Fiberglass HVAC Duct Mold Contamiantion

Fiberglass HVAC Duct Mold Contamiantion

Why is Mold Found in HVAC Ducts & in Fiberglass Duct Insulation

- POST a QUESTION or COMMENT about Mold in Air Ducts: cause, detection, cure, & prevention of moldy HVAC ductwork

Causes of mold growth in HVAC ducts & in building insulation:

This article explains the cause, detection, and hazards of mold growth in fiberglass insulation in residential and light-commercial building and gives advice about dealing with moldy building insulation or ductwork.

Mold may grow at extensive or problematic levels in some building insulation materials used in walls, floors, ceilings as well as in HVAC air duct systems.

We describe the types (genera/species) of mold most often found in HVAC ducts and the relationship between mold in ductwork and indoor air quality complaints by building occupants. We include authoritative citations for key research on mold contamination in HVAC ductwork.

Page top photo: I was using my finger to point to moldy insulation in this air handler but Google thought my hand was something else inappropriate so we greyed out my hand and index finger.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Where & Why Does Mold Grow in HVAC Ductwork & in Building Insulation?

Mold growth & Mold Contamination are Common in HVAC Systems

This website discusses health hazards associated with moldy fiberglass in buildings, with focus on fiberglass insulation, fiberglass fragments, fiberglass in heating and air conditioning duct work, and invisible but toxic mold growth in fiberglass which has been wet, exposed to high humidity, or exposed to other moldy conditions.

[Click to enlarge any image]

Mold is often found in basement fiberglass insulation, crawl space fiberglass insulation, fiberglass wall insulation, heating or cooling duct fiberglass insulation, and attic or roof insulation in buildings which have either been wet or have been exposed to high levels of mold from other sources.

It is common for a careful inspection of air handlers and HVAC ductwork to find mold contamination on the duct interior as well as in the air handler on the blower assembly squirrel cage fan blades and other components.

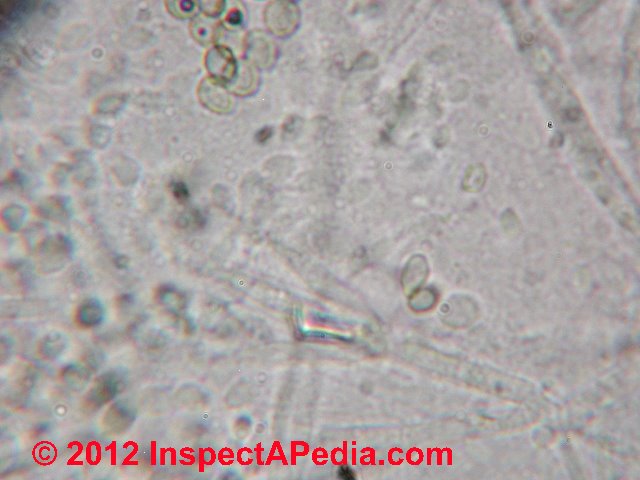

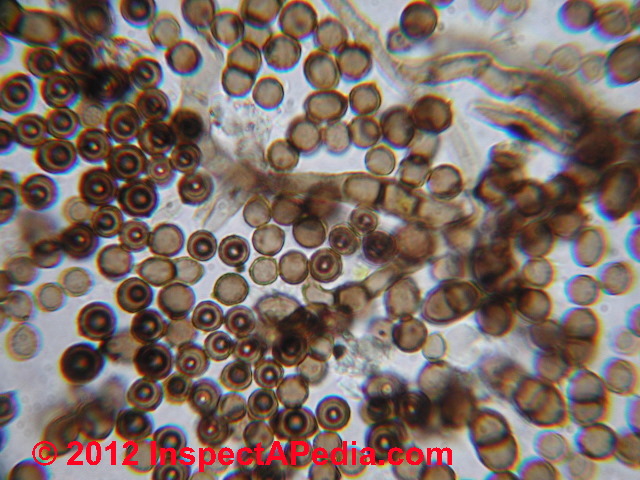

In our experience as both field and lab investigators, several genera/species of mold are quite common in these environments (as well as in fiberglass and possibly some other building insulation products).

