuses) power the compressor/condenser unit and the indoor air handler/blower assembly.

Air conditioner / heat pump control circuit board

(typically a "control board" shown in our photo at left) and a contactor relay (shown in our photo below) are used in the compressor/condenser to turn it off and on in response to the indoor thermostat's call for cooling.

While diagnosing a circuit or component problem within an air conditioner or heat pump control board is beyond the skill of most homeowners, a simple visual inspection might show you that the control board has been visibly burned, broken, or damaged. Of course the board may look OK and still be damaged.

See CONTROL CIRCUIT BOARD, A/C for details.

A/C heat pump Contactor Relay

A/C and heat pump systems use a contactor relay (circled at left) because the little 12-24V wall thermostat circuit and switches are not capable of handling the higher voltage used by the compressor/condenser motors.

The contactor relay is basically a low-voltage-operated switch [typically 12-14 volts] controlled by the low-voltage room thermostat) that switches a heavier-duty electrical relay to give 120V or 240V electrical power to the compressor/condenser unit.

Most A/C and heat pump contactor relays use an electromagnetic 24-volt two-pole contactor relay that is rated for 30 amps. The "two poles" simply means that the relay switches two electrical wires simultaneously - which is what you'd expect if your heat pump motor is running on 240 Volts.

See details at CONTACTOR RELAY DIAGNOSIS & REPAIR

Also see A/C - HEAT PUMP CONTROLS & SWITCHES

Watch out: Some of our readers report successfully replacing minor electrical components such as switches, relays, and contactors. But unless you are qualified to do so we do not recommend trying to do work on electrical systems and components in your home as there are potentially fatal electrical shock hazards. Because air conditioner compressor/condenser units include start/run capacitors, even when you have turned off power you can get a nasty shock if you're not careful.

See CAPACITORS for HARD STARTING MOTORS

Also see SAFETY for ELECTRICAL INSPECTORS

and DMMs VOMs SAFE USE OF.

Air conditioner or heat pump compressor motor crankcase heaters:

A crankcase heater is used to warm an air conditioner or heat pump compressor motor to help protect against liquid slugging damage to the compressor and to assure that lubrication oil residing in the compressor motor base will be distributed properly when the compressor motor first starts operation. Not all compressor models use a crankcase heater.

For models that do use a crankcase heater to permit system operation without damage at lower temperatures, manufacturers give power-on requirement warnings such as the following:

Furnish power to crankcase heater a minimum of 24 hr before

starting unit. To furnish power to heater only, set thermostat to

OFF and close electrical disconnect to outdoor unit.

HVACR Compressor Motor Crankcase Heater Warnings

NOTE: On 24ANA7 models, starting the compressor without a

minimum of 12 hours of crankcase heat prior to initial start--up

may result in a compressor chattering noise and possible damage to the compressor. [2]

At REFRIGERANT FLOODBACK, LIQUID SLUGGING

we explain how liquid refrigerant entering a heat pump or air conditioner compressor motor can destroy it and we discuss the recommended time that the system should be LEFT OFF if was switched off while it was running

Fan on or in the outdoor compressor/condenser unit:

the fan in the outdoor condenser unit is required to move air across the condensing coils (in cooling mode) or if a heat pump is in heating mode, across the same coil used as an evaporator to obtain heat form outdoor air. Even if the compressor is working properly, if the fan fails to operate controls on the compressor/condenser unit will shut it down.

See FAN, COMPRESSOR / CONDENSER UNIT

If the fan in the condenser unit is not running, also

see MOTOR OVERLOAD RESET SWITCH.

Indoor Components of Heat Pump & Air Conditioning Systems

Please see AIR HANDLER / BLOWER UNITS for details about the blower unit or indoor components of heat pump & air conditioning systems.

Or for wall-mounted cooling or heating convector units

see WALL CONVECTORS HVAC - home

...

...

Continue reading at COMPRESSOR / CONDENSER DIAGNOSTICS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- AIR CONDITIONER COMPONENT PARTS

- AIR HANDLER / BLOWER UNITS - blower unit or indoor components of heat pump & air conditioning systems

- COMPRESSOR / CONDENSER REPAIR - home

- AIR CONDITIONER/ HEAT PUMP LIFE EXPECTANCY - separate article

- COMPRESSOR / CONDENSER INSPECTION CHECKLIST for a simple checklist for the outdoor compressor/condenser unit.

- COMPRESSOR / CONDENSER OPERATION - how it works to heat or cool a building

- COMPRESSOR / CONDENSER UNIT COMPONENT PARTS - separate article

- COMPRESSOR / CONDENSER ENVIRONMENT & SAFETY WARNINGS

- COMPRESSOR / CONDENSER TYPES

- COMPRESSOR / CONDENSER VALVES

- COMPRESSOR / CONDENSER OILS

- COMPRESSOR / CONDENSER REPAIR GUIDE

- COMPRESSOR FAILURE DIAGNOSIS - Initial, simple diagnostic checks of the air conditioning compressor are also described

- DIAGNOSTIC GUIDE A/C or HEAT PUMP - suggestions for diagnosing compressor or condenser fan and coil problems that can mean intermittent or totally lost cooling capacity of your system.

- DUCT SYSTEM DESIGN SIZE & DEFECTS - separate article series

- AIR CONDITIONING & HEAT PUMP SYSTEMS - home

- SPLIT SYSTEM AC / HEAT PUMP REPAIRS

Suggested citation for this web page

COMPRESSOR / CONDENSER UNIT COMPONENT PARTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Air Conditioning SEER - New DOE Air Conditioner and Heat Pump Efficiency Standard

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.