Our photo of a moldy air handler interior in a Florida home (below) is provided by home inspector & educator Mark Cramer.[3]

...

Where conditions support mold growth within the HVAC system air handler and ductwork, we also may find significant mold colonization of the surfaces of air supply registers or the ceilings around them. (Next photo, below).

HVAC Studies for Mold Contamation - Methodological Error Risks

Tests for mold in HVAC systems are vulnerable to methodology errors, particularly in the selection of sampling sites.

Tests for mold in HVAC systems are vulnerable to methodology errors, particularly in the selection of sampling sites.

Variations in moisture and uneven distribution of organic debris and dust through the system are very important effects on what mold is found where.

For example, sampling immediately downstream from the blower assembly we are more likely to find more water-tolerant fungi (Cladosporium spp.) associated with condensate blow-off spun into that area by the blower fan.

Sampling further into the duct system may discover Aspergillus spp. that prefers somewhat drier surfaces.

Ducts exposed to special conditions (flooding, greases or organics from cooking, etc) may support additional or different-dominant mold genera/species.

Fungal growth on fiberglass appears to be supported by the normal organic debris (skin cells that dominate house and other building dust), combined with moisture or even condensation and water found in the HVAC system.

But we also find mold contamination even in some clean-looking fiberglass building insulation, possibly supported by a combination of moisture and some organic resins or binders, or at times, simply having been absorbed by insulation that is installed in a very moldy environment whose mold is from another source reservoir.

Details are

at INSPECTION of INSULATION for MOLD.

Also see BLOWER LEAKS, RUST & MOLD

and also AIRBORNE PARTICLE & MOLD LEVELS in DUCTWORK.

Common Mold Genera/Species Found in HVAC Systems & Ductwork & Building IAQ Complaints

Experts studying both mold contamination in HVAC ductwork and related building indoor air complaints have confirmed our own lab experience that identifies Cladosporium spp. or C. herbarum, (most common), Aspergillus versicolor (common) A. flavus (common), and A. fumigatis. [5][6][7][8][9]

Those studies also point out that even when apparently modest levels of mold contamination traced to HVAC systems are removed (usually by removing the contaminated or "mold colonized" duct insulation or if that isn't possible, by replacing the ductwork) building IAQ complaints decline significantly.

Dirty HVAC Ducts That Cannot be Cleaned

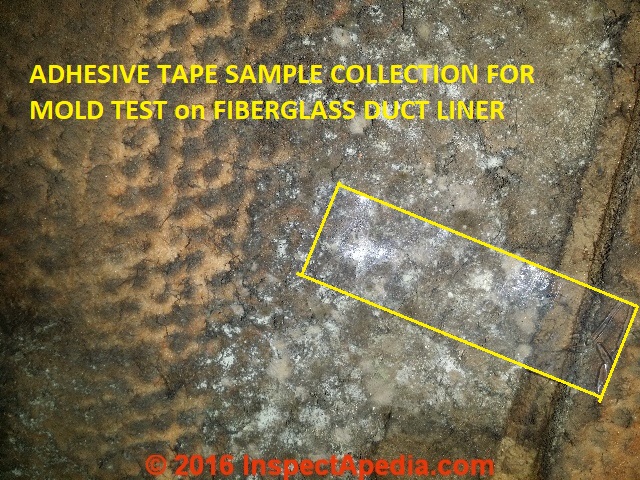

The photo above shows how fragile is the fiberglass insulation in some HVAC ducts. The rough surface attracts and collects organic and other particulate debris moving through the duct system (unless good filtration is installed at the return air inlets).

The surface of an HVAC duct lined with fiberglass cannot be mechanically cleaned - you can see what happens when someone tries to brush or vacuum it by looking at this photo.

Once disturbed by improper "cleaning' efforts, the release of airborne asbestos in the building will certainly increase.

If this insulation is wet by leaks or improper condensate handling, or if the building is exposed to high levels of airborne mold from another source, ducts that look like this are likely to become a problem mold reservoir and will need to be replaced.

The photo just above shows typical debris, usually skin cells and fabric fibers, which collects on the rough surface of exposed fiberglass inside ductwork. A return opening filter would have helped keep this duct clean and thus extend its life.

Water or condensate leaks into an HVAC duct system

such as those shown by the photographs above and below of stains on the interior of this rooftop mounted commercial HVAC duct (left) and indoor residential air handler unit (right), are an invitation to mold or bacterial contamination in the system.

DF-OPINION: it is more (or less) likely that problematic mold will be found growing in or present in building insulation at a level sufficient to be a potential problem for building occupants in these conditions:

- Low-risk insulation:

Mold requires moisture and organic material for nourishment, as well as other growing requirements that vary by mold genera and species. So perfectly clean, dry fiberglass or other building insulation is unlikely to harbor a problem mold reservoir. - Wet or "dirty" building insulation:

often is found to be moldy, either on the kraft paper or foil/paper insulation backing or in the insulation itself. Insulation which is old and has become populated or "soiled" with organic debris such as animal dander (a home housing animals, especially dogs) or insect fragments (an old house with old insulation) contains plenty of organic debris which can support fungal growth.

When such insulation is wet by a single event such as a roof leak or basement flood or when it is exposed to recurrent high interior moisture conditions, the growth of problem mold is a real risk. If there are building occupant IAQ complaints, investigation of the insulation may be in order in this case. - Clean fiberglass insulation exposed to moldy air:

I have found very high levels of mold contamination in otherwise apparently clean fiberglass insulation in cases where the insulation has been exposed to high levels of moldy air.

Aspergillus sp. and on less frequent occasions, Penicillium sp. or even basidiomycetes are found in insulation which may be rather new and which may appear perfectly clean to the naked eye.

A typical scenario producing this condition is the presence of un-protected, exposed fiberglass insulation in the ceiling of a basement where there has been a significant mold contamination, perhaps even a mold remediation project. High airborne mold levels readily move small spores such as those in the Aspergillus/Penicillium group through building insulation by ordinary indoor air and convection currents.

Mold Growth on Fiberglass HVAC Duct Interiors

Below: a photograph of white or light gray mold growth on the interior surface of a fiberglass-lined air duct.

While more investigation was required, we speculated that the Atlanta Georgia home where this duct mold was found had either suffered water or high moisture in the ductwork or there had been another source of high levels of Aspergillus, Penicillium, and perhaps other molds in the building's indoor air.

Details of this air duct mold contamination study are found

at FIBERGLASS AIR DUCT MOLD TEST.

Advice for Suspected or Known Mold-Contamination in HVAC Ductwork

This topic is now found

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Insulating the exterior rather than interior of HVAC ducts avoids some problems but I still have an IAQ complaint

In Canada we use insulation on the outside of the duct work not on the inside lining the ducts

Can this help prevent this problem I am experiencing a scratchy throat - On 2017-10-14 by Anonymous -

Reply by (mod) -

Yeah well Anon, currently it's clear that Canadians are orders of magnitude smarter than their yank cousins, just look at how trumplandia, I mean the U.S., is being governed.

And I agree completely that external duct insulation is preferable: that makes it possible to actually clean the interior of metal ductwork work.

If you're suspecting air quality problems from your ducts nevertheless, inspect the air handler, blower fan, plenums, and accessible duct areas for a build-up of debris that might be worth cleaning; and of course check those air filters.

My A/C system duct smells musty and is wet

I replaced my AC system and after almost a year I started to noticing musty smell. Almost like an old dirt smell.

Checked the AC and found the unit and ductwork were saturated with water. After a lot of back and forth, they found the unit was not installed properly and water was flinging off the coil and going into the unit and ductwork.

They reinsulated the unit, replaced part of the supply and return ductwork and the smell still has not gone away. They determined the smell was coming from the unit and ultimately replaced the whole coil/blower and a short run of R/A ductwork and the supply plenum.

The smell is still very evident, musty/dirty smell.

Could whatever is causing the smell penetrated more of the fiberboard ductwork and giving off this musty smell?

House is in south Florida and has fiberboard ductwork with flex ducting down to registers. I had a mold company do an air test and the only thing they found was Asperillus/Penicillium-Like, Raw count 1, count/m3 - 13. Is that enough to cause the musty smell. On 2017-04-11 by Bill Danford

Reply by (mod) -

Bill:

When you smell mold typically you're smelling volatile organic compounds or mold-volatile-organic compounds (MVOCs) that can permeate soft materials such as duct insulation. Considering how much material has been replaced, I'd think your onsite experts will want to

- examine/replace other ductwork in the HVAC system

- inspect for other leaks and thus possible hidden mold reservoirs.

Air tests for mold, particularly when results are negative, are almost entirely unreliable. Airborne dust, debris, mold levels can vary by several orders of magnitude depending on just how and when a "test" is conducted.

...

Continue reading at WHEN to TEST INSULATION for MOLD or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BLOWER LEAKS, RUST & MOLD for Readers concerned with mold contamination in heating and air conditioning air handlers and ductwork

- FIBERGLASS AIR DUCT MOLD TEST - using tape to test & identify debris on HVAC duct interior surfaces

- FIBERGLASS INSULATION MOLD - home

- INSPECTION of INSULATION for MOLD before testing - noting that contaminated building insulation may look clean to the naked eye.

- INSULATION MOLD CONTAMINATION TEST

- INSULATION STAINS - AIR BYPASS LEAKS

- SLAB DUCTWORK - the role of in-slab placement of air ducts in the formation of mold contamination in HVAC systems.

- TEST CHOICES for MOLD in FIBERGLASS

- TEST PROCEDURE for MOLD in FIBERGLASS

- VACUUM TEST INSULATION CONTAMINANTS

- WHEN to TEST INSULATION for MOLD

- WHY DOES MOLD GROW in INSULATION? that includes photos and test results examining suspected mold on the surface of fiberglass-lined HVAC ductwork.

Suggested citation for this web page

WHY DOES MOLD GROW in INSULATION? at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to MOLD CONTAMINATION & REMEDIATION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Should You Have the Air Ducts in Your Home Cleaned, U.S. Environmental Protection Agency, Indoor Environments Division, EPA-402-K-97-002, web search 8/5/11, original source: http://www.epa.gov/iaq/pdfs/airducts.pdf

- "Indoor Mold and Health,

A Fungus AmonG Us", Florida State Department of Health, Florida Department of Health

Division of Environmental Health

Bureau of Community Environmental Health

Radon and Indoor Toxics

4052 Bald Cypress Way, Bin A08

Tallahassee, FL 32311

1-850-245-4288

1-800-543-8279, web search 08/05/2011, original source: http://www.doh.state.fl.us/environment/community/indoor-air/Indoor_Mold_and_Health.pdf. Quoting:

The Florida Department of Health has developed this brochure to address some of the most common questions and concerns about indoor mold, how it affects human health, and ways in which you can prevent or remove it. - [5] Ahearn, D.G., S A Crow, R B Simmons, D L Price, J A Noble, S K Mishra and D L Pierson, "Fungal colonization of fiberglass insulation in the air distribution system of a multi-story office building: VOC production and possible relationship to a sick building syndrome", Journal of Industrial Microbiology & Biotechnology, Volume 16, Number 5 (1996), 280-285, DOI: 10.1007/BF01570035. Abstract:

Complaints characteristic of those for sick building syndrome prompted mycological investigations of a modern multi-story office building on the Gulf coast in the Southeastern United States (Houston-Galveston area). The air handling units and fiberglass duct liner of the heating, ventilating and air conditioning system of the building, without a history of catastrophic or chronic water damage, demonstrated extensive colonization with Penicillium spp and Cladosporium herbarum. Although dense fungal growth was observed on surfaces within the heating-cooling system, most air samples yielded fewer than 200 CFU m–3. Several volatile compounds found in the building air were released also from colonized fiberglass. Removal of colonized insulation from the floor receiving the majority of complaints of mouldy air and continuous operation of the units supplying this floor resulted in a reduction in the number of complaints. - [6] Ahearn, D.G., S.A. Crow, R.B. Simmons, D.L. Price, S.K. Mishra and D.L. Pierson, "Fungal Colonization of Air Filters and Insulation in a Multi-Story Office Building: Production of Volatile Organics", Current Microbiology Volume 35, Number 5 (1997), 305-308, DOI: 10.1007/s002849900259, Abstract:

Secondary air filters in the air-handling units on four floors of a multi-story office building with a history of fungal colonization of insulation within the air distribution system were examined for the presence of growing fungi and production of volatile organic compounds. Fungal mycelium and conidia of Cladosporium and Penicillium spp. were observed on insulation from all floors and both sides of the air filters from one floor. Lower concentrations of volatile organics were released from air filter medium colonized with fungi as compared with noncolonized filter medium. However, the volatiles from the colonized filter medium included fungal metabolites such as acetone and a carbonyl sulfide-like compound that were not released from noncolonized filter medium. The growth of fungi in air distribution systems may affect the content of volatile organics in indoor air. - [7] Price,D. L., R. B. Simmons, I. M. Ezeonu, S. A. Crow and D. G. Ahearn, "Colonization of fiberglass insulation used in heating, ventilation and air conditioning systems", Journal of Industrial Microbiology & Biotechnology Volume 13, Number 3 (1994), 154-158, DOI: 10.1007/BF01584000, Abstract: The number of fungal species colonizing thermal and acoustic fiberglass insulations used in heating, ventilation, and air conditioning (HVAC) systems was fewer than that obtained from initial direct culture of these insulations. The colonization, determined by the microscopic observation of conidiophores with conidia, was primarily of acrylic-latex-facing material, but eventually the fungi permeated the fiberglass matrix. Isolates of Aspergillus versicolor were most often obtained from non-challenged insulation, whereasAcremonium obclavatum appeared to be the primary colonizing fungus in high-humidity (>90%) challenge chambers. At a lower humidity (about 70%) Aspergillus flavus was one of the more prominent fungi. Not all duct liner samples were equally susceptible to colonization and duct board appeared relatively resistant to colonization.

- [8] Simmons, R. B. and S. A. Crow, "Fungal colonization of air filters for use in heating, ventilating, and air conditioning (HVAC) systems", Journal of Industrial Microbiology & Biotechnology Volume 14, Number 1 (1995), 41-45, DOI: 10.1007/BF01570065, Abstract:

New and used cellulosic air filters for HVAC systems including those treated with antimicrobials were suspended in vessels with a range of relative humidities (55–99%) and containing non-sterile potting soil which stimulates fungal growth. Most filters yielded fungi prior to suspension in the chambers but only two of 14 nontreated filters demonstrated fungal colonization following use in HVAC systems. Filters treated with antimicrobials, particularly a phosphated amine complex, demonstrated markedly less fungal colonization than nontreated filters. In comparison with nontreated cellulosic filters, fungal colonization of antimicrobial-treated cellulosic filters was selective and delayed. - [9] Ifeoma M. Ezeonu, Daniel L. Price, Sidney A. Crow and Donald G. Ahearn, "Effects of extracts of fiberglass insulations on the growth of Aspergillus fumigatus and A. versicolor", Mycopathologia Volume 132, Number 2 (1995), 65-69, DOI: 10.1007/BF01103777

, Abstract:

Water extracts of thermal and acoustic fiberglass insulations used in the duct work of heating, ventilation and air conditioning (HVAC) systems supported germination of conidia and growth of Aspergillus versicolor (Vuillemin) Tiraboschi 1908–9 and Aspergillus fumigatus Fresenius 1863. Urea, formaldehyde and unidentified organics were detected in the extracts. Formaldehyde in concentrations similar to those found in the extracts restricted the growth of both species in enriched media. A. versicolor, the more common species associated with fiberglass insulations, was more resistant to formaldehyde than A. fumigatus. - Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- A BRIEF GUIDE to MOLD, MOISTURE, and YOUR HOME, [PDF] U.S. Environmental Protection Agency US EPA - includes basic advice for building owners, occupants, and mold cleanup operations. See http://www.epa.gov/mold/moldguide.htm

- US EPA - Mold Remediation in Schools and Commercial Building [ copy on file as /sickhouse/EPA_Mold_Remediation_in_Schools.pdf ] - US EPA

- US EPA - UNA BREVA GUIA a MOHO / HONGO - en Espanol

- Fiberglass carcinogenicity: "Glass Wool Fibers Expert Panel Report, Part B - Recommendation for Listing Status for Glass Wool Fibers and Scientific Justification for the Recommendation", The Report on Carcinogens (RoC) expert panel for glass wool fibers exposures met at the Sheraton Chapel Hill Hotel, Chapel Hill, North Carolina on June 9-10, 2009, to peer review the draft background document on glass wool fibers exposures and make a recommendation for listing status in the 12th Edition of the RoC. The National Institute of Environmental Health Sciences is one of the National Institutes of Health within the U.S. Department of Health and Human Services. The National Toxicology Program is headquartered on the NIEHS campus in Research Triangle Park, NC. The National Institute of Environmental Health Sciences is one of the National Institutes of Health within the U.S. Department of Health and Human Services. The National Toxicology Program is headquartered on the NIEHS campus in Research Triangle Park, NC.

Following a discussion of the body of knowledge, the expert panel reviewed the RoC listing criteria and made its recommendation. The expert panel recommended by a vote of 8 yes/0 no that glass wool fibers, with the exception of special fibers of concern (characterized physically below), should not be classified either as known to be a human carcinogen or reasonably anticipated to be a human carcinogen. The expert panel also recommended by a vote of 7 yes/0 no/1 abstention, based on sufficient evidence of carcinogenicity in well-conducted animal inhalation studies, that special-purpose glass fibers with the physical characteristics as follows longer, thinner, less soluble fibers (for 1 example, > 15 μm length with a kdis of < 100 ng/cm2/h) are reasonably anticipated to be a human carcinogen for the listing status in the RoC. The major considerations discussed that led the panel to its recommendation include the observations of tumors in multiple species of animals (rats and hamsters). Both inhalation and intraperitoneal routes of exposure produced tumors, although inhalation was considered more relevant for humans. - WHO- World Health Organization - IARC MONOGRAPHS ON THE IDENTIFICATION OF CARCINOGENIC HAZARDS TO HUMANS large PDF over 6MB)

https://publications.iarc.fr/ENG/Monographs/vol81/mono81-6A.pdf - article details

https://publications.iarc.fr/ENG/Monographs/vol81/mono81-6C.pdf - studies of cancer in experimental animals in re vitreous fibers such as fiberglass;

https://publications.iarc.fr/ENG/Monographs/vol81/mono81-6E.pdf - summary of data reported & evaluation

https://publications.iarc.fr/ENG/Monographs/vol81/mono81-6F.pdf for the article references

To search the IARC monographs on various environmental concerns and carcinogens, use https://publications.iarc.fr/ENG/Monographs/PDFs/index.php - In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